APRIL / MAY 2023 SAWMILLING • LOGGING • BIOMASS • RENEWABLE ENERGY SAWLINES Chippers Access to the Timber Stand Feller Bunchers SHOWLIGNA ISSUE

Maximized Throughput, Precise Results

Introducing the Peterson 5710E tracked horizontal grinder, the latest in high-capacity grinding technology. The 5710E offers increased grinding power in a lighter package to help you leverage efficiency and reduce material handling costs.

BUILT TO CONNECT

See the newest horizontal grinder.

38

www.usnr.com

International Forest Industries | APRIL / MAY 2023 1

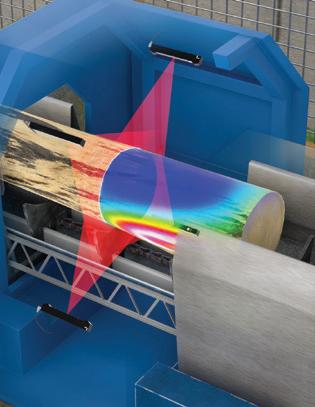

33 MICROTEC

Lucidyne Scanner with Fully Integrated MiCROTEC Ai to be Installed at Cal-Tex Lumber Company

44 ACCESS TO THE TIMBER STAND Opening forest roads, especially in wooded areas and forests, requires highperforming, compact equipment that can work with agility around vegetation

42 33 28 CHIPPERS LOGGING • BIOMASS CONTENTS

42 FELLER BUNCHERS Tigercat offers the broadest range of both track and drive-to-tree feller bunchers in the industry / MAY 2023 REGULAR FEATURES 6 Logging News 48 Advertising Index LUMBER PROCESSING CONTENTS APRIL / MAY 2023

44 SAWMILLING • LOGGING • BIOMASS • RENEWABLE ENERGY SAWLINES Chippers Access to the Timber Stand Feller Bunchers

APRIL SHOWLIGNA ISSUE

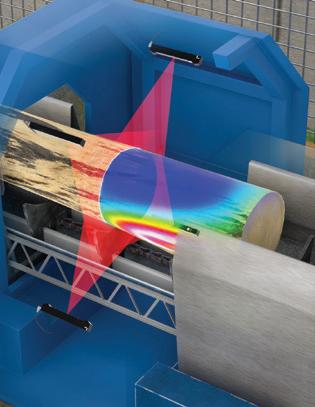

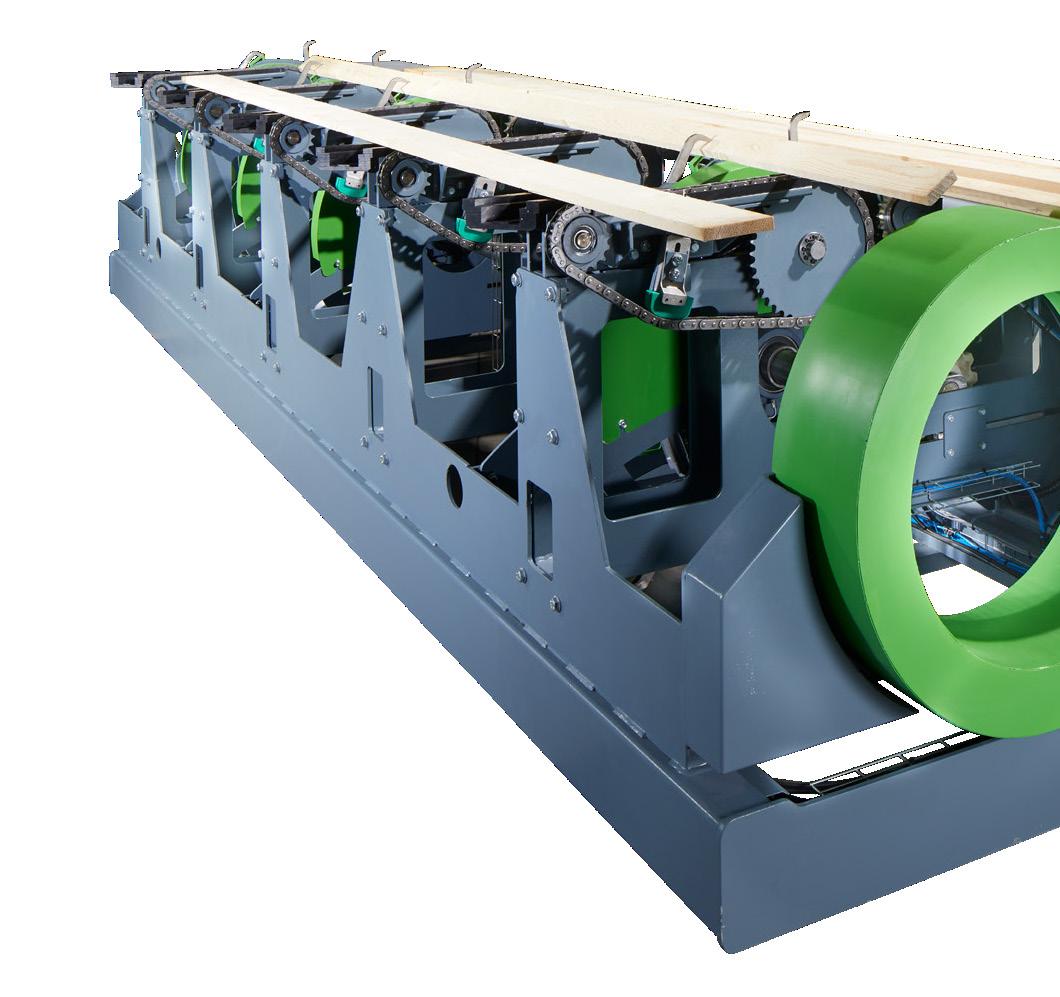

COVER - USNR LOGMASTER HPS

See the Logmaster HPS on display at Ligna in Hall 25 Stand D65. This high-speed, thin-kerf, curve-sawing bandmill is highly versatile, maximizing production and performance with thin saw kerfs, resulting in excellent yields. The 6’ model is designed for feed speeds up to 590 feet/min and saw speeds up to 328 feet/sec, with proven outstanding cutting accuracy. Electronic blade monitoring and self-adjusting features

ensure system stability and reliability. Logmaster HPS can be delivered as a log or cant breakdown machine, with or without a reducer unit. It can also be combined with profiling and sweep sawing technology. Learn more at

Hekotek AS has signed a supply contract for the delivery of a new log sorting line to Versowood OY in Finland

Recent mergers and acquisitions have solidified USNR’s leadership position in providing equipment and technology for the global wood processing industry

MEET US @ LIGNA 2023

Hall 25, Booth F26 May, 15 - 19 Hannover, Germany

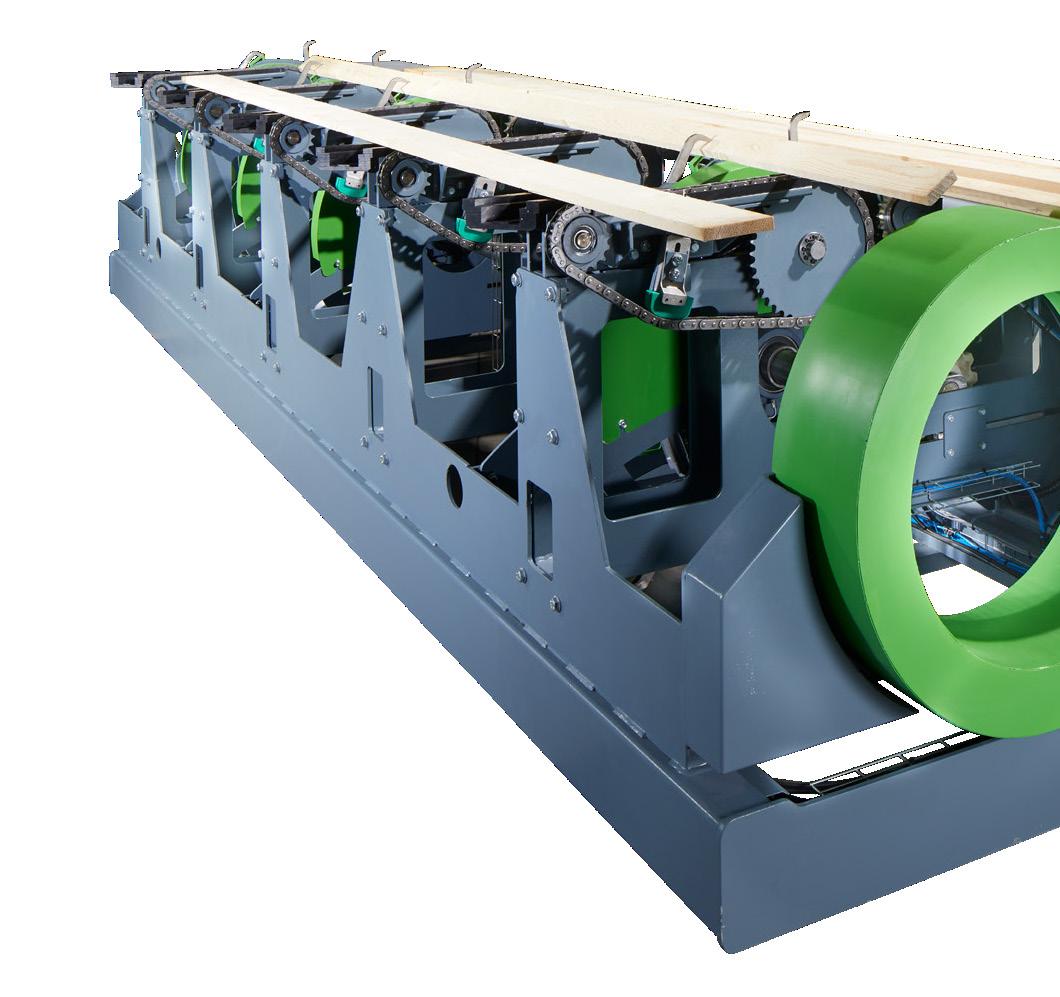

E-LOADER

a new high speed feeder solution for lumber sorting

See our latest innovative product development at LIGNA 2023

For over 35 years, Gilbert Products has been a market leader in the design and manufacturing of planermill equipment

2 International Forest Industries | APRIL / MAY 2023 LUMBER PROCESSING

30 BID GROUP BID places great Technologies emphasis on wood drying with the help of professionals who have developed innovative systems

32 30

32 MICROTEC MiCROTEC is finding new ways to fine tune their AI technology, adapting to industry needs and leveling up the scanning technology game

28 GILBERT

28 SAWLINES 34

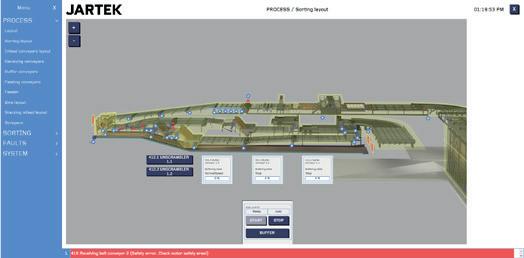

34 JARTEK Jartek’s ThermoWood® business is growing globally

21 HEKOTEK

26 USNR

21 26

Springer USA Inc. | 550 Brookshire Road, Suite A | Greer, SC 29651, USA Phone: 864 908 3822 | E-mail: office@springer-usa.com | www.springer-usa.com

SUBSCRIPTIONS

SUBSCRIPTIONS

Tel: +44 (0)1442 877 583 emma@internationalforestindustries.com

Tel: +44 (0)1442 877 583 emma@internationalforestindustries.com

Annual Subscription

Annual Subscription

There’s No Business Like Show Business

U K and Europe £160, € 230 Rest of the world US$270

U K and Europe £160, € 230 Rest of the world US$270

EDITORIAL

EDITORIAL

T: +44 (0)1442 877 583

T: +44 (0)1442 877 583

Well, it’s finally here.

