DEVELON log loaders are proven to do difficult work in extreme conditions. They’re equipped with safety features to protect operators, heavy-duty components to stand up to obstacles, and easy maintenance access to preserve your productivity.

DEVELON – proven to put logging challenges in the done pile.

Five Oregon sawmills have closed so far in 2024 in response to weak lumber prices, inflationary costs, unreliable public timber supplies, and increased regulation and labor burdens.

However, the outlook is improving as forest product analysts anticipate sustained housing demand will lead toward future improved markets with higher lumber price indices for the remainder of this year.

The cumulative Oregon economic impact of these closures is an estimated reduction of approximately 700–1,000 direct workers statewide, including 326 mill employee layoffs, suppliers, and contractors who are idled. Additional indirect and induced job losses will increase, annualized, as the curtailment duration prolongs.

All five mills rely on state and federal forests for some of their raw material — public sources that are increasingly unreliable, costly, and declining contributors to the regional timber supply chain.

C&D Lumber Co. permanently closed its Riddle dimension sawmill in early May, laying off 93 employees. C&D said the closure was due to “the unprecedented challenges facing the industry today,” including low lumber prices, rising operating costs, unharvested burn areas, Private Forest Accord changes, regulation burdens, and timber shortages from public lands.

Prairie Wood Products indefinitely closed its Prairie City sawmill in March due to federal timber supply challenges and unresolved conflicts in a timber-biomass transportation grant with the U.S. Forest Service. An idled co-generation biomass power plant is also at the site.

Interfor indefinitely closed its Philomath dimension sawmill complex in February. Hampton Lumber closed its Banks dimension sawmill in January (it had been idled a couple months), and Rosboro Co. closed its Springfield stud mill in January for up to two years as it invests $100 million to upgrade its Springfield dimension mill, planers, kilns, and glue-lam beam plant.

U.S. Forest Service Chief Randy Moore faced withering criticism from a top Senate Republican recently after suggesting his agency shouldn’t necessarily focus its wildfire prevention efforts at treating more acres.

At an Energy and Natural Resources

Committee hearing, ranking member John Barrasso (R-Wyo.) ripped Moore for downplaying the significance of acreage goals. “We haven’t been doing a very good job of protecting against wildfire.” Barrasso said. “To me this seems a complete lack of urgency by your department with all of this.”

Barrasso and others are concerned that the agency’s removal of wildfire fuel hasn’t increased at the pace lawmakers envisioned.

Looking at acres treated may be an outdated approach, Moore said, given that the nation’s forest landscape — including rapid development in fire-prone areas — has changed dramatically in the century since the Forest Service was created.

With all that development, where forests are thinned and homes protected may matter more than how big those areas are, suggested Moore. “Is that the right metric for performance?” he asked.

Unconvinced, Barrasso responded, “If you don’t like the results, then you change the metrics — that’s ridiculous.”

With less than two months before a draft is published, counties are trying to offer input while the U.S. Forest Service works toward an amendment to a rule guiding protections for old-growth forests.

The amendment would comprehensively guide policies for 128 national forests nationwide, but critics say the process has left counties out until past the time their input could be meaningfully considered. County officials have likened adding their comments to the plan to jumping on a moving train.

“What the Forest Service is trying to do feels like they’ve worked on this for some time, and they’ve given a very short window to ‘cooperate’ with counties on plans that impact us on a large scale locally and a broad brush plan for the country that doesn’t make any sense,” said Klamath County (Oregon) Commissioner Derrick DeGroot.

The amendment follows President Biden’s executive order in 2022 to develop policies, with robust opportunity for public comment, to institutionalize climate-smart management and conservation strategies that address threats to mature and oldgrowth forests on federal lands.

The opportunity for public comment, however, is largely restricted to cooperating agencies, a mechanism that is only now being finalized by the Forest Service. Cooperating agencies receive more information and

(continued on page 6)

Editor: Tim Cox, tim@forestnet.com

Contributing Editors: Mike Albrecht, Mary Bullwinkel, Steve Wilent

Send both OLD and NEW Circulation information to: TimberWest Magazine Attn: Subscriptions P.O. Box 610, Edmonds, WA 98020 Fax: (425) 771-3623 • subscribetw@forestnet.com

CEO / Advertising Sales: Anthony Robinson – arobinson@forestnet.com Phone: (778) 991-3500

Associate Publisher/Advertising Sales: Hannah Robinson – hannah@forestnet.com Phone: (604) 990-9970

Publisher & Production Manager: Sheila Ringdahl – sringdahl@forestnet.com

Digital Marketing: Anthony Robinson arobinson@forestnet.com

Social Media: Kaitlin Davidson

Accounting Manager: Shelina Jessa – accounting@forestnet.com

Corporate Office Information: Phone: (425) 778-3388 • Fax: (425) 771-3623 timberwest@forestnet.com • www.forestnet.com

TImberWest Publications, LLC P.O. Box 610 (300 Admiral Way, Suite 105) Edmonds, WA 98020-0610

PUBLISHER’S EDITORIAL STATEMENT: TimberWest reports on the logging and lumber segment of the forest industry in the Western United States with emphasis on the states of AK, WA, OR, ID, MT and CA, providing current information on timber harvesting techniques, sawmill operations, news, legislation, events, people and products pertinent to this market.

TIMBERWEST (USPS #024858) is published bi-monthly (Jan/ Feb, Mar/Apr, May/Jun, Jul/Aug, Sept/Oct, Nov/Dec) by TimberWest Publications, LLC, 300 Admiral Way, Suite 105, Edmonds, WA, 98020. Periodicals postage paid at Edmonds, WA and at additional mailing offices. Copyright 2023. All rights reserved. Subscription rates to qualified subscribers are Free and all non-qualified subscriptions in U.S. are $22 per year payable in advance. Canada $35 (U.S.). Other $60 (U.S.). Single copies paid in advance $4. Company affiliation, title, date and signature must appear on subscription forms. Publisher reserves the right to refuse non-industry subscriptions and advertising. All other advertising is accepted at the discretion of the publisher. Publisher does not assume any responsibility for the contents of any advertisement and all representations or warranties made in such advertising are those of the advertiser and not of the publisher. Back issues, if available, $4 each. Directory and Calendar issue $10 each.

Advertising created by TimberWest Publications, LLC is the sole property of TimberWest Publications, LLC and may not be copied or reproduced without the express written permission of the publisher.

Canadian Publication Mail Product Sales Agreement #40740074. Return Undeliverable Canadian Addresses to P.O. Box 86670 Stn. Main, North Vancouver, BC V7L 4L2

Printed in Canada at Mitchell Press

Printed on FSC®certified paper.

POSTMASTER: Please send address changes to TimberWest, P.O. Box 610, Edmonds, WA, 98020-0610

Woodsman Pro tree harvesters and felling heads have been terrifying trees and leaving forestry professionals speechless for decades. Faster, stronger and packing proprietary technology that’ll supercharge your productivity, New Zealand’s Woodsman Pro range is now available in the USA.

For features and specifications of our TREE HARVESTERS & FELLING HEADS visit www.woodsmanpro.co.nz or email david@ensign.co.nz

(continued from page 4)

engagement in the process, which can give their feedback more weight than that from the general population.

County leaders are applying to become cooperating agencies to gain more information and offer more input, but no counties have been successful, according to the National Association of Counties, which is working directly with the Forest Service on providing feedback.

Washington had fewer dead or dying trees last year, but beetles that feed on dry trees caused greater damage across the state.

The state’s annual forest health survey found that Washington’s forests are suffering from increased heat, drought and wildfires, making them more susceptible to deadly beetles that feed on bark.

About 348,000 acres of trees last year showed signs of bark beetle damage, according to the survey. That’s slightly up from 2022’s 346,000 acres.

Glenn Kohler, a state forest entomologist, said it’s hard to tell for sure if the drought is causing the beetle populations to spread, but it is likely. “I think they’re just breeding up in drought-stressed trees and moving to other drought-stressed trees,” Kohler said. “As long as these drought effects remain, I anticipate we’ll see more.”

The outlook for this year isn’t better. Much of Washington is already considered abnormally dry or in a moderate drought.

local, state, tribal, and federal agency admin istrators, and fire management officers for a briefing on the 2024 fire season and called for greater collaboration from the federal government on active forest management.

suppress fires and minimize their impact on families, homes, and property,” said

Gianforte. “Together, we can continue to build healthier, more resilient forests but we need better cooperation in order to get the job done. That’s why I’m calling on everyone here to join us and get more private, state, tribal, and federal acres actively managed.”

Amanda Kaster, director of the state Department of Natural Resources and Conservation, said Montana is ready for the fire season. “Not only through our fire protection program, but also through the work we do to reduce wildfire risks through crossboundary, landscape scaled forest management,” she said.

In 2023, DNRC kept 96 percent of fires in its direct protection to 10 acres or less. The state also placed over 36,000 forested acres under management in 2023, compared to 11,000 acres in 2020.

