The Log Max 5000V is a modern and reliable harvesting head that can handle a wide range of logging challenges. This is the perfect mid-range head for both thinning and final felling. The head can be equipped with a 82 cm saw bar and has a maximum cutting diameter of 74 cm. It also features Log Max’s Multi-stemming MK2, that is agile and lightweight, making thinning work easier. The Log Max 5000V is suitable for those who seek the perfect balance between agility, capacity, and durability. A versatile head, ready for large trees.

“The cutting and feeding are brutally good and in combination with the new length measuring unit, Log Max is unstoppable ; )” What customers say:

Tigercat

USNR’s VAB-brand Lineal Autograder is a highly innovative grading solution for planer mill applications. Using measurable dimensions and artificial intelligence for exceptional accuracy, the system can manage standard and custom grades. With over 70 installations in North America, this system has a proven track record. Its small footprint simplifies installation making it easy to integrate into existing production lines. Completed over two weekends to limit downtime, mills are usually grading to norm within a few hours from start-up. Lumber producers can expect to maximize finished wood volume, minimize trim loss, and reduce the need for manual graders. Contact us today!

www.usnr.com

20 MICROTEC

Koskisen chooses MiCROTEC.

28

In the ever-evolving landscape of wood processing, a groundbreaking innovation from BID Group, the ResawExpert by Comact, emerges as a transformative solution set to redefine operational efficiency in sawmills.

24 JARTEK

Cutting edge automated solutionslong term customer relations.

34 USNR

Lineal scanning and optimization at USNR.

26 JOESCAN

Super Snapshot Scanning for Sawmills Or How to Prevent the Waney Board Blues.

36 BID GROUP

BID’s New AI-Powered Robotic Automation: A complete solution to intelligently pick, sort and stack trim blocks and boards.

“The Logeye Stereo alone gives us about 5% more cutting performance.”

Pfeifle Holz, Germany

X 360° real shape reconstruction during rolling

X Increase of throughput speed, yield and cutting performance

X Easy operation on the bandsaw or carriage

X Efficient and modular solution

X Direct connection to cutting optimization (Maxicut) and cutting line visualization software (Optiline)

The Logeye Stereo stereoscopic imaging system is the only worldwide scanner that provides a full 360-degree scan of a log as it‘s rolling into your Carriage, Headrig, End Dogger, or from a transverse to lineal conveyor. Since the scanning takes place as it‘s transferred into the position, the log is already fully optimized and ready for sawing the instant it is dogged or sent through your sawline.

SUBSCRIPTIONS

SUBSCRIPTIONS

Tel: +44 (0)1442 877 583 emma@internationalforestindustries.com

Tel: +44 (0)1442 877 583 emma@internationalforestindustries.com

Annual Subscription

Annual Subscription

U K and Europe £160, € 230 Rest of the world US$270

U K and Europe £160, € 230 Rest of the world US$270

EDITORIAL

EDITORIAL

T: +44 (0)1442 877 583

T: +44 (0)1442 877 583

F: +44 (0)1442 870 617

Continuing our climate change themes we highlight some of the topics on the agenda at Wood Transport & Logistics 2024.

www.internationalforestindustries.com

F: +44 (0)1442 870 617 www.internationalforestindustries.com

2 Claridge Court, Lower Kings Road

Berkhamsted, Herts. HP4 2AF, UK

2 Claridge Court, Lower Kings Road Berkhamsted, Herts. HP4 2AF, UK

Editor

Robin Peach robin@internationalforestindustries.com

Editor Robin Peach robin@internationalforestindustries.com

Editorial Board

Kevin Lapham

J.P.Media Inc

Tel: +1 (630) 420 9752

Also, Check out issues - (June July 2023How much money is needed to save the rainforests?) (Aug Sept 2023 - Switch from fossil fuels to renewables) (Oct Nov 2023 - The rich can go a long way to saving the planet) (Dec Jan 2024 - Can Amazon save the Amazon?

And from Finland, Ponsse has teamed up with Epec, a manufacturing company that specialising in electric/hybrid electric vehicle and autonomous systems, to

Fax: +1 (630) 420 9763

Dr Patrick Moore – Chairman and Chief Professor Piotr Paschalis-Jakubowicz –Warsaw Agricultural University (Poland) Mr Kim Carstensen Director General Forest Stewardship Council

Eduardo Morales

Email: lapham@jpmediainc.com

South American Forestry Consultant

WEB OPTIMIZATION

Jo English

ADVERTISING AND PROMOTIONS

ADVERTISING AND PROMOTIONS

International Forest Industries Ltd

International Forest Industries Ltd

Advertising Manager

Advertising Manager

On-site and virtual registrations to this year’s Wood Transport & Logistics 2024 event along with interest in the Log Transport Safety Council driver certification and Trimble Forestry pre-conference workshops continue to flow in. In an earlier update, the organisers incorrectly mentioned that discounted early-bird registrations will be closing. These had in fact closed on 30 March, but a raft of special discounted rates are still on offer to those looking to register for the event.

Emma Smith emma@internationalforestindustries.com

Emma Smith emma@internationalforestindustries.com

jo@internationalforestindustries.com +44 (0)1442 877 583

+44 (0)1442 877 583

Associate Editor

Publisher Robin Peach robin@internationalforestindustries.com

Robin Peach robin@internationalforestindustries.com

Advertising Production Enquiries

Advertising Production Enquiries

Emma Smith emma@internationalforestindustries.com

Emma Smith emma@internationalforestindustries.com

Studio Manager

Luke Evans luke@lecreative.co.uk

International Forest Industries is published by International Forest Industries Ltd,

Accounts

2 Claridge Cour t, Lower Kings Road Berkhamsted, Her ts. HP4 2AF, UK

Nicola Shukla nicolas@internationalforestindustries.com

International Forest Industries (ISSN 1755-6732) is published bi-monthly by International Forest Industries Ltd GBR and is distributed in the USA by Asendia USA, 17B South Middlesex Avenue, Monroe NJ 08831 and additional mailing offices. Periodicals postage paid at New Brunswick NJ. POSTMASTE R: send address changes to International Forest Industries, 17B South Middlesex Avenue, Monroe NJ 08831 © International Forest Industries Ltd 2007 – 2019 I FI uses, as preference, SI units throughout. All dollars are US unless otherwise stated.

International Forest Industries is published by International Forest Industries Ltd, 2 Claridge Cour t, Lower Kings Road Berkhamsted, Her ts. HP4 2AF, UK International Forest Industries (ISSN 1755-6732) is published bi-monthly by International Forest Industries Ltd GBR and is distributed in the USA by Asendia USA, 701C Ashland Avenue, Folcroft, PA 19032 and additional mailing offices. Periodicals postage paid at New Brunswick NJ. POSTMASTE R: send address changes to International Forest Industries, 17B South Middlesex Avenue, Monroe NJ 08831 © International Forest Industries Ltd 2007 – 2023 I FI uses, as preference, SI units throughout. All dollars are US unless otherwise stated.

In addition to innovations around decarbonising log transport fleets, a first look into efforts being made into log harvesting operations has been added to this year’s programme. Mike Hurring Logging has been operating NZ’s first Logset 8H GTE diesel-electric hybrid wheeled harvester in production thinning operations in Otago/Southland forests. How’s the new dual-fuel machine performing?

develop another first, an electric machine concept for forwarders with 15-tonne load-carrying capacity. Epec’s technology is already beimg used in electric or hybridelectric commercial vehicles and non-road mobile machines.

As part of this year’s Wood Transport & Logistics 2024 event, both Mike Hurring and Ponsse will be providing early insights for local forestry companies and contractors on future options for taking electric or electric hybrid machines out into the forest.

» 40” diameter capacity

» Heavy-duty 50” diameter x 66” wide hammermill

» 20 hammer inserts

» Caterpillar C32, 1,200 horsepower engine

» Standard impact detection system

The countless industries that use lifting equipment are being urged to unite in support of Global Lifting Awareness Day on Thursday 18 July.

