February 2020 #316 News / Events / Updates Installations / New products KBB Preview / Saws & Cutting Technology Edgebanding Materials & Technology

www.furnitureproduction.net

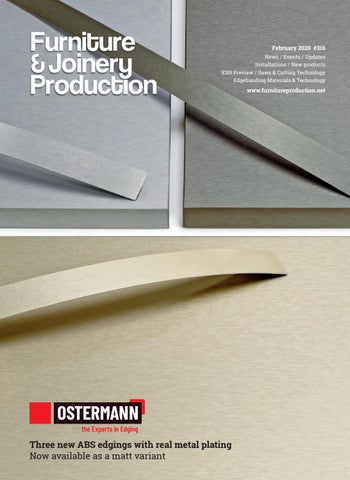

Three new ABS edgings with real metal plating Now available as a matt variant FP316_Pages.indd 1

28/01/2020 09:31

2 INSTALLATIONS

SERVICE, DIVERSITY AND SPEED

SO MUCH MORE THAN EDGINGS Apart from Europe’s largest range of edgings, we supply a continuously growing range of products for the carpentry and furniture industry. From fittings and handles to lighting solutions, fastening systems and innovative designer surfaces: as the experts in edging, we always have the answer for your project.

www.ostermann.eu

FP316_Pages.indd 2 Full page USE.indd 1 Anzeige_UK_Kantenball_216x297_def.indd 1

28/01/2020 09:31 04/09/2019 13:19 04.09.19 12:00

19 12:00 13:19 19

3 EDITORIAL DIRECTOR John Legg Tel: 01424 776104 john@gearingmediagroup.com Twitter: @FurnitureProdEd EDITORIAL Paul Farley paul@gearingmediagroup.com Tel: 01424 776101 ADVERTISING MANAGER Lisa Williams Tel: 01424 776102 lisa@gearingmediagroup.com PRODUCTION MANAGER James Ash Tel: 01424 817430 james@gearingmediagroup.com DIGITAL CONTENT MANAGER Nyall McCurrach Tel: 01424 776107 nyall@gearingmediagroup.com COPY ADMINISTRATION & DATA Steve Merrick Tel: 01424 776108 production@gearingmediagroup.com CHAIRMAN Nigel Gearing ACCOUNTS Wendy Williams Tel: 01424 774982 wendy@gearingmediagroup.com SUBSCRIPTIONS Magazine (UK-£65, Europe-£85, RoW-£95) Connect VIP packages (UK-£95, Europe-£110, RoW-£120) 01424 774982 subscriptions@gearingmediagroup.com REPRO, PRINT and DISTRIBUTION Stephens & George

Comment Towards the end of last year, some commentators were predicting the likelihood of a Boris bounce to follow the new year after a strong general election performance from his party – and I know it’s only February, but things appear to be much the same (of course). With many such similar events, the furniture and joinery making business is, generally speaking, a decent and robust industry in which to ply one’s trade, despite on going political machinations I encountered a clear (if not necessarily representative) indication of this status quo on my travels in the latter part of 2019. I was impressed by a run of businesses which I visited who were enjoying a pretty reasonable year, albeit marked with greater peaks and deeper troughs which, other than a summer slow-down, were less predictable than normal. There were common denominators among these companies, such as a clear awareness of current market needs, an efficient production process, and a good marketing strategy – all the traits one would normally associate with a well-run company. Three modest kitchen and bespoke interiors businesses in a row told me that they had billed a record month or two during the year, but that was offset by some quieter periods. One character they all shared was an ambitious outlook – all three had continued to invest in technology, better designs, sharper production and training to advance their interests. In these challenging times, opportunities abound, where, with cheap borrowing, investment and training will stand a business in good stead. But as we go to press, there are stories which suggest friction-less trade will be impossible after Brexit. Business, however, will I’m sure find a way. In this issue, we hear from Montgomery, organiser of the W Exhibition and Elements event which takes place in September this year at the NEC in Birmingham. The event’s MD, Nickie West, says that the 2020 show will see a ‘tech takeover’ manifest itself, with a strong uplift of interest from exhibitors featuring software, robotics and wider technologies in furniture and joinery applications. A reminder of the date for this year’s event – it’s being held from September 27-30th this year. Regarding the W Exhibition, we are delighted to announce that we will once again producing the official show catalogue on behalf of the organiser and will be delivering our usual preview issues from July.

DISCLAIMER: All material submitted for inclusion in Furniture Production is done so entirely at the contributor’s own risk. No responsibility is accepted for the safe-keeping of contributors’ materials. Whilst all attempts are made to ensure accurate reproduction, Furniture Production accepts no responsibility for variations. Artwork undertaken by our studio remains the copyright of Gearing Media Group Ltd and may not be reproduced or stored without prior permission. Some articles in Furniture Production have been submitted by companies and organisations. Monies may have been accepted in some instances to offset production costs. All rights reserved. In respect of artwork originated free of charge as part of a booking, clients should know that excessive work (more than one set of corrections, known as ‘authors corrections’) is chargeable at £55 per hour.

I hope you enjoy the issue.

John Legg EDITORIAL DIRECTOR john@gearingmediagroup.com @FurnitureProdEd

Content 6 News 14 KBB preview 24 Installations 34 Edgebanding Materials & Technology 42 Saws 50 Updates 65 Classifieds & SOS

DATA PROTECTION “OPT OUT” STATEMENT: Readership data held by Gearing Media Group Ltd may be shared with any member of the Gearing Media Group Ltd and associated companies for the purposes of customer information, direct marketing or publication. Data may also be made available to external parties on a list rental/lease basis for the purposes of direct marketing. If you do not wish data to be made available to external parties for list rental or lease please write to: Data Protection Co-ordinator, Gearing Media Group Ltd, 4 Red Barn Mews, High Street, Battle, East Sussex TN33 0AG. SUBSCRIPTIONS: Refunds on cancelled subscriptions will only be provided at the publisher’s discretion, unless specifically guaranteed within the terms of the offer

© Gearing Media Group 2020 www.furnitureproduction.net

ISSN 2396-9024 MEDIA PARTNERS

FP316_Pages.indd 3

30/01/2020 11:33

4 NEWS

Mirka achieves Investors in People Silver Award Mirka UK has been awarded the Investors in People (IIP) Silver Award for its first assessment. The IIP practitioner praised the company’s proactive, peoplefocused organisation, resulting in a very efficient and effective delivery, underpinned by a clear vision and business objectives. The assessment found that Mirka has an engaging relationship with its customers and other stakeholders. Continuous professional development and training, spearheaded by the Mirka UK Training Centre, ensures a collaborative approach and best practice is implemented across the business.

Craig Daycock, MD of Mirka UK, says: “We’re absolutely delighted to have achieved the IIP Silver Award at our first attempt. This accreditation recognises the commitment of our staff to engage in continuous improvement to ensure our customers and business partners receive the best service and high levels of support possible. “The Mirka way is to empower our people, creating a culture of trust and a ‘can-do’ attitude, which means decisions can be made and acted upon quickly to the benefit of all our stakeholders.” www.mirka.com

Weinig UK appoints new area sales manager Steven Brockie is Weinig UK’s new area sales manager for Scotland. Covering the Weinig and Holz-Her brands across the region, Steven has joined the company to strengthen sales and develop key relationships with new and existing customers. With over 15 years of experience in the woodworking sector, Steven embarked on a joinery apprenticeship at 16 and, in the following years, worked on several large-scale joinery projects in Scotland including the Chris Hoy Velodrome and the construction of the SSE Hydro Arena. More recently, Steven has used his woodworking skills and industry

knowledge to carve out a career in technical sales, working most recently for power tool suppliers, DeWalt and Milwaukee. Steven says: “Thanks to my solid background in woodworking, I have a good understanding of both traditional woodworking methods and modern machining. My experience allows me to appreciate what machinists are trying to achieve and what equipment they need to get the very best results. I believe this will help me cement relationships with new and existing customers, whilst presenting me with more opportunities to showcase the breadth of the Weinig

and Holz-Her brands to those in the industry.” Malcolm Cuthbertson, MD of Michael Weinig (UK), adds: “Steven’s practical background and proven technical sales skills are a superb fit for Weinig UK. Not only can he offer valuable technical advice and a high level of aftercare service for our customers in Scotland, he has the ability to truly understand what our customers want and need. I’m confident that this, mixed with his natural enthusiasm and commitment to the sector, will make him an invaluable member of the team.” www.weinig.co.uk

Steven Brockie, Weinig UK area sales manager for Scotland

Combilift nominated in two 2020 IFOY Award categories For the second year in a row Combilift is a finalist in the IFOY Awards – one of the most prestigious and hotly contested international awards in the materials handling industry. The company is the only manufacturer to have two of its products nominated for a 2020 IFOY Award (International Intralogistics and Forklift Truck of the Year) which honours the best products and solutions of the year. The Combi-CBE4 is a finalist in the Special Vehicle Category. This 4000kg capacity electric-powered, all-wheel drive forklift incorporates compact counterbalance design with multidirectional capability for the versatile handling of mixed sized loads. It features the company’s internationally patented independent electric traction (EP.2956350) which provides all front and rear drive wheels with 100% traction control, therefore negating the need for differential

FP316_Pages.indd 4

lock on slippery surfaces. By inputting the wheelbase parameters, the traction commands are calculated by the control system. As the truck drives and steers, the speed and rotational direction of the wheels are controlled independently, allowing the truck to negotiate tight turns with no tyre wear.