Highlighting the importance of action and collaboration from federal partners, the governor said, “We can continue building on our success immediately. We have the model and infrastructure in place. My challenge to folks around this table is to find projects, build partnerships, and utilize the tools available to bring more acres under active management.”

A proposal to build a wood pellet manufacturing facility in Hoquiam, Washington, has received approval from regional air quality officials to move forward with construction.

The Olympic Region Clean Air Agency (ORCAA) issued its final determination on a 2023 air quality permit from Pacific Northwest Renewable Energy to build a plant that would turn woody biomass into

will produce about 450,000 tons of wood pellets per year and export them.

The Montana Department of Natural Resources and Conservation has awarded $3.1 million for 13 projects to reduce wildfire risk to communities and improve forest health. The funding money is part of the $15 million Montana Forest Action Plan, which takes a big-picture approach to reducing the risk of wildfires.

Wyatt Frampton, deputy division administrator of forestry and trust lands for the department, said the money will be used to foster fire-management cooperation between state and private landowners across 3,200 acres of forest.

“Through a variety of activities, such as prescribed fire, logging, mechanical thinning, hand activities as well as tree planting,” Frampton outlined.

Frampton said the DNR is aiming to create a cohesive fire-reduction plan across Montana’s landscape, which has until now been inconsistent because of different sets of land-management practices.

A state forestry official says the 2024 Oregon wildfire season looks to be a moderate one so far.

Al De Vos, a public information officer with the state Department of Forestry’s Incident Management Team 2, said the outlook between now and late June is fairly decent across Oregon, Washington and northern California.

posal meets all air quality criteria required by Washington state, including compliance with local, state and federal standards and

With the decision, Pacific Northwest Renewable Energy has the go-ahead to construct pellet mills, storage silos and a conveyor on a 60-acre parcel, property leased through the Port of Grays Harbor. The plant

“We’re looking pretty well in terms of snowpack and precipitation and what-not,” said De Vos. “But a couple months in, there’s certain areas that are a little more on the dry side.”

De Vos said come summer, fire managers will be doing weekly outlooks. Even in damp conditions, all it takes is a few days of sustained easterly winds to dry out terrain and make it susceptible to fire, he noted.

“So even though we have non-drought or normal precipitation conditions there are still fire risks out there,” he said.

Increasingly warm and dry conditions have been recorded through many parts of the Pacific Northwest in recent years. A particularly damp and heavy winter has helped alleviate drought conditions in many areas of Oregon.

On a brisk but sunny January day in the Southeast, an instructor was hosting a chainsaw safety training workshop at a fenced-in workshop and training compound. At the end of the training, in the mid-afternoon, the instructor and a young staff member were setting up two pine logs on support skids using a log grapple (lifting tongs) attached to a farm tractor. Both individuals were wearing personal protective equipment: hard hats, steel-toed boots, high-visibility vests, leather gloves, safety glasses, and hearing protection.

The staff member was operating the farm tractor, moving logs from a nearby storage area to the training site. Once a log was transported to the training site, the staff member would lower the log onto two support skids. The instructor would then move in to manually release the log grapple and swing them on top of the log.

The second log that was placed on the skids initially had too much overhang on one side for training purposes; therefore, the staff member lifted the log again and moved it into the right position. When the log was lowered, one of the four corners of the log grapple became caught on a support skid, allowing the tractor boom to be loosely supported on the log grapple.

Unaware of the dangerous situation, the instructor proceeded to manually

release the log grapple. When getting into position, he noticed the log grapple was caught on one corner and observed that the wood underneath the corner was breaking loose. Before he could move out of the way, the weight of the boom broke off the wood and suddenly opened the log grapple, swinging wideopen and striking the instructor in the face.

The instructor stumbled backward and then lowered himself to the ground. Injuries included a deep laceration below the lip and extensive dental damage, as several upper front teeth were broken.

The injured instructor initially refused medical care. The young staffer eventually called 911, but he was unable to provide an exact address. The instructor was able to provide the information, which was conveyed to the 911 dispatcher. The initial 911 call was routed to the improper county dispatch center. Instead of immediately accepting this transfer, the young staff member tried to argue with the dispatcher and further

explain the location of the accident.

When the dispatcher asked for accident details, the young staffer had trouble explaining what had happened. The instructor, still lying on the ground and bleeding, coached the young staff member on providing more details to the dispatcher.

First responders arrived after a few minutes and began assessing injuries and administering first aid. A cervical collar was placed on the instructor to prevent spinal injuries, and he was then transported to a regional medical center for treatment.

• Always assess potentially dangerous situations, including stored energy hazards, before approaching operational heavy machinery.

• Adopt an Emergency Action Plan and periodically rehearse emergency response situations. This includes ensuring all employees receive basic first aid training and are educated on directing emergency personnel to work and training sites.

• Never argue with first responders and emergency personnel. Time is critical!

• Enlist the help of staff members and other bystanders to retrieve first aid kits, call 911, etc.

(Source: Forest Resources Association (FRA), a national advocacy organization representing the entire wood supply chain. Visit them at www.forestresources. org.)

Marks Lumber has completed a major retooling of its sawmill. A refurbished combination gangedger and other improvements completed in 2023 doubled production capacity. The company’s 15-20 employees now can produce 2 million board feet of specialty lumber products a year.

Located in Clancy, Montana, about 10 miles south of the capital of Helena, Marks Lumber manufactures siding, tongue-andgroove boards for paneling, trim and fascia, flooring, rough-sawn timbers, and other products – primarily of Douglas fir. It is both a manufacturer and lumber retailer. The company also has significant sales of mill residuals and firewood.

The company’s operations are housed in seven buildings totaling 55,000 square feet. Most products are sold retail to local end users or building contractors within 150 miles, although some orders are shipped to customers in far away states. Marks Lumber markets through its website and email. Most sales are to repeat customers.

In the past the company has primarily been buying logs from logging contractors. A few years ago owner Steve Marks purchased logging equipment and began employing his own loggers.

Marks has shown a preference in the past for buying used equipment at auction and having it refurbished. An important partner in those projects has been Columbia Construction Inc. in Columbia Falls in northwest Montana, which specializes in sawmill equipment rebuilding and

installation. Marks also has made a couple of investments in new equipment in recent years that also have paid dividends: a JoeScan log scanner and Paw Taw John Services optimized controls for machine centers.

The Marks family established a cattle ranch in the 1890s. His grandfather installed an American #1 sawmill and began cutting timbers for mining and lumber for other ranchers in 1938. The family operated the mill, mainly to supplement their cattle ranch operation, through the 1960s.

Marks began retrofitting the old mill and cutting crossties in 1989. He later designed and built a larger mill that began operating in 2000. It served the family well for more than 20 years, but Marks knew he’d have to make improvements in order to keep the mill going for another 20 years and beyond.

The mill continues to use a circular saw on its headrig, a process that leaves distinctive marks on sawn lumber. “Circle-sawn flooring and siding is pretty popular,” said Marks. “A lot of people like the old-fashioned look.”

The Morbark headrig can handle 40-inch

Columbia Construction refurbished this

logs up to 30 feet long. “But we don’t get a lot of that size timber here on the east side of the Rockies,” noted Marks. “We pretty much run 16 foot logs and shorter, random lengths.”

The most recent upgrades were the

refurbishing of a Ukiah Machine gangedger and an Irvington-Moore trimmer by Columbia Construction. Scott Bye, the owner of Columbia Construction, worked for Ukiah Machine in the past and knows edgers well.

“We started talking,” said Marks, “and he said, ‘You know, we’ve got a Ukiah edger here in the yard that I think we can make work.’ So we started brainstorming.” Marks wanted to be able to cut 1-inch boards and 2-inch boards and also to edge boards on the same machine. “So Scott and his engineers started redesigning and reengineering this edger, took it to the shop and stripped it down, and made it work for us.”

The refurbished gang-edger can saw cants up to 8 inches. “So now we can optimize what we want out of each cut,” said Marks. “I can change from one inch to two inch onthe-fly and quarter-saw cants on the fly.”

Previously, the mill was equipped with an old Union Ironworks edger that could only saw 4-inch and 6-inch cants. The saw quill had to be manually put on the arbor to a fixed position. The quill was loaded with saw blades with spacers of 1-inch and 2-inches.

The refurbished Irvington-Moore 20foot trimmer also has helped speed up production.

“In the old days,” said Marks, “the tail sawyer would stop the board and trim one end, and then it would go on to another stop where they would trim the other end. It didn’t take long, but you can imagine what it did to production when you had to stop every board a couple of times. The carriage was always waiting for them.”

The refurbished Irvington-Moore trimmer never stops as boards are fed into it continuously.

“The production improvement has been a huge success,” said Marks.