F: +44 (0)1442 870 617 www.internationalforestindustries.com

F: +44 (0)1442 870 617 www.internationalforestindustries.com

2 Claridge Court, Lower Kings Road Berkhamsted, Herts. HP4 2AF, UK

2 Claridge Court, Lower Kings Road Berkhamsted, Herts. HP4 2AF, UK

Editor

Robin Peach robin@internationalforestindustries.com

Publisher Robin Peach robin@internationalforestindustries.com

Editorial Board

NORTH AMERICAN SALES

Dr Patrick Moore – Chairman and Chief Professor Piotr Paschalis-Jakubowicz –Warsaw Agricultural University (Poland)

Mr Kim Carstensen

Director General

Forest Stewardship Council

Eduardo Morales

South American Forestry Consultant

WEB OPTIMIZATION

jo@internationalforestindustries.com

ADVERTISING AND PROMOTIONS

ADVERTISING AND PROMOTIONS

International Forest Industries Ltd

International Forest Industries Ltd

For sawmillers or forestry groups, that statement will relate to different events. Chronologically, we’re talking about Ligna 2023, which is about kick off in Hannover, Germany (May 15-19). The Ligna wood industries show has become an industry institution over almost 40 years and has grown into the crucial meeting place for European wood producers and just about anyone looking to establish themselves in the European market.

release of which is likely to have been timed to coincide with these massive industry events; while forestry companies will be both excited at the range of new machines to choose from and determined to make the right purchase decision for the business.

Advertising Manager Emma Smith emma@internationalforestindustries.com

Advertising Manager

Emma Smith emma@internationalforestindustries.com

+44 (0)1442 877 583

+44 (0)1442 877 583

Associate Editor Robin Peach robin@internationalforestindustries.com

Associate Editor Robin Peach robin@internationalforestindustries.com

Advertising Production Enquiries

Advertising Production Enquiries

Emma Smith emma@internationalforestindustries.com

Emma Smith emma@internationalforestindustries.com

Studio Manager

Luke Evans luke@lecreative.co.uk

This year, the range of activity will include conferencing, lectures and discussions covering topical industry trends. And while these events will no doubt be well attended and prove to be exceptionally interesting – as they have in past years – the real action will take place in the exhibition halls and out in the exhibiting lots – where the latest technologies will be put through their paces in front of potential clients. That’s where we will be stalking manufacturers to glean an insight into breakthrough technologies that may make wood production more profitable and could change the way the industry operates.

This northern summer represents a crucial period for the forestry industry during which order books need to be bolstered and sawmills/harvesting fleets need to be equipped to handle the volatile market conditions we’re currently enduring. For our part, we will do our best to make sure our readers continue to be kept abreast of the latest machinery developments so they are able to make informed decisions. With the huge volume of new equipment being released onto the market, this will provide a challenge for us. That challenge has already started with our team working overtime to produce the current edition and Digital edition – our biggest ever – in time for the show season.

Robin Peach Associate Editor

EUROFOREST 2023

International Forest Industries is published by International Forest Industries Ltd, 2 Claridge Cour t, Lower Kings Road Berkhamsted, Her ts. HP4 2AF, UK

Central to these technologies is likely to be AI. Artificial Intelligence (AI) has triggered the start of a major revolution in the wood processing industry. AI is here to stay, and we can already notice its presence more often in various areas of sawmills and planer mills. We are carrying many articles on AI and the theme will be ever present at Ligna.

Accounts

Nicola Shukla nicolas@internationalforestindustries.com

International Forest Industries (ISSN 1755-6732) is published bi-monthly by International Forest Industries Ltd GBR and is distributed in the USA by Asendia USA, 17B South Middlesex Avenue, Monroe NJ 08831 and additional mailing offices. Periodicals postage paid at New Brunswick NJ. POSTMASTE R: send address changes to International Forest Industries, 17B South Middlesex Avenue, Monroe NJ 08831

06/22/2023–06/24/2023

Saint-Bonnet-de-Joux BOURGOGNEFRANCHE-COMTÉ (France)

© International Forest Industries Ltd 2007 – 2019 I FI uses, as preference, SI units throughout. All dollars are US unless otherwise stated.

International Forest Industries is published by International Forest Industries Ltd, 2 Claridge Cour t, Lower Kings Road Berkhamsted, Her ts. HP4 2AF, UK International Forest Industries (ISSN 1755-6732) is published bi-monthly by International Forest Industries Ltd GBR and is distributed in the USA by Asendia USA,

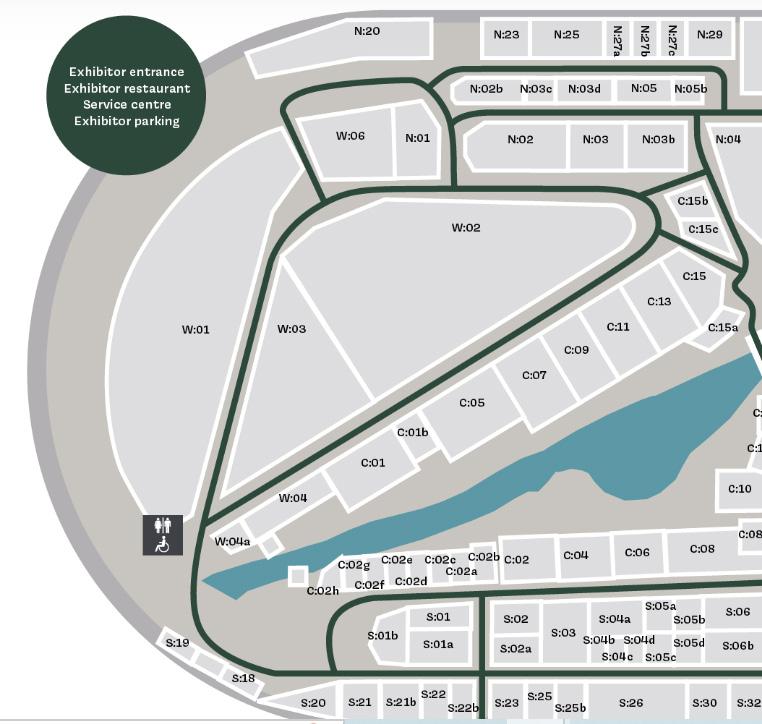

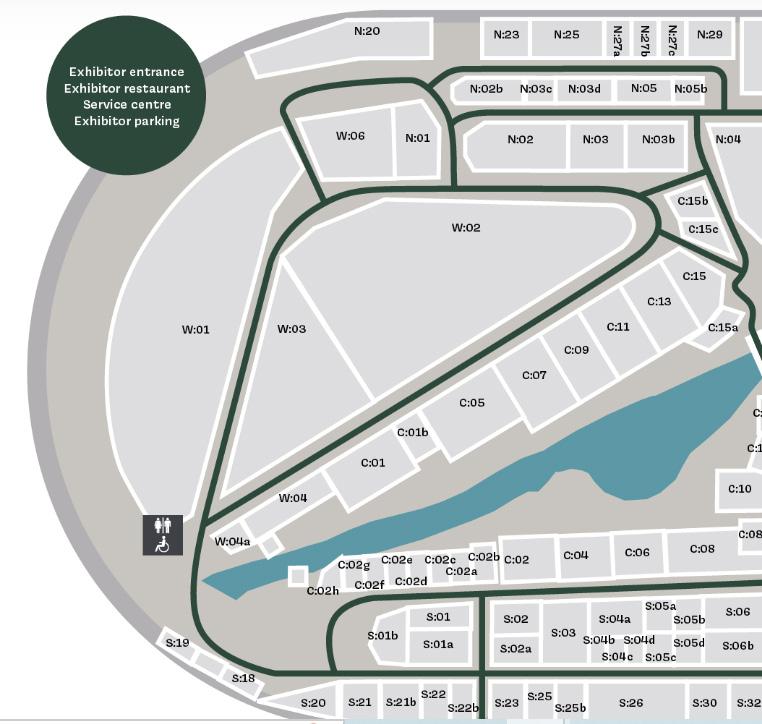

It will be a very similar story later this summer at the Swedish Forestry Expo2023 Stockholm 1-3 June, where forestry companies will be engaged in lectures and discussion sessions on the challenges facing the industry, but will ultimately be there to critique the latest in harvesting equipment. That is, of course, why we’ll be there, too.

