BID Group, a leader in transformational wood processing technologies and integrated solutions

SAWLINES

Harvesters

Chipper Trucks

FEBRUARY / MARCH 2023

• LOGGING • BIOMASS • RENEWABLE ENERGY

SAWMILLING

www.logmax.com

A SMALL, FAST AND RELIABLE THINNING HEAD

The unit is small, just over a meter high and weighs about 420kg, but can cut down trees with a diameter of up to 41 cm. It feeds about 4 m/s and has the very best performance to withstand a tough everyday life in the forest.

Log Max 2000T complements our thinning units in the T-Series.

your local dealer for more information or visit logmax.com

Contact

COVER - BID GROUP

BID Group provides industry-leading solutions for its highly valued customers in the wood processing industry. BID is a leader in Operational Lifecycle Excellence, transformational wood processing technologies, and integrated solutions. It’s at the forefront of Artificial Intelligence and Digital Solutions in the industry, empowering customers to achieve their best overall performance.

BID adds strategic value to its customers through its ability to provide complete, smart connected,

turnkey manufacturing facilities that include engineering, project management, equipment, software, installation, startup, and after sales parts and services. BID is dedicated to delivering its customers performance, innovation, remarkable service, and results through continuous improvement of its products and services.

www.bidgroup.ca

International Forest Industries | FEBRUARY / MARCH 2023 1 44

RENEWABLE ENERGY

CLIMATE

introduced a Renewable Energy section exploring the opportunities available to the forestry industry to assist in averting further climate change and at the same time

new business opportunities 10 COMBILIFT Loading lumber is quicker and way more efficient with a Combi-CSS 40 TRUCK MOUNTED CHIPPERS Highest

with technical innovations 10 40

28 HARVESTERS LOGGING • BIOMASS CONTENTS FEBRUARY / MARCH 2023 REGULAR FEATURES 8 Logging News 48 Advertising Index LUMBER PROCESSING CONTENTS FEBRUARY / MARCH 2023 SAWMILLING • LOGGING • BIOMASS • RENEWABLE ENERGY SAWLINES Harvesters Chipper Trucks BID Group, a leader in transformational wood processing technologies and integrated solutions

- 47

&

CHANGE We’ve

discover

capacity self-propelled Chippertruck hybrid 2.0 impresses

44-47

18

19

20

Stenner staff are all looking forward to the return of Ligna for the first time since 2019. Machines on show are the VHET100 & ST100R range. Hall 25, Stand L46 24

Upgrading your planer system is a worthwhile investment that can greatly increase its efficiency

Hekotek supplied equipment for processing logs with collecting conveyors for sawing leftovers to Etablissements

Video monitoring is vital for sawmill operations

Lampe & Malphrus Lumber to receive new End Dogging Carriage line

Artificial Intelligence (AI) has triggered the start of a major revolution in the wood processing industry

2 International Forest Industries | FEBRUARY / MARCH 2023 LUMBER PROCESSING

OPTICOM

22 USNR

22 20

HEKOTEK

GAIFFE SARL.