Shutting down the mill, removing the old equipment, installing the rebuilt machines

and bringing them up to speed was a lengthy process. The mill was shut down in April 2023, and Marks and employees and a Columbia Construction team “started cutting things apart.” Marks had hoped to get back up and running by July 1, but sensors and other equipment were still hard to get because of the lingering effects of the covid 19 pandemic on manufacturers.

“With any retrofit you’ll have hiccups and problems,” observed Marks, “but this kept pushing us back and back, and we didn’t really get going until the first of September. That’s a long downtime, and it was hard on my crew.”

However, the production gains have been substantial. “Our production has more than doubled,” said Marks. “We could cut three times as much if I could add more folks to my crew.”

The improvements have increased yield, too. “We can optimize our logs better than we used to, so we’re getting more out of everything we run through the mill,” said Marks.

“We really had to do that. We might’ve limped along for a few years, but I probably would’ve had to shut down the mill at some point. Now I’ve got a really nice mill that’s efficient and well-maintained.”

The other principal machines in the mill are a Brewco B1600 grade resaw system – a bandsaw that cuts 1-inch or 2-inch boards from wide cants – and a Stetson-Ross 612 planer that can surface lumber or cut profiles.

The scanner from Washington-based JoeScan was installed in 2019. It scans the log on the Morbark carriage and sets the taper as programmed instantly, basically on the fly.

Steve remodeled the carriage and installed linear positioners on each knee in 2006; Paw Taw John Services did the programming and

(continued on page 12)

View from the edger control station. All of the main machine centers are controlled and optimized by control systems from Paw Taw John Services.

The log basically is scanned on the fly by a JoeScan scanner when it is on the carriage. The carriage was remodeled with linear positioners on each knee. Programming and automation have been upgraded by Paw Taw John Services.

• Enhanced detection with AI (Artificial Intelligence)

• Grading performance with value recovery over 99%

• Quick payback on AI upgrades and new systems

• Easy to install, it fits anywhere

(continued from page 11)

automation work. Additional equipment and programming modifications were done at the headrig last year. Now, the sawyer can dump slabs to the waste line or to the resaw, and cants and boards can be routed to the edger or resaw; timbers can be sent directly to a green chain.

The largest diameter log the headrig can cut efficiently is 40 inches with a 56-inch saw and a 36-40-inch top saw running Simonds blades. The scanning data optimizes how the log should be processed and records the board footage.

The scanner is an expensive piece of equipment, noted Marks. “But it’s a pretty cool deal. And it’s fast. It’s the best thing you can put in front of your headrig.”

All of the main machine centers – the JoeScan sensors, switches, the headrig, the Brewco resaw, the Ukiah gang-edger, and the Irvington Moore trimmer – are controlled and optimized by control systems from Paw Taw John Services, another Idaho company. Paw Taw John Services provides control systems for sawmill primary and secondary log break down operations. The company is a leading nationwide authorized repair center in the U.S. for Temposonics industrial sensors.

Marks Lumber also produces and sells firewood. Marks bought a Multitek 2040XP2 firewood processor in 2020 to produce firewood. “It’s been an excellent machine,” he said. “Last year we sold approximately two and a half million pounds of firewood.” The company sells firewood by weight. Customer trucks are weighed as they enter the wood yard and weighed again as they leave. Dead lodgepole pine is plentiful on nearby national forests and private land, and Marks also buys some low-grade Douglas fir logs for firewood.

Firewood is stored in a fabric-topped building from Norseman Structures in Saskatchewan. Marks has another Norseman Structures building for sawdust storage. Both buildings were installed as part of the mill refurbishing project in 2023.

Marks invested in a Rotochopper B66-L horizontal grinder in 2022, replacing a Rotochopper B66 purchased in 2007. The Rotochopper grinds scrap material that is used to fuel a boiler system that provides hot water for a dry kiln – a 40,000 board foot kiln that was built by Marks Lumber employees.

The wood products industry in Montana has been in the news of late with the closures of two major mills: Pyramid Mountain Lumber in Seeley Lake and Roseburg Forest Products particleboard plant in Missoula.

(continued on page 14)

Our

Qualified Technical Support Network

Maintenance & Inspection Programs

Customer Experience Specialists

Repair Parts & Kits

Free Factory Training

Online

Optimization Consulting

this

for Marks

It can saw cants up to 8 inches and change from 1-inch to 2-inch boards on the fly.

(continued from page 12)

The effects of the closures will have profound impacts on employment in both communities, as well as other mills in the region – including Marks Lumber.

“Pyramid Mountain Lumber used to use a lot of ponderosa pine, and we were able to offload any ponderosa pine we had,” said Marks. “So now if we get some ponderosa pine logs, there’s no place to offload them. Pine logs are worth basically nothing.

They’re pulp logs, and the pulp log market is poor as well.”

The Roseburg particleboard mill was a market for sawdust. “I don’t make a lot of sawdust like the big mills do,” said Marks, “but if you create a load or more of sawdust every week, and now there’s no place to ship it, you’ve got a big problem.”

Now Marks hauls sawdust to a Weyerhaeuser medium density fiberboard plant in Columbia Falls – an additional 120 miles away. “The freight eats up any revenue that was there,” he said.

As for the future, Marks says remaining flexible is the key to success.

“We’re unconventional compared to larger mills that produce commodities such as framing lumber,” said Marks, “but it works for us. It’s kind of old school, but also new school. You just try to take opportunities that come along and try to make the best of it with the mindset that this may not last forever. You’ve got to be nimble, and that’s been a big part of our success. We’ve learned how to shift gears on the fly.”

“We still continue to tweak things, to make things work smoother,” said Marks. “Anybody who’s been in the sawmill business knows that you’re always doing that.”

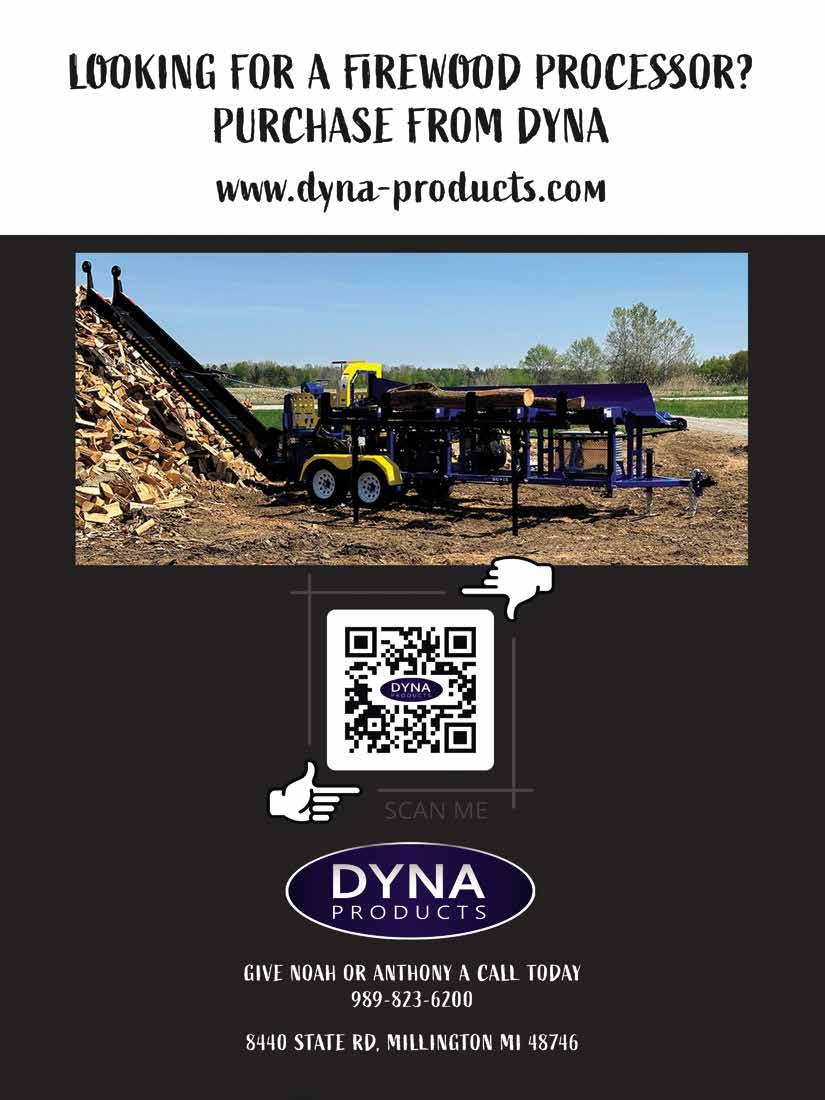

Centerpiece of firewood production for Ivester Tree is a DYNA Products SC-16 Rapid Split firewood processor. Bottom photo, firewood for home heating is loaded into sacks that hold one-third cord; sacks have loop handles for lifting by forklift tines.

than two-thirds of an acre. That’s how much firewood Chris Ivester and his Utah company, Ivester Tree, produced last year.