Driven by the Lifting Equipment Engineers Association (LEEA), #GLAD2024 is an established event where its members, manufacturers, and suppliers lead those sharing material that promotes safe and high quality load lifting across the world. Social media posts, videos, articles, and in-person activity are bound together by the hashtag. However, LEEA and supporting stakeholders recognise that the continued growth of the concept — and realisation of the association’s

daily work and #GLAD2024 campaigning points.

Ross Moloney, CEO at LEEA, said: “To take GLAD from an idea to a globally recognised movement required us to garner support from major stakeholders in our industry, many of which are LEEA members and long-time collaborators. Empowered by their support, and that of fellow trade authorities, media, and a select group of users, we must now energise more people with lifting equipment in their hands and on their person, as well as those responsible for sourcing it.”

The latest campaign messaging harmonises with the launch of new promotional

central to which is that the safe application of our technologies and solutions is their lifeblood

with the industry, at all levels of the supply chain. Industry representatives

Independently certified

MEET US AT: IN TER M AT Paris, 24-27 April CeMAT Singapore, 15-17 May TOC Europ e Rotterdam, 11-13 June

Offering a vast variety of radio remote control products, adaptable to a multitude of applications, throughout many industries, not limited to:

Agriculture & Forestry Equipment - Cranes & Material Handling - Mobile Hydraulic Machinery – Emergency & Recovery Vehicles - Industrial Doors & Gates – Propane and Tanker Trucks – Construction Equipment & Machines –Pumps & Aggregates, PLC Control – Recycling Machinery and more…

FAE updates its line of midsize stone crushers with the introduction of the new STCM line. The new head — which will replace the current STC line — can crush stones up to 30 cm in diameter and 20 cm deep and has a working width of up to 230 cm. The STCM works with 80-280 hp tractors.

FAE’s STCM stone crusher is the perfect solution to clear stony land and prepare fields for farming.

Compared to the previous version, the STC, the STCM features significant technical improvements. The opening has been enlarged to allow for the intake of more material from the surface and underground. The adjustable counter blade is now hydraulic for added granulometry control during processing.

In addition to these upgrades, there are a number of other features. The internal

Hardox® counter blades help to produce uniform results for all the material entering the crushing chamber. The sturdy protection chains limit material output to a minimum, protecting the drive motor. Finally, the ultra-strong, wearresistant steel used for the frame, the interchangeable internal and external guards,

FAE expands its line for small excavators with the new PML/EX family for 2–7.5 ton excavators. The new line replaces the PML/HY and PMM/HY lines and the previous version of the PML/EX.

The new PML/EX can mulch light vegetation, shrubs, and trees up to 5 cm in diameter. Light and compact, it’s the perfect tool for managing and protecting wildlife habitats and maintaining commercial parks

and sports grounds.

The head is designed for high productivity, durability, and easy installation and maintenance.

The PML/EX’s Direct Drive motor minimizes maintenance and allows for a smaller machine body for better maneuverability. With a flow regulator valve built into the motor and a thumb bracket integrated into the frame, the

and the heat-treated, forgedsteel tooth holder together guarantee a robust structure that can stand up to even the most challenging tasks.

The STCM is available in seven models and five widths. The line includes three different types of teeth that can be selected based on the working conditions.

head maintains a clean profile and compact build.

The hydraulic motor is compatible with excavators that do not have a drainage line, making the head easier to install. This feature makes the head a plug-and-play piece of equipment.

The new PML/EX can be equipped with PML hammers or Y-flails and comes in an operating width of 75, 100, 125, or 150.

Tigercat adds fifth model to harvesting head line-up with the new three-wheel drive 573. In late September 2023,

visitors to the PLC live demo event held in Washington state got a sneak peak of the new Tigercat 573 harvesting head

processing logs on the end of a Tigercat 875E logger. Since then, multiple units have been testing in far flung regions from Alberta to Australia and the results are in. The 573 is shaping up to be a high performing, reliable head for roadside processing and harvesting.

Best suited to medium and large tree profiles, the 573 has a 800 mm (31 in) maximum cut capacity and offers optimal

performance in 400-600 mm (16-24 in) diameter timber. The feed rollers close down to 60 mm (2.4 in), allowing the 573 to smoothly delimb and process smaller diameter trees and thus achieve higher value fibre recovery.

The compact frame design deftly handles poor stem form and contributes to tidy delimbing performance. The triangulated feed wheel arm configuration operates in locked three-wheel drive. This, combined with timed knife arms, provide the operator with fast picking and positive stem control for high productivity in roadside processing applications. Independently mounted, trailing-arm length measuring ensures reliable tracking and accuracy.

The top knife and lower/ back knife pivot on the same side of the chassis frame, aligning the position and flow of each stem centrally through the head. This arrangement promotes positive contact with all three feed rollers and the measuring wheel at all times. The result is better quality and accuracy, reduced fuel consumption, and greater processing speed. The orientation also provides the operator with a clear sightline to the measuring wheel.

The 573 is standard equipped with continuous rotation for ease of use and superior hose routing and protection. Quick, stable WiFi connectivity between the cab and attachment modules reduces wire routing along the boom and provides excellent command response.

The Tigercat D7 control system is available with Priority or Optimization levels and is fully compatible and compliant with StanForD Classic and 2010.

The 573 is a great fit for the H250D, 850 and 875E for roadside processing applications and the H822E and H855E carriers for in-stand harvesting.

With near zero tail-swing, the LX830E is a powerhouse in a compact package. Stable and responsive, it’s well matched to tough terrain and steep slopes in selective cut or final fell.

Modern forestry applications must first and foremost reduce fuel consumption and minimize emissions. No matter the power source, conventional or alternative fuels, hydrogen, or electrification: ZF is contributing to reducing emissions from less to zero.

ZF cPOWER – CVT technology

High loads, continuously variable speeds, and therefore comfortable maneuvering – the cPOWER power-split CVT technology combines these characteristics with improved fuel consumption of up to 25 percent. It operates at low engine speeds, thus increasing efficiency and driver comfort in forestry equipment like forwarders and skidders even more. The gain in tractive power through the innovative transmission system

is particularly beneficial for the user when driving on challenging terrain types, like steep slopes, soft ground, or deep snow.

Whilst the Group´s transmission is already being well-established in the North American full-tree skidder market for several years now, the technology is recently also finding its way into the cut-to-length forwarder market, mainly to be found in the European area.

Heavy loads, continuously adjustable speed, and easy maneuverability – the fully power-split CVT transmission cPOWER combines these characteristics with improved fuel consumption of up to 25 percent (image: ZF)

Being in series production for forwarders since more than three years now, the fully power-split, continuously variable transmission offers significant fuel consumption benefits and productivity increases for the vehicle owner. Because of rising fuel prices and a growing awareness of CO²-emissions, the market demands more efficient drive systems.

In Off-Highway applications, hydrostatic power-split transmissions ensure significant consumption benefits compared to hydrodynamic transmissions and purely hydrostatic concepts.

Efficient, clean and safe: this is how we envision future off-road operation with intelligent system solutions.

As a full-range supplier, we supply comprehensive drive systems for off-road machinery from one source. We develop axles and transmissions with advanced software functions and combine them with state-of-the-art braking technology, connectivity and safety solutions. Our answer to meeting the industry’s challenges: comprehensive and intelligent system solutions, thoroughly matched to each other. In doing so, we always keep an eye on reducing emissions and remain on our path to Vision Zero. ZF.com/construction

The continuously variable transmissions clearly demonstrate their benefits in all ranges of the typical forestry operating cycle, i.e. transporting, or loading.

In this process, the percentage of hydrostatic power is kept low whereby; an optimal degree of efficiency can be achieved.

Already in the start-up process there is a power split between mechanical and hydrostatic drive. The share of the mechanical power increases with the vehicle speed up to 100%.

The application of an elaborate hydraulic transmission-control unit and transmission-integrated onboard electronic unit optimally completes driving functions. The application of these units is done with reference to sensitivity and driving comfort and realizes an aligned power management.

The cPOWER series deploys well-known and -proven construction kit modules and benefits from ZF competence in transmission and vehicle system engineering.