23 USNR

19 SAWLINES 23

24 BID GROUP

STENNER

18

Cutting costs. Significantly. #teamfranzen2023

franzen-machines.com

SUBSCRIPTIONS

SUBSCRIPTIONS

Tel: +44 (0)1442 877 583 emma@internationalforestindustries.com

GUEST COMMENTATOR

Tel: +44 (0)1442 877 583

emma@internationalforestindustries.com

Annual Subscription

Annual Subscription

U K and Europe £160, € 230 Rest of the world US$270

U K and Europe £160, € 230 Rest of the world US$270

EDITORIAL

EDITORIAL

T: +44 (0)1442 877 583

T: +44 (0)1442 877 583

F: +44 (0)1442 870 617 www.internationalforestindustries.com

F: +44 (0)1442 870 617 www.internationalforestindustries.com

2 Claridge Court, Lower Kings Road Berkhamsted, Herts. HP4 2AF, UK

2 Claridge Court, Lower Kings Road Berkhamsted, Herts. HP4 2AF, UK

Publisher

Robin Peach robin@internationalforestindustries.com

Editor Robin Peach robin@internationalforestindustries.com

Editorial Board

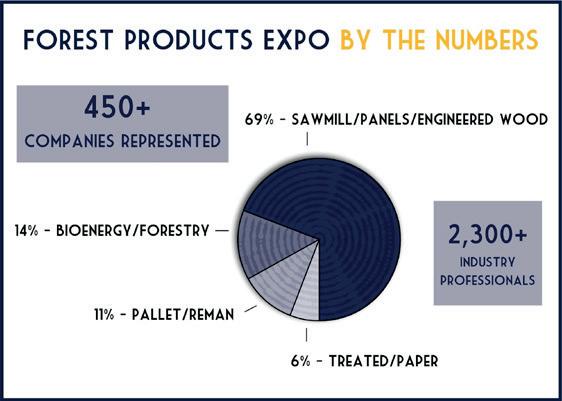

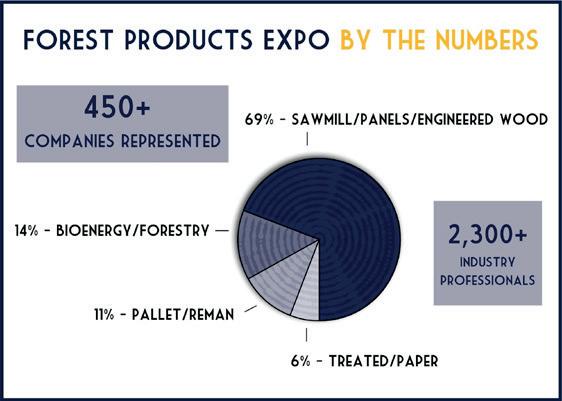

We invited Eric Gee, executive director of the Southern Forest Products Association, to give the low down on USA’s biggest forest products machinery and manufacturing show this year: The Forest Products Machinery & Equipment Exposition.

Do you want to be at the center of the forest products community?

A Connected Community

NORTH AMERICAN SALES

Kevin Lapham

Dr Patrick Moore – Chairman and Chief Professor Piotr Paschalis-Jakubowicz –Warsaw Agricultural University (Poland)

J.P.Media Inc

Mr Kim Carstensen

Tel: +1 (630) 420 9752

Director General

Fax: +1 (630) 420 9763

Forest Stewardship Council

Eduardo Morales

Email: lapham@jpmediainc.com

South American Forestry Consultant

WEB OPTIMIZATION

Jo English

jo@internationalforestindustries.com

ADVERTISING AND PROMOTIONS

ADVERTISING AND PROMOTIONS

International Forest Industries Ltd

International Forest Industries Ltd

Advertising Manager

Advertising Manager

Emma Smith emma@internationalforestindustries.com

Emma Smith emma@internationalforestindustries.com

+44 (0)1442 877 583

+44 (0)1442 877 583

Associate Editor Robin Peach robin@internationalforestindustries.com

Associate Editor Robin Peach robin@internationalforestindustries.com

Advertising Production Enquiries

Advertising Production Enquiries

Emma Smith emma@internationalforestindustries.com

Emma Smith emma@internationalforestindustries.com

Studio Manager

Luke Evans luke@lecreative.co.uk

Accounts

International Forest Industries is published by International Forest Industries Ltd, 2 Claridge Cour t, Lower Kings Road Berkhamsted, Her ts. HP4 2AF, UK

Nicola Shukla nicolas@internationalforestindustries.com

International Forest Industries (ISSN 1755-6732) is published bi-monthly by International Forest Industries Ltd GBR and is distributed in the USA by Asendia USA, 17B South Middlesex

International Forest Industries is published by International Forest Industries Ltd, 2 Claridge Cour t, Lower Kings Road Berkhamsted, Her ts. HP4 2AF, UK International Forest Industries (ISSN 1755-6732) is published bi-monthly by International Forest Industries Ltd GBR and is distributed in the USA by Asendia USA, 17B South Middlesex Avenue, Monroe NJ 08831 and additional mailing offices. Periodicals postage paid at New Brunswick NJ. POSTMASTE R: send address changes to International Forest Industries, 17B South Middlesex Avenue, Monroe NJ 08831

© International Forest Industries Ltd 2007 – 2023 I FI uses, as preference, SI units throughout. All dollars are US unless otherwise stated.

Connect

Are you ready to see how adaptive technology is influencing manufacturing decisions? Is your company part of the new manufacturing age at this critical moment for the industry?

If you answered yes to any of the above questions, don’t second-guess attending the 37th Forest Products Machinery & Equipment Exposition. It’s the place to network with leading equipment manufacturing companies and industry professionals as they develop and share technologies, which adapt to new markets, adjust quickly to increased demand, and bolster operations for the future.

EXPO 2023, set for August 23-25, 2023, in Nashville will provide you with solutions for nearly every stage of manufacturing. From raw material handling to crane operations; metal detection and scanning technologies; log optimization, drying, grading, sorting, packaging, and distribution, there’s an exhibiting company representative on site to explore these solutions with you face to face.

Make no mistake, this new era of work has arrived. An era of connected systems, responsive manufacturing, and innovative technologies – it will all be under a single roof at EXPO 2023.