Of course, they didn’t cut and split all that firewood by hand. They had the help of a DYNA Products SC-16 Rapid Split firewood processor.

The company, with six employees in

addition to Ivester and his son, Noah, 17, is based in Duchesne in northeast Utah, about 115 miles southeast of Salt Lake City. Duchesne is south of the Ashley National Forest and the Uinta-Wasatch-Cache National Forest.

Ivester, 36, has done civil engineering, trucking, and tree service work. He began

producing and selling firewood part-time in 2005, and it became a full-time business for him in 2021. He started his logging business in 2023.

Most of Ivester Tree’s logging work has been on state and federal lands, although he also has bought timber on private land, plus mulching brush in power line corridors and other lands to reduce the threat of wildfire. Revenue from timber harvests on land managed by the Utah Trust Lands Administration supports the state’s public schools. On U.S. Forest Service land, Ivester Tree works on forest health projects, primarily thinning and performing select cuts.

Although he only began logging last year, so far a typical logging job is 400-600 acres, which generates about 300-500 loads of wood. The dominant species are Engelmann spruce, lodgepole pine, and subalpine fir.

DYNA Products SC-16 Rapid Split is powered by a Kohler 56 hp diesel engine. It can process logs up to 22 inches in diameter and 24 feet long.

Ivester and

“Last year we had a Forest Service project with seven units,” said Ivester, “and we completed harvesting on three of them. We go in there and harvest and process the timber, leaving the forest looking much cleaner when we’re done. We plan to get the other four units harvested this year, along with a state lands sale, so by the end of this year we will have brought something like 350 truckloads to our wood yard.” That pencils out to a volume of about 1.75 million board feet.

All logs are hauled to the 15-acre wood yard and sorted and stacked. Grade logs are later delivered to sawmills. The unmerchantable logs are used to produce firewood.

Engelmann spruce and lodgepole pine are the preferred species for firewood. Most Douglas fir and white fir logs are supplied to sawmills. Firewood sales account for about 40 percent of Ivester Tree’s business.

Ivester Tree is equipped with a Timbco 445EXL feller buncher, a Link-Belt 240LX excavator with a Denharco stroke delimber, John Deere and Timberjack skidders, and a John Deere log loader. A Hitachi EX270 excavator handles logs at the wood yard. The company has one log truck, so Ivester also uses trucking contractors for hauling wood.

(continued on page 18)

(continued from page 17)

For forestry mulching the company has a pair of Kubota mini-excavators, a KX080-5 and a U55-5, and a Rut Mfg. disk mulcher with Quadco teeth.

Ivester bought his first firewood processor from DYNA Products, a model SC-15, in 2021. To increase productivity, he traded that machine in for an SC-16 in 2022 and then for an upgraded SC-16 Rapid Split model this year.

The DYNA Products SC-16 Rapid Split is powered by a Kohler 56 hp diesel engine. It has a 25-inch bar saw for bucking, so it can process logs up to 22 inches in diameter. The DYNA SC-16 Rapid Split comes with an adjustable 4-way splitting wedge; 6- and 8-way wedges are optional, and Ivester has one of each.

“A lot of guys think that the wood processors with bar saws are not as good as processors with circular saws,” noted Iveter. “With the wood we cut — no hardwoods, except for aspen — the DYNA’s bar saw is phenomenal for us. It goes through the wood faster than any of the processors with circular saws that I’ve seen.”

The SC-16 Rapid Split can handle 24foot logs, but Ivester’s team expanded the log

In addition to this John Deere skidder, Ivester Tree is equipped with a Timbco 445EXL feller buncher, a Link-Belt 240LX excavator with a Denharco stroke delimber, a Timberjack skidder, and a John Deere log loader.

deck to hold longer wood. “Instead of bucking them, we can run a full 41-foot log right through our processor,” he said.

Among the new features are a two-speed splitter autocycle and adjustable stroke length. “The SC-16 Rapid Split has a lot more electronics instead of hydraulics, so it’s a much faster, more productive machine,” said Ivester. “We set the stroke length at 20 inches, since we cut all of our firewood at 16 inches in length, rather than having the plunger go out to the full 24 or 26 inches,” Ivester said. “The

photo eye sensor on the splitting plunger automatically returns the plunger when it hits that 20-inch length. The plunger goes only as far as we need it to go, and no longer do we have to return the plunger manually, which makes splitting each piece quicker.” In addition, the hydraulic hoses on the SC-16 Rapid Split are larger than previous models, allowing the plunger to move faster.

“The older SC-16 had something like a

(continued on page 20)

(continued from page 18)

seven-second cycle time,” said Ivester. “With the auto-return feature, we’re seeing cycle times right around 2.8 to 2.9 seconds.”

DYNA Products is based in Michigan. The company manufactures firewood processors, firewood splitters and conveyors, tumblers for cleaning firewood, and the Vortx brand of brush chippers. It also distributes the Boxer 700HDX mini skid steer. (For more information about DYNA Products, visit www.dyna-products.com.)

Ivester Tree also has two DYNA Products 20-foot firewood conveyors; one is used for home-heating firewood and one for bundled firewood. An employee sorts the pieces as they are split. The company also has a Timberwolf 12-foot conveyor that handles for scrap wood caught by flashing that was added under and around the firewood processor.

Firewood for home heating is placed in special sacks on pallets that, when full, are moved to separate drying areas for green and seasoned wood. After processing, the

firewood is allowed to air-dry, uncovered, in the sacks. The heavy-duty, nylon mesh sacks hold 1/3 of a cord. They have loop handles for lifting by a forklift or other machine. The bags can be reused 8 to 10 times, Ivester said. A moisture meter is used weekly to check the moisture content of green firewood. In most cases, the moisture content of firewood produced from standing dead trees is less than 30 percent, which is dry enough to burn.

“By using these sacks, the firewood is ventilated on all four sides,” explained Ivester. “I had racks specially designed so we could store our firewood and never have it touch the ground. With our arid climate here in Utah, it only takes two to three months, even in winter, to go from 50 percent moisture content down to 20 percent moisture content.”

Ivester’s delivers firewood in sacks to residential customers throughout a wide area. One of the company’s two trucks can carry 24 sacks on pallets, or eight full cords in total; the other can carry 18 sacks. In some cases, the delivery crew tips one or more sacks off of the truck, empties them, and then folds them up for later re-use. In some cases, ranchers or others who have forklifts or loaders unload the sacks of firewood themselves and sometimes keep the sacks. The company also sells firewood directly to people who come to the wood yard.

Ivester said he is impressed by the quality of DYNA Products equipment as well as its customer service.

“I daresay this machine could probably handle up to 3,000 cords a year,” he said. “With our other work, we’re not producing firewood five days a week, eight hours a day. We’ll run the firewood processor for a week or two and get 300 or 400 sacks filled and then focus on some of our other projects. Right now, home heating firewood sales are tapering off, because we’re coming to the end of the winter season.”

A DYNA Products bundling machine wraps bundles of firewood with plastic film. Ivester Tree sold about 45,000 bundles of firewood last year. The bundled firewood includes smaller pieces up to three inches in diameter, with fewer knots and straighter grain, which is easier to bundle. Bundled firewood is sold to grocery and other stores throughout the state, primarily in the Salt Lake City area. Ivester has a warehouse for storing bundled firewood in Tooele, which is near Salt Lake City.

Ivester plans to expand his business by adding a portable sawmill. He has ordered a portable band mill from Alabama-based Cook’s Saw Manufacturing. Ivester chose a model AC-36 with the high-production

(continued on page 22)

package. According to Cook’s, the mill can cut more than 10,000 board feet per day.

“It’ll all be rough-cut dimensional lumber,” said Ivester. “People like to use rough-cut wood as siding or beams,” said Ivester. “We’ll be able to cut up to a 40-inch log, 24 feet long, so we can make pretty much any beam that anybody needs.”

Ivester plans to construct a concrete pad and shed for the new mill and likely will hire two or three workers for the mill operations. When the shed is built he will move the firewood processor into it, too.

Ivester and his employees built a dry kiln that he plans to use to produce biochar from scrap wood. He potentially can sell it to Scott’s Miracle-Gro, which has a plant in the Salt Lake City area that produces a variety of bagged garden soils and soil amendments.

“None of our product goes to waste,” Ivester said. “We capture all of the sawdust and waste material from our firewood processor. The sawdust typically goes to farmers and ranchers who use it for their livestock pens and as a soil amendment, and there are oil companies that buy a lot of it to use as an absorbent. And we’re going to start turning scrap wood into biochar that we’ll sell as a soil amendment. Biochar sort of

Hitachi EX270 excavator handles loading and unloading chores in the company’s wood yard. All logs are hauled to the 15-acre wood yard and sorted and stacked.

super-activates the soil and allows the bacteria and nutrients in the soil to thrive, so there’s more nutrition available to plants.”