The Combi-CS has been nominated in the Warehouse Truck Lowlifter category. It is the only pedestrian counterbalance stacker that will operate in a conventional reach truck aisle for space saving and productive storage and handling. It features Combilift’s unique, internationally patented multi-

position tiller arm, which can be turned to the left or right of the unit to position the rear drive wheel, allowing the operator to remain at the side of the machine rather than at the rear as is the case with other pedestrian stackers. This ensures optimum visibility of the load and surroundings as well as guaranteeing maximum safety in areas where other personnel or members of the public may be present. The competition will enter its next round when finalists undergo the IFOY audit and innovation check by industry experts in mid-February in Hanover, Germany. “Following the nomination of the Combi-PPT powered pallet truck last year, we are delighted that the IFOY committee has recognised two of our innovative products as being worthy of finalist status in 2020,” says Combilift CEO and cofounder, Martin McVicar. www.combilift.com

28/01/2020 09:31

Full pag

SCM_G

THE MOST COMPLETE RANGE OF ENTRY-LEVEL EDGEBANDERS TO FIT THE SPECIFIC NEEDS OF YOUR BUSINESS

olimpic k 560

olimpic k 360

olimpic k 230 evo

olimpic k 100 evo

SCM UK Tel. + 44 (0)115 9770044 scmgroupuk@scmgroup.com - www.scmwood.com

FP316_Pages.indd 5 Full page.indd 1 SCM_G_USC_BORDATURA_216X297_UK_BOIS MAG_069_1.indd 1

28/01/2020 20/01/2020 09:31 11:55 31/07/19 11:17

6 NEWS

Homag will be running demonstrations of its award-winning intelliGuide light guidance system

Homag to showcase new decade technology trends at March Open House Last year was extremely successful for Homag UK. It was a year which saw the company dominate the woodworking market with its impressive machine and software developments and launches. As the new decade begins, Homag UK is preparing to set the upcoming trends at its Open House event on Wednesday 4th to Friday 6th March 2020 held at its Castle Donington showroom. Simon Brooks, managing director of Homag UK explains: “The last couple of years have really highlighted the importance and benefits of implementing technology and automation within woodworking production facilities – whatever size of company. “We had a great response at Ligna 2019 when we showcased our latest digital solutions and 2020 will see further exciting developments. Visitors to our March Open House will see demonstrations of all our latest technology, as well as exclusive trends for 2020, from machinery through to software and applications.” Edging technology from Homag UK Homag will be demonstrating a host of edge banding technology at the Open House. This

FP316_Pages.indd 6

will range from entry-level machines through to edge banding for industry and high volume production. The compact Edgeteq T-200 will be demonstrated as a flexible solution for the edge banding and processing of shaped parts. Continuing with entry-level edge banding, the Edgeteq S-240 will be on show throughout the event. With zero-joint airTec technology, it boasts perfect edge processing on a wide variety of materials. For higher volume processing, Homag UK will be showcasing the Edgeteq S-300. Utilising multi-level technology, the edge bander can be used with fine trimmers, profile trimmers and scrapers. Recent enhancements have added the function of workpiece corner processing making the S-300 a versatile system. Homag will be demonstrating the benefits of the different edge sealing methods available including EVA and PUR glue as well as airTec hot air bonding technology. In addition to the S-300, visitors to Homag UK will also see a full demonstration of the Edgeteq S-380. The combination of perfect joints, simple handling and complete automation means that edging has never been faster or simpler.

Cutting competition with Homag’s panel saws Visitors to Castle Donington can also expect live demonstrations of Homag’s panel saws including the Sawteq B-130. It may be the smallest saw in the Homag range, but it is equipped as standard with everything you need for cutting single panels and small batches. Ideal for entry-level and smaller sized workshops, the B-130 offers top Homag quality at a truly competitive price. Alongside the B-130, Homag will demonstrate its labelling and identification system which guarantees that production runs smoothly after the saw processing. The label printing station creates custom labels directly at the saw using a barcode, text or graphics. Facilities with Homag’s Cut Rite optimisation software find it extremely useful as the label printer ensures that the material goes directly to the next process step with printed instructions. For larger sized manufacturers, Homag will demonstrate the Sawteq B-300. This panel diving saw is suitable for producing in batch size one as well as smaller series. The flexible system can be used as a single saw fed manually from the front or with a built-in lifting

28/01/2020 09:31

7

Centateq E-310 – a high-performance and versatile CNC solution

table for additional automated feeding from the rear of the saw. As well as being flexible to handle a wide range of cutting applications, the B-300 comes ready for networked production which is essential for a connected and intelligent production facility. Homag will demonstrate its full features including Power Concept Practive which allows several strips with different cross-cuts to be cut to length simultaneously for significantly increased throughput. As well as this, visitors can expect to see Homag’s combiTec technology in action on the saws which allows for automatic recuts during the cutting process. This creates savings for materials, time and money as well as reducing waste. In addition to automated handling, Homag UK will be demonstrating its award-winning intelliGuide professional software. The software makes the operation of Homag saws easier and more efficient than ever with its light guidance system which provides operators with step by step instructions. High-performance CNC machining centres Homag’s range of CNC machining centres offers cutting edge technology at accessible prices for all sizes of manufacturers. The superior technology allows for highly efficient production for a large range of panel and solid wood processing. During the three day event in March, visitors to Homag’s UK showroom will have the opportunity to see many different models in action including the Drillteq V-200. The flexible and compact system offers increased throughput with efficient drilling, trimming and grooving. Also on show will be the Centateq P-110. Homag will be demonstrating the 5-axis model which offers high-performance and versatility for small and medium-sized carpentry and joinery companies. With three and four-axis models also available, the P-110 is a versatile and affordable solution. Boasting a compact design, the machine is freely accessible from all sides due to its bumper safety technology. The Centateq N-500 jumbo sheet nesting machine in a gantry design enables the

FP316_Pages.indd 7

The Edgeteq S-380 – perfect joints, simple handling and complete automation

optimised cutting, processing and dividing of materials. This nesting model is ideal for the creation and construction of carcass and frame furniture. Homag’s Centateq E-310 is a highperformance CNC solution that has the added benefit of shaped edge banding incorporating Homag’s powerEdge Pro Duo gluing technology. The E-310 boasts a high level of innovative technology as the multi-tasking machine offers the versatile production of formatting, profiling, drilling and edging of shaped parts. It is available with both EVA glue and airTec bonding technology for the perfect ‘invisible joint’ finish. Homag software for efficient and intelligent working Homag’s range of software has been created to increase production efficiency whilst also simplifying machine operation. Designed with the user in mind for fast and simple programming, Homag’s software has never been so advanced or intuitive. At the March Open House, visitors can experience live demonstrations of woodWOP, woodCAD|CAM and MagiCut software. This software will save money and optimise the use of materials for efficient production. Simon Brooks concludes: “For any company, large or small, wishing to take advantage of automation and digital technology, our March Open House is a must-visit event. Not only will we be showcasing our technology trends for 2020, but also all the machines in our showroom will be connected to our digital platform, tapio. “This will allow visitors to explore and