The Southern Forest Products Association established EXPO to help advance the southern pine and greater lumber industry and provide a forum for the exchange of ideas contributing to improved sawmill efficiency. As the industry has become more efficient, typical EXPO attendees have evolved to include:

• key decision makers who control major purchasing budgets, mill supervisors looking to improve

marketing experts seeking promotional vision, and young professionals making tomorrow’s

The three-day show provides a place to connect and reconnect with colleagues, discover new trends, and explore opportunities. Both firsttime and returning attendees alike play a vital role in the continued progress of the lumber industry. Each exhibiting company has contributed to the industry’s success throughout the years, and attendees will find the EXPO 2023 halls decked out with dynamic displays showcasing the latest in wood processing technology.

More importantly, EXPO provides a place where in-person meetings are valued over emails and phone calls; where a handshake and a smile between colleagues communicate genuine respect; and where sharing ideas is best accomplished face-to-face.

Continued on p6

4 International Forest Industries | FEBRUARY / MARCH 2023

Avenue, Monroe NJ

and additional mailing offices. Periodicals postage paid at New Brunswick NJ. POSTMASTE R: send address changes to International Forest Industries, 17B South Middlesex Avenue, Monroe NJ 08831 © International Forest Industries Ltd 2007 – 2019 I FI uses, as preference, SI units throughout. All dollars are US unless otherwise stated. ISSUE 91 February / March 2023

08831

with the entire wood products manufacturing community TUESDAY, APRIL 18 REGISTRATION OPENS Start planning your experience today at SFPAEXPO.com! August 23-25, 2023 • Music City Center • Nashville, Tennessee Bringing the sawmill industry together for more than 70 years, the Forest Products Machinery & Equipment Exposition is a major event featuring equipment and services for both hardwood and softwood sawmills. SFPAEXPO.COM

BID’s AI-powered Smart Vision is there to help! Contact us to upgrade your mill. 450-435-2121 | info@bidgroup.ca | bidgroup.ca GET BETTER UPTIME AND FLOW OF OPERATIONS IN A SAFER ENVIRONMENT WITH: • Identification of production anomalies to prevent major production stoppages and equipment breakdown • Automated process monitoring allowing to optimize productivity and resource allocation • Accident reduction due to limited human interventions BID’S AI-POWERED SMART VISION FEEL CONFIDENT AND IN CONTROL

EXPO: A History of Innovation

On April 19, 1950, leaders from across the southern lumber manufacturing region gathered in New Orleans to open the first North American equipment trade event dedicated to improving lumber manufacturing.

More than 500 lumbermen attended and witnessed $1 million of equipment on display at the inaugural Logging and Sawmill Machinery Exposition (EXPO) held at the Municipal Auditorium in New Orleans.

A Place for Softwoods and Hardwoods

While the sawmill machinery show originated from leaders looking for a way to improve softwood lumber production, today’s EXPO showcases machinery and equipment for hardwood and softwood sawmills.

“Without a doubt, the hardwood lumber industry has long been represented at this show,” said SFPA Executive Director Eric Gee. “People come to EXPO with an exploration mindset, looking for opportunities to invest in their operations.”

A long list of manufacturers serving the hardwood industry have had a stalwart presence in EXPO for many years, including, but not limited to, companies like Corley Manufacturing, Oleson Saw, SII Dry Kilns, McDonough Manufacturing, TS Manufacturing, and Wood-Mizer.

Why Nashville in 2023?

It had been more than 10 years since EXPO had visited a city other than Atlanta, and EXPO attendee and exhibitor surveys showed it was time for a change. With that information in hand, more than 17 cities were examined as the next host city. In the end, Nashville was selected for several factors, but, most importantly, Nashville is positioned smack in the middle of the forest action.

The surrounding areas, including the Eastern U.S. hardwood community, represent 42% of all lumber manufactured in the United States. And in case you’re curious, Nashville is within easy driving distance for 35% of Southern Pine sawmills

and 73% of hardwood sawmills. That’s just a four-hour drive from more than half of Southern sawmills!

With 766 million acres, forests comprise more than one-third of the entire U.S. landscape. Annually producing more than $100 billion in forest products, the South’s variety of tree species and yearlong harvesting make the region a first choice for mills that rely on an available, affordable supply of sustainable wood products – and Nashville is right in the center of it all.

EXPO 2023 will be held at the Music City Center in downtown Nashville. Located in the middle of all the action, the MCC is the perfect home base for a fun-filled visit to Nashville. You’ll experience a modern business atmosphere in the new state-ofthe-art facility surrounded by a thriving culinary, music, sports, and cultural scene, including the Country Music Hall of Fame, the historic Ryman Auditorium, and the always fun and famous honky tonks – all within walking distance!