The next few months, therefore, promises to be an extremely anxious and busy time for the industry: manufacturers will show and receive feedback on technologies the

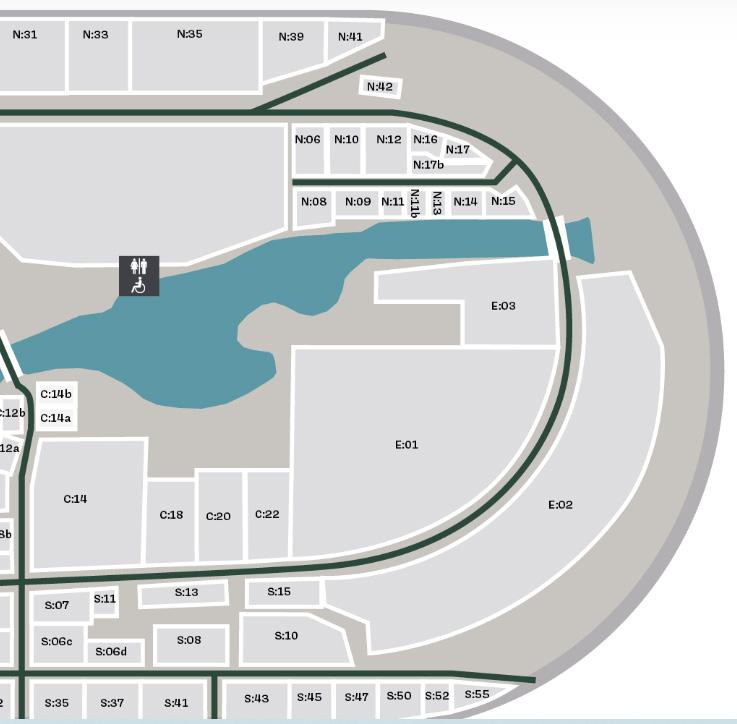

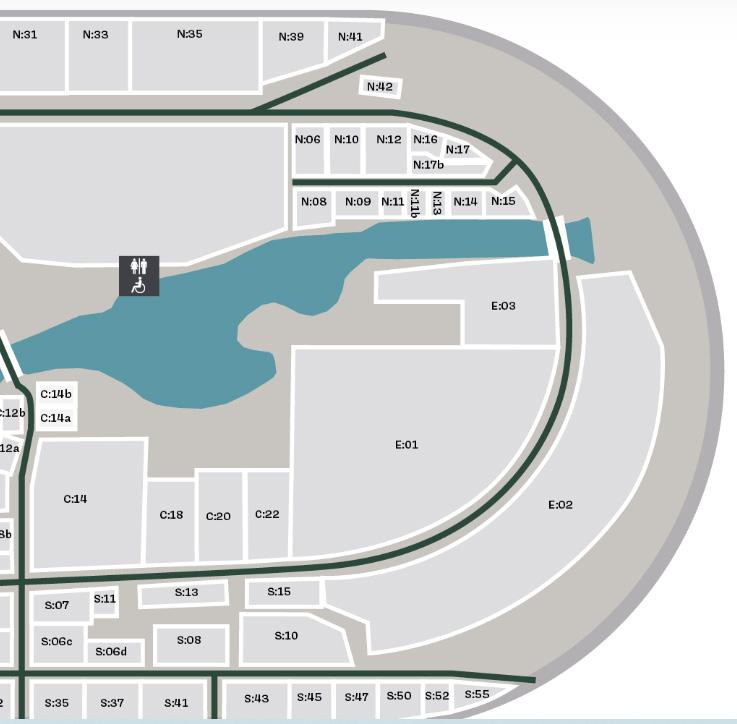

SFPAExpo2023

August 23 - 26 Nashville

More shows on Page 48!

4 International Forest Industries | APRIL / MAY 2023

ISSUE 92 April / May 2023

17B South Middlesex Avenue, Monroe NJ 08831 and additional mailing offices. Periodicals postage paid at New Brunswick NJ. POSTMASTE R: send address changes to International Forest Industries, 17B South Middlesex Avenue, Monroe NJ 08831 © International Forest Industries Ltd 2007 – 2023 I FI uses, as preference, SI units throughout. All dollars are US unless otherwise stated. Kevin Lapham

English J.P.Media Inc Tel: +1 (630) 420 9752 Fax: +1 (630) 420 9763 Email: lapham@jpmediainc.com

Jo

Major brands on show at Ligna 2023

USNR - Advanced technology solutions for lumber production

USNR - Blades, knives, and tooling; automated sharpening and levelling systems

USNR - Advanced technology solutions for engineered wood products

MICROTEC - SAWMILL

MICROTEC - SECONDARY PROCESSING

Hall 25, Stand D65

Hall 25, Stand D69

Hall 26, Stand D08

Hall 27, Stand J28

Hall 27, Stand F20

SPRINGER MASCHINENFABRIK

Hall 25, Booth F26

GILBERT PRODUCTS

Hall 25, Stand C14/1

JARTEK INVEST

JOESCAN

COMBILIFT - LOGISTICS - SAWMILLSTRANSPORT - LARGE SCALE FORESTRY EQUIPMENT \ Stand M61

COMBILIFT

Hall 13, Stand G18

STENNER Hall 25, Stand L46

FRANZEN, JOHANNES

Hall 25, Stand E69

Hall 25, Stand E24

Hall 25, Stand G65

Open-air site (FG),

International Forest Industries | APRIL / MAY 2023 5

Patented efficiency

Business Finland funding boosts product development of Ponsse & Epec

Forest machine manufacturer Ponsse and technology company Epec believe that the emissions and environmental impact of mobile work machines can be significantly reduced with new technology. In the field of mobile work machines, there are several development targets towards sustainable development.

Business Finland has granted EUR 10 million in funding to Ponsse’s FORWARD’27 programme in its challenge competition for leading companies. The funding is used to accelerate the product development of mobile work machines.

The aim of Ponsse’s FORWARD’27 programme is to significantly reduce emissions from mobile work machines, reduce their energy consumption and improve productivity. Improving operator working conditions with auxiliary functions and automation are also among the key components of the programme.

“Ponsse aims to be a technological pioneer in CTL forest machines and it aims at producing carbon neutral, sustainable and increasingly competitive solutions. With funding granted by Business Finland to leading companies, we can accelerate our development of sustainable and digital solutions for mobile work machines”, says Juho Nummela, Ponsse’s President and CEO.

In addition, Business Finland has granted EUR 20 million in funding to the ecosystem companies associated with the programme.

Towards sustainable mobile work machines

Ponsse and Epec will implement the FORWARD’27 together and will invest more than EUR 25 million to developing sustainable mobile work machines in the next few years.

The companies will create an extensive ecosystem around the development work.

The first partners have already been selected.

“Epec innovates and develops technological solutions for future work machines to enable zero emission. The joint competence of Ponsse and Epec develops continuously and FORWARD’27 programme will take our abilities even further. The group of companies and partners included in the ecosystem created also play a key part”, says Jyri Kylä-Kaila, Epec’s Managing Director.

6 International Forest Industries | APRIL / MAY 2023

Juho Nummela, Ponsse’s President and CEO

Jyri Kylä-Kaila, Epec’s Managing Director.

Seppi M. - mulching equipment specialists Tel. Europe: +39-0461 178 75 00 Tel. USA & CA: +1 513-443-6339 sales@seppi.com www.seppi.com

Machines equipped with the new V-LOCK tool system are marked with this logo. A long tool life, a perfect fit and easy replacement are all central features of this device.

Soil tilling, stones crushing and wood mulching with higher efficiency and lower energy consumption.

2-speed POWESRHIFT system allows the machine to switch speed.

us at

Visite

International Forest Industries | APRIL / MAY 2023 7

Extensive

ZF Redulus Gearboxes for large shredder power units

As a main supplier for large shredder drives of 180 kW and above, ZF supports customers with the optimal drive solution for large mobile and stationary shredders.

Thanks to many years of experience, a unique customer approach and inhouse know-how, ZF provides customized solutions based on standard industrial gearbox designs.

The company is not just a component supplier, but a partner. The partnership starts at the first contact, with an idea and a unique concept. Of course, it doesn’t stop after development or installation. Then the team is there for the partners providing them with exceptional services.

Redulus GME/GMH – 70 to 150 kNm output torque and higher GME/GMH for shredders based on the very well-tried ZF industrial gearbox design. Highly robust and with exceptional feasibility are attributes of these multistaged planetary gearboxes. Flexibility and customization based on high standards are our strength.

Helical bevel gears IMK –400 to 500 kW ZF’s industrial gears IMK have been designed for installation in industrial applications like recycling machines and shredders. Tough operating conditions require customer-specific solutions – powerful and reliable gearboxes are essential for these applications.

Condition monitoring system – ProVID ProVID, approved and established in Ropeways, is now extended to main industrial applications as well as for the shredder business.

The Future of Forestry

About ZF

ZF is a global technology company supplying systems for passenger cars, commercial vehicles and industrial technology, enabling the next generation of mobility.

ZF allows vehicles to see, think and act. In the four technology domains of Vehicle Motion Control, Integrated Safety, Automated Driving, and Electric Mobility, ZF offers comprehensive product and software solutions for established vehicle manufacturers and newly emerging transport and mobility service providers.

ZF electrifies a wide range of vehicle types. With its products, the company contributes to reducing emissions, protecting the climate and enhancing safe mobility.

With some 157,500 employees worldwide, ZF reported sales of €38.3 billion in fiscal 2021. The company operates 188 production locations in 31 countries.

Efficient,

8 International Forest Industries | APRIL / MAY 2023

drive solutions for large mobile and stationary shredders from ZF

Visit us at Swedish Forestry, June 1-3, 2023, booth C:20

From Less to Zero CO 2

clean, and safe: this is how we imagine the future of forestry. No matter the power source, conventional or alternative fuels, hydrogen or electrification – with our strive for zero emissions, increased productivity, driving comfort and safety, we always concentrate on the driveline as a whole to make our vision come true. ZF.com/construction

COMPACT CHIPPERS

∙ 20XP or 2090 (20” capacity)

275 – 350 horsepower engine options

270-degree swivel or forestry-style discharge

∙ Optional Kelsa loader

HIGH PRODUCTION TRACK CHIPPERS

∙ 4- models available (20” – 30” capacity)

415 – 875 horsepower engine options

Select models available with cab and loader

∙ Durable Caterpillar track undercarriage

CAB AND LOADER TOWABLE CHIPPERS

∙ 2-models available (2590 or 3590XL)

Rotobec cab and loader

Cab swivels with loader for easy operation

∙ Eliminates the need for an auxiliary loader

TRELAN DISC-STYLE CHIPPERS

∙ 2-models available (686 or 786)

800 to 1,050 horsepower engine options

Produces a high-quality paper chip

∙ ¾”, 7/8” or 1” chip sizes

If you haven’t tried a Bandit unit for your operation, please contact a local Bandit dealer, email marketing@banditchippers.com or visit our website www.banditchippers.com and we will be happy to assist you!

Ponsse’s 19,000th forest machine completed at Vieremä factory

On 17 February, the 19,000th PONSSE forest machine was handed over to Scottish long-term customer Elliot Henderson Ltd, with the Royal Burgh of Annan Pipe Band playing in the background. The PONSSE Scorpion Giant harvester with H8 harvester head will work at logging sites in the Scottish Borders and Scottish Lowlands.

“Thank you to the Elliot Henderson group and the Royal Burgh of Annan Pipe Band for coming to Vieremä to celebrate the 19,000th machine milestone with us. I understand this is the first time a pipe band has played at Vieremä village, which makes this day even more special for all of us, as this is Ponsse UK’s first milestone machine. This is a day that we will remember for years to come,” says Gary Glendinning, Managing Director Ponsse UK.

Elliot Henderson Ltd

Elliot Henderson Ltd is based in Selkirk in Scotland. The company started more than 35 years ago, planting trees with a small squad of men. Over the years, the business has grown and diversified into forestry, construction, and scaffolding. Today, Elliot Henderson Ltd comprises more than 40 forest machines which can undertake clear fell, thinning, steep ground harvesting operations, ground preparation or the construction of forest roads. Elliot Henderson Ltd also has the capability for site brash clearance, stump removal and servicing the biomass industry. The company is also a founding member of the Forest Industry Safety Accord and is a member of the Forestry Contractors Association.