The Homag Edgeteq T-200 – entry-level edge banding for shaped parts

understand the tapio system in much more depth than at previous shows. The platform works to optimise production facilities and keep machines running at their maximum output and we’re excited to be able to demonstrate this advanced technology on a large scale. “As well as all our live demonstrations, our team will be here to answer any queries you may have regarding all aspects of our machining technology, software, servicing and finance solutions. Given the popularity of the event, we recommend you pre-book an appointment with one of our sales team to secure your chance to learn about the fantastic opportunities the new technology offers. We look forward to welcoming you to Castle Donington this March!” Contact Adele Hunt on 01332 856424 or email info-uk@homag.com for appointment bookings and further Open House information. 01332 856500 www.homag.com

28/01/2020 09:31

8 NEWS

Snickers Workwear new ALLroundWork jackets and gilets

Mirka Switches Up the value with new year campaign

These new ALLroundWork jackets and gilets are just what the name suggests – delivering a great all-round performance on site with a Ripstop water-resistant outer fabric and a coated inner fabric for extra durability. They are wind-resistant too and all have the features and functionality that customers would expect in Snickers Workwear clothing. Designed for optimum comfort and flexibility when on the move, they are great-looking working clothes that will keep the user feeling comfortable wherever and whatever the job in cold and windy weather. With smart designs and an ergonomic fit, Snickers Workwear ALLroundWork garments are packed with must-have features that focus on functionality and freedom of movement as well as using innovative fabrics that deliver

Mirka UK is launching a new campaign in 2020, offering users the chance to ‘Switch Up’ their old sander for a new Mirka electric sander or battery tool during February and March and receive a free Mirka tool bag containing four boxes of Abranet® abrasives worth over £200*. End users can ‘Switch Up’ any brand or make of electric or air sander – working or non-working – and buy a new Mirka electric or cordless tool including the Mirka DEROS, DEOS, DEOS Delta, LEROS, ARP-B, AROP-B, AROS-S or AOS-B. They then simply register the new Mirka tool’s proof of purchase and warranty registration along with the returned tool’s details and serial number within 30 days to receive their added-value goodies. All old returned sanders will be disposed of safely and compliantly by the nominated Mirka Service

long lasting protection. There is also a range of Baseand Mid-layer garments plus accessories like gloves, hats, face warmers and beanies to ensure that every part of the user stays dry and warm. www.snickersworkwear.co.uk

Centre. Pete Sartain, industrial sales manager for Mirka UK, says: “We’re kicking off 2020 with an exciting promotion that we are confident will appeal to Mirka customers and current non-Mirka customers alike. We hope it will be an opportunity for end users to ‘Switch Up’ their old sanders, whether they are working or not, and try out the extensive range of Mirka sanders on offer. It’s Mirka’s way of saying ‘Happy New Year’!” www.mirka.com *Based on 150mm discs

Mighton Products’ Avia Smart Lock wins global 2020 IoT Breakthrough Award Mighton Products’ Avia Smart Lock has been selected as the global winner of the Smart Lock Product of the Year award in the 4th Annual IoT Breakthrough Awards programme from IoT Breakthrough, a leading market intelligence organisation that recognises the top companies, technologies and products in the global Internet-ofThings (IoT) market today. Avia is the ultimate secure smart home security system available for multipoint locking doors. Avia is Apple HomeKit enabled and packed with online security features. The Avia secure smart lock is the first smart lock to be accredited by Sold Secure which is administered by the UK’s Master Locksmiths Association and aimed at reducing the risk of crime by assessing security products. Avia has designed all its products with security at its heart and to meet the enhanced security requirements of external agencies and industry standards and regulations. Avia was also the first smart lock to be compliant with the UK Government code of practice for

FP316_Pages.indd 8

consumer IoT and ETSI TS 103 645 Consumer IoT security technical specification, providing users with the confidence that it is safe and secure at home and online. Avia was also the very first smart lock to achieve the prestigious BSI Internet of Things Verified – residential IoT accreditation. “Unlike many other smart locks, Avia uses the latest advanced 256bit encryption for the transfer of data, and Apple HomeKit is widely acknowledged to be the most secure platform available, so the communication between the phone and the lock is protected at the highest level possible,“ said James Johnson, managing director at IoT Breakthrough. “Their innovations with the Avia product continue with their introduction of child safety features, and simply put – Mighton Products is now a leading force of innovation in the smart lock arena. We extend our congratulations to the entire Mighton Products team for taking home this 2020 IoT Breakthrough Award.” The mission of the IoT Breakthrough Awards program

is to recognise the innovators, leaders and visionaries from around the globe in a range of IoT categories, including Industrial and Enterprise IoT, Smart City technology, Connected Home and Home Automation, Connected Car, and many more. This year’s program attracted more than 3700 nominations from companies all over the world. Mighton Products has also developed ‘optical pairing’ as part of the process for adding a lock to consumer home system and devices. Optical pairing is a Bluetooth pairing method developed by Mighton Products Ltd as a form of Bluetooth out-of-band pairing. It is known to be secure against ‘man-in-the-middle’ attacks due to its inherent privacy, made possible by the close physical proximity and the single ‘point-to-point’ procedure. It works by communicating one of the Bluetooth pairing encryption keys through a ‘light flashing pattern’ from one device to the other. When optical pairing, only the devices that participate will communicate with each other.

“We believe that every smart lock should be subject to the industry’s most rigorous testing, including both hardware and software components,” said Mike Derham, chairman, Mighton Products. “Avia is all about security and about peace of mind, so we didn’t want to make Avia just secure, we wanted to be able to prove Avia’s security credentials too. That’s why we have sent Avia to the world’s best security testing houses for both physical and cyber security testing to be completely scrutinised, and we are proud to receive their validation, as well as the validation from IoT Breakthrough with this 2020 IoT Breakthrough Award designation.” www.mightonproducts.com www.IoTBreakthrough.com

28/01/2020 09:31

T J M

Y

R e

THE UK’S NUMBER ONE JOINERY & FURNITURE MANUFACTURING EVENT Your ticket to see: Running woodwork machinery & equipment Components, materials and finishes Industry insights, education and demonstrations 9,000 of your peers Exclusive show discounts & offers

Alongside:

Register for FREE for your industry’s number one event today: Wexhibiton.co.uk

FP316_Pages.indd 9

28/01/2020 09:31

10 NEWS

Tech takeover for the W Exhibition 27-30th September 2020 | NEC, Birmingham | www.wexhibition.co.uk

in design and manufacturing software for staircases. Joinery design and manufacturing software providers such as Cinch Software, CNC Software Solutions and Planet Software are also set to exhibit. They join an extensive lineup, with over 85 percent of stands already booked for The W Exhibition 2020. Speaking about the growing tech lineup, The W Exhibition and Elements MD, Nickie West says: “As in industry, robotics, software and wider technology are having a massive impact on the way that furniture is manufactured and it is important that the W Exhibition moves with the

times and reflects the needs of the industry. “We’re excited to see an uplift in the number of software and tech suppliers who have committed to exhibit at the W Exhibition this year and will be reflecting the appetite for this type of content through new show features and our brand new CPD Approved learning programme.” The W Exhibition has over 40 years of heritage, and continues to grow. It will return to the NEC for its bi-ennial four-day showcase from September 27th-30th. The show brings together some of the world’s leading suppliers of woodworking machinery, materials and tooling.

All our shown and mentioned decors are reproductions.

The W Exhibition, the UK’s number one event for the joinery and furniture manufacturing industry, is set for a ‘tech takeover’ when it opens its doors to visitors at the NEC in September 27th-30th. Software companies have been signing up to exhibit at the show, with the W Exhibition organisers reporting a spike in ‘tech’ related brands that have identified the event as a key platform to help them reach prospective customers. The lineup includes the likes of Staircon, SEMA GmbH and Compass Software who specialise

FP316_Pages.indd 10

28/01/2020 09:31

Full pag

Discover the power of more.

All our shown and mentioned decors are reproductions.