Main features:

• Continuously variable drive over the whole drive range

• Hydrostatic-mechanical power splitting in all driving ranges, including the frequently used range up to 10 km/h

• Reduction of diesel motor speed independent of driving speed

• No wear through heavy loads as there is no mechanical connection between engine and driveline

ZF eTRAC – electric driveline technology

For the future, technology and innovation leader ZF is up to many more projects in the field of forestry, seeking into electric drive solutions already today.

The eTRAC electric drive system satisfies all the expectations for performance and productivity found in traditional drivelines and combines them with the extensive benefits and opportunities that electric systems have to offer. Thanks to its modular design this new range of electric central drives can easily be adapted for various vehicle applications.

Zero emissions without compromising on performance –the electric drive system eTRAC eCD50/70/90 from ZF

A newly launched system for forestry applications consists of a 2-speed powershift transmission, electric motor, and inverter. It can be scaled up to peak torque 850 Nm and continuous power of 80 kW. Three power classes of the electric central drive system eCD50, eCD70 and eCD90 are available to cover different vehicle sizes in the targeted applications.

To complete the customers´ demand, not only in regards of traction drive, ZF also offers the so called ePTO, e.g., to run the working hydraulic.

Main features:

• One supplier for transmission, eMotor and inverter

• “Best in class solution“ for power density

• Zero emissions without compromising on performance

• Low noise level

• Efficient electrical components

• Robust and reliable mechanical driveline

• Compact installation space

Key Figures electric central drive eTRAC eCD50/70/90

• Modular platform for 650 V

• Up to 80 kW continuous power

• Liquid cooled PSM e-motor

• 2 speed powershift transmission

• Integrated park brake

• Optional axle disconnect (2WD/4WD)

To complete the range of electric drives for larger construction vehicles, ZF is offering the eTRAC eCD110210 series, consisting of an electro-mechanical powershift transmission and one e-motor for traction and ePTO each. An electric drive control unit for overall system performance and power management completes the system. With a 650 V operating voltage, the system can be scaled up to 120 kW continuous power; the

ePTO ranges from 30 to 70 kW continuous power. Thanks to its modular design, the system can be integrated in various other vehicle applications as well and can be driven independently from the power source. The company´s solutions fit in both batteryelectric vehicles and fuel-cell battery electric vehicles, which will also play a big role in the future of construction machineries.

Key Figures electric central drive eTRAC eCD110 - 210

• e-drive: 650 V (50-120 kW continuous power)

• ePTO: 650 V (30-70 kW continuous power)

• eDCU: Drive Control Unit for overall system performance and power management

• Drop-In replacement for current conventional driveline

BMH Technology has signed a contract with NAVIGATOR Pulp Setubal for the delivery and installation of a wood fines handling system in Portugal to convert one of the gas burning kilns into biomass.

The main driver for the project is to reduce the consumption of natural gas which is a major source of emissions and represents a significant portion of production costs. The project aims to convert the normal operation of the existing Lime Kiln 1, making it entirely independent from fossil fuels. This solution aims to eventually make the lime kiln operation 100% fossil free.

The delivery includes the design, manufacture, erection and commissioning of an external fuel handling system for wood fines biomass. The system consists of receiving station, storage silo, grinding mill and pneumatic piping to feed the powder silo.

“We have seen an Increased demand for these solutions which will help to decarbonize Industries and BMH is

Marcos Arizti, Sales Manager of BMH Technology Oy.

The

The cooperation between Junnikkala Oy and Veisto Oy first started in 2008, when Veisto delivered a sawing line to Junnikkala’s Oulainen sawmill.

An agreement between Junnikkala and Veisto to supply the sawing line to Oulu was signed in early summer 2021. After signing Veisto and Junnikkala worked closely together for two years, discussing issues, such as the length of the line and equipment compatibility. Project Manager Timo Mäkelä and Plant Manager Antti Kyröläinen took lead of the project. When all details were finalised, Junnikkala started construction work on the site and Veisto began manufacturing the machines. Installation began in September 2023, and commissioning took place in December, according to the pre-agreed schedule. The line is expected to operate at 100 % capacity in July 2024.

The world’s most modern sawing line

Veisto Oy is a Finnish familyowned company founded in 1964, with a production plant in Mäntyharju. The company, which has grown rapidly in recent years, and currently employs approximately 300 people.

Junnikkala and Veisto have a lot in common; both are Finnish family-owned companies of roughly the same age that have grown over the decades to become major players in their respective fields.

Marko Järvinen, Technical Director of Veisto Oy, tells us about the sawing line delivered to our sawmill in Oulu, the process and our cooperation.

The Oulu line represents “the latest and greatest in sawmill technology”. Sawing is done in three stages with three main machine units, optimization takes less than a second and the 101-metre line has a speed of 60–180 meters per minute.

The sawing line uses technology, that takes into account Junnikkala’s wish to have the option to add DX-units, which would allow two-stage through-sawing at a line speed of 250 metres per minute. To improve energy efficiency, we have done product development especially in the hydraulic system, which is as energyefficient and quiet in operation as possible, says Järvinen.

For the last couple of months we have been practising sawing and matching equipment from different suppliers. We have also been training Junnikkala staff to use and maintain the line to get it up to speed before it goes into full production — and to avoid unnecessary breakdowns,” says Järvinen.

We have a great sawmill on the way and we are looking forward to its completion. We haven’t had a chance to test all the variations yet, and there are bound to be challenges ahead, but I believe that by working together with Veisto, we can always find a solution to any problems,” says Kyröläinen.

At Veisto, the Oulu project has kept sales, design, and production teams busy. During the field installation, there were up to thirty Veisto staff and their subcontractors working simultaneously on site. In the current commissioning phase, there are still 1–5 Veisto employees present, mainly in training roles. For Junnikkala, the project has also employed a wide range of people including production planning, operational management, operators, and maintenance.

Long and smooth cooperation

Junnikkala has a good team and realistic goals. They have been very well-planned and well-managed, which is why the cooperation has gone extremely well and without any major surprises. Our project manager has especially praised Junnikkala’s performance

Marko Järvinen, Technical Director of Veisto Oy

Marko Järvinen, Technical Director of Veisto Oy

Plant Manager

Antti Kyröläinen

Plant Manager

Antti Kyröläinen

during the most critical phase, the installation, when the company stuck strictly to the schedule and enabled everyone to work efficiently and safely. The cooperation with our customers will always continue throughout the 25–30 year lifetime of our equipment, including developing and upgrading new functions for existing lines. In this way, they remain at the highest technological level for decades,” says Järvinen.

Kyröläinen has also been very happy with the cooperation. ‘Veisto has had enough competent staff on site at all times. The company has also shown flexibility and patience with other equipment suppliers, who we have sometimes had to wait for to proceed. Our cooperation will continue, to ensure we reach and maintain full capacity, as well as warranty maintenance and inspections.’

Metsä Group and Sweco, a specialist in the built environment and industry, have signed an agreement for the implementation planning of the new Kerto LVL mill in Äänekoski, Finland.

“We have strong confidence in Sweco’s expertise and resources from our previous collaboration projects. It is therefore natural that we continue our cooperation in this project to develop the Äänekoski mill area,” says Jaakko Anttila, Executive Vice President at Metsä Wood.

Sweco is responsible for the complete implementation planning of the mill project, including structural, process and plant design. Sweco was also responsible for the design of Metsä Group’s Äänekoski bioproduct mill, which started operations in 2017, and the planned wood product mill will apply the synergy benefits

offered by the mill area.

“For example, the steam needed in the production process of Kerto LVL will be produced at the Äänekoski bioproduct mill, and the condensate generated in the process will be utilized for heating the building. It is great to be involved in designing a resource-efficient production plant whose material-efficient wood products store carbon and reduce the carbon footprint of construction,” says Tuulamari Helaja, Business Unit Director, Industry and Energy at Sweco Finland.

Construction of the Kerto LVL mill in Äänekoski has progressed according to plan. Land construction works and the main frame installations are currently underway in the area.

The mill will have an annual production capacity of around 160,000 cubic metres of Kerto

LVL and is expected to start production in the second half of 2026. When completed, the mill will employ around 150 people directly and 200 people in its value chain.

Opticom Tech, a leader in industrial video monitoring solutions, announces its new CC04-IP5MV3 camera, an upgrade to the CC04-IP3MV camera.