With Elliot Henderson Ltd being a long-standing customer for well over 20 years, it’s a fitting tribute to the relationship between the

customer and manufacturer that the landmark 19,000th machine is joining the fleet.

“Elliot Henderson Ltd has always been at the forefront of new machine releases over the years, which in turn keeps the harvesting fleet productive and at the vanguard of innovation. We are excited to be adding this Scorpion Giant to the fleet. This machine will go straight to work in the windblow resulting from Storm Arwen and we feel the extra power and H8 head will benefit us in this application. We look forward to seeing what it can do! We are currently running PONSSE Scorpion, Ergo, three Elephants and one Buffalo.” says Neil Purves, Director of Harvesting for Elliot Henderson Group.

Ponsse UK

Ponsse UK was established in 1996, and since 2017, the company has operated at Annan, Scotland. The first PONSSE forest machine was already delivered to the country in 1994, and the fleet now comprises nearly 400 Ponsse machines. The Annan service centre is a workplace for about 30 Ponsse professionals.

For more information, please contact

Marko Mattila, Chief Sales, Service & Marketing Officer, Ponsse Plc, tel.+358 400 596 297, marko.mattila@ponsse. com

Gary Glendinning, Managing Director, Ponsse UK and Ponsse Machines Ireland Ltd. tel. +44 7753 720906, gary. glendinning@ponsse.com

PONSSE Scorpion Giant harvester

The PONSSE Scorpion Giant is a versatile harvester for demanding conditions. Scorpion Giant can be equipped with either the H8 harvester head or with any of Ponsse’s smaller harvester heads. Scorpion Giant features many solutions familiar from the Scorpion product range, which has been developed even further, including an increased tractive force and an even more powerful C50+ crane. The cabin offers excellent visibility to the logging site, and the machine includes advanced active levelling and suspension systems. PONSSE Scorpion Giant is equipped with a onepiece windscreen that extends

Gary Glendinning, Managing Director Ponsse UK

to the roof of the cabin. As a result, visibility from the cabin is even better, and working is safe in all conditions. The cabin is like a practical and quiet office with a view, developed to support the operator’s comfort and wellbeing.

10 International Forest Industries | APRIL / MAY 2023

LOGGING & BIOMASS NEWS

www.logmax.com

A SMALL, FAST AND RELIABLE THINNING HEAD

The unit is small, just over a meter high and weighs about 420kg, but can cut down trees with a diameter of up to 41 cm. It feeds about 4 m/s and has the very best performance to withstand a tough everyday life in the forest.

Log Max 2000T complements our thinning units in the T-Series.

Contact your local dealer for more information or visit logmax.com

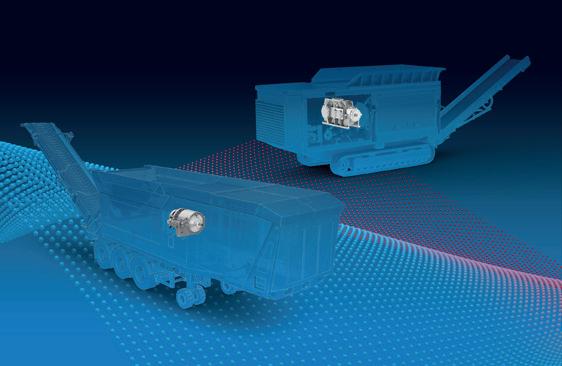

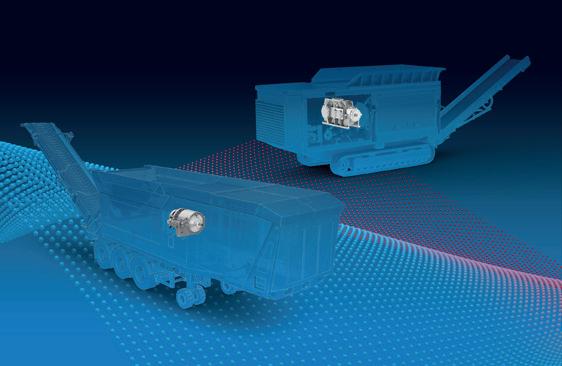

Peterson horizontal grinder from Astec suits land clearing and other uses requiring mobility

The new Peterson 5710E horizontal grinder from Astec Industries is suited for land clearing operations or other applications where mobility is desired. The horizontal grinder is equipped with several features designed to improve efficiency and help operators reduce material handling costs.

The 5710E features a larger rotor that can accommodate a greater number of grinding bits. The new rotor is 8 percent larger and 19 percent heavier than the previous model, giving it more grinding power. To keep up with this improved power, the screening area has also been increased, to allow for greater throughput. Additionally, the grate change process has been simplified. While weight and size have been increased where it counts, the machine is lighter

overall. The redesign has been used to maximize efficiency and simplicity throughout the grinding process. This has been applied from the rotor to the

New Niche Skidder

The Tigercat 612 series skidder platform was created to manage the extraction function in challenging terrain selective felling applications, while preserving the value and quality of the residual stand. The machine can be equipped with a dual winch, a movable back shield and fairlead

system, as well as a crane, and front blade tongs.

The 612 is equipped with the Tigercat FPT N67 Stage V engine, delivering 155 kW (208 hp). Combined with Tigercat’s efficient drive system, the 612 impressively handles adverse terrain while minimizing wheel spin.

screens, as well as in the new compression roll cylinders, which offer better downforce to help process material being fed into the rotor.

A narrow stance allows easy navigation through tight trails and rough ground conditions. The movable shield can be used as an anchor while winching. The dual winch and moving fairlead system allow the operator independent control over two separate cables when operating in

tight stand conditions. The optional heavy-duty crane and blade tongs offer even more versatility for extracting, maneuvering and sorting logs.

The operator’s cab is spacious with generous sized windows providing clear sightlines. Creature comforts include a climate-controlled cup holder and dedicated storage. Key to ergonomics and operating the machine effectively is the Turnaround seat. Turnaround provides increased comfort, clear sightlines, and easy entry and exit from either side of the machine. The operator enjoys full control of all machine functions in any position within the 220° range.

12 International Forest Industries | APRIL / MAY 2023

The new Peterson 5710E horizontal grinder is ideal for applications requiring mobility. Astec Industries

COMFORT LINE 3

adjustable suspension

between three different presets. adjustments for increased serviceability. All valves and accumulators gathered in one place. Visit us at www.rottne.com

ORIGINAL HAS BECOME EVEN BETTER! Our goal is to make driving a Rottne comfortable. We have now taken the market’s best cabin comfort to the next level.

New

Choose

THE

Morbark debuted new horizontal grinder at CONEXPO 2023

Morbark, Rayco, Denis Cimaf, Boxer, and Timberwolf showcased new equipment at shared booth

Morbark, LLC debuted the next-generation 6400XT Wood Hog horizontal grinder with a transport system at CONEXPOCON/AGG 2023. Other new equipment offerings included a Denis Cimaf open-face carbide mulching attachment and a Timberwolf TW 280HB HYBRID brush chipper.

The Morbark transport dolly for the next-generation 6400XT was developed to simplify how users transport the machine. Equipped with an independent air-ride suspension and remote-controlled front and rear hydraulic locks, a single operator can attach the transport dolly in minutes, eliminating the need for a specialized Low-Boy trailer. In addition to the new transport dolly system, the 6400XT has undergone a few other updates:

• Enhanced frame design allows for transport dolly attachment while keeping machine width to three metres providing uniformity for both domestic and other global markets

• Automatic hammermill drivebelt tension system

• PT Tech hydraulic torque limiter provides driveline protection while allowing ease of setting adjustments based on grinding application.

Denis Cimaf, an affiliated Morbark brand, have introduced a new line of openface, carbide tip mulching

heads for dedicated carriers, skid steers, and excavators known as the Denis Cimaf DX series of mulching heads.

The DX features carbide teeth that rip through hard and soft wood up to eight inches in diameter. The DX is ideal for tackling mulching or brush clearing with power and hammer-style force. In addition, it is well-suited for land clearing, vegetation management, and utility and roadside maintenance in unknown or rocky terrain.

Timberwolf joined Morbark at CONEXPO-CON/AGG 2023 and showcased the TW 280HB HYBRID brush chipper.

The Timberwolf TW 280HB HYBRID was developed to meet the growing industry trend toward more sustainable solutions. With a processing throughput of over seven tonnes/hr, the TW 280HB HYBRID offers a maximum

power of 62 horsepower but only 25 horsepower enginelevel emissions. Simple to maintain, the TW 280HB is ideal for companies and organizations committed to minimizing their emissions without compromising performance.

Supplementing engine generation power is a power-dense hybrid system. An Inmotion generator synchronous motor (GSM) and energy-efficient SECH supercapacitors are integral to this system. Providing swift recharge capability, in contrast to lithium-ion batteries, supercapacitors store and release energy quickly, coping with the variable duty cycle of the arborist’s job. Furthermore, this is integrated into a selfsupported system that does not need external charging to operate. As the arborist’s working environment is

continuously changing and the work schedule is often long, the TW 280HB HYBRID will perform throughout the day.

“Balancing performance and emissions was a challenge that could not be met by simply dialing down engine sizes,” explains Guy Marshlain, sales and marketing director for Timberwolf. “Therefore, our journey towards net zero began with the decision for Timberwolf to lead its own hybrid powertrain development program. The TW 280HB HYBRID is simply the first step in using our technical expertise to meet the sustainability challenges of the future. There is certainly more to follow.”

Also, in the Morbark booth was the tried-and-true Morbark 3000XT Wood Hog horizontal grinder and the 1821 and 1415 brush chippers. From Rayco, the C120 forestry mulcher, 4000AWL articulated wheel loader, and RG80 stump cutter. From Timberwolf, the TW 230HB brush chipper and from Boxer the 600HD mini-skid steer.

14 International Forest Industries | APRIL / MAY 2023

A Morbark 6400XT horizontal grinder with a dolly transport system

Maximize productivity with an all-Tigercat CTL package. Pair the 1165 harvester with the Tigercat 534 harvesting head for unmatched efficiency and performance. PACKAGE THE FULL www.tigercat.com Scan to learn more 1165 534

Raute receives order of EUR 49.6 million to Uruguay

with analyzers for grading and MillSIGHTS software for data capturing.

Raute Corporation has signed a contract worth EUR 49.6 million with Lumin in Uruguay for the technology delivery of a new plywood mill. This project was earlier referred to in the stock exchange release dated March 9, 2023 (Raute plans directed share issue, rights issue and junior loan to support targeted growth and strengthening of capital structure and proposes combination of share classes). Following the receipt of an advance payment for the project it has become effective as of today.

Lumin will build a greenfield plywood mill in Melo, Cerro Largo, Uruguay. The new mill will increase their plywood

production capacity from 304 000 m3 to nearly 500 000 m3, making Lumin the second largest plywood producer in South America.