Egger Decorative Collection 2020–22

Justinas Jelinskas Fabricator

More choices, more textures, more services, more opportunities, with the new EGGER Decorative Collection. Discover the power of more via the new EGGER app, helping you create new designs and amazing spaces. Âť Bring your ideas to life egger.com/decorative-collection

FP316_Pages.indd Full page.indd 1 11

28/01/2020 15/01/2020 09:31 10:48

12 NEWS

Get more from the impressive new Egger Decorative Collection 2020-22…

Egger – ready to seize your opportunities This month sees the introduction of the new Egger Decorative Collection 2020-22. This is the biggest product launch for the company since 2017, offering the company’s best décors and textures with a focus on the latest design trends. Building on the success of the current collection, the new Egger Decorative Collection 2020-22 includes new décors, featuring up-to-date textures, colours and woodgrains. Created by Egger’s team of experts, the collection brings together design trends from across the world to provide some of the best finishes and surfaces for all interiors. The selection of woodgrain

FP316_Pages.indd 12

finishes has never been so extensive, with new décors added to the popular Feelwood range. High-end material reproductions of marble, granite and ceramic have been developed to meet demand, and new solid colours have been added to achieve bold contrasts in design. Egger’s award-winning PerfectSense collection has been refreshed with the addition of material décors, available in gloss, matt and topmatt. And an increased range of matching and accent edging means a high-value look can be created with minimal effort. Egger is a one-stop shop for decorative surfaces providing a cost-effective option that does

not compromise on style or performance. The total collection comprises more than 250 décors, with matching boards, laminate and edging available for every single one. New digital services, meanwhile, will help to bring the new collection to life, making it easier to select, visualise and present Egger. Alongside the Egger Decorative Collection 2020-22, Egger will also be launching a new and improved collection of beautifully detailed, tactile and durable worktops in a range of sizes and thicknesses, including the elegant and versatile 16mm. Elliott Fairlie, senior decor manager (UK and Ireland), says: “Our new collection will provide

customers with the freedom to develop amazing design concepts, knowing that Egger will provide high-quality products that will bring their ideas to life. “The real strengths of our new collection are in the impressive, on-trend décors and top-quality textures, but also in the fact we can provide all of these in matching products – MFC, laminate and edging – opening up endless possibilities for designers and manufacturers. If you combine our commitment to providing high-quality products and services with our focus on sustainability and reducing waste, you get a very exciting offering for the market.” www.egger.com

28/01/2020 09:31

Full pa

GETS YOU CLOSER FOR PERFECTION. Mirka® DEOS IMAGINE THE PERFECT S U R FA C E . FP316_Pages.indd Full page.indd 1 13

Thanks to the new Mirka® DEOS electric sander, you can obtain that flawless end result easier and quicker than ever before. By getting you closer to the surface, we bring your sanding experience to a completely new level - you will never go back to hand sanding again. Mirka® DEOS boasts smart Bluetooth technology with an integrated vibration sensor allowing you to monitor vibration levels while sanding.

For further information or to arrange a demonstration, please contact Customer Services on 01908 866100

www.mirka.co.uk 28/01/2020 08/01/2020 09:31 10:53

14 KBB PREVIEW

Titus launches TeraBlack cabinet hardware at kbb

Cabinet hardware expert Titus is set to make a big impact at this year’s kbb by launching innovative TeraBlack versions of many of its most popular products, including its successful T-type hinges. Visitors to the event – which takes place from 1st-4th March at the NEC in Birmingham – will be able to see the new products and other developments from Titus on stand W101. Titus closely monitors emerging trends in the international furniture market, and this has led the company to develop new Tera (Titus Enhanced Resistance Application) versions of its products. These feature an attractive non-reflective dark grey finish, which not only retains its attractive appearance throughout its working life but also offers enhanced resistance to corrosion. Particularly well suited to applications in high-end premium kitchen furniture, Titus TeraBlack products fully meet the requirements of designers and consumers looking for unobtrusive yet impressive cabinet hardware.

FP316_Pages.indd 14

They have highly uniform surfaces and a velvet feel that complements their quality and enhances consumer appeal. Among the first products to be offered in TeraBlack versions are Titus’ renowned T-type hinges. These feature Titus Confident Close, the consumer-preferred reliable and consistent softclose damping action characterised by late-start deceleration and quiet landing in the last stage of closing as the door contacts the cabinet side. In addition, T-type hinges require only a shallow hinge cup, which makes them suitable for use with door thicknesses from 15-26 mm. All of the new TeraBlack products are Titusengineered solutions supported by tightly controlled, repeatable, efficient, flexible and scalable manufacturing processes that provide the performance, consistency and quality essential to manufacturers of high-end furniture. “Titus is a world leader in high-end kitchen hardware and recently we’ve seen a growing demand for cabinet hardware with a dark matte finish,” said Gary McMahon, Titus UK marketing

manager. “We wanted to respond with a marketleading solution that was not simply a colour variant but also offered other benefits for our customers and for furniture end-users. And, with the durable high-performance TeraBlack products we’re launching at the kbb show, we believe that’s exactly what we’ve achieved.” www.titusplus.com

28/01/2020 09:31

Full pag

FP316_Pages.indd Full page.indd 1 15

28/01/2020 14/01/2020 09:31 11:34

g

16 KBB PREVIEW

I K A P M

Kinvaro T-Slim – a new dimension of invisibility Overhead wall cabinets are still one of the most popular storage solutions in the kitchen. With Kinvaro, the Grass portfolio offers a range of different flap lift mechanisms. In 2019, the portfolio has now been spectacularly extended. The motto is Super. Slim. T-Slim. Kinvaro T-Slim is the thinnest, most efficient fitting ever developed by Grass. It combines purist looks with outstanding durability and the art of unrestricted movement in a unique way. Reduction is what it is all about. “If less is more, then maybe nothing is everything.” This quote, by pioneering architect Rem Koolhaas inspired the development of Kinvaro T-Slim. The new flap lift mechanism makes the dream of invisible fittings come true – and will therefore provide furniture designers all over the world with inspiration. “We have been a furniture industry pioneer for over 70 years,” says Grass flap lift mechanism product manager Harald Küper. “With Kinvaro T-Slim, we are adding a new chapter to our innovation history. After the first-ever concealed hinge or the invention of the double wall drawer, we have now developed a new dimension of invisibility with Kinvaro T-Slim.” Kinvaro T-Slim blends into the furniture almost invisibly, thereby unlocking completely new possibilities for overhead wall cabinets in

A movement mechanism that does not distract from the design The challenge here is obvious, as every technical detail is visible on a piece of furniture fitted at eye level. This fact prompted the development of Kinvaro T-Slim. Grass’ engineers have managed to reduce the complex mechanism of a lift-up fitting down to an overall size of 12mm. This minimal size provides furniture designers with maximum flexibility. Anything is possible from a minimum side wall thickness of 16mm upwards. In material terms, there are hardly any limitations – wood can just as easily be used as MDF, and Kinvaro T-Slim’s effect on the furniture’s aesthetics really comes into its own on glass front flaps with aluminium frames. The fitting becomes one with the furniture. “The best movement mechanisms distinguish themselves by the fact that they give precedence to the design of the furniture they have been fitted to,” says brand manager Harald Klüh. “Kinvaro T-Slim perfectly exemplifies this philosophy.” Besides the obvious aesthetic bonus, this reduction in size offers another advantage –the flap lift-up mechanism takes up very little room, so the available storage space can be used to its full potential. A fascinating display of kinetics The Kinvaro T-Slim flap lift-up mechanism joints are made of nickel-plated steel. Moving Kinvaro T-Slim’s five-part jointed hinge arms reveals a display of well-co-ordinated technical expertise – nothing seems to be left to chance. The precise interaction of the matte shiny leverage elements follows a cleverly choreographed sequence of forces – apparently designed to defy the laws of physics. This effortlessness is also transferred to the user – the cabinet front is so easy to move that it appears to be lifted up by an invisible force. The soft-close technology, already proven millions of times over, ensures an elegant, gently dampened closing movement, a comfort feature that is particularly important on overhead wall cabinets. With an opening angle of 107°, the flap opens well beyond the user’s area of movement – conveniently, it can therefore stay open without getting in the way. It comes with an integrated opening angle limiting stay that prevents the

FP316_Pages.indd 16

k t

response to the current trend. Particularly wide, rather than tall, storage solutions with lift-up flaps are currently undergoing a renaissance. Whether fitted at eye level directly above the kitchen worktop, sink or cooker, or above a desk or the television in the living room, or next to the mirror in the bathroom, overhead wall cabinets with flaps are an essential design feature in modern interiors,” states Grass

front from being lifted up too high on overhead wall cabinets that are mounted directly below the ceiling. It can also be equipped with Tipmatic for handleless cabinet versions. A wider range of fitting possibilities When it comes to the fitting options, the latest Grass product offers several possibilities – Kinvaro T-Slim can either be inset, or overlaid and screwed on, the most commonly used alternative in the industry. The design of this fitting version is also impressively slim and space-saving. No tools are needed to fit and remove the two-part covering pelmet. The flap lift system can therefore also be adjusted after it has been fitted, if necessary. It is attached to the front with a clip, a solution that is as elegant as it is simple. The fully adjustable spring tension can be adjusted from the front – to ensure that the fronts move easily and elegantly. Kinvaro T-Slim is also available in a choice of design versions – Grass offers the mechanism in its standard colours Ice, Stone and Silver. A paintable covering pelmet is also available which can simply be painted to match the body finish. 0121 500 5824 www.grass.eu

28/01/2020 09:31

k

AD_200

Invi kinvaro t-slim. si ble. grass.eu

Kinvaro T-Slim Flap System

INVISIBLE, SECURE, PRECISE AND MAGICAL. KINVARO T-SLIM COMBINES PURIST AESTHETICS, A VERY STABLE CONSTRUCTION AND THE ART OF PERFECT MOVEMENT IN A VIRTUALLY UNIQUE MANNER. SEE FOR YOURSELF!