The new CC04 camera offers a higher resolution than its predecessor—5 megapixel compared to 3 MP. It also supports artificial intelligence (AI) functions such as object detection, intrusion detection,

line crossing, object counting, and more.

“We’re excited to offer these upgrades to new and existing customers,” said Heidi Schmidt, Global Sales Manager at Opticom. “High-resolution video is vital for operations monitoring and security in industrial facilities. And AI is becoming a reality of our world, so having cameras equipped to support that emerging technology puts facilities ahead of their competition.”

The CC04 camera is NDAA compliant, utilizes the ONVIF protocol and can withstand high-vibration, hazardous and controlled environments. It can also withstand direct hits by

logs, boards, rocks, and other objects, making it an ideal video monitoring solution for industrial facilities.

For more information, visit www.OpticomTech.com.

About Opticom Tech

Founded in 1973, Opticom Tech provides integrated video monitoring solutions for industrial applications, including sawmills, mines, food processing facilities, and more. Built to withstand harsh environments, Opticom’s rugged cameras and equipment stand the test of time. For more information, visit www.opticomtech.com.

Opticom

JS-50 X6B CARRIAGES & SHORT-INFEED EDGERS

JS-50 TRIMMERS

JS-50 Z8 END-DOGGER, C FRAME & HI SPEED SNAPSHOT

Established in Finland in 1909, Koskisen is a forerunner in the mechanical wood industry with over 900 employees. The Koskinen group processes Finnish wood into sawn goods, plywood, veneer and chipboard with customers over the world.

Koskisen has invested in a new log sorting line with a Logeye for their state of the art sawmill in Järvelä. The Logeye is a multi-sensor scanner that utilizes laser, colour, and X-ray channels to provide a high-precision real 360° shape of the log with a wealth of data for log sorting and cutting optimization. The Logeye has a high precision both in over and under bark detection, as well as log inner properties, making it a great choice and a successful product for the northern markets.

Koskisen Production Director Lassi Santala explains that the long and successful cooperation with MiCROTEC Espoo on the Finscan product line as well as the technical

features of the Logeye was a big impact on their decision.

The Logeye from MiCROTEC stood out from the competition with the technology of the advanced hardware of the inhouse crometic color cameras within the multi-sensor approach. We see brightly on our future needs with the innovation and technology at MiCROTEC as well as the

Located in the woods of Fagersta, Sweden, Karl Segerström AB is a fourth-generation familyowned sawmill with a yearly production of 60 000 m3 sawn products each year. Karl Segerström is specialized in spruce, with export mainly to the European markets.

When investing in a new measuring system in the logyard, Karl Segerström AB evaluated different manufacturers and decided

on MiCROTEC based on the technical features and benefits of the Logeye.

The Logeye multi-sensor scanner utilizes laser and colour to generate a highprecision real 360° shape of the log, based on very accurate measurement data for Log Sorting and cutting optimization.

The Logeye has a high precision both for over and under bark detection, even in the presence of ice and snow,

Lassi Santala, Production Director, Timber Industry at Koskisen Oyj

making it an excellent choice for the northern market.

The features we were looking for, that MiCROTEC was able to provide, were the combination of color cameras and laser triangulation that provides an underbark measurement that has worked very well says Björn Segerström , CEO Karl Segerström AB.

The Logeye was installed in 2023 and is used for measuring, payment grading

cooperation going forward continues Santala, Installation will take place in Q4 of 2024. Juha Ropilo, MD of MiCROTEC Espoo comments on the investment from Koskisen.

“With this partnership we are even further strengthening our position as a provider on the Finnish market, not only within lumber products but also with our wide known log scanners. We look forward to a continuous successful collaboration and installation together with Koskisen.”

and sorting. After installation, the Logeye at Karl Sgerström has been producing since day 1.

“The installation of the Logeye went very well according to schedule and we were running on the scheduled date.” continues Björn Segerström.

For a smaller sawmill like Karl Segerström, Logeye is an ideal investment because of its cost efficiency and high performance.

Ladysmith, British Columbia Local government representatives joined Western Forest Products employees to celebrate the completion of the first continuous dry kiln on the coast of B.C. at the Company’s Saltair sawmill. The Company also plans to continue accelerating its transition to higher value products with approximately $35 million of investments for two additional continuous dry kilns.

The newly installed $12 million continuous dry kiln at the Saltair Sawmill increases the mill’s capacity for continuous drying of lumber, and also provides environmental benefits by reducing energy consumption. The new kiln adds to the three existing kilns on site for drying lumber. The Saltair sawmill is the largest single-line sawmill on the coast of B.C. following previous multi-phase strategic capital investments of over $42 million to modernize the sawmill since 2013.

Wellons Canada, based in Surrey, spearheaded the design and construction of the project, with John Wallace, Capital Sales Representative with Wellons, present to showcase the innovative production enhancements. Wallace explained the operational mechanics, emphasizing the utilization of an alternating track system to enhance energy efficiency. This system not only reduces gas consumption but

also doubles the workload capacity of the kiln.

Moreover, Wallace highlighted the incorporation of sensors every 20 feet within the kiln, enabling adaptive control of the drying process based on the moisture content of the lumber. He underscored the environmentally conscious approach by mentioning the collection and treatment of steam condensate to prevent discharge into natural water bodies.

In terms of performance, the kiln is designed to facilitate the drying of lumber at a rate of approximately three and a half feet per hour. This translates to a drying cycle of a little over three days for a full kiln load of cut lumber. Anticipated production figures indicate a capacity to dry 72 million board feet annually, operating at 190°F with a natural gas burner.

John Wallace Capital Sales Representative at Wellons

Additional Investment in B.C. Coastal Operations

Following the successful completion of its first continuous dry kiln, Western is pushing ahead with two additional continuous dry kiln projects. One of the kilns will be constructed at the Company’s Duke Point sawmill in Nanaimo, B.C. and the other one at its Value-Added Division in Chemainus, B.C. Each of the new kilns will have an annual capacity of approximately 70 million board feet.

Walling, Chargehand Electrician Cory Wilson

The newly installed $12 million continuous dry kiln at the Saltair Sawmill supplied by Wellons Canada, increases the mill’s capacity for continuous drying of lumber, and also provides environmental benefits by reducing energy consumption.

The additional capacity will support increased volumes of kiln dried products, including lumber used to produce glued laminated timber for mass timber applications. Western has made significant investments in its B.C. Coastal manufacturing operations to modernize its primary manufacturing facilities, increase kiln drying and planing capacity and expand its engineered wood products and remanufacturing capacity. The approximately

$35 million investment in two new continuous dry kilns is on top of the $29 million in investments announced in 2022.

The previously announced projects are in various stages of advancement, with the Company most recently having completed the installation of a machine stress rated lumber grader at its Duke Point sawmill to support increased production of higher

Cont’d on Page 48

In recent years, many machine suppliers in the sawmill industry have thrived, and Jartek is no exception. While nearterm investment levels may taper off, the outlook for the distant future appears promising, with investment levels poised to rise once again.

The utilization of renewable materials continues to surge, with lumber standing out as one of the most favorable options. Throughout these prosperous years, Jartek has experienced growth while remaining true to its origins as a family-owned company, placing a strong emphasis on cultivating partnerships.

The ThermoWood® business has enjoyed global success for years, and the lumber handling sector is gradually following suit. Jartek maintains openness to all markets, though its primary focus remains on European countries, with a few select markets outside of Europe.

“We’ve received a warm reception in Germanspeaking countries,” notes Kari Puustinen, Sales and Marketing Director of Jartek. “We’re introducing some innovative, out-of-the-box concepts to the market, which is always beneficial,” Puustinen adds.

Despite Jartek’s emphasis on constructing sorting lines with lifespans of up to 50 years or more, our on-site commissioning typically spans only up to two years, depending on project size,”

Our after-sales objective is to collaborate with customers on both minor and major investments to further enhance line productivity.

Kari Puustinen, Sales Director of JartekJartek doesn’t operate any web shops or after-sales platforms. “We might lean towards traditionality, but to us, human connections are paramount for fostering enduring partnerships,” states Kari Puustinen.