The order for Raute’s technology includes all main production processes to this new eucalyptus plywood mill: a log handling line, a veneer peeling line, two veneer drying lines with grading, three veneer composing lines, two plywood lay-up lines, two plywood pressing lines, panel repairing and sawing lines with extensive service package and long-term on-site management. All lines are of the most modern automated R7-Series technology equipped

Pfeifer Group buys Raute

Pfeifer Group, Austria has invested in Raute’s latest panel repairing technology. The automated Panel Repair Station R5, including the latest machine vision technology, will be used for repairing 2,1x5,2m

three-ply massive wood panels with polyurethane filler. With the new automated way of repairing, Pfeifer is able to save repair material and labor, increase capacity, and secure constant panel quality.

“We are very pleased to receive this order, which shows our ability to serve our customers as a complete, one-stop-supplier. Lumin is our long-term customer with multiple technology deliveries from Raute over the years”, says Mika Saariaho, CEO of Raute.

The ordered machinery and equipment will be delivered between February 2024 and June 2025. They will be manufactured at Raute’s production units in Lahti and Kajaani in Finland, and in the company’s partnership network.

This new mill, which will be in full operation in 2026, is part of Lumin’s strategy to capitalize on the growing global demand for sustainable timber products for the construction and furniture sectors. On the other hand, they are giving added value in Uruguay, instead of exporting timber, to the tree farms that they have been

Mika Saariaho, CEO of Raute

sustainably managing for more than 15 years in Cerro Largo and Treinta y Tres.

Lumin, employing 780 people, is a leader in forestry and forest products in Uruguay. With more than 25 years of experience it manages 120,000 hectares of timberland and has two plywood mills in Uruguay. Lumin is dedicated to the sustainable production of plywood panels destined for international markets. It is owned by a consortium of long-term investors.

www.lumin.com

Raute was selected for being the one-stop shop from design to all the way to installation. The line will be delivered in December 2023.

Further information: Jari Myyryläinen, CCO jari.myyrylainen@raute.com

16 International Forest Industries | APRIL / MAY 2023

SMART 3D LASER PROFILERS visit www.lmi3d.com/wood-IFI/ Proven smart 3D solutions for log and board optimization ACCURATE COST-EFFICIENT EASY-TO-USE

Johanna Harjula appointed Mill Manager

Johanna Harjula has been appointed Sawmill Manager at Metsä Fibre’s Rauma sawmill and will start in her new position on 12 June 2023. Harjula has worked in Metsä Group in various production positions since 2010, currently

as Technical Manager of Metsä Fibre’s Rauma pulp mill. Harjula will report to Virva Juhola, SVP Production, Sawmill Business.

Liisa-Maija Perävainio, current Rauma sawmill Sawmill Manager, has decided

to continue her career with another employer. Ilkka Poikolainen, VP, Production Technology will act as the temporary Mill Manager of Rauma sawmill from 4.4.2023 to 11.6.2023.

More information:

Virva Juhola, SVP Production, Sawmill Business, Metsä Fibre, tel. +358 40 719 5826

LUMIN, Uruguay invests in the new Raute Green Veneer Composing Line R7

Lumin, Uruguay has decided to invest in the new Raute Green Veneer Composing Line R7. The line will be installed as an inline solution into a non-Raute brand peeling line and will be used to combine green veneer sheets to handle full sheets instead of randoms.

With the green veneer composing line, LUMIN is expecting to maximize the utilization of raw material,

improve overall recovery, save manpower, and increase drying process efficiency.

“In this new project, Raute and LUMIN did together a raw material test at the mill before ordering the equipment. This was an excellent opportunity to know better the behavior of the local raw material at the composer and also at the drying process”, says Ricardo Inciarte, COO of LUMIN.

Load/Unload a container in under 6 minutes with the COMBi-CSS

Load and unload containers quickly and safely with the Combi-CSS. Add loads of up to 30,000 kg in 6 minutes.

The Combi-CSS is the ultimate alternative to traditional container loading and unloading. All loading is done outside the container. The load can be safely and quickly formed on the platform by one forklift and a single operator.

This will be the first new generation Green Veneer Composing Line R7 to be delivered in Latin America.

The line will be delivered by the end of 2023.

18 International Forest Industries | APRIL / MAY 2023

Hannover Messe, Hanover Germany 15 - 19 May 2023 LIGNA HA N N OVE R combilift.com

forest timber industry 210x148 rev 2.2.indd 1 11/04/2023 14:13:39

WANT TO GET THE MOST OUT OF YOUR PRODUCTION?

OUR ADVANCED ROBOTS ARE DESIGNED TO PICK AND SORT TRIM BLOCKS BASED ON THEIR GRADE AND VALUE, ENSURING THAT YOU MAXIMIZE YOUR RECOVERY.

Partner with us for:

• precision and efficiency • consistent decision-making

• maximized production • increased profits

• reduced labor costs

• increased safety

Don’t get left behind in the race for progress. 450-435-2121 | bidgroup.ca

BID’S ROBOTIC AUTOMATION IS THE ANSWER.

USNR & Burton Mill Solutions are well positioned to serve the industry

With over $74 million in inventory and 17 customer service centers across North America, USNR and Burton Mill Solutions are perfectly positioned to serve the industry.

Their warehouses are stocked with the consumable items and wear parts you need,

ready to ship when you need them.

USNR’s buying power has enabled them to negotiate very favorable pricing for brandname industrial components that are widely used across the industry. Save time and money by consolidating your parts orders with USNR.

They can save you the shipping cost on some items by having your USNR or Burton representative bring them to you on their scheduled visit. Call your representative to learn more.

Call

Swedish Wood is shaping the hardwood industry of the future - forming a new committee for hardwood sawmills

Demand for Swedish wood is increasing from the country’s furniture and interior design producers. Today, the majority of the wood that domestic companies use for production is imported, which is challenging both from a logistical and sustainability perspective. The industry organization Swedish Wood sees great opportunities with wood products from the country’s hardwoods and forms the first committee to represent Swedish hardwood sawmills.

- By bringing together sawmills for hardwood, we strive to create dialogue and conditions for a long-term and sustainable hardwood industry. We see great potential in using more hardwood from Swedish forests and promoting that development is the purpose of the committee, says Björn Nordin, head of architecture and design at Svenskt Trä and responsible for the new Hardwood Sawmill Committee.

The timber volume of the trees in the Swedish forest consists of 20 percent hardwoods and 40 percent each of spruce and pine, according to figures from the Forest Industries. Despite that, the share of Swedish

hardwood in domestic furniture and interior design products is marginal, and this is also the case for construction materials in the construction industry. Dependence on the outside world makes the industry vulnerable to, for example, price changes, an uncertain supply of raw materials and difficult supply chains. At the same time, consumers increasingly want to know which wood is used in the products they buy. Many actors are facing increased demands on resource efficiency, traceability and circular flows, and here hardwood can be an enabler.

- We want to increase interest in the Swedish hardwood forest as there is great potential to refine more hardwood. To be able to do it together with an industry organization such as Svenskt Trä and other actors in the industry feels very good. It gives greater weight when we jointly spread knowledge about the benefits and possibilities of Swedish hardwood, says Johan Ingvarsson, CEO of KG List, one of the companies that is part of the committee.

According to the Norwegian Forestry Agency’s analysis

of future forestry, SKA 22, deciduous trees will also play an important role for the forestry industry going forward. A continued high pressure on wood products will require an increased use of hardwood, according to the analysis, and further emphasizes that more hardwood trees can contribute to biological diversity and promote a diversification of Swedish forests.

- The construction industry is also showing an increased interest in hardwood products and there is a demand for research projects around the use of hardwood for construction purposes. Promoting research in both the furniture and construction industries will therefore be an important issue for the Hardwood Sawmill Committee. As a first step, Svenskt Trä represented the hardwood sawmills during an industry seminar in Nässjö where the future hardwood industry was on the agenda, says Björn Nordin.

More information

In addition to Svenskt Trä, the Lövträ sawmill committee is represented by the following companies: KG List, Vanhälls Björkså, Specialträ, Kährs and

Billingsfors Lövträ.

Svenskt Trä’s coordination of the hardwood sawmills is part of the work to promote the conditions for a sustainable and long-term use of wood products in Sweden. Resource efficiency, traceability, circular flows and local raw material supply are important focus areas that are part of the trade association’s various projects.

20 International Forest Industries | APRIL / MAY 2023

Johan Ingvarsson CEO KG List

Bjorn Nordin, head of architecture and design at Svenskt Tra

us. We do this every day. +1 800.BUY.USNR

Hekotek AS has signed a supply contract for the delivery of a new log

New log sorting line for Kissakoski Sawmill in Finland

parameters, the receiving measurement of the logs is also performed on the sorting line - using an X-ray and 3D meter, and the obtained measurement results are the basis for invoicing with the log suppliers.

Delivery and installation of Hekotek is planned to start in summer 2023. As usual, Hekotek is responsible for the production of the equipment as well as the full installation and start-up.

International Forest Industries | APRIL / MAY 2023 21

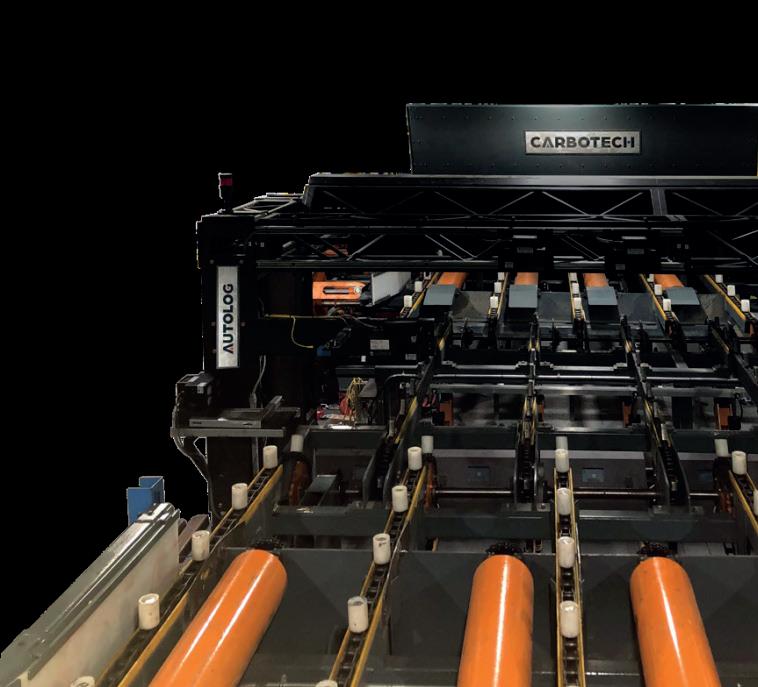

819-362-6317 | info@carbotech.ca | carbotech.ca 450-434-8389 | info@autolog.com | autolog.com WE CARE ABOUT YOUR SUCCESS LET US ASSIST YOU WITH YOUR LOG AND LUMBER PROCESSING PROJECTS TURNKEY PROJECTS CUSTOMIZED SOLUTIONS AFTER SALES SUPPORT

Holmen invests in a new drying plant at Iggesund Sawmill

Iggesund Sawmill has been further modernised to allow for an increase in production. Holmen has invested SEK 70 million in a new drying plant which increases its drying capacity from 400 000 to 500 000 m3.