In his free time Ivester enjoys riding motorcycles with his eldest son, snowmobile riding with his family, and hunting. He and wife have two boys and she is pregnant with their third child.

In addition to his other business duties,

Ivester handles marketing for firewood. “I do a lot of social media,” he said. “Ninety percent of my advertising is through social media, and people ‘like’ and share the messaging. We also sponsor the Duchesne County Fair — it gets our name out there and helps keep the community going.”

Steam production is a big deal for Cox Interior, which makes interior and exterior building products. The company has extensive lumber drying operations that require steam, and it also uses steam to heat its facilities and to produce electricity.

The company recently turned to Hurst Boiler & Welding Co. to make significant improvements to its aging boiler plant. The investment and upgrades are paying off in a number of ways.

Cox Interior manufactures interior and exterior home building supplies, including molding, solid hardwood doors, stair systems, and custom trim and millwork. The company’s sawmill and manufacturing facilities are located in Campbellsville, Kentucky, and it has warehouses and sales representatives in six states. Cox Interior has about 500 employees, including less than 400 who work in Campbellsville. Sales average more than $4 million per month.

The sawmill cuts all hardwoods. It can saw about 100,000 board feet of lumber each

week. The company also buys some specialty lumber, such as mahogany.

Cox Interior also has 11 lumber kilns with a combined capacity of 1 million board feet to produce kiln-dried lumber products. It dries lumber for its own products and also dries material for a nearby cooperage that makes barrels for bourbon distillers.

It sells direct to contractors and homeowners – not to ‘big box’ home improvement stores or independent lumber yards. Marketing is achieved through the Internet, word of mouth, and the company’s sales

Hurst Boiler built and installed this integrated control system modular control room; it houses the equipment control panels and PLCs.The boiler plant is directly behind the modular control room.

force, with a sales office at each warehouse.

Using the mill residual wastes, the boiler plant provides steam to generate power, to heat company buildings, and to heat the lumber dry kilns. The company generates 71 percent of the power it needs in warm months and 50 percent in the winter months, when more steam is allocated for heat and lumber drying.

Cox Interior purchased two boilers in used condition from Armstrong Rubber Co. in 1992. Hurst Boiler provided controls and peripheral technology when the boilers were installed at Cox Interior. The boilers performed “pretty decently” since then, noted Shane Turner, manager of Cox Waste To Energy, a subsidiary. Turner manages the boiler and steam production operations. His duties extend to the lumber dry kilns as well as to the grinding equipment and operations.

Mill residuals provide about 60 percent

of the wood fiber used to fuel the boilers; the company obtains more from other sources.

“A lot of the mix is pallets hauled in from other companies,” said Turner. The company has two trailer-mounted horizontal grinders to reduce the scrap wood, a Morbark 4600XL and a Peterson 4700.

Turner had discussions with Hurst Boiler personnel and proposed the improvements to Cox Interior ownership. Owners and management considered the project as well as investing in a new boiler plant, evaluating and weighing the options for about two years before reaching a final decision. One of the biggest factors in the decision-making process was the cost differential between a new boiler plant and making improvements to the existing plant.

“It was an overdue improvement for the system, for sure,” said Turner. The old controls were outdated and obsolete.

Georgia-based Hurst Boiler & Welding Company has been designing, engineering, and servicing a complete line of solid fuel, solid waste, biomass, gas, coal, and oil-fired steam and hot water boilers since 1967. It is a custom manufacturer of engineered packaged boilers and boiler systems, biomass boiler systems, and integrated PLC-based boiler controls and accessories. The company also offers major repairs as well as service and preventative maintenance. (For more information, visit www.hurstboiler.com.)

Hurst Boiler provided upgrades to the furnace, controls, emissions equipment, and ash handling systems. The company also replaced a few fans as well as the insulating refractories throughout the entire boilers.

“The control system fully integrates the

(continued on page

(continued from page 25)

operations of both boilers, deaerator, fuel storage, emissions and control valves, controlling loops downstream of the steam turbine,” said Cliff Hurst, domestic solid fuel sales manager for Hurst Boiler. “The induced draft fan, multi-cyclone collectors, refractory furnace liner, main ash drag chain, and dry ash conveyance systems also received updates as part of the upgrades.”

One of the previous induced draft fans, one of the most critical parts of a boiler, failed while the Hurst Boiler team was onsite, making the improvements. “That’s just one example that shows why the upgrades were needed,” observed Hurst.

One of the key improvements of the control system was a complete human-machine interface that is easy to learn and operate. “All essential data of the system is available from a few desktop monitors,” said Hurst. “Alarms, setpoints, adjustments, troubleshooting – all can be done from one location. We also have the ability to remotely monitor, adjust and control the system. This aids in troubleshooting issues with professional programmers and engineers available to support Cox Interior in real time.”

Hurst Boiler also built and installed an integrated control system modular control room that houses the equipment control panels and PLCs. These are displayed via an ethernet cable to the new desktop moni tors within the existing control room. This enables Cox Interior to display the control screens without needing to accommodate the control panels in the general production area. This approach enabled Cox Interior to main tain ongoing operations on one of their two boilers for the duration of the plant upgrade.

“The control room was positioned so that it was a real challenge to incorporate the multi-cyclone collectors in a close proxim ity,” noted Hurst. “This approach ended up being a really nice solution.”

The upgrades improve the efficiency of the boiler plant. Better control of fuel and air mixtures in the boilers enable cleaner, more efficient combustion. Finally, the improve ments also reduced power consumption because electrical motors operate on variable frequency drives at a set point rather than with on/off type controls.

The project took about six weeks. The upgrades, completed in December last year, cost about $2.5 million, according to Turner.

“They’ve worked out great so far,” said Turner.

Since the fuel burns cleaner and more ef ficiently, less is required – about 15 percent less. That translates into savings of about $15,000 per month.

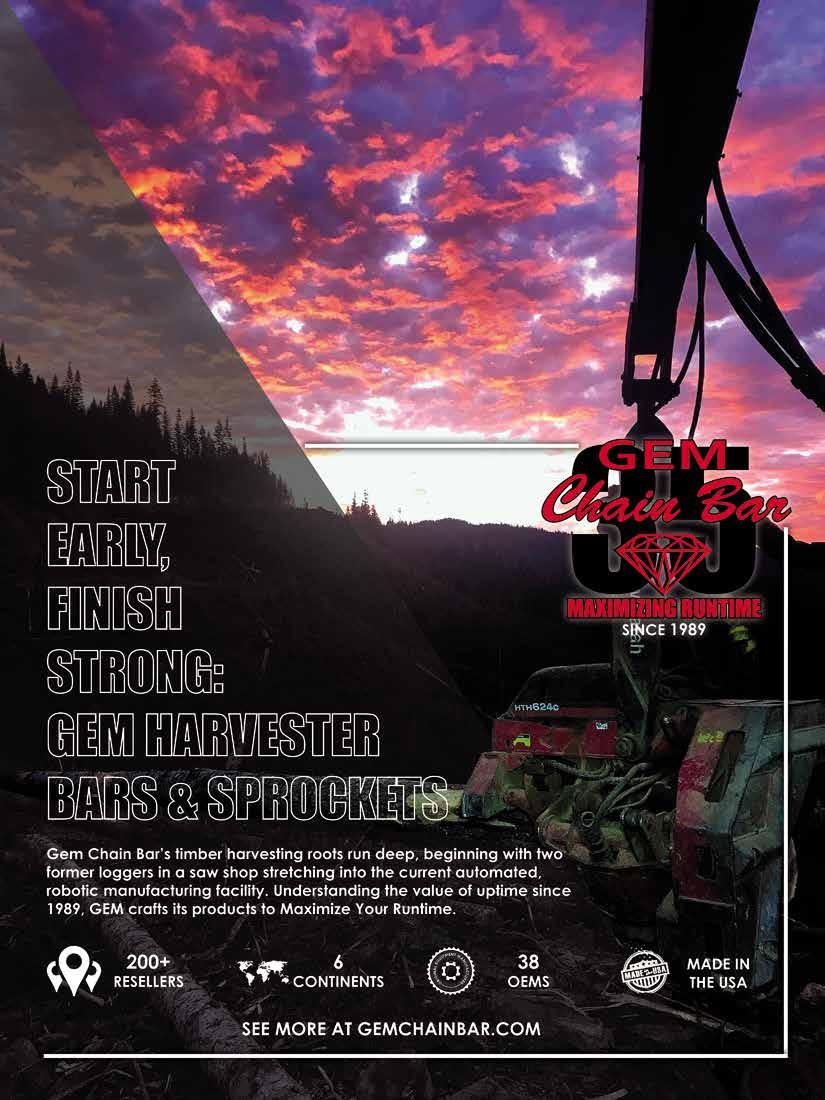

Gem Chain Bar harvester bar on a Waratah processor head belonging to Pine Creek Logging.

Gem Chain Bar supplies bars and sprockets to 38 original equipment manufacturers around the world.