KT

To achieve the highest degree of transparency, a movement system must be able to disappear. Kinvaro T-Slim has this ability. Inobtrusive. Elegant. Strong. Beautiful.

Feel more WOW.

kinvaro.com FP316_Pages.indd 17 AD_2001_F&J_Kinvaro_T-Slim_216x297+3_EN_RIGHT.indd 1

With a branded product, you know what you’re getting. GRASS is the best case in point. Our premium movement systems combine technological advance, comfortable functionality, top quality and precision all the way through to the smallest detail.

28/01/2020 09:31 15.01.20 10:49

18 KBB PREVIEW

Lamello returns To kbb Birmingham Furniture fixings specialist, Lamello, will be returning to kbb Birmingham this March to demonstrate its newly extended range of furniture connectors and hand tools on stand T112. This year, the Swiss manufacturer will be showcasing its new Cabineo 8 M6 for the first time in the UK, alongside its complete P-System range. The Cabineo 8 M6 is the first connector in the Lamello portfolio created to join hard materials like aluminium, steel and HPL, and has been designed with fuss-free installation in mind.

FP316_Pages.indd 18

The clever one-piece connector can be inserted straight into a range of hard materials without the need for dowel holes and, where the thread hole cannot be cut directly into the substrate, the new fixing can be partnered with a steel nut for an even stronger joint. It is an ideal solution for those creating detachable corner and dividing panel joints with a heavy load. The hardy design of the Cabineo 8 M6 also makes the insert a go-to option for those looking to assemble and reassemble furniture multiple times without compromising on product strength, and with two insert nuts available to work with 14-16mm and 17-25mm-thick materials, the new fitting brings a wealth of design opportunities to the table. Visitors to Lamello’s 18m2 stand will also be the first to see a brand new P-System connector, which is set to launch at the show. Designed exclusively for use on CNC machines, it will offer users a new approach to furniture design. Live demonstrations of the Tenso P self-clamp fixings, Clamex P detachable furniture connectors and invisible magnetic joining element, Invis, will also be taking place throughout the four-day event. Shaye Chatfield, Lamello area sales manager comments: “kbb Birmingham is a great platform for us to present our award-winning products to

the UK. Our P-System connectors are a modernday alternative to cams, dowels and glues and offer effective and versatile design solutions that don’t compromise on strength, quality or aesthetics. Our team will be on hand throughout the exhibition to demonstrate just how how versatile our P-System is. If you’re designing, manufacturing or fitting furniture, let us show you the benefits of using Lamello.” Visit Lamello on stand T112 from the 1st-4th March at the NEC, Birmingham. For more information or to book a demonstration visit Lamello’s website or email/ telephone Shaye per the details below. 0789 1025 646 s.chatfield@lamello.com www.lamello.co.uk

28/01/2020 09:32

Full pag

NEW

Cabineo 8 M6 Wear-resistant cabinet connector for various materials and increased strength High clamping force

Cabineo 8 M6 metric thread M6

Cabineo 8 M6 black metric thread M6

Wear-free connection

Various materials

Cabineo insert nut M6×15.3 for materials 17 – 25 mm

Cabineo insert nut M6×12.3 for materials 14 – 16 mm

Lamello AG | Joining technology | Hauptstrasse 149 | CH-4416 Bubendorf

oth T112 t kbb Bo V is it u s a rch 2020 01-0 4 M a

Shaye Chatfield | Area Manager UK, Ireland | Mobile +44 (0) 789 1025 646 | s.chatfield@lamello.com | www.lamello.co.uk

FP316_Pages.indd 19 Full page.indd 1

28/01/2020 20/01/2020 09:32 11:53

20 KBB PREVIEW

Blum set to reveal a trio of new products alongside updates and innovations Blum is getting ready to unveil a selection of brand new products at kbb Birmingham this month. This new launch harnesses Blum’s Moving Ideas concept. As a company, Blum specialises in the manufacture and distribution of lift, hinge and pull-out systems for furniture in all living spaces. With movement and ingenious ways to achieve this at its core, Blum is always moving forward. At kbb, Blum will launch a series of brand new products that will transform the way we design and live in our homes‌ Space Step This brand new plinth solution takes storage to new levels with the ability to bring multifunctionality to cabinet plinths. A practical solution to compact living spaces, Space Step is not only a step, but also creates extra storage behind the toe-kicks of base units. It is ideal for lending a helping hand when reaching taller cupboard or shelf space above and allows for the design of floor-to-ceiling cabinets. Aventos HK Top A lift system which, while small in stature, is set to inspire designers, retailers, fitters, architects, suppliers and homeowners alike, thanks to its multiple integrated features. Benefits include a safety mechanism and opening angle stop while large and heavy fronts are able to open and close with ease. This lift system is incredibly easy to install, making projects a whole lot simpler and quicker for fitters and cabinet makers alike. Pull-Out Shelf Lock A discreet, space-saving mechanism that securely holds an open pull-out shelf in place,

Blum has developed a practical lock-open stop for its Movento and Tandem pull-out shelves. No need to worry about wobbles or shelves sliding back in, even if small appliances and gadgets are placed on top. As well as this trio of brand new products, Blum will also showcase some exciting new finishes. Easystick Blum’s computer-aided automatic stop system, Easystick allows cabinet makers and manufacturers to produce precise and finely crafted pieces of furniture without fuss. When used in conjunction with the new MiniPress top drilling and insertion machine, Easystick automatically calculates all fixing positions and the stops automatically move to the correct position. Legrabox This sleek and slim box system boasts clear contours, parallel drawer side design and accent

FP316_Pages.indd 20

lines, with exciting new finishes alongside personalisation options being launched at Kbb. Movento Blum has evolved its runner system into something even more precise with synchronised smooth running action and advanced adjustment options. Blumotion Clip Top Blumotion combines innovative technology with award-winning design and top quality motion for the smallest of spaces, as soft-close Blumotion is seamlessly integrated into the boss. Check out standard and onyx black finishes to take your design to the next level. Aventos This lift system brings top quality motion to wall cabinets, even those with large or heavy fronts, for freedom of movement. 01908 285700 www.blum.com

28/01/2020 09:32

KBB PREVIEW 21

Salice set to stand out from the crowd at kbb Salice will be exhibiting its range of furniture fittings for kitchens, bedrooms and bathrooms at the KBB show, held at the NEC from 1st-4th March. Salice will be located in hall 17, stand O100/ N104 ,where its show-stopping stand with plush carpets, greenery and displayed cabinetry, will enable visitors to view, and see in operation, the company’s ever-expanding selection of products, ranging from award winning hinges, sliding systems, lift systems, runners and drawers, accessories for furniture including stylish storage to discreet waste management solutions. Renowned for its attractively designed products, Salice’s Excessories range is something special, offering a variety of storage solutions created to optimise space and to facilitate the ideal arrangement of bedroom wardrobe interior fittings. The collection allows wardrobes and walkin wardrobes of all styles to accommodate elegant hangers, scarves and tie hangers, bag hangers, cotton garment holder bags, trouser hangers and shoe racks – all elements of singular refinement and efficiency. In addition, glovebox trays, watch-holder trays, ring-holders and earring-holders are available in various dimensions, with multiple finishes from fabrics to leather and a variety of colours from racing

1/2 page landscape.indd 1

FP316_Pages.indd 21

green to rich cream. Visitors can also experience Salice’s Exedra – the updated version of its industrystandard pocket door system. The new version incorporates a linear magnetic damper that gently controls the movement of the door as it moves smoothly and silently into and out of its recess. In addition, a Smove piston cushions the door as it closes onto the cabinet.