The new drying plant is what is known as a tunnel dryer. It is much more energy efficient than the old kiln dryers which it will partly replace. The greater drying capacity is primarily used for dried wood products for the joinery industry.

In addition to investing in new dryers, the group had previously agreed to invest in land for timber storage and warehouse space. As a result, Holmen is taking advantage of the new local plan that was adopted many years ago and has started to prepare for the expansion by increasing the land around the sawmill.

After a 10-hectare expansion, the sawmill will cover a total surface area of 40 hectares. In the longer term, Holmen is looking at the possibility of expanding the sawmill with finishing options, in particular in the form of a planing mill.

“The group has shown great faith in us through this investment, which takes Iggesund Sawmill on into the future. The investment improves our competitiveness and places us in an excellent position to develop the sawmill further,” says Iggesund Sawmill’s manager, Magnus Malmström.

The investment is the biggest made at the sawmill since the investment in the trimming saw 20 years ago.

“The fact that Holmen made an investment for the future in such a turbulent period is a sign of strength and

courage. In the long term, the expansion will ensure that job opportunities are safeguarded in the region and that Holmen and Iggesund Sawmill can continue to contribute to a sustainable world through the production of climate-smart products,” says Johan Padel, Holmen’s Senior Vice President Wood Products.

22 International Forest Industries | APRIL / MAY 2023 Stenner Ltd Hartnoll Business Centre, Post Hill, Tiverton EX16 4NG, United Kingdom Tel: + 44 (0) 1884 255700 Fax: + 44 (0) 1884 257794 Email: sales@stenner.co.uk Website: www.stenner.co.uk STENNER HORIZONTAL RESAWS MHS10 machines in-line producing finished components at speeds up to 200 feet per minute Contact: Stenner Ltd, 0044 1884255700 or sales@stenner.co.uk for details. Visit us at Ligna 2023 Hall 25, Stand L46

Johan Padel, Senior Vice President Wood Products

HASSLACHER Group acquires 40% of Egoin Wood Group

HASSLACHER Group has acquired a 40% stake in Egoin Wood Group. This domestically and internationally active company, with production facilities in Ea (Biscay) and Legutio (Araba), has more than 30 years of experience in the development of constructional timber solutions and currently employs around 160 people.

“The HASSLACHER Group’s 40 percent holding represents an important strategic step for the Egoin Wood Group to strengthen its position in the field of industrial timber construction and timber engineering in Spain and the international markets,” says Unai Agirre, CEO of Egoin Wood Group. “This partnership is an ideal synergy and enables the exchange of know-how and optimization ranging from forest management through the production of highquality system solutions for modern timber construction to renewable energy solutions

such as biomass and photovoltaic systems.”

Specialists in engineered timber

“The 40 percent stake in the Egoin Wood Group is an ideal opportunity to drive further the expansion of the HASSLACHER Group and strengthens our position in Southwest Europe,” says Christoph Kulterer, CEO and owner of the HASSLACHER Group. “In addition, from the family origin and the culture and values by which we live, we also share the strategic vision in terms of development, circular economy, and decarbonization as well as sustainable forest management and thus the preservation of forests.”

About Egoin Wood Group

Based in Spain, Egoin Wood Group is an international timber industry company with sites in Ea (Biscay) and Legutio (Araba) and has an experienced team of over 30 engineers who

work with leading architects, developers and contractors in the design of timber construction solutions. Egoin Wood Group currently employs around 160 people in total and, once the new cross laminated timber plant in Legutio is up and running, the Basque timber industry company will employ over 200 people. Egoin Wood Group currently has a total production capacity of 22,000 m³ engineered timber products

(14,000 m³ cross laminated timber, 8,000 m³ glulam), which is expected to double to up to 52,000 m³ when the third cross laminated timber plant in Legutio comes on stream in mid-2023.

International Forest Industries | APRIL / MAY 2023 23

Unai Aguirre (CEO Egoin Wood Group) and Franz Meließnig (CFO HASSLACHER Group) celebrating HASSLACHER Group’s 40 percent stake in Egoin Wood Group. © HASSLACHER Group

Lumin to invest $136M in new plywood mill in Uruguay, expanding production capacity to nearly 500,000 m3

Lumin, a leading timberland and forest products company, will invest ~US$ 136 million to build its third industrial plant in Uruguay, which is expected to create more than 300 jobs and significantly increase the country’s sustainable plywood production. The announcement was recently made in Melo at an event attended by the President of Uruguay, Luis Lacalle Pou, the Mayor of Cerro Largo Department, José Yurramendi, and Lumin´s CEO, Álvaro Molinari.

Following approval by Lumin’s Board of Directors, which includes representatives of the BTG Pactual Timberland Investment Group (TIG) and British Columbia Investment Management Corporation (BCI), construction of the new plant began in the first quarter of 2023, with operations expected to commence the first quarter of 2026.

The expansion is part of Lumin’s strategy to capitalize on the growing global demand for sustainable timber products for the construction and furniture sectors. All of Lumin’s 120,000 hectares of commercial forests are independently certified as meeting the global standards for responsible

forest management of the FSC® (FSC-C162602).

This new investment complements investments of US$ 48 million made over the last two years into the company’s existing facilities, which includes the construction of a thin peel line and a new warehouse facility.

Álvaro Molinari, Lumin’s CEO, said: “Lumin currently employs 780 people and produces 304,000 cubic meters of plywood per year at its two existing plants in Tacuarembó. We expect this new plant to create 320 additional jobs and to expand Lumin’s production capacity to nearly 500,000 cubic meters. Based on current figures, this would make Uruguay the second largest producer of plywood in Latin America.”

The new plant aims to capitalize on tree farms that Lumin has been sustainably managing for more than 15 years in the departments of Cerro Largo and Treinta y Tres.

About Lumin

Lumin is a leader in forestry and forest products in Uruguay. With more than 25 years of experience, Lumin manages 120,000 hectares of timberland

in Uruguay in the departments of Rivera, Tacuarembó, Cerro Largo and Treinta y Tres. www.lumin.com

About BTG Pactual Timberland Investment Group

BTG Pactual (BPAC11) is the largest investment bank in Latin America, operating in the Investment Banking, Corporate Lending, Sales & Trading, Wealth Management and Asset Management markets. BTG Pactual Asset Management has an international presence with over US$ 100 billion in assets under management and administration. BTG Pactual Timberland Investment Group (TIG), a division of BTG Pactual Asset Management, is one of the world’s oldest and largest timberland investment managers with US$ 5.6 billion

in assets and commitments and 3.0 million acres under management globally as of Q4 2022.

About BCI

BCI’s infrastructure & renewable resources program (I&RR), valued at approximately C$20.2 billion, invests in tangible long-life assets in the Americas, Europe, and Asia Pacific, including a portfolio of direct investments in regulated utilities, energy, telecommunications, transportation, timberlands, and agri-businesses.

24 International Forest Industries | APRIL / MAY 2023

LUMBER PROCESSING NEWS WASTEWOODHOGS.COM 1-866-ROCWEAR (762-9327) SALES

COMPLETE

VERTICAL

PARTS SERVICE

LINE-UP OF THE MOST PRODUCTIVE AND COST EFFICIENT WOOD GRINDERS

& HORIZONTAL MODELS AVAILABLE

International Forest Industries | APRIL / MAY 2023 25

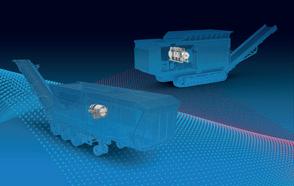

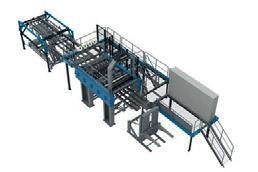

Applying deep learning AI upstream in the sawmill enables USNR’s BioLuma grading systems to capture the highest value by detecting biological and geometric defects early in the process

Advances in AI-powered grading and flexible processing at LIGNA

Recent mergers and acquisitions have solidified USNR’s leadership position in providing equipment and technology for the global wood processing industry, and they are sharing recent advances with you at LIGNA this May 15-19, in Hannover, Germany

Experience the future of efficient lumber manufacturing technology in Hall 25 Stand D65 to learn about USNR’s AI-powered scanning, optimization, and lumber grading systems, along with flexible solutions for log and cant processing.

USNR’s application of deep learning AI has brought a new level of accuracy to grading solutions, along with much faster start-ups. Deep learning AI technology has been applied to all USNR autograding platforms including the industry leading THG and LHG planer grading systems, BioLuma sawmill edger and trimmer grade optimizers, and the AddVantage chop and rip optimizers.

On display you’ll see the BioLuma sawmill grading system, USNR’s VAB-brand lineal planer mill grading system, and the LogMaster HPS bandmill. USNR’s VABbrand grading optimizer is designed to increase premium grades and decrease economy grades. It also decreases trim

loss, increases production, and reduces the need for labor by eliminating the time required by manual graders to analyze boards.

The system can manage multiple grades in one recipe. Mills capture more wood volume. Its small footprint simplifies installation making it easy to integrate into existing

production lines.

USNR will also display the industry’s fastest bandsaw at LIGNA. The Logmaster HPS effectively satisfies your need for high-speed bandsaw production. The design maximizes production and performance with its thin saw kerfs, and the result is excellent yields.

Logmaster HPS is designed for feed speeds up to 180 m/min (590 feet/min) and saw speeds up to 100 m/ sec (330 feet/sec), with excellent product accuracy. Electronic monitoring and self-adjusting features ensure system stability and reliability. Logmaster HPS can be configured as a log or cant breakdown machine, with or without a reducer unit. Its high precision feedworks system guarantees the best accuracy for both straight and sweep sawing.

26 International Forest Industries | APRIL / MAY 2023

USNR’s patented Multi-Point Diverter system delivers significant recovery and productivity gains including improved random recovery, reduced sheet-width variance, downtime reduction, manpower reduction, and increased production

Installed and operating with impressive results, mills are reporting improved cutting accuracy and volume increases with thinner kerf sawing compared to circular saw blades.

Advances in AI-powered defect detection and random stacking for EWP

If you manufacture engineered wood or components, you’ll want to visit USNR’s panel stand in Hall 26 Stand D08 to learn the details about our AI-powered scanning, optimization, and veneer grading systems, along with powerful solutions for panel processing.

Now with deep learning AI technology that was developed and proven in our sawmill grade optimizers, the NV4g green-end and GSc2000 dryend veneer grading platforms deliver a paradigm shift in solution accuracy. The results achieve a new level of defect detection that makes grading solutions more accurate and

more profitable.