How does the ethos of “More than Mechanics” align with this? While proficient mechanics form the foundation, they’re not the sole requisite. We also prioritize top-notch automation and continual line development. Jartek strives to provide cutting-edge automation solutions, which have been warmly embraced by our customers. These solutions perfectly match industry needs, boasting userfriendly interfaces, exceptional diagnostic capabilities, and seamless integration with third-party systems like reporting tools, whose significance continues to grow. Looking ahead, rather than focusing solely on modern platforms, we’re enhancing our after-sales support through more traditional

investments to further enhance line productivity. Finnish sawmills, renowned for their efficiency despite their age, have taught us the significance of even small enhancements. Hence, we prefer to use terms like “service” or “partnership” instead of “after-sales,” emphasizing the continuous nature of our relationship.

As a key supplier to Finnish sawmills, Jartek encourages them to engage with our sales team to explore how we can collectively maximize line efficiency.

Roughly one year ago, Jartek commenced the installation of its largest project in Finland.

means. Our aim is to better assist customers postproject handover, fostering discussions on optimizing line output. Despite Jartek’s emphasis on constructing sorting lines with lifespans of up to 50 years or more, our on-site commissioning typically spans only up to two years, depending on project size,” notes Kari Puustinen.

Our after-sales objective is to collaborate with customers on both minor and major

This mill stands as one of the most advanced sawmills globally. Logs are seamlessly fed into the saw infeed by forklift, and the point at which the forklift touches the lumber marks the readiness for shipment to the customer. Jartek provided a comprehensive supply package, encompassing green and dry sorting, along with stick and drying load moving systems and lumber feeding from sawline to greensorting,

all of which operate fully automatically.

The layout was meticulously tailored to suit the site’s specific requirements, given its compact nature, making a fully automated process the only viable option. Collaboration with the Junnikkala team has been exceptionally fruitful, particularly in the conceptual planning phase. The production lines feature a blend of standardized working solutions complemented by customized

fittings to adhere to the overarching concept. This fusion ensures both high capacity and functionality, alongside an excellent layout. Currently undergoing startup procedures, the mill is poised to serve as a benchmark, showcasing our capabilities to customers worldwide with pride.

We all know that sawmilling is a special type of manufacturing. Instead of assembling products from a variety of known components, we produce goods by breaking down logs into finished lumber. The logs we start with are not standardized components with known sizes and shapes (wouldn’t that be nice?), but complex organic structures that can vary wildly from one piece to the next. Even within the same species, no two logs are exactly alike. It’s this variability that makes scanning a mission critical part of the lumber manufacturing process. It’s also this difference that makes sawmill scanning equipment so unique when compared to other industries. For example, consider the sawmill snapshot scanner–a device so specialized for breaking down wood that you won’t find it used in any other industries.

A 3D laser scanner uses lasers and cameras to define the size and shape of an object. In a sawmill, this object can be a stem, log, flitch, cant, or board. Optimization software uses this measurement to determine the best cutting solution for each piece. “Best” usually boils down to “maximizes profit”, but there are many complex decisions made at each step of the breakdown process.

In most machine centers, the log or board moves through the lasers, allowing the scanner to capture its size and shape hundreds of times per second. These measurements are combined to generate a very accurate and dense 3D model of the wood.

JoeScan’s newest Z8 Super Snapshot scan head delivers twice as much data for your sawmill.

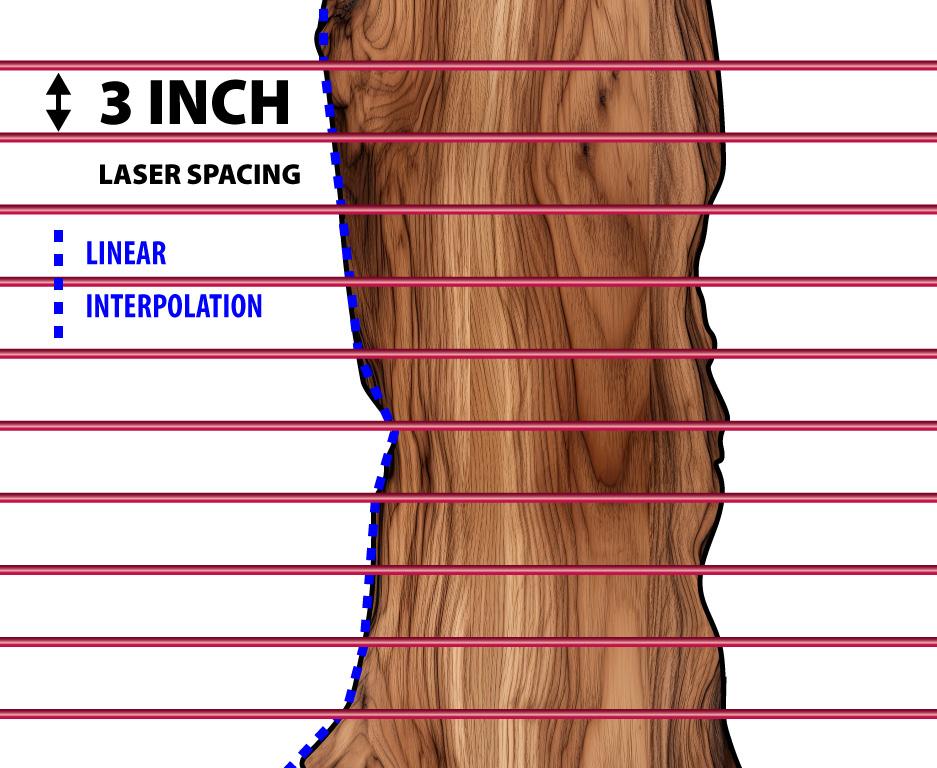

A true snapshot scan–one that does not move the piece at all–leaves gaps in the measurement, basically anywhere there isn’t a laser. The closer the lasers are to each other, the smaller those gaps are. This distance between lasers is referred to as the laser spacing of a snapshot scanner.

The industry standard for laser spacing has been around six inches for many years. However, as you’ll see below, a lot can happen in those six-inch sections between measurements.

However, in certain sawmill systems, it’s impractical to move the piece in order to scan it. This commonly occurs with end doggers, C-frames or other very short-coupled machine centers. Here, a snapshot scanner combines many lasers together in one package to take many measurements simultaneously, at each laser cross-section on wood. Multiple snapshot scan heads are arranged end-to-end to cover the entire length of the pieces being scanned.

So, why should a sawmill care about missing data in their snapshot scans? Because it costs them money!

Timber Processing & Energy Expo (TP&EE) September 25-27, 2024, Portland, Oregon

When faced with gaps in the data, optimization software typically uses a method like “linear interpolation” to fill them in. This is essentially connecting the dots between known data points using straight lines. The problem occurs when the linear interpolation inaccurately represents the scanned wood. For example, the optimizer may think it’s providing the solution for a square-edged board, but the machine puts out a waney board instead.

So, how does this happen?

Wherever a log or flitch narrows within a 6 inch section between lasers, as in the example above, the scanner will not see it. Remember, it can only see where the laser touches the wood. Consequently, the optimizer assumes there is good wood where there is none, resulting in a solution that doesn’t reflect reality. Errors like these end up costing you in the form of lower-quality

boards and unusable waste. Fortunately, there’s a simple fix!

By reducing the laser spacing to three inches, JoeScan’s newest Z8 scan head can see

Your optimizer, like you, wants as much relevant information as possible to make an informed decision.

Snapshot-style scanners are also found in machine centers that don’t require a

twice as much as before. This leads to fewer and smaller undetected areas, reducing unexpected wane in your cuts.

true snapshot. Places like the carriage headrig and shortcoupled edgers also benefit from the tight laser spacing. A

six-inch laser spacing allows for scanning an entire log or board’s length in just six inches of travel. This allows for faster scan speeds, affording more time for optimization, while also significantly reducing the length of infeeds when space is limited. Further reducing laser spacing will let you operate even faster without sacrificing quality.