(Editor’s Note: In this issue we begin a new feature, the Supplier Spotlight. These features will shine a spotlight on suppliers to the logging and forest products industry.)

By Tim Cox, EditorFrom a little town in Idaho, a small company with family roots manufactures a product that is sought after by loggers and logging equipment manufacturers around the world.

Gem Chain Bar supplies global customers with harvester bars, replacement tips, sprockets, chain, and chain loops. The company is based in Grangeville, which is located in the lower half of the Idaho panhandle, just below the southeast corner of the Nez Perce Reservation. Gem Chain Bar employs 30 people working in two buildings with about 10,000 square feet under roof. Annual sales are in the range of multi-millions.

The company is led by owner Kim Peterson. The business was started by her late

husband, Rick, and his father, ‘Pete’ Peterson, also deceased. The elder Peterson was a logger and also operated a shop, selling and repairing chainsaws. Rick earned a welding certificate from Lewis-Clark State College and then worked briefly at the Hanford nuclear site before going to work in logging.

A logger friend of Pete had one of the very first mechanical harvesters in the region. He asked Pete if they could repair the harvester saw bar, which Rick did. A few weeks later Rick was asked if he could make a new replacement bar for the harvester, and – with his expertise in welding, metal fabrication and blue prints – he started Gem Chain Bar and made a couple.

The harvester was manufactured by Wisconsin-based Timbco, at the time owned by founder Pat Crawford. On a visit to Idaho, Crawford noticed the different harvester bar and asked who had made it. That led to Gem Chain Bar manufacturing harvester bars for Timbco.

(continued on page 30)

Cutting sheets of specialized through-hardened steel with water jet technology. Gem Chain Bar can manufacture harvester bars with the strongest material in the industry while maintaining hardness without any heat-affected zone.

(continued from page 28)

“It kind of ballooned from there,” recalled Peterson, as the growing business also began manufacturing harvester bars for other companies, such as Pierce Pacific and Waratah,

makers of forestry attachments.

Her husband began working full-time in the business in 1991. Father and son worked in the business together for a few years before growth prompted them to begin hiring employees. Originally located in Kooskia, they relocated about 30-some miles south to Grangeville in 2005.

“When we first started, everything was done manually,” recalled Peterson. Bars were cut out with a torch and put through a grinding process to form the groove for

the chain. The bar rails were heat-treated to temper and strengthen them. All of it was done by hand.

“It’s progressed a lot,” noted Peterson.

Today the company uses advanced machinery and automation in its manufacturing processes. Gem Chain Bar purchased its first waterjet, a machine that uses high-pressure water and garnet to cut material, in 2007 and added its first milling machine in 2008. The investments in industrial equipment were a “game changer,” said Peterson. Gem Chain Bar now has 11 CNC milling machines, five of which are enhanced with robots that feed material.

In addition, the company uses a harder, more durable raw material that does not require heat-treating.

“We’ve done a lot of research, development and engineering,” said Peterson, “as well as creating and implementing automated processes.” The advanced technology and operations are “a far cry from what we started out with,” she acknowledged.

Harvester bars and sprockets for harvesters are the company’s primary products. Gem Chain Bar supplies bars and sprockets to 38 original equipment manufacturers around the world. Originally selling to loggers and equipment dealers in the Northwest, as the company grew it set up dealers throughout the U.S., Canada, and elsewhere. Its products now are exported to 16 countries on six continents, and it continues to sell through a global dealer network.

Gem Chain Bar buys steel from American mills, and all its milling equipment is American-made.

“Everything is made here in our shop,” noted Peterson. “It comes in as a raw material and goes out as a finished product. We don’t outsource any manufacturing processes.”

“We’ve been told by numerous customers that being a solely in-house, made in the U.S.A. manufacturer is something to be proud of.”

Gem Chain Bar launched a new product line this year, its WearXtreme line of bars, which were in development for several years. The new bars were developed at the prodding of original equipment manufacturers and local customers who desired bars with even longer wear life. The bars are made from ballistic grade steel. They have a bigger sprocket in the tip, a more streamlined profile, more rivets in the bar/tip connection point and other features for improved durability and extended life.

The company initially worked with two original equipment manufacturers in the WearXtreme product development process, initially only supplying them to those customers, then began marketing them to other customers. The WearXtreme line is now

publicly available to all customers in both ¾ and .404 bars.

Products are quality checked multiple times during each step of the manufacturing process, including machine laser probes, repeat bench specification testing, visual inspections, and thorough performance testing. The quality control team includes design staff, quality control technicians, and senior management.

Gem Chain Bar used to also provide repair of saw bars but discontinued that segment of the business in recent years. “It’s

very time consuming,” noted Peterson. “Our main focus needs to be manufacturing.” Requests for repairs are referred to a local business partner.

Having strong relationships with customers has been an important factor in the company’s growth and success. “We build relationships,” said Peterson. “It’s more about how can we work with them, listen to what they’re saying, and improve the product to make it better.”

(continued on page 32)

Th e key to maximizing productivity from a mulching attachment is not to bite off too much – or too little – material at one time. That’s why we gave the new Battle Ax rotor unique depth gauges that optimize the material feed rate to always keep the machine operating at top efficiency.

Th oroughly process material with the exclusive two-stage cutting chamber featuring an adjustable primary shear bar.

(continued from page 31)

“It is a strong balance of: how is the business relationship best for them, and how is it best for us? Staying in regular contact and soliciting feedback makes a world of difference.”

On a recent new vendor conference call, the customer told Peterson, ‘I think this is the best vendor call I’ve ever had.’ Numerous customers have been with Gem for 20-30 years. And in some cases, those business relationships have become personal friendships.

Many original equipment manufacturers have their brand name on the Gem harvester bars. “We’re happy to brand our products for our customers,” said Peterson, “flattered that they trust our quality enough to have us put their name on our products.”

“We are a company that is willing to work with our customers to create something that works for them,” said Peterson, “a product they’re going to sell, something they can be proud of, that will be reliable and work well for them.”

“Having those solid relationships with our customers has been huge for us. They’re not just a number out there that we’re trying to make money off. We want it to be a twoway street of mutual benefit.”

The employee culture at Gem Chain Bar is one of collaboration.

“A lot of past and present employees comment on our business culture,” said Peterson. “We’re not a huge corporation. We empower our employees to be part of the product design and manufacturing process. We come to a decision as a group about the best course of action. We work together as a company and a true team. We strive to foster that collaboration with both our internal (employees) and external customers.”

(For more information about Gem Chain Bar products, visit www.gemchainbar. com.)

Gem Chain Bar is equipped with five robots for automated sprocket manufacturing – two Versabuilt/ABB robotic systems, two Universal Robot Systems, and one utilizing Midaco pallet changers.

In forestry, where safety and efficiency go hand in hand, log loaders play a crucial role in a timber company’s success. With roots dating back to 1937, DEVELON has a history of building high-performing heavy equipment for extreme conditions. But today’s worksite demands are pushing manufacturers like DEVELON to drive new innovations to meet timber’s tough demands.

Fortunately, DEVELON advancements are paving the way for a safer, more productive forestry future.

DEVELON is integrating advanced safety features to help mitigate operator risks. An optional forestry cab includes additional window guarding and escape hatch, plus heavy-duty latches and hinges to stand up to logging challenges.

Sightlines are critical for job site safety, and DEVELON log loaders are designed with narrow cab pillars that afford less obstructed views. A standard rearview camera and optional around view monitor (AVM) camera system provide a full view of timber’s tough work spaces.

The stress of heavy loads and strain from rugged terrain can do a number on forestry equipment. DEVELON log loaders are specially designed to maximize uptime.

Featuring quarter-inch steel side panels, DEVELON log loaders are built to withstand shocks and impacts. The fortified side panels provide added protection for the machine’s vital components.

DEVELON log loader tracks feature heavy-duty links with double grouser shoes and full-length track guiding guards. It’s all backed by a superior standard warranty (36 months, 5,000 hours) on 2024 models and newer.

DEVELON streamlined maintenance features help prolong a machine’s lifespan and minimize downtime.

Log loader access panels are easy to find and open from the top, bottom and sides. A large panel provides ample room to reach the top side of the engine, while a hinged belly pan allows access from the bottom. Centralized grease banks on the base of the boom offer easy access to multiple grease points from one central location.

By prioritizing safety, durability and maintenance, DEVELON is not only enhancing the performance of its log loaders but is also boosting forestry companies’ bottom lines. Scan to learn more about DEVELON and the company’s expanding lineup of log loaders. Or contact your local authorized DEVELON dealer.

Associated California Loggers has honored Vicki Albrecht with the organization’s first-ever Lady Logger of the Year award. The award is intended to recognize women and their roles in logging.

Albrecht, who worked more than 25 years with Sierra Resource Management Inc. in Sonora, was recognized at the organization’s annual meeting earlier this year.