Several deep learning systems are installed and operating with impressive results. Mills are reporting improved grading accuracy and more higher-grade finished products. Deep learning AI is the ultimate defect classifier; faster to startup up, more accurate, and easier to use than a traditional neural net classifier.

Effective Sheet and Random Stacking

USNR’s patented invention of the Multi-Point Diverter System (MPDS) has made green random veneer stacking not only possible but efficient. The MPDS uses data from the AI-powered NV4g green veneer defect scanner to precisely track and sort trash into the haul back and divert fishtail/ random onto the trays.

The MPDS can eliminate the tipple section and the cumbersome transitions to multiple trays by loading each tray from discrete divert points.

The system is configurable to customer-specific requirements.

USNR’s random stacker significantly reduces head count by automating the stacking process and eliminating pullers. The system stacks veneer sheets from 6” minimum to full size using spike belts (needle belts) instead of vacuum plenums so there is very little dust. Other key benefits include reduced noise and reduced power consumption compared to USNR vacuum-based stackers.

Visit USNR at

more about these advances that will make your process more efficient, improving your operation and bottom line.

800.BUY.USNR, +1.360.225.8267 or usnr.com

• Hall 25, D65 - Advanced technology solutions for lumber production

• Hall 26, D08 - Advanced technology solutions for engineered wood products

franzen-machines.com Profitable chain sharpening. #teamfranzen2023

International Forest Industries | APRIL / MAY 2023 27

Our USNR veneer grade sorting and stacking systems help reduce your veneer drying costs and increase recovery by sorting accurately and stacking precisely. Available for green and dry applications, these stackers deliver the high-speed reliability necessary for today’s toughest veneer handling requirements. LIGNA to learn

• Hall 25, D69 - Blades, knives, and tooling; automated sharpening and levelling systems

Gilbert has installed over 200 planer projects world wide

For over 35 years, Gilbert Products has been a market leader in the design and manufacturing of planermill equipment.

Totally oriented towards innovation, quality and production, Gilbert offers highly profitable methods and technological equipment surpassing the industry standards. With a dedicated Sales team and Sales Agents in each continent, Gilbert has succeeded in installing over 200 planer projects worldwide in 11 different countries.

Gilbert: A multitasking machine!

Gilbert is well known in Roberval, Canada for its state-of-the-art manufacturing technologies. By using the most modern equipment to operate the factory, Gilbert’s engineering team has replicated the same technology in its planer equipment.

Many planermills require extra flexibility and capacity today.

The Gilbert technology can be compared to a CNC tooling machine.

Tools can be used to plane high quality lumber from low speeds of 200 fpm (60mpm) up to high performing speeds up

to 4000fpm (1200 mpm)! From 0,5’’ to 6’’ thickness and up to 16’’ wide.

Then, different tools can be used to split the lumber in two, three or more pieces. Vertically and horizontally.

Gilbert has always been recognized for being the fastest planer in the world! And now, has proven to split at the fastest speeds as well, over 2000 fpm (600 mpm)

Special side head tools can be used to make special patterns, such as tongue and groove.

Gilbert has developed 6’’ (150mm) side heads with three or more patterns. If the mill changes from one product to the other, the side heads can automatically switch from one pattern to the other. Side heads can stay in the planer 3 times longer.

This Moulder Planer sold to AB Karl Hedin in Sweden is designed to run lumber at over 200 lugs per minute, and with the same machine, make special profiles and split the lumber at the end. This is their second Gilbert Moulder; with the most recent upgrades. Their first planer was installed in 2008 and has been running successfully since.

Safety, a Priority!

In order to always offer its customers the best planing solutions, Gilbert has continually been developing a range of automatic upgrades designed to increase planer efficiency and make the planer room a much SAFER environment.

The Gilbert Automatic Cutterhead Positioning System controls the cutterheads and

28 International Forest Industries | APRIL / MAY 2023

Gilbert Moulder Planer sold to AB Karl Hedin, Krylbo Sweden

an unlimited number of axes for optimal precision and higher grades. Easy to use, the automatic positioning system allows fast and easy recipe changes offering greater flexibility, less downtime and a safe environment.

Many automatic and safety functions have been developed over the past years, like top and bottom head jointers, side head jointers, top head pressure plate, width and height adjustment, aftercut shoes and triple pattern side heads. Very precise, these automatic upgrades increase the quality of the wood finish, ensure safety

and efficiency. Adjustments are made remotely from the HMI screen outside the planer room, or from a tablet or phone anywhere in the mill. With special features like the triple pattern side heads, the operator can remotely switch from one pattern to the other, without stopping for jointing, or changing side heads on the machine. Keeps nicer finish, and less work required!

Gilbert’s Engineering team is presently working on the 4.0 Intelligent Planer with fully automatic self-adjustments.

Gilbert is comprised of a team of 135 workers, all devoted to making the best

planer in the world, and a grand team of after-sale technicians, available 24/7 to support customers worldwide.

Distance is no obstacle to our service team who easily and efficiently offers online remote controlled service to customers worldwide.

We invite you to visit www. gilbert-tech.com to view the complete line of planers and learn more about the company and all its divisions.

International Forest Industries | APRIL / MAY 2023 29 Australia Germany Idaho, USA North Carolina, USA Sweden New Zealand Florida, USA Canada Denmark Brazil From Moulding applications, to High Speed Planermills, Gilbert has the right machine for your mill TRUST THE PLANER EXPERTS T 1 418.275.5041 sales@gilbert-tech.com www.gilbert-tech.com Your #1 worldwide planer supplier

SAWLINES

BID places great emphasis on wood drying with the help of professionals who have developed innovative systems. As specialists in wood drying, BID offers a great product range to meet the diverse needs of customers. With their expertise and commitment to quality, BID and its DelTech brand are trusted names in the wood drying industry.

BID’S Wood Drying Technologies

BID Group is constantly striving to exceed limits and has conceived the following innovations to simplify and enhance productivity for sawmills.

DelTech’s Thermal Oil System for Wood Drying

Make the most of your wood residues with DelTech’s Thermal Oil System. By burning residues like bark, this innovative system heats thermal oil through pipes, generating heat that’s sent straight to the dryers. With the ability to valorize wood residues, sawmills can make the most of every bit of their timber.

But that’s not all, there are plenty of benefits to using the Thermal Oil System. For one, it puts you in control of your costs since you’re not relying on expensive natural

gas. Plus, it helps reduce carbon footprint, making it an eco-friendly option. And unlike steam systems with high pressure that require 24/7 supervision, BID’s Thermal Oil System is designed to be efficient and low maintenance, allowing you to focus on what matters most: your business.

More operational features of DelTech’s Thermal Oil System include the following:

• Continuous operation

• Clean and stable combustion

• High turndown (4:1 thermal turndown or greater –while maintaining proper combustion)

• True fully automatic ash handling system

• Handles wide range of fuel moisture (30 – 55% wet basis typical)

• High system availability

• Long Life, high alloy reciprocating grate bar design (does not require water-cooling)

Upgrade

Your Thermal Oil System with DelTech’s Filtration Skid

Keep your thermal oil system running smoothly with DelTech’s cost-effective Filtration Skid. As thermal oil travels through the pipes, it accumulates impurities that can clog up your machinery and reduce the efficiency of your operations. But with BID’s Skid Filtration System, you can keep your thermal oil clean and pure, so you can save money by avoiding costly system cleaning, flushing and thermal oil replacement.

What’s more, DelTech’s Filtration Skid System is

30 International Forest Industries | APRIL / MAY 2023 SAWLINES

70MMBtu/hr Biomass Thermal Oil System. Fuel Storage Bin and Fuel infeed to Furnace

DelTech ESP attached to 70MMBtu/Hr Biomass Thermal Oil System

designed to be easy to install and maintain, so you can get up and running quickly without having to worry about downtime or costly repairs. If you already have a thermal oil system in place, DelTech’s filtration system can be seamlessly integrated into your existing setup for maximum convenience.

More benefits of using DelTech’s Filtration Skid include the following:

• Cleaner oil reduces pump bearing and seal wear

• Improved heat transfer

• Improved thermal oil properties

• Reduced sludge build-up in low flow areas of thermal oil circuit

• Increases plant up-time.

• Effectively reduce oil contamination from: oil degradation products and oxidations by-products, and water from the system

Real Time Kiln Moisture

Tracking for Continuous Kilns

BID takes pride in employing state-of-the-art technology to maximize the effectiveness

and excellence of its clients’ operations. One way BID and its DelTech brand achieve this is through a partnership with a cutting-edge sensor technology provider. By using specialized sensors, it becomes possible to monitor and regulate the moisture content of the wood in real-time. This means the kilns can adjust their push rate and temperature as necessary to ensure optimal drying conditions and reduce wet or overdried wood.

The benefits of this system are numerous. With better control over the temperature and humidity of the wood, productivity increases, and more consistent results are easily achievable. The system is fully integrated within the operator interface, making it easy to read and adapt to the data provided.

DelTech HMI provides a high level of control and traceability for each load including moisture information kiln so operators can ensure that it meets the required standards for exportation. The system also helps operators to make informed decisions during

product changes and seasonal variations to maintain optimal performance with less staff.

In short, the humidity sensor system is a gamechanger for wood drying. With its advanced technology and ease of use, it becomes possible to deliver highquality results with maximum efficiency.

All things considered, BID and DelTech utilize cuttingedge technology to optimize the efficiency and quality of its

clients’ operations. Through the use of innovative systems, such as the Thermal Oil System, Skid Filtration, and Real Time Kiln Moisture Tracking Sensors, BID is able to simplify and enhance productivity for sawmills while reducing their environmental impact. With their expertise and commitment to quality, BID is a trusted partner for sawmills looking to maximize the value of their timber while minimizing costs and waste.

International Forest Industries | APRIL / MAY 2023 31 WOOD DRYING TECHNOLOGY Optimise your production plan... Optimise your operations www.halcosoftware.com Whatever your mill... Maximize profit by resolving trade-offs between recovery, production rate, and value HALCO Software Systems Vancouver, Canada• Tel: 1 604 731 9311 HALCO AD:Layout 3 3/8/10 17:22 Page 1 OVER 25 SYSTEMS SOLD

70MMBtu/hr Biomass Thermal Oil System

SAWLINES

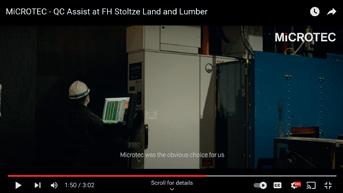

MiCROTEC Leads the Way in Wood Product Industry’s AI Revolution with MiCROTEC Ai

Since its inception in 1980, MiCROTEC has pushed the limit in auto grading technology and innovation. While artificial intelligence (AI) seems to be the tipping point in the timber industry’s revolution, MiCROTEC is finding new ways to fine tune their AI technology, adapting to industry needs and leveling up the scanning technology game. After Lucidyne’s introduction of “Perceptive Sight” in 2017, MiCROTEC continued with MiCROTEC Ai after Lucidyne’s acquisition in April 2020.