Salice’s pioneering hinges will of course be on the stand too, including the Silentia+ range. Designed to offer the most advanced deceleration system, Silentia+ delivers a consistent closing action across a range of hinges for doors of all sizes, weights and applications. 01480 413831 www.saliceuk.co.uk

16/01/2020 11:59

28/01/2020 09:32

We may have only a couple of days to do an impossible job, but ALPHACAM makes it possible.”

ALPHACAM

Jason Szukalski Director Anarchy Ltd

Simple yet powerful CAM software for wood

By the numbers

45,000+

Active users worldwide According to the latest CMA Benchmark Study, more woodworkers choose our products than any other software system. In fact, it’s not even close.

37 97% 85/11

Years developing software Satisfaction with our support

Countries/Languages Our software can be found all over the world and it’s available in 11 languages.

| alphacam.com

FP316_Pages.indd 22 Double Page Spread.indd 1

28/01/2020 09:32

s

CABINET VISION The complete solution for the casegoods industry From cutlists, renderings, shop drawings, bidding and pricing, to CNC output, CABINET VISION makes the easy jobs simple and the complex ones possible. • • •

Custom cabinet & room designs Photo realistic renderings Material Optimisation

• •

Full costing direct from design Cutlists & bill of materials

We use CABINET VISION every day, and we can’t live without it.” Terry Moore Vice President of Design Sunrise Wood Designs

| cabinetvision.com Join us at KBB from 1-4 March 2020 on Stand O85

FP316_Pages.indd 23

28/01/2020 20/01/2020 09:32 14:49

24 INSTALLATIONS

After seeing a machine he believed would benefit his company’s production, Senator Group – Specialist Division production manager Phil Haggerty made contact with JJ Smith to examine the option more closely.

Senator Group – Specialist Division installs second MZ Pluris CNC working centre MZ Pluris CNC working centre

The Senator Group, based in Accrington, Lancashire is recognised as a world-leading manufacturer of office furniture exporting to a total of 70 different countries. Founded in 1976 by Colin Mustoe, now the chairman, the company comprises three brands, Senator, Allemuir and Torasen, which in total employ over 1200 people with manufacturing floor space exceeding one million ft2, which includes its plant in Ohio, USA. In addition, Senator has international sales offices and showrooms in Europe, Asia, Africa, Australasia, North America and, of course, the UK. Despite its size, Senator is proud that it remains an independent, family-owned business with all the things that were important in the beginning – attention to detail, integrity, investment in people and passion for design – still very much running through the veins of the

FP316_Pages.indd 24

business today. There has also always been the philosophy of investing in the very latest and best manufacturing equipment available which has recently been highlighted in the machinery installed at the Specialist Division in Huncoat. The Specialist Division came about in 2009, and in 2011 a previously-acquired frame manufacturer, Timack, was integrated into the Specialist site. The pre-upholstered part of the site had previously been nesting all the OSB, ply, MDF and chipboard components that make up the various frames which are then supplied to the Seating Division. To do this it had a standard nesting CNC router with auto loading and unloading. Although the machine had the capability to machine more than one sheet at a time, this was dependant on the size of the part and the material it was being produced from.

As a result, production manager Phil Haggerty started to investigate if there were other machines available better suited to meet his requirements. By chance he was looking one day on Twitter and came across a video clip posted by JJ Smith on an MZ Pluris CNC working centre. The video intrigued Phil as he had not seen a machine like this before, and as result he contacted JJ Smith to set up a meeting so he could learn more about what it could do. JJ Smith sales director, Guy Stanley, visited the site and reviewed all the parts Senator needed to produce, and he confirmed they could indeed be made on the machine Phil had seen in the video, but with some significant benefits over its current process. First off, and probably most importantly, the Pluris incorporates a CNC bandsaw that can automatically swivel +/- 90° meaning it can

28/01/2020 09:32

25

cut parts a lot faster than a standard router, in addition to being able to cut some shapes of parts a router can not. Also, as the bandsaw blade thickness is only 0.8mm, it is possible to create a much tighter nested program which results in more parts and less material wastage. Secondly, it does not use any vacuum to hold the sheets down – instead panel grippers are used meaning it is possible to hold and machine a stack of three, four or five panels totalling about a maximum of 60mm in thickness – be it that the bandsaw/router can cut higher. Thus production output is significantly higher then when just cutting one sheet on a conventional router. Thirdly, when equipped with the optional automatic lift table, the Pluris is a one-man operation where cut parts are actually being produced and collected by the operator whilst the machine is still working. The router head is used when it is not possible to use the bandsaw, or when it is necessary to make a hole enabling the bandsaw to turn. If there is a requirement to drill holes there is a five-spindle point-to-point drilling unit. As a result of this meeting a factory visit to see a Pluris in operation at a furniture

manufacturer in North Wales was set up. Seeing the machine in full production just reinforced Phil’s belief this was a machine Senator needed to invest in. To back this up, sample part drawings were sent over to MZ Project who then created nested drawings, and gave estimated production times for each. Once Phil compared these to current timings and number of parts produced it was in his words a “no brainer” as to which direction he should go, and he quickly put forward a justification proposal to the main board which was passed straight away, and an order then placed. The machine was specified with a working sheet size capacity of 2500 x 1550mm, automatic lift table, CNC bandsaw, router and drilling group together with automatic set up and moving of the clamps and support rails through the program. Included as standard is a side conveyor belt for cut parts and an internal conveyor for waste. Programming is carried out using Alphacam nesting software. The machine was ready on Cut parts discharged on to side conveyor belt

One of the many seating systems Senator design and manufacture

schedule and prior to dispatch from Italy, Phil and his team went over to the MZ factory for training and inspection testing. The MZ Pluris has now been installed at Senator for 18 months and such has been its success a second Pluris was installed just a month ago. Phil comments: “As soon as I saw it in operation on site I was convinced it was the machine for us, and this has been borne out by the increased productivity and reduced waste we have experienced since it was installed. “Therefore when it became apparent we needed to step up production even further, it was an easy decision to order a second machine. We have been delighted with the performance of both and it has also been a pleasure to work with both JJ Smith and MZ Project who have been very helpful and professional from the outset.” Guy Stanley concludes: “The MZ Pluris has proved to be a real winning machine for us as it offers a number of significant tangible advantages over standard CNC routers and we are delighted that Senator are reaping the benefits.” 0151 548 9000 sales@jjsmith.co.uk www.jjsmith.co.uk

MZ Pluris can machine multiple sheets

Automatic loading of sheet material

FP316_Pages.indd 25

28/01/2020 09:32

C

Dedicated

#371 February 2020 www.furniturenews.net

MODERN HISTORY

to the furniture industry

Cintique’s evolving heritage

FEATURING

Hotel, restaurant and bar design FOR

Designers, architects, specifiers, operators

INTERIOR DESIGN FOR HOTEL S , RES TAUR ANTS , BARS & CLUBS ISSUE 87 | JANUARY - FEBRUARY 2020

Direct delivery The Very Group reaches out Cyber security for SMEs Slumberland’s digital development

BFM FABRIC SHOW LONDON BEDROOM / LIVING / TRADE SERVICES

FN371_Cover.indd 1

www.hospitalityinteriors.net 28/01/2020 12:44

FEATURING

Domestic furniture, furnishings and services FOR

Retailers, designers, suppliers February 2020 #316 News / Events / Updates Installations / New products

www.furniturenews.net

KBB Preview / Saws & Cutting Technology Edgebanding Materials & Technology

www.furnitureproduction.net

HI87_Pages.indd 1

29/01/2020 14:47

FEATURING

Machinery and components FOR

www.hldc.co.uk

Manufacturers, joiners, cabinetmakers www.furnitureproduction.net

Three new ABS edgings with real metal plating Now available as a matt variant FP316_Pages.indd 1

www.thehishow.co.uk

28/01/2020 09:31

Delivering specialist publications and marketing solutions since 1984

www.gmgconnect.com

INFORMING INDUSTRY

GMGad_FN(fullpage)2020.indd 2 FP316_Pages.indd 26

BUILDING BUSINESS

29/01/2020 30/01/2020 14:49 12:36

Full pag

20 11:50

CNC Machinery Available and Ready For Demonstration

AES Sirius 950M CNC Drilling Machine With Router This machine is a "must have" for anyone producing kitchen or bedroom furniture. Cutting and edging are always a relatively quick and easy process, but assembly is where problems can arise when using manual methods where both speed and accuracy can be open to question. The AES Sirius allows you to accurately and efficently process panels ready for assembly.