The modern automated sawmill is a unique kind of factory requiring specialized equipment. Scanning hardware is no exception, and we’ve spent the last 20 years designing scanners specifically for sawmills. JoeScan’s new Z8 is just the latest iteration of doing what we do best: making scanners that improve sawmills. For more information about other scanning applications in sawmills, we invite you to check out our website at joescan.com.

In the ever-evolving landscape of wood processing, a groundbreaking innovation from BID Group, the ResawExpert by Comact, emerges as a transformative solution set to redefine operational efficiency in sawmills. Guided by a thorough comprehension of the intricacies in the wood processing sector, this innovation embodies creative design, premium materials, and state-ofthe-art technology, signifying a notable progression in the field of resaw optimization. Its main benefits include maximizing recovery and product value, setting a new standard for efficiency in the industry.

The ResawExpert by Comact: Pioneering Vision and AI Integration

Traditionally, wood processing has seen the integration of Artificial Intelligence (AI) in various stages, such as grading, trimming, edging, and breakdown. However, the resawing process has remained a crucial focal point where the right decisions are vital to prevent costly consequences. The ResawExpert by Comact steps into this critical role as the first resaw optimizer powered by both vision and AI, addressing challenges in decision-making precision and dimensional accuracy.

At the heart of the challenge lies the pivotal role of the resaw, a step of wood processing that is common for the production of softwood specialty products and hardwood. A wrong decision at this juncture can potentially reduce the quality and value of the products as well as increase wastes. Ensuring precision in reading dimensions and identifying defects becomes imperative to optimize the cutting process

effectively. The conventional approach relies on basic scanners to measure block sizes, with operators manually deciding the cutting strategy based on visual inspection. Once a cut is completed, altering the decision becomes impossible.

The ResawExpert introduces a revolution in resaw optimization, employing precise geometrical measurement and AI-driven visual defect detection, ensuring the maximization of recovery and product value. Unlike the traditional approach, where operators rely on visual cues, this innovative system utilizes AI to assess different combinations of cuttings based on the grade of each face, and the downstream operations like edging and trimming. The optimization logic considers the total surface value, introducing an innovative approach to resaw optimization.

ResawExpert accommodates both manual and automated turning solutions. Thanks to the integrated rotation scanner, the system validates the execution using an end camera, ensuring accuracy and accountability in the process. If rotation is not executed properly, the system will rotate around the block again to send the right face to the resaw. This integration of vision and AI not only enhances decision precision but also introduces a level of consistency that is unattainable through manual processes.

Designed for practicality, the ResawExpert can be seamlessly added to existing production lines. Its installation between

two sets of rolls requires only 10 to 12 feet of space, with no significant speed limitations imposed by the scanner, as it can optimize up to 450 feet per minute. It is compatible with various types of resaws, whether horizontal or vertical. Block sizes can vary from 3 to 30 inches, with no length limitation. The scanner measures the block with a precision of 0.030 inches for the thickness and width, and 0.125 inches for the length, offering a scan density of 0.125 inches.

The optimization parameters align with industry best-in-class, utilizing the same software and platform as other successful Comact scanners like the TrimExpert, EdgExpert, and GradExpert. The system optimizes based on industry grades like NHLA ones, but

also based on clear wood cuttings and any in-house grade, allowing the flexibility required to manage a broad basket of products to maximize yield and value. Comact’s proven AI engine leverages the images coming from 4K colour cameras, which are integral to the ResawExpert’s success and form the backbone of all Comact optimizers. Developed in-house, the AI deep learning models for hardwood are specifically tailored for wood processing, derived from extensive data analysis and a deep understanding of the unique characteristics of hardwood.

This in-house approach to our AI development not only ensures high performance but also allows BID and its Comact brand to continually refine and enhance its models based on real-world wood processing challenges. The utilization of AI in wood processing is not merely a trend; it is a proven strategy that delivers tangible results, as evident by the success of BID’s AI-powered solutions across the industry.

Transforming Resawing for the

The ResawExpert by Comact emerges as a trailblazer in the wood processing industry, introducing a transformative solution to the critical process of resawing. By seamlessly integrating vision and AI, it addresses longstanding challenges in decision precision and consistency. Not only does this innovation enhance operational efficiency as well as maximize recovery and product value, but it also marks a significant step towards a more intelligent and automated future for wood processing.

Integrated scanner to validate an executed rotation. Sends a signal for additional rotation if it was not executed properly

As sawmills navigate the complexities of wood processing, embracing technologies like the ResawExpert becomes crucial for staying at the forefront of efficiency, productivity, and quality. BID Group’s commitment to excellence shines through in this pioneering solution, offering a glimpse into the future of resaw optimization. For further details and to explore the transformative capabilities of the ResawExpert, reach out to your BID Group sales representative.

Scan this QR code to see the ResawExpert in action

ABB’s control room environment, power distribution and robotics have been a part of Metsä Fibre’s technologically advanced sawmill’s pioneering levels of productivity and efficiency. The customer’s Rauma mill is Finland’s largest ever sawmill investment at €260 million and uses machine vision, artificial intelligence (AI) and integrated information systems for consistent quality and cost efficiency.

Building on a long-term relationship with parent company Metsä Group, ABB provided Extended Operator Workplace (EOW) tables for maximum ergonomics, visualization and communication, as well as electrical power distribution, transformers and robots. Since the technologies were commissioned a year ago the sawmill has turned out 40 logs per minute on a 130-meter sawline with a maximum sawing speed of 250 meters per minute, all managed from an ABB-designed central control room. The sawn pine timber is exported worldwide and can be used in construction – including windows, doors and general joinery, woodworking, furniture and packaging.

“With the support of partners, including ABB, we are achieving productivity that is at least three times higher than what is possible across the rest of Europe,” said Jaakko Vierola, Technical Director of the Rauma sawmill project, Metsä Fibre. “The durability of components and the service ABB provides exactly when we need it are crucial.”

The electrical distribution system with medium voltage and distribution transformers was designed and delivered by ABB. ABB’s robots, motors and drives were connected to other equipment, with 1,000 variable speed drives considered to be crucial to automation optimization. The overall speed of the process is also due to a group of six robots equipped with machine vision.

Metsä Fibre and ABB specialists have worked together to maximize automated data collection through a third-party automation system. The strategy has been to use high levels of monitoring for quality and performance, minimize wood waste through sawing and sizing optimization and eliminate manual handling through robots and automatic loading at the 24/7 mill. The sawmill’s by-products such as wood chips, sawdust and bark

ABB electrical power distribution equipment set up

are used to produce pulp and bioenergy.

“The Rauma sawmill operates much like a process industry plant, where equipment cannot be maintained at night or on weekends, but electrical devices must always be reliable,” said Esa Kivioja, Industry Segment Manager for ABB in Finland. “Here, we implemented the sawmill’s power distribution with the same quality standards as we did in Metsä Fibre’s bioproduct mills in Äänekoski and Kemi. This is a whole new concept in mechanical forest industry facilities.”

“The energy efficiency of motors and other electrical equipment also plays a role. The impact of ABB’s deliveries is even more evident in the fact

that production can continue without disruptions, and there is no idle time for the equipment.”

To support the Metsä Fibre team and the installed technologies on site, ABB also offers its spare parts and spare equipment services, as well as technical support.

ABB’s Process Automation business automates, electrifies and digitalizes industrial operations that address a wide range of essential needs.

For decades the lumber industry has been using lineal scanning and optimization in both hardwood and softwood production. Much like other industries, the technology being used by sawmills to maximize the value and volume of high-quality products produced from each log is evolving and becoming more precise. Scanners have moved from images taken at frequencies from 6 (six) to 12 (twelve) inches of laser lines that are used to construct three dimensional models, to systems today that integrate vision and artificial intelligence along with the 3D scans every 0.01 (one hundredth) of an inch to identify, construct, and classify natural and mechanical defects found in wood.

At USNR today, there are lineal scanners available for log positioning, primary and secondary breakdown, as well as for edgers. There is also the AddVantage scanner for chop and rip saw applications, and in the planer mill, where the highest degree of precision and consistency is necessary, USNR manufactures and supplies the Lineal High Grader (LHG) and the most recent addition to the family, the VAB-brand Lineal Autograder. Optimization is key in every step in the processing of logs to lumber. Note that USNR also manufactures transverse scanning systems for a variety of applications.