Patrick Freeman, MiCROTEC’s Group CTO, referenced MiCROTEC’s inspiration for the introduction of deep learning applied to the wood products industry, “In 2012, AlexNet, the best-known deep learning convolutional neural network, was launched for the processing of image data. We wanted to introduce this new technology to the industry as quickly as possible, in which we succeeded. Ten years ago, students developed AlexNet. Today, we have an experienced team and a large data pool to draw from. Thanks to these framework conditions, we are one step ahead today.”

MiCROTEC’s deep learning pool is based off 36 years of data and has evolved to real scanning applications. “We have been working with artificial intelligence since 1987. Already five years ago, we built the first industrial scanner as a complete solution using deep learning AI technology,” explains Freeman of MiCROTEC’s history. MiCROTEC’s extensive database utilizes historical images as well as current data from MiCROTEC scanners to improve grading results as mills have them in use. “Our large database usually contains data on similar types of wood which often have comparable properties and characteristics. We use them as a starting point and usually achieve good results very quickly,” explains Freeman. When it comes to artificial intelligence, the tools and application are just as important as the database it learns from. Speaking on the database MiCROTEC’s Ai utilizes, Freeman commented, “This allows us to collect all

the necessary data so that our AI can learn in the best possible way. Then, we just need the right tools to process the data and as many samples as possible so that the AI keeps getting better.”

Currently, the advantages of auto-grading technology equipped with AI are being reviewed by many operating saw and planer mills. Explaining the advantages of high-tech solutions Freeman explains, “Some of the

characteristics of wood are easier to recognize and don’t require AI. As for the rest, AI will help us and customers achieve even better sorting results in the future.” Freeman continues, “Anyone who sells a scanner must ensure that certain quality requirements of the various grading classes are met. With MiCROTEC Ai, we can also make sure that hardly any wood is graded too low in terms of its quality, saving our customers a lot of

32 International Forest Industries | APRIL / MAY 2023

money as a result.” Beyond basic grading technology, integrated AI technology allows the further analysis of logs for accurate volume and aesthetic. “When there is frozen snow on the logs, their volume is often overestimated. Using MiCROTEC Ai, the scanner can distinguish snow much better from wood and measure the logs more precisely.” Freeman adds, “MiCROTEC Ai recognizes certain patterns that are aesthetically desired, thereby ensuring appealing surfaces. Until now, no scanner has been able to do that.”

Artificial intelligence doesn’t stop at scanning technology, but also the tools applied to the grading process. Seeing the need for additional AI analysis and expert MiCROTEC support, MiCROTEC introduced “QC Assist,” the company’s proprietary software tool providing seamless communication with scanners

Patrick Freeman, Group Chief Technology Officer, Microtec

equipped with MiCROTEC Ai. Commenting on the evolution of deep learning support, Freeman says “We have made the use of the deep learning AI as simple as possible for customers. Our web-based application QC Assist supports them and us in the automated collection of data, which are then used to train our networks.”

MiCROTEC’s log to board solutions provide customers with virtual inventories and a look inside their product.

Says Freeman of the emerging technology, “Everyone knows ‘Intel Inside’ in connection with computers. We could call it ‘MiCROTEC AI Inside.’” At Ligna 2023, MiCROTEC will be presenting their next step in AI technology. The

company is looking forward to bringing the Ai knowledge of all MiCROTEC branches and the existing MiCROTEC technology together to take possibilities of deep learning AI in the timber industry to a new level.

Lucidyne Scanner with Fully Integrated MiCROTEC Ai to be Installed at Cal-Tex Lumber Company

The Lucidyne scanner, equipped with MiCROTEC Ai and the QC Assist quality control tool, offers unparalleled precision and efficiency in wood processing and quality control, allowing Cal-Tex Lumber Company to get the most value and recovery out of their system.

Cal-Tex Lumber Company, a leading SYP producing lumber mill, is streamlining production processes, minimizing downtime, reducing trim loss, and increasing product consistency with the purchase of a MiCROTEC Lucidyne scanner for installation in its Nacogdoches, TX facility.

Cal-Tex Lumber Company is committed to investing in the latest technology and processes to remain a leader in the wood processing industry. With a history of efficiency, innovation, and a commitment to producing high-quality Southern Yellow Pine products, Cal-Tex Lumber Company has a high standard for the systems used in their mills. Cal-Tex Lumber Company and MiCROTEC have a long relationship, with the first

Lucidyne Grade Mark Reader being installed in 1991. Over the years, these GMR systems have been upgraded to the latest version. Cal-Tex Lumber Company mentioned their excitement about the newest project and how it will improve their grading efficiency.

The Lucidyne scanner will be installed near the beginning of 2024. For more information about the Lucidyne scanner, MiCROTEC Ai, or QC Assist software, please visit microtec. us.

International Forest Industries | APRIL / MAY 2023 33

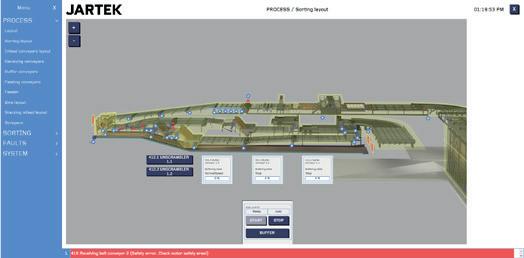

Co-operation with Jartek during the project was easy and project steps went on schedule from start to finish

Ingrida Vizbaraitė the CEO of BROLIS TIMBER

MORE FOCUS ON CUSTOMERS

The leading technology supplier in the sawmill industry Jartek’s business has been developing well in the past years. Their ThermoWood® business has been global for years, and now the sawmill business will follow.

In the future, the ThermoWood® business will stay global, and the sawmill business will go global with selected steps.

One of the first steps is active sales and marketing work in the whole of Europe.

“We have already installed a superior reference to France, so we have taken some steps”, says Kari Puustinen Sales and Marketing Director of Jartek.

Jartek sees a lot of new potential for both ThermoWood® and sawmill business areas. In the past years, Jartek has changed its strategy from offering a wide range of product lines to a limited number of customers to focusing on developing selected products for a wider range of customers.

MORE THAN MECHANICS

Jartek changed its slogan a bit more than one year ago to MORE THAN MECHANICS. Why, while many companies already highlight innovativeness or added value to customers?

“Jartek also adds value, but we like to highlight the things we are good at”, says Kari Puustinen.

Behind the slogan is what happened in 2020. Jartek used to make projects with thirdparty automation partners – the result was not bad, but it was clearly noticed that when a company wants to bring something new to the market it is better to make it independently.

So Jartek did. In the spring of 2020, Jartek AI, an own automation company, was established and already at end of the year, the first project was running in action. The fast timetable was possible due to the Beckhoff automation system and Jartek’s engineering experts.

“We have to remember, that our engineers started from line 1 with coding, and roughly after six months the first line was running. Today we are realizing the choice was correct”, Kari Puustinen tells.

MORE THAN MECHANICS means that when mechanics and automation fully integrate, then 1+1 is more than 2. In automation and mechanics, Jartek is not focusing on trending things like webshops, IOT or AI, etc. – these are naturally important in the future, but more important is that the customer can operate the lines as simply as possible with high efficiency.

Jartek also adds value, but we like to highlight the things we are good at

Kari Puustinen, Sales Director of Jartek

Kari Puustinen, Sales Director of Jartek

34 International Forest Industries | APRIL / MAY 2023 SAWLINES

ThermoWood® business is growing globally – The forerunner Jartek is continuously developing novelty solutions for the market

“For example, a line has to be as robust as possible. The line consists of as many standard parts as possible which don’t need to be bought from any special webshop. Still, the key to making the line run optimally is to run it with the best available automation, and at Jartek we feel that we have that”, says Kari Puustinen.

The visualization of the automation makes it unique, as it is something the sawmill business has not seen. The software is a fully integrated

open solution which means there are many functions that are already included as a standard without any extra work or cost.

“For example, a diagnostic tool can be added to all automation platforms, but normally it is a third-party tool. The automation system is open, so it is easy to add any third-party functions, for example, scanner, press, or condition monitor system. We do it without any cost”, Puustinen says.

International Forest Industries | APRIL / MAY 2023 35

The new BROLIS ThermoWood® plant by Jartek is ready and running

BROLIS TIMBER is proud to announce that their new topnotch ThermoWood® plant by Jartek is ready and running!

The Lithuanian company has been specializing in modified timbers since 2009. These scientifically enhanced types of wood, with remarkably improved chemical and physical properties, have embodied a new generation of sustainable and functional timber products, that have gained their attention and involvement ever since.

In 2022, BROLIS TIMBER invested €7M into the new thermo treatment production and warehouses, and implemented the project in less than one year, settling in the Free Economic Zone in Kaunas.

ThermoWood® – the outstandingly durable and sustainable material, modified purely by heat, water, and steam – has become their favorite, a forerunner in all countries with changing seasons.

“Co-operation with Jartek during the project was easy and project steps went on schedule from start to finish”, says Ingrida Vizbaraitė the CEO of BROLIS TIMBER. “The plant was handed over to us on schedule and our own

Showtime for Combilift at Ligna

Open air site. Stand M61

In the four years since the last Ligna took place, Irish handling specialist Combilift has been busy introducing new models, finessing technology and expanding its global markets even further. Ligna 2023 also coincides with the company’s 25th anniversary, and visitors will experience an action packed stand in the heart of the outdoor area. The company’s innovations and new product launches

will be the main focus but Combilift also likes to entertain as well as inform, so expect dancing trucks, Irish music and refreshments too.

Around 16 exhibits will demonstrate that Combilift has a solution for pretty much every handling and storage scenario that companies in the timber, joinery and furniture sectors face, and these range from small pedestrian 1,000kg capacity stackers to straddle carriers and mobile gantries which can lift loads of 100,000kg and over.

So let’s take a virtual walk around the stand to pick out some of this year’s highlights. Starting at the back we have two of the largest Combilift models, the Combi-SC Straddle Carrier and the Combi-CSS Slip Sheet, both of which guarantee

safer and more productive operation when working with containers. The Combi-CSS, premiered at the last Ligna, was designed for fast loading

first ThermoWood® load was made before Christmas. Our production staff was trained during the project and Jartek professionals gave support during the first months of operation.”

of freight containers. It allows a full container load cycle can be completed in under 6 minutes, and also keeps the risk of product damage to a minimum.

To the side of the Straddle carrier we find a couple of the compact counterbalance design Combi-CBE models and Combi-MR4, described

36 International Forest Industries | APRIL / MAY 2023

The C5000XLE Electric - a tough machine for tough jobs – will be at Ligna.