AES Extreme 1632 CNC Nesting Machine The AES Extreme machines are available as a "stand alone" machine or as a through feed nesting line. All machines are heavily engineered using quality branded components and with linear speeds of 70 m/min to ensure efficiency, durability and productivity. The machine is supplied with alphacam CAD/CAM software.

AES Vega Evo 1332 Door and Panel Machine This machine is the ideal multi-function CNC machining centre, whether processing door blanks or domestic or office furniture. The machine is equipped with two working zones, an eight position linear tool change, can face and end drill and has a dedicated horizontal router head to allow mortising of locks and recessing for hinges. Along with easy to use macros, the machine is supplied with Alphacam.CAD/CAM software

AES machines distributed in the UK by J&C O'Meara Ltd. J&C O'Meara Ltd. Unit 4, Falcon Place Burscough Lancashire L40 8RT 01704 893109 www.ukwoodworkingmachinery.co.uk

FP316_Pages.indd Full page.indd 1 27

28/01/2020 06/12/2019 09:32 10:28

28 INSTALLATIONS

Ferwood: sawing ahead at leading caravan manufacturer Atlas Leisure Homes are one of the UK’s leading caravan manufacturers, producing upwards of 44 caravans a week from its manufacturing facilities in Hull. But, when faced with an ageing beam saw that was breaking down three or four times a day and increasingly challenging turnaround times, the company needed to source a replacement or run the risk of falling short on their weekly orders. The solution was a Holzma Profiline HPL 510 beam saw from reconditioned machinery specialist, Ferwood. “In our line of work, we can’t afford for breakdowns to impact our production lines,” begins Michael Mason, Machine Shop Manager at Atlas Leisure Homes. “We pride ourselves on offering our customers the very best service and a high quality product. We can’t have our lead times dictated by unreliable machinery and continual breakdowns. When our production showed signs of slowing down due to our beam saw, we chose to work with Ferwood to find an alternative.” Atlas Leisure Homes is no stranger to purchasing used machinery and have found it an economical way of purchasing highspecification machinery for their factory. “We’ve found that buying used machinery can be really good value for money and if, like us, you have a good idea of the kind of machine you want, it’s often a really straightforward way of doing business,” Michael points out. “We were running our old Holzma beam saw for 18 years and were keen to continue using a brand that, until recently, had served us well. In addition to the build quality, the new model needed to work quickly and efficiently on batch orders and cut 400 panels over the course of two 10 hour shifts per day.

FP316_Pages.indd 28

“It also needed to work with 12 and 25mm MFC, 11 and 25mm Sterling board, chipboard and plywood so both a main sawing unit and scoring unit were needed. The option of remote programming and integrated optimisation software that could help us reduce material waste and man-hours was also desirable.” Following an online search, Michael got in touch with Ferwood, who stock a wide range of beam saw brands including Holzma. “We knew of Ferwood and came across several Holzma beam saws on their website that looked like they could work for us. Unlike other suppliers who often just service the machine before selling them on, Ferwood offered us a ‘Ferwood Approved’ beam saw that had been fully reconditioned from top to bottom and a six-month warranty to boot. Not only was this machine considerably cheaper that a new machine of the same specification, we were getting a reconditioned, fully serviced machine delivered to us at a time that suited us. It was a major selling point.” Once fully tested by Ferwood’s specialist engineers, Michael flew to Italy to see the beam saw in action and, following an in-depth demonstration using their own materials, agreed for the machine to be stored until their summer shutdown. “Our manufacturing facilities close for three weeks during the summer. It’s the only time we can afford to not have the beam saw up and running. The installation of the new saw had to take place during this timeframe and be ready to work as soon as we re-opened.” True to their word, the new Holzma Profiline HPL 510 beam saw beam saw was delivered and fitted within the agreed timeframe. The engineers even worked around a new extraction system that was being installed at the same time. As Michael says: “It went like clockwork.”

With its new beam saw in place, Atlas is poised to increase productivity. The new machine not only has rear rollers designed to speed up lateral preloading of the machine, but once loaded, it can also cut up to seven panels at a time, cutting the overall running time when putting time-sensitive, batch orders through the saw. Its software has also de-skilled the job of the operator and has reduced the risk of errors thanks to its clear and precise cutting patterns. The machine gives a clear indication of what needs to be done to optimise each job and directs the operator if re-cuts are needed. It even highlights what needs to be completed and when. “These functions are already proving valuable to production and have led to faster cutting, more effective use of labour and reduced material wastage.” Michael adds: “Now we have good quality machinery in place, our next step it to look at more ways to automate our manufacturing processes and streamline our production. We’re already looking to incorporate rainbow stacking alongside the new beam saw to increase efficiencies further – something we would not have been able to consider without the installation of a fast and reliable beam saw. The Holzma beam saw has certainly impacted our business positively and we’re excited to see where our relationship with Ferwood will take us.” 0113 286 6689 www.ferwoodgroup.com

29/01/2020 10:46

GMGa

WE’VE GOT A HANDLE ON THINGS

over 50 years serving the trade

With over 18,000 products in stock for NEXT DAY DELIVERY, we always make sure you get the service and the product needed for the job. Visit us online today. CALL: 7am-8pm 7 days a week

0808 168 28 28 ONLINE: Shop 24/7

IronmongeryDirect.co.uk FP316_Pages.indd Full page.indd 129

30/01/2020 11:34 20/01/2020 11:50

30 INSTALLATIONS

Editing floor plans has slashed programming time for custom cabinetmaker, Sunrise Wood Designs…

Cabinet Vision overcomes grain matching nightmare

A wooden furniture design specialist uses Cabinet Vision to produce a high volume of custom residential projects. Sunrise Wood Designs uses what it describes as a “masterful combination of talent and technology” to serve the largest residential market in the US. Located in Dallas, Texas, the 12-year-old company serves the greater Dallas-Fort Worth area, for which it builds cabinetry for roughly one-third of all of the region’s new homes. Two plants turn out cabinetry for about 30 houses per day — including jobs that range from modular to highly customised kitchens, bathrooms and dens. COO Geoffrey Athey says: “We’re the largest custom residential-cabinetmaker in North Texas, and two things make us unique: first, we design, produce, and install our own cabinets; and second, we work in both the volume homebuilding and high-end custom homebuilding segments.” Continued overleaf >>

FP316_Pages.indd 30

30/01/2020 11:36

2213

Make your space the place

ROOMS O T T H G BROU

LIFE

decofoil deco foil 3D Forming Veneers for kitchen, bedroom and bathroom furniture We offer an exciting range of contemporary and traditional styles, all with excellent board matches Find out more about our exciting range of contemporary LG Hausys PVC foil materials for kitchen, bedroom and bathroom.

Call: +44 (0)1376 518037

FP316_Pages.indd 31 Decofoil-FurnitureProd.indd 1 2213-Clouting Advert

28/01/2020 09:32 28/02/2018 12:58

32 INSTALLATIONS

<<

Sunrise Wood Designs produces about 2000 cabinets each week, with a workforce of 300. On any given day, the company delivers products to between 130 and 150 different addresses. About 80% of the company’s work is high-volume, custom cabinetry, while 10% is high-end or luxury cabinets, with the remaining 10% being more modular. “Multiple floor plans for a particular subdivision may be similar, but most of what we do is custom cabinetry, because most framers don’t follow their floor plans,” Geoffrey says. Sunrise Wood Designs transitioned to the Cabinet Vision Screen-to-Machine (S2M) solution in 2016, to produce its high volume of custom cabinetry. Vice president of design, Terry Moore, says: “We use Cabinet Vision every day, and we couldn’t live without it. We rely on its design, job-planning and CNC production capabilities to manage jobs across roughly 11 different product lines. The program generates drawings and cut sheets for us and, without it, we couldn’t do what we do. Every department uses it.” With any Cabinet Vision project, the Sunrise design team begins each job by using the dimensions of the space in which the project will be installed, and then builds the job within that virtual space. Due to the volume of their projects, the team uses a master plan that contains several floor plans for each subdivision. Once the actual building site is measured, those existing floor plans are adjusted to reflect accurate dimensions. As Cabinet Vision enables users to save processes, Terry and his design team are able to edit and re-use processes saved from previous programs. This cuts programming time, and is especially helpful for jobs that are similar or nearly identical. “Our term for saved processes is ‘Do Likes,’ because we know there are jobs that we can do in the same way as we’ve done previous jobs.” While saved processes are helpful for any kind

of similar jobs, editing residential subdivision floor plans simplifies the management of the company’s large, detailed projects. “We’ll save the design as the plan number, which we get from the purchase order, and then save the tweaked plan as the actual address of the project. This makes everything a lot easier to work with.” Cabinet Vision’s ability to quickly generate shop drawings also makes the software a useful graphical tool for communicating job details at a glance. “We’re production based, so the blackand-white lines and bird’s-eye views that we can generate just by clicking a button are great,” he says. Sunrise Wood Designs takes advantage of Cabinet Vision’s User Created Standards (UCSs) to automatically apply custom construction methods under specific job conditions. For