She was honored, and also very humbled, she said, because she believes so many other women in the logging industry deserve the award more than she does. She listed numerous examples, including women who get up before dawn to send off their husbands, sons, or both, with homemade lunches to get them through their 13-hour work days.

Albrecht married her husband, Mike, of Sierra Resource Management in 1998. They started the company Special Projects CA of Sonora in 2005. Two years later they helped a Canadian developer start the California Wood Shavings plant; she served as the plant’s general manager until it was purchased by American Wood Fibers in 2011.

Albrecht retired as chief financial officer of Sierra Resource Management in 2021. She has served on the board of directors of

the nonprofit Sonora Area Foundation for the past three and a half years.

Associated Oregon Loggers will hold a sporting clays fundraiser to benefit the organization’s Political Action Committee.

The event will be held Aug. 3 at MidValley Clays in Gervais. Mid-Valley Clays features a 15-station sporting clays course.

Player fee of $200 includes 100 targets, shotgun shells, and lunch.

All monies raised will be donated to the OR-Loggers State PAC Fund.

For more information or to register, visit the AOL website at www.oregonloggers.org.

Associated Oregon Loggers honored Kelly Mitchell as the 2023 Woman of the Year. She was recognized at the organization’s annual convention earlier this year.

The award acknowledges a leader who demonstrates courage, initiative, dedication, or achievement in Oregon’s forest contract business.

Mitchell is a successful business owneroperator, leading a log hauling company,

Gene Whitaker Inc. in southwest Oregon.

The company was started by her father, Gene Whitaker. Mitchell worked as a dispatcher for the business for 25 years. Now she oversees the company, which has nearly 50 heavy trucks.

Mitchell says her top goals are providing reliable, safe, and efficient drivers for their contractors, and to be a safe and welcoming environment for people to work.

Associated Oregon Loggers will hold a golf tournament to benefit Log-A-Load for Kids and the three Children’s Miracle Network hospitals in Oregon.

The tournament will be held June 21 at Tokatee Golf Club in McKenzie Bridge. AOL and sponsors cover all administrative costs of the tournament.

Designed by renowned architect Ted Robinson, the 18-hole course is golf in the rugged outdoors with straightforward holes that are enhanced by their views of distant mountains and their use of native ponds and streams. Tokatee Golf Club is easily walkable.

For more information or to register for the tournament, visit the AOL website at www.oregonloggers.org.

TRANSPORT DOLLY

Equipped with independent air-ride suspension and remotecontrolled front and rear hydraulic locks. A single operator can attach the transport dolly in minutes.

The patent-pending PT Tech Hydraulic Torque Limiter provides the ultimate driveline protection while allowing for ease of setting adjustments based on the grinding application.

Whether you are processing organic waste into compost, hog fuel, or mulch, the Nex Gen 6400XT Wood Hog Horizontal Grinder delivers more efficiency, versatility, power, durability, and now greater transportablity to keep pace with you. To learn more about the 6400XT with Dolly Transport System contact your local, authorized Morbark Dealer or scan the QR Code below.

Scan the QR Code with your mobile camera to access specs for the 6400XT with Dolly System

BELT TENSIONING SYSTEM

The 6400XT Hydraulic Belt Tensioning System, uses hydraulic pressure to tension the belt as soon as the engine starts, eliminating the need for adjusting the belt manually.

MAINTENANCE PLATFORM

The Extended Maintenance Platform is designed to provide ample working space and easy access to the hammermill for changing screens and conducting maintenance.

Brandt Tractor: Serving All Canadian Provinces Ph: +1 888.227-2638

www.brandt.ca

Pape Machinery: Serving Idaho, Oregon, Washington, California, and Nevada Ph: 458-221-3156 www.pape.com

integrated 12-foot conveyor makes for easy loading of finished firewood. The processor comes standard with 4-way wedge, automatic bar and chain oiler, last log measuring grid, and integrated tail lights. www.bruteforceusa.com

Timberwolf’s Pro-HD commercial firewood processors are designed to cut and split the gnarliest of logs with ease. With a 74 hp diesel engine, overbuilt frame, and dual roller feed system, the Pro-HD is capable of processing logs up to 24 inches in diameter and 32 feet long. The 2024 Pro-HD series now features a Parker bent axis piston saw motor that dramatically increases the processor’s efficiency, bringing its average output to 5-plus cords per hour. www.timberwolfequip.com sales@timberwolfequip.com

The Blacks Creek model 2500 firewood processor is powered by a 35 hp Briggs & Stratton electric start engine. It can process logs up to 23 inches in diameter and 16 feet long. The processor uses a bar

saw for bucking and a 4x24 splitting cylinder and adjustable four-way wedge for splitting. Hydraulics are powered by two pumps. Options include six-way wedge, live deck, hydraulic log stop, and more. www.blackscreek.ca

The BruteForce commercial series 14-24 firewood processor, the smallest made by BruteForce, comes standard with a Kohler 26.5 hp engine with a diesel engine optional. It can process logs up 18 inches in diameter and can produce 1-3 cords of firewood per hour. It features a 2-strand live log deck that can convert into a log lift. An

The DYNA SC-16 Rapid Split firewood processor is powered by a Cat 49 hp diesel engine coupled with a 5x30 hydraulic cylinder. With a splitter cycle less than 4 seconds, it can produce six cords of firewood per hour. The splitter autocycle and adjustable stroke length on the cylinder help save more time processing firewood. Capacity is

logs up to 22 inches in diameter and 24 feet long. Bucking is with a bar saw while a clamp secures the log. www.dyna-products.com

Halverson manufactures firewood processors that operate as attachments to skid steers and other machines as well as tractors and stand-alone firewood processors. The HWP-150 attaches to a skid

steer or other machine and is the largest model, designed for maximum production. The processor lifts a log onto the deck, clamps it securely, and bucks it. The cut piece falls into the splitting chamber and is immediately split.

www.halversonwoodproducts.com sales@halversonwp.com

The Multitek 2040XP2 is the company’s flagship processor. It is built to handle the most crooked and difficult logs. With Multitek’s patented shuttle grapple, the 2040XP2 can produce seven cords of

firewood per hour. Powered by a John Deere 125 hp diesel engine, it can process logs up to 23 inches in diameter and 40 feet long. It uses a 60-inch circular saw for bucking and comes standard with a hydraulic saw brake.

www.multitekinc.com

advanced model. It features an intuitive autopilot control that is easy and safe to use. It is powered by a Duetz 74 hp diesel engine and bucks logs up to 30 feet long with a 40-inch circular saw. It has 24 tons of splitting force standard – a 3 second splitter cycle time – with 42 tons optional. Features include adjustable splitter head, saw blade stop, auto cycle splitter, and four strand live deck.

www.eastonmadewoodsplitters.com

Sales@eastonmadewoodsplitters.com

Tajfun USA offers firewood processors that are powered by tractor PTO. The RCA 500 JOY model can process logs up to 20 inches

The Eastonmade 40C firewood processor is the company’s most

in diameter and 19 feet long. It uses a bar saw for bucking and has 25 tons of splitting force with two splitting speeds. They are available with a wide range of accessories, including discharge conveyor, stationary or portable live deck, various splitting wedges, and more.

www.tajfunusa.com

tajfunusa@tajfun.com

(continued on page 38)

(continued from page 37)

Cord King manufactures firewood processors that use either a bar saw or circular saw for bucking. The CS16-30 (model 36) is powered by a 50 hp diesel engine and has a 36-inch carbide tooth slasher saw.

It can process logs up to 30 inches in diameter and 16 feet long and produce four cords of firewood per hour. The processor has 29 tons of splitting force and has a fixed 6-way or 8-way splitting wedge. An automatic clamp secures the log for bucking. Numerous options are available.

www.cordking.ca info@cordking.ca

The Vallee Forestry Equipment JOY SR firewood processor boasts a pivoting exit conveyor, heavy-duty belts, and a complete road package. It can process logs up to 20 inches in diameter and produce

four face cords of firewood per hour. It is powered by a Honda 22 hp gas engine. All operations are regrouped and controlled with a simple joystick. The hydraulic outfeed conveyor swivels from left to right.

www.valleeforestryequipment.com

info@valleeforestryequipment.com

The RR25T is the newest firewood processor offered by Range Road. It can process logs up to 19 inches in diameter. It is powered by a Rato 30 hp engine and has a 25-ton hydraulic ram for a 7 second

cycle time. Features include hydraulic infeed and log hold-down, conveyor, and adjustable 4-way splitter (optional 6-way available), and joystick control. The processor also has an emergency kill switch. www.range-road.com

sors as well as stand-alone machines that feature either a winch log infeed or live deck infeed. The WP1624 firewood process has a live deck and can process logs up to 16 inches in diameter and 16 feet

long. It is powered by a Vanguard 40 hp engine and has 20 tons of splitting force. Average cutting cycle time is 12 seconds, and full

www.wallensteinequipment.com

The annual Intermountain Logging Conference and Equipment Show featured exhibits of forestry equipment as well as a program of various presentations of interest to the industry.