For the first cut into any log that will take the round log and create flat surfaces, positioning of that log in reference to the saw blade or canter heads is critical. For softwood, this will determine a successful or potentially low material yield, (# of cubic meters of logs to produce 1 (one) cubic meter of finished product) and in hardwood, where the high value fiber is determined.

The VAB-brand Lineal Autograder uses measurable dimensions along with AI for exceptional accuracy in managing standard and custom grades

be sent through a planer to meet consistent dimensions and construction grades that are specific to markets around the world. A lineal scanner installed after the planer like the LHG or the VAB-brand Lineal Autograder will provide a complete scan of each board, analyze the make-up of the board including all defects, and then measure that against a list of grades and the monetary values associated with the dimensions and grades to maximize the value and volume of the finished product.

In the sawmill, the goal is to produce the most volume with the least defects that reduce value.

The next step in the processing of wood is kiln drying. This puts stress on the fibers and can amplify defects such as splits, cracks, and checks. Because of the high cost of kiln drying and dressing building materials and finished materials, any defects that can be removed before drying increase the potential for profit.

For high value building materials that are graded on visual criteria such as flooring, interior and exterior sidings, and window and door components, defects that appear in the middle of a board, such as unsound knots, can be identified by the AddVantage optimizer, a high-speed precision scanner that identifies the defects and controls rip and chop saws to maximize production and recovery.

In the softwood industry, once boards have been dried, the rough-sawn material must

An astounding fact about USNR planer mill scanners is that they can read 100% of each board in high definition at speeds surpassing 4,000 feet per minute or 1,219 meters per minute

The algorithms created to determine and combine such characteristics as coloration (dark versus light colored) and surface holes allow for very good identification of basic rot, but when it comes to specific defects such as white spec or dry rot, a new technology was needed. Artificial Intelligence has been found to be that tool.

The way deep learning artificial intelligence works is quite simple. Physical examples containing a specific defect are identified, agreed upon by quality control and AI technicians, and accumulated then run through the lineal scanner. Each board scan is then reviewed by both technicians and quality control

The Lineal High Grader classifies and verifies all the important lumber defects as well as MSR/MEL strength classification, wane evaluation, and skip control in a very small footprint

specialists at the mill, and the specific defect is isolated and becomes a part of the initial database. Once a sufficient number of specific defects are added to the database, the database is brought online as a baseline comparison with new board scans. The AI then establishes each board to the database of samples and establish grade accordingly. After 2 to 4 weeks, a review is done by the AI technicians and QC to determine whether the AI model is complete or needs to be slightly adjusted with new samples added to the database. It is the AI technician and Quality Control specialist who determine the parameters of what constitutes a defect and what does not. The AI will not go beyond the parameters established. To date, AI is being used to determine the

species of wood in productions containing multiple species. It is being used to detect knots, establish their construction through the actual board, and classify them accordingly. AI is also being used to read the number of growth rings to estimate the density of the board as well as identify wood that has signs of compression and very specific types of decay.

An astounding fact about USNR planer mill scanners is that they can read 100% of each board in high definition at speeds surpassing 4,000 feet per minute or 1,219 meters per minute.

For more information on how USNR optimization can help with your specific scanning needs, please visit www.usnr.com and go to the Contact Us section to be

directed to the representatives in your area. We look forward to working with you soon. Millwide. Worldwide.

The AddVantage chop and rip saw optimizer can classify most wood characteristics and optimize for the highest value cut solution.

A complete solution to intelligently pick, sort and stack trim blocks and boards.

In the ever-evolving landscape of Artificial Intelligence (AI), BID stands as a pioneer in robotic automation, transforming the trim block production handling process for sawmills worldwide. With unrivaled precision, efficiency, and profitability, BID’s AIpowered robots continue to revolutionize the way trim blocks are picked and sorted, ensuring no valuable piece goes to waste.

This innovation comes just at a perfect time where industries face daily challenges around the workforce attraction and retention, safety, cost, control, sustainability and growth. People do not want to do dull and dangerous jobs anymore, especially the younger generations. Robotic automation, especially those that are AI-powered, eliminates the need for employees to perform unfulfilling or dirty jobs and addresses challenges arising from low unemployment rates and an aging workforce in remote locations.

At the heart of this innovation lies a sophisticated AI-powered system that employs cuttingedge scanning and tracking capabilities. The first step in the trim block line involves presorting, where sawdust and undersized trims are efficiently removed, ensuring the purity and quality of the blocks.

BID’s system then arranges the blocks into a single layer, setting the stage for subsequent steps with ease and accuracy.

The true brilliance of BID’s technology lies in its AI-powered robots, which swiftly identify valuable blocks, separating them from the reject ones destined for the chipper. This advanced technology enables the robots to make precise decisions, guaranteeing that each piece meets the desired grade. However, BID’s AI-powered system goes beyond mere identification. It utilizes AI scanning, optimization, and tracking to fine-tune each block’s solution thus maximizing its potential value. Depending on the mill’s production, the system will either have one pick and place robot with a pace of up to 30 blocks per minute, or two robots with a capacity of up to 48 blocks per minute. Three or more solutions are also available for higher piece

count. 6-axis robots are used to allow better reach and freedom of movement.

The process continues with stamping and tier generation, ensuring an organized and efficient workflow. Notably, BID’s robotic solutions excel in stacking not only trim blocks but also boards, enhancing overall production capabilities. At BID, each solution layout is specific to the customer’s needs. The robotic system can handle wood products that are up to:

• Thickness: 8’’

• Width: 12’’

• Cross section: 8x8’’ or 2x12’’

• Length: 12’

• Species: engineered for both softwood and hardwood

The robotics system can be smartly connected to BID’s digital platform, OPER8TM, to provide real-time feedback on the trim block line’s operations.

BID’s robotic system is built for durability and safety, with concrete bases providing stability in case of an emergency stop. The robotic system area has a lock door switch on all doors, a push button box to ensure safe access, and a push button to restart the line.

Installation and start-up are hassle-free, requiring no specific expertise. Training on the global process is provided by BID, while robotic training is handled by specialized partners. BID’s PLC standards enable programming without the need for internal robotic knowledge.

The advantages of an AI-powered robotic automation

There are various advantages of choosing BID’s robotic automation. Firstly, it surpasses traditional laborbased methods by operating at a faster rate, delivering results with remarkable speed. During BID’s research and development phase, it has been assessed that yield could be increased up to 50% in comparison to human sorting and stacking which often leads to inaccurate categorizing and high-quality blocks sent to chipper.

Secondly, BID’s system leverages sophisticated AI algorithms to analyze data and boards, making informed decisions based on real-time

information. By identifying and handling blocks more efficiently than standard robotic applications that use photocells only, BID’s vision scanner and grading rules ensure precise decision-making for higher-quality and yield outcomes.

Moreover, BID’s robotic automation operates continuously without breaks, maximizing production output and efficiency. With precision and consistency, businesses can streamline their operations, reducing labor costs while increasing profits. Thanks to its strategic partnership with Yaskawa Motoman, BID Group robotic systems are supported 24/7 ensuring peace of mind and an uninterrupted workflow.

The decision to embrace robotics in manufacturing is driven by several key factors. One of the most crucial considerations is safety. Robotics eliminate the need for employees to engage in dangerous tasks, ensuring a safer work environment. Additionally, with a scarcity of available skilled labor, robotics offer a solution by taking over repetitive and physically demanding tasks.

Cost-effectiveness and reliability are other significant advantages of using robotics. BID’s complete solutions, which are fully integrated with

mechanical, PLC, optimization, and robotic elements enhanced by Artificial Intelligence, handle complex problems with efficiency and precision. Consistent decision-making and maximized production and revenue make BID’s system a superior choice.

Conclusion

BID’s AI-powered robotic automation has ushered in a new era of trim block production. Its precision, efficiency, and profitability are unmatched, making it the ultimate choice for sawmills looking to stay ahead in the race for progress. By integrating the transformative power of BID’s technology, businesses can revolutionize their operations and secure a competitive edge in the industry.