FP316_Pages.indd 32

instance, if a user prefers a certain construction method when working with a particular type of material, Cabinet Vision applies a UCS for that method when the material is used. Further embracing the customisable nature of the software, the Sunrise design team also creates custom cut lists for its shop floor staff. Terry notes that CNC production allows the company to complete several operations in one setup, which saves time and reduces scrap. With the use of Cabinet Vision, more complex jobs — such as those that require grain matching — can be completed both quickly and without error. “When we do the grain matching, it works so well for us — and doing that by hand is a nightmare to get right. Now, we just cut them out on a router and label them, and it goes together perfectly.” www.cabinetvision.com

30/01/2020 11:37

33

DOOR PROCESSING MACHINERY SHOW 24th—26th March 2020 THE LATEST TECHNOLOGY AND EQUIPMENT DEDICATED FOR THE MACHINING OF DOORS AND FRAMES.

Essepigi - Through Feed CNC Door Machining Centauro - Flexible CNC Machining centres for doors and frames Emintosun - Machines for cutting and machining for frames Stromab Matrix F - Programmable cross cut and trenching Omga - TRF mitre saws for glazing beads

CNC Robotics - Robotic door handing systems Plus a wide selection of standard woodworking machinery!

OPENING HOURS 8:30—5PM

For further information or to register your attendance please send your details to:

sales@jjsmith.co.uk or +44 (0) 151 548 9000

JJ Smith (Woodworking Machinery) Ltd, Unit 4, Moorgate Point, Moorgate Road, Knowsley Industrial Park, Liverpool, L33 7DR

www.jjsmith.co.uk

FP316_Pages.indd 33

30/01/2020 11:37

34 EDGEBANDING MATERIALS & TECHNOLOGY

Three new ABS edgings with real metal plating The trend of matt designs has now reached metal surfaces as well. And Ostermann always has an answer when it comes to the right edging. Under the names Alu Acciaio Hamilton, Alu Argento Dukat and Alu Oro Cortez, customers will find three new ABS edgings with a particularly matt real metal plating. Under the name Fenix NTA, Italian manufacturer Arpa Industriale launched three new metal decors. The surfaces – named Acciaio Hamilton, Argento Dukat and Oro Cortez –have a real metal structure and are

FP316_Pages.indd 34

characterised by their extremely matt look and their soft touch. In Germany, they have already been awarded with the Interzum High Product Quality Award and the Red Dot Award Product Design. Edgings specialist Ostermann has now selected three new edgings with a matt metal look to match these surface finishes. The silver-, gold- and stainless steel-coloured ABS edgings Alu Argento Dukat, Alu Oro Cortez and Alu Acciaio Hamilton have a thin layer of real metal. They have an extremely matt, brushed surface finish. The new edgings are available from stock in the standard

dimensions 23, 33, 43 and 100 x 1mm, and just as easy to process as standard ABS edgings. With its familiar fast delivery service, Ostermann supplies edgings in every length starting from 1m, and in every width up to 100mm. Europe’s largest range of edgings comprises more than 14,000 edgings to match the board surfaces of more than 70 board suppliers. For further information on the new edgings, type “highlights012020” into the search field of the Ostermann website. www.ostermann.eu

28/01/2020 09:32

Full pa

KEEPING BRITAIN BONDED SINCE 1979!

Edgebanding Adhesive Specialist PUR - inc Micro Emissions - EVA - PO

Letâ&#x20AC;&#x2122;s Talk Glue

Visit www.kenyon-group.co.uk Call 0161 627 1001 FP316_Pages.indd Full page.indd 1 35

28/01/2020 20/01/2020 09:32 11:52

36 EDGEBANDING MATERIALS & TECHNOLOGY

Feel-good edgings The large variety of surface structures and gloss levels that can be found in furniture boards are reflected in the range of edgings as well. A few years back, edgings were offered with a minipearl finish, for the most part. Now, Ostermann provides its customers with a choice of 20 different surface finishes. Chipboard panels with wood- or stone-look décors do not only convince with optically perfect printings. They also have an extremely realistic feel, which makes it hard to distinguish between the decor and the real material. To maintain the impression at the edging as well, Ostermann offers edgings with a large number of different embossings – from the unobtrusive, slender wood pore to the deep Linea structure. Uni decors can be felt as well With the surfaces minipearl, satin finish or velvet structure, even plain-coloured boards can be

FP316_Pages.indd 36

equipped with an individual feel. Minipearl is still a perfect all-rounder. For more refined surface finishes, you can choose the satin finish. A velvet structure is particularly soft. This is why Ostermann has matched edgings with a velvet structure to the Forbo Desktop surfaces. Different types of matt Ostermann meets the variety of gloss levels with numerous different surface finishes, ranging from ‘Excellent Matt’ with a gloss level <5, to its counterpart ‘Excellent Gloss’ with a gloss grade >90. In between, there are many additional gloss levels to choose from, such as super matt, smooth, gloss or high gloss. Always remarkable – metal and mirror look The more than 60 different ABS edgings with a real metal coating from the Ostermann range have a ‘brushed’ finish, which makes them a perfect addition to wood materials with a real

metal surface. Among the edgings, there are three completely new ABS edgings with a matt metal look. Particularly for mirror surfaces, the edgings specialist provides an edging coated with a layer of reflective aluminium. Edgings from 1m Notwithstanding the great diversity, it is very easy to find the right edging to a wood-based panel at Ostermann. Just type the board name or board number into the search field at the starting page of the online shop and the edging which matches the board perfectly regarding both embossing and gloss level will be shown. The selected edgings are supplied in every length from 1m. All stock items ordered before 4pm are sent that same day. For further information on the new edgings, type the search item “edging finishes” into the search field of the Ostermann website. www.ostermann.eu

28/01/2020 09:32

Full pag

FP316_Pages.indd 37 Full page.indd 1

28/01/2020 23/07/2019 09:32 09:22

38 EDGEBANDING MATERIALS & TECHNOLOGY

Kenyon Group edgebandging specialist at the Kenyon Group gives his view of edgebanding adhesives…

Don’t underestimate edgebanding adhesives “There are edgebanding adhesives, and then there are Henkel edgebanding adhesives – it’s really that simple,” says James. “Henkel edgebanding adhesives cover PUR, PO and EVA technologies, and offer superior products at the right price with proven results – just ask anyone using Henkel edgebanding adhesives! “Henkel offer an exceptional range of PUR adhesives supplied in granules, 2kg blocks, 20kg drums and 200kg drums for all known edgebanding machines and applications – and they are also available in ME (Micro Emissions). “The tried and tested, marketleading Technomelt 270-7 has a proven, winning background and is probably the most versatile grade on the market offering exceptional high performance. However, it’s not just the adhesive that makes Henkel PUR adhesives the market leader, it’s the technical and on-site

support offered by both Henkel and Kenyon’s that separates us from the rest of the field. We don’t just sell adhesives, we live them and this includes supporting you! “Yes, PUR adhesives dominate the market. Over the years PUR adhesives have been more accessible to customers which are edging – and as technologies advance, PUR adhesives’ outstanding performance has become available to all edging customers delivering the finished goods to the highest standards. “EVA-based adhesives are still a big player and Henkel offers a range from filled to unfilled, and everything else in between to suit every application. Edgebanding using EVA hot-melt is commonly used due to the ease of use, but PUR adhesives have rapidly gained ground with incomparable benefits. If joints need exceptional water or heat resistance then PUR adhesives

James Hamilton, edgebanding specialist at the Kenyon Group

are recommended as they have a significantly superior performance versus an EVA adhesive. “EVA hot-melt adhesives are classed as filled and unfilled. Filled adhesives such as Technomelt KS220 and Technomelt 611 are generally lower costing but still offer exceptional performance and a high final bond strength. The addition of fillers can offer advantages such as preventing stringing and can be beneficial when running porous chipboard. Unfilled hot melt adhesives such as Technomelt