The theme of this year’s event, held over three days in April in Spokane Valley, Washington, was technology and diversification. Fittingly, the keynote speaker for the event was Chace Barber, CEO and cofounder with Eric Little of Edison Motors, a British Columbia company that manufactures electric log trucks.

The Intermountain Logging Conference serves the forest products industry and its many suppliers operating in the geographic area called the Inland Empire region. It encompasses portions of Washington, Oregon, Montana, Idaho, South Dakota, and Alberta and British Columbia. The conference represents more than 500 companies.

The program featured updates on equipment with remarks by dealer or factory representatives of Schaeffer Manufacturing, Caterpillar, Link-Belt, and John Deere. Another panel on cable assist technology featured speakers from Technical Forest Solutions, Falcon Forestry and Summit Equipment. A presentation on trials of new technology featured Kodama Systems and Eagle Carriage.

Other panels covered insights into business issues and opportunities in forestry, the future of the industry, using technology and diversity to advance the forestry workforce, and a hands-on technical session with equipment dealers.

Barber and Little started a trucking business – hauling for loggers – after college. The business grew and expanded to hauling and installing power generation systems. In 2019 they started designing and installing off-grid solar hybrid power systems. After their first successful project they began to design a

Tigercat launched its new 120 winch assist machine at the Intermountain Logging Conference. It's the company's latest development for safe logging operations on steep terrain.

diesel-electric semi-tractor using the same principles of a high voltage off-grid solar project.

Edison Motors offers both fully electric and diesel-electric vocational trucks depending on customer requirements. Barber discussed the research and development process of the company’s trucks. They average a 50-70 percent reduction in fuel driving in mountainous conditions in British Columbia, he said. For city driving, the savings is 30-50 percent, and for highway driving, 0-10 percent.

The next Intermountain Logging Conference and Equipment Show will be held April 2-4, 2025.

By Mary Bullwinkel

By Mary Bullwinkel

Unseasonal warm and sunny weather helped draw a record number of attendees to this year’s annual Redwood Region Logging Conference recently. About 6,000 people attended the event in Eureka, California, according to organizers.

Logging equipment – modern day and historic – was on display, and activities during the three-day event included a log loader competition and the Association of Western Forestry Clubs conclave.

It was the 86th annual event of the conference. “We had an amazing year because of the support of an incredible industry and a dedicated group of directors, both current and past,” said Jeannie Fulton, executive director of the Redwood Region Logging Conference.

The theme of this year’s event was ‘Growing a Stronger Industry for the Next Generation – One Tree at a Time.’ Students from Humboldt and Mendocino Counties competed for cash prizes in an art contest focused on the conference theme.

Two Humboldt County residents were honored with achievement awards. The two, Bob Canevari and Gloria Cottrell have been long-time members of the timber industry and have made significant contributions to the local community.

Canevari, 93 and retired, began his career in the timber industry in Mendocino County in 1949. He formed a business with partners in 1955, and they moved their logging operations to Humboldt County in 1961. Eventually buying out his partners,

he formed Canevari Timber prior to 1970 and added sand and gravel operations to his company in the early 1990s. Canevari served as president of the Redwood Region Logging Conference in 1997 and is a past director of the Pacific Logging Congress.

Cottrell and family operate Three Rivers Logging and the Cottrell Ranch near Bridgeville. Cottrell received her award in recognition of her family’s contributions to timber and ranching. She and her late husband, Graham, started Three Rivers Logging Company in 1958. The company has been conducting sustainable logging and ranching activities on the property since then.

In conjunction with the conference, the 2024 Association of Western Forestry Clubs conclave drew students from 10 colleges in California, Oregon, Arizona, Colorado, Montana, and Idaho. The students demonstrated logging-related skills, including single bucking, crosscut sawing, pole climbing, and throwing wrappers over a load of logs. Cal Poly-Humboldt hosted the conclave and captured first place in the three-day competition. The second-place team was Flathead Valley Community College in Montana, and third place went to Cal Poly-San Luis Obispo. It was the first time the event was held in Humboldt County in more than a decade.

One of the more popular events at the conference was the log loader competition. Contestants could choose to operate a 538 CAT or Link-Belt 3740B log loader. The top three times, one in less than three minutes and two in less than four minutes, earned cash awards for the skilled operators. First place was Ryan Anderson, of Anderson Trucking, second place was Doug Parmeter of Parmeter Logging, and third place was Bryann Chipps

of Green Diamond Resource Company.

The latest in firefighting technology was on display at the event. Boosting local firefighting capabilities will be a Sikorsky S70i Fire Hawk helicopter. When compared to the current UH-1H Super Huey helicopter being used, the new helicopter has two engines, a greater lift capacity, can carry a larger crew, and has a 1,000-gallon fixed water tank. The Fire Hawk is a civilian version of the Black Hawk military helicopter.

The next annual Redwood Region Logging Conference will be held in Ukiah in Mendocino County in March 2025.

Bob Canevari and Gloria Cottrell were recognized with achievement awards. Canevari is a retired contractor, past president of the Redwood Region Logging Conference,and past director of the Pacific Logging Congress. Cottrell and family operate Three Rivers Logging and the Cottrell Ranch.

Wood-Mizer has introduced the WM2500 industrial sawmill. Engineered for peak production and starting at $124,995, the WM2500 includes advanced features to ensure precision, stability, and operational efficiency.

Combining a powerful electric 30 hp motor with a maximum log diameter of 41 inches and maximum cut width of 33 inches, the WM2500 operates seamlessly as a stand-alone primary headrig to saw pallet boards, grade or dimensional lumber or as a vital component of a complete sawmilling system. Material handling equipment can be added before and after the WM2500 to enhance productivity.

Features include heavy-duty construction, user-friendly controls, and high-production hydraulic log handling capabilities. The standalone operator stand is accompanied by an operator control console with joystick controls, presets, setworks, and independent hydraulic controls, making operation fast, easy, and efficient.

The high-speed head up/down servo drive reduces saw head positioning time so more time can be spent sawing lumber. In addition, the high-performance blade wheel belt system minimizes vibration and sawdust interference to extend blade life. The WM2500 also is equipped with a hydraulic pump unit, stand-alone central electric box, and pantograph that ensures that cabling is secure and dust-free while minimizing cable wear during operation.

Wood-Mizer manufactures sawmills, resaws, edgers, material handling equipment, and complete sawmilling systems.

For more information or to order, visit woodmizer.com or contact your local WoodMizer representative.

Fecon, a leading global manufacturer of heavy-duty site preparation attachments and forestry accessories, has launched Fusion, a user-friendly telematics platform.

Fusion uses state-of-the-art features, such as automatic machine calibration,

location services and performance tracking, to make industry-changing productivity gains in mulching operations.

Fusion automatically calibrates the attachment to the carrier in real-time to optimize performance, minimize downtime, and expand the machine’s lifespan. Fusion is initially available on high-flow Bull Hog and Blackhawk attachments.

This Fecon intelligent control technology drastically improves mulching operations. Fusion automates mulcher set-up to improve performance and productivity through its Plug n’ Play design, which eliminates manual set-up and tuning. Customers can attach their mulcher to any compatible carrier and run the machine with increased performance. The mulcher is optimized to the carrier and working conditions at all times with no extra work for the user.

The technology continually collects and adapts to information based on dynamic conditions, such as temperature, altitude, carrier settings, and carrier efficiency. For example, at the start of the day Fusion will detect a cold carrier and automatically adjust and tailor machine settings to those that work best in colder temperatures. As the machine warms up, Fusion will tune the settings for the higher temperatures. The machine starts learning as soon as it is attached to a carrier, but an operator also can choose to initiate a learn sequence through the Fusion app. This learning system ensures a Fecon mulcher is always operating at peak performance.

For more information, visit www.fecon. com.

Intercomp, the world’s largest manufacturer of portable vehicle weighing and measurement products, has introduced the LTR788TM dual platform scale to the global industrial scale market.

The LTR788TM is NTEP certified for commercial vehicle weight enforcement.

Bringing new capabilities to wheel load scales, the LTR788TM was developed for direct measurement of individual tire loading in a dual-tire configuration.

Although tire failures within dual-tire set-ups have historically occurred more frequently on inner tires than outer tires, individual tires in a dual-wheel configuration were assumed to carry near equivalent loads because there was no scale that could directly measure individual tire weights.

Now it is possible to identify and correct unequal weight distribution within a dual tire configuration by setting the tire air pressures to properly load both tires. Using this information, operators will be able to increase road safety, avoid many common equipment failures relating to uneven tire wear, and save money through fuel economy and decreased repair costs.

Proper load distribution through load balancing increases safety by reducing issues related to uneven wear, tire blowouts, and accidents involving overturned trucks.