Contact BID today to experience the future of trim block production and take your business to new heights. Do not miss this opportunity to shape the future of your industry. info@bidgroup.ca

Growing a productive forest requires hard work and commitment. Correctly timed thinning improves the forest’s growth conditions and makes trees grow sturdier more quickly.

“Thinning can also be called improvement felling, as it ensures the productivity of the forest, and the high quality and health of trees,” says Tuomo Moilanen, forest specialist at Ponsse.

“The better a forest grows, the better it sequesters carbon. Thinning ensures that trees can be processed into highquality products that sequester carbon for dozens or even hundreds of years,” says Moilanen.

In cut-to-length (CTL) harvesting, trees are already processed up to the intended length in the forest, enabling thinning to be ecological. When the harvester operator plans trails so that they can be driven by the forwarder, trees can be both felled and forwarded without needing to move around unnecessarily in the forest.

“At thinning sites, the distance between trails is roughly 20 meters, and trees remaining by the side of the trail will grow in Finnish conditions 20–25 per cent more quickly, because they will have room to grow, both above and below,” Moilanen says.

PONSSE’S PRODUCT RANGE HAS ALSO BEEN DESIGNED FOR THINNING SITES

The six-wheeled PONSSE Beaver, Ponsse’s harvester in the smaller size category, is ideal solution for first thinning. At heavier thinning sites, the PONSSE Cobra and Scorpion harvesters, combined with the H5 or H6 harvester head, are the best choices in terms

of productivity. In PONSSE Scorpion, the unobstructed visibility in all directions, together with cabin and crane levelling, makes working smooth even at dense thinning sites. As eight-wheeler machines, both models are also excellent in soft terrain.

At thinning sites, the harvester head should be selected according to the dominant tree species.

However, it should be considered that damaged trees and other trees in poor condition must also be removed from thinning sites, calling for sawing and feed force from the harvester head. The harvester head must be agile at thinning sites because a large number of trees are produced quickly during each shift.

The profession of a forest machine operator is both responsible and demanding. Operators must be skilled in forestry, machine operation and technology, as well as work planning. They must also have knowledge of the Forest Act, the Nature Conservation Act and other criteria presented by forest certifications, all of which guide harvesting activities.

Thinning plays a significant role in forest productivity. This is why forest machine operators need to know what trees to leave standing and what to remove. Technologies are being developed to help operators make these selections and decisions.

In 2022, we presented the Thinning Density Assistant, a technological concept which is not yet commercially available, but is being studied and tested actively.

The concept uses lidar technology to identify trees around the machine and generate a tree map of the logging site. The technology draws an image of the exact location of the machine relative to trees and the adjacent trail on a computer screen.

“As the system does not select any stems for processing, the forest machine operator’s expertise will still be needed in the future,”

says Markku Savolainen from Ponsse.

With the technology being developed, the number of standing trees can be measured for the first time in addition to felled trees. The data collected helps operators achieve the correct and best possible thinning density for forest management, which is also documented.

“A stand-specific stem density –stems per hectare – is given for the system, which the system then starts to teach the operator. As the system operates in real time, no calculations are made afterwards, and the operator sees the situation as it is. The thinning density can be checked on the Opti screen during normal operations,” says Savolainen.

When the operator drives the machine forward on the trail, the view will be updated with new stems. If there is another trail next to the machine, the Thinning Density Assistant shows its location and the exact distance between the two trails. As a result, the system also guides the operator if the distance between trails is too long or short.

As the system does not select any stems for processing, the forest machine operator’s expertise will still be needed in the future

Markku Savolainen, Product Manager, Equipment Automation at Ponsse Oyj

Rottne’s smallest harvester in a large package. The well-known stand-operated harvester has now been improved in several areas. The machine will feature the newly developed joystick panels that were previously introduced in Rottne’s new forwarder series. These provide a much more modern impression as well as better ergonomics for the driver with more adjustment options. The panels have a much higher safety rating due to more redundant functions and high-quality components.

The cabin is painted blue instead of being wrapped in foil. This is partly for visual design but also to keep it looking good during many hours in the forest. H8E has completely unique characteristics for stand-operated thinning. The machine’s narrowest configuration is only 205cm. The wheels are mounted on pendulum arms which always ensure that the machine remains equally wide despite side slopes or obstacles to be passed. With a combination of the driver’s commands and the machine’s smart pendulum arm system, good ground contact can always be achieved. The machine is very easy to operate within the stand to extract timber to the forwarder’s skid trails.

With this thinning method, it is always possible to maintain a slightly longer distance between the skid trails, thus reducing the road area and providing a larger area for the production forest remaining after thinning. The driver also always sits upright and thus works much more efficiently. The machine’s substantial pulling force is automatically distributed to the wheels with the best grip using an active flow divider, thereby minimizing slippage with damage to the ground and roots as a result. The machine’s low weight and wide tires provide good load-bearing capacity, which is a major advantage when harvesting in areas with poor bearing capacity.

Despite its small size, H8E has the same cabin as Rottne’s larger harvesters. This provides the driver with a spacious and quiet driving environment with good climate control. The machine also has a generously sized diesel engine with the

latest exhaust emission control technology. Despite its small size, the serviceability of the machine is fantastic with easily removable protective covers and good storage of tools and spare parts. It is easy to refill fluids using electric pumps with overflow protection.

The 7-meter-long crane is developed for H8E and provides superior performance in both strength and speed. It can, of course, be equipped with RCA as an option. A good support for both the beginner and the experienced driver. The driver determines the direction and speed at which the grapple should move. The system then performs the task using robust sensors on the crane and software developed for the purpose. As the name suggests, the system assists the driver in operating the crane with good precision and the right speed throughout the work shift. The system optimizes the crane’s functions in a better and more energyefficient way, saving both time and money.

The driver receives better support during operation and will thus maintain higher production throughout the shift. RCA also provides an easier path for the less experienced driver to achieve higher production. The system can, of course, be individually customized with different speeds, smart features in the machine’s control system.

The machine has a welladapted attachment, EGS406. The attachment is designed exclusively for H8E, with weight and performance completely tailored to the base machine’s conditions and performance. This allows for the best possible harvesting of thinning forests and smaller final fellings, both for the forest and for economic benefit. The maximum limb diameter is 33cm and the maximum cutting diameter is 43cm. EGS406 can be equipped with multi-tree handling, color marking, and stump treatment if desired. If the market demands sprinkler equipment, it is also integrated into the machine’s control system. Work lighting is continuously updated with the latest technology; we have chosen lamps with less risk of reflection in those positions. Lamps that illuminate the crane are of that model. The software in the harvester is continuously updated to the latest forestry standard. RCA also allows for crane position to be saved in the harvester’s production file for later analysis by third-party programs, such as thinning monitoring. It is possible to display realtime information about the harvester’s production calculated according to a piecework price list and hourly cost that can be entered in the machine’s menus, yet another improvement in Rottne’s smallest harvester in a large package.

Tigercat mulching products are used across many industries including land clearing, silviculture, and forest management, including fire mitigation — wherever highly mobile, durable and reliable carriers are required for rugged terrain, high duty cycle applications, extreme temperatures and high levels of airborne debris.

The 480B is a powerful, robust mulcher, able to tackle the toughest terrain with ease. Tigercat heavy duty build quality provides superior durability with high uptime for large-scale, timesensitive right-of-way and site preparation projects.

The 480B is equipped with an efficient, high-capacity cooling system with a variable speed fan and automatic reversing cycle, a dedicated attachment pump, and an efficient closed loop track drive system. The Tigercat FPT C13 engine provides 411 kW (552 hp. Inside the cab, the operator has ergonomic electronic joysticks and excellent sightlines.

Utilizing the same Tigercat build quality and superior durability, the smaller design of the 470 makes it well suited to right-of-way and site preparation projects where a narrow, agile machine with extremely low ground pressure is required. Zero tail swing, even with the optional recovery winch allows the 470 to manoeuvre in tight areas without disturbing surrounding trees.

supporting single and dual tire installations to maximize performance in tough terrain.

A large attachment pump provides high flow to the mulching head, all important in mulching applications.