It’s Time to Get Down to Business; Face-To-Face is Back

The forest products manufacturing community knows EXPO is the place to get up close to the materials, resources, equipment, and technology they need now. With more than 50,000 square feet of displays, you’ll connect with the best professionals in the business.

For nearly 70 years, this associationsponsored trade event has successfully connected the lumber manufacturing community. EXPO has a longstanding reputation as the place where connections are formed, relationships are strengthened, and deals are closed.

What are you waiting for? Plan your experience today at sfpaexpo.com!

6 International Forest Industries | FEBRUARY / MARCH 2023

GUEST COMMENTATOR Cont’d from p4

International Forest Industries | FEBRUARY / MARCH 2023 7

Katja Paananen appointed Chief Responsibility Officer at Ponsse

Katja Paananen, M.A., has been appointed the Chief Responsibility Officer of Ponsse Plc and a member of the Management Team starting from 16 January 2023. Paananen will report to Petri Härkönen, CFO and Deputy CEO, and her workplace will be in Vieremä.

“The role of responsibility in Ponsse’s business has grown strongly due to the company’s new strategy and goals, as well as the requirements of our stakeholders. Responsibility guides the company’s future, growth and development. Consequently, we want to

strengthen its role both in the management and in all our operations. Ponsse’s values have always been based on responsible operating methods. This provides us with a solid foundation for our development work”, says Juho Nummela, President and CEO of Ponsse Plc.

Katja Paananen has more than 20 years of work experience at Ponsse Plc in responsibility, communication and marketing duties. Paananen will transfer to the new position from her previous post as Sustainability Manager at Ponsse Plc, which

she has held since April 2021. Before this, Paananen was responsible for the Group’s communications.

Other members of Ponsse Plc’s nine-member Management Team in addition to Chief Responsibility Office Katja Paananen are:

• Juho Nummela, President and CEO

• Petri Härkönen, Chief Financial Officer and Deputy CEO

• Juha Inberg, Chief R&D and Technology Officer

• Tiina Kautonen, Chief Human Resources Officer

• Marko Mattila, Chief, Sales, Service & Marketing Officer

• Tapio Mertanen, Chief Service Business Officer

• Miika Soininen, Chief Digital Officer

• Tommi Väänänen, Chief Operations Officer

FAE RCU-55 and RCU-75 remote controlled tracked carriers

Launched on the market in 2022, the RCU is a highperforming, compact remote controlled tracked carrier capable of managing and maintaining greenery even on especially steep and hard-toreach slopes, up to 55°. Its sweet spot is forestry work: clearing slopes with small vegetation located in hard-toreach places.

The RCU is powered by the Kohler common rail electronic fuel injection engine, a compact and powerful and fuelefficient propulsion system (56 hp for the RCU-55 and 74 hp for the RCU-75) that complies with the most stringent emission standards. The dual hydrostatic transmission makes it easier to manage traction and the attachment. Electronically controlled piston pumps combined with a dedicated electronic control unit provide an integrated technological system. RCU vehicles have

an ergonomic remote control with a large 3.5 inch display and a 2.4 GHz transmission frequency to better manage all vehicle and head functions.

The Heavy Duty undercarriage has a variable hydraulic design with independent rollers, an automatic tensioning system, a triple flange oscillating roller system, and triple flange idler wheels. This type of undercarriage, combined with the standard High Profile rubber tracks (with a 72 pitch - 250 mm / 10 in width for RCU-55 or an 86 pitch - 320 mm / 13 in width for RCU-75) allow FAE RCUs to operate in the toughest conditions.

For the RCU-75, there is also the option of a steel undercarriage, with outstanding traction on especially demanding terrain. There are 3 FAE forestry mulchers specially designed to work with the RCUs (depending

on the model).

The BL2/RCU head can mulch branches and wood up to 15 cm / 6 in in diameter, and the BL1/RCU head can mulch branches and wood up to 12 cm / 5 in in diameter. Both heads are equipped with a fixedblade rotor and Bite Limiter technology that provides high output, even with less horsepower, due to the low power absorption.

The PML/RCU head is another swinging hammer forestry mulcher that is ideal for mulching grass and small branches up to 5 cm / 2 in in diameter.

8 International Forest Industries | FEBRUARY / MARCH 2023 LOGGING & BIOMASS NEWS

FOR ELEVATED

The Tigercat 180 swing yarder combines the speed and stability of conventional yarders with the advantages of increased mobility and modern joystick controls. The purpose-built undercarriage and blade lend to powerful line pull and increased stability. The hydraulic driven winches offer great efficiency. Each winch can be run independently in either direction, contributing to easier operation and increased production.

Scan to watch the Tigercat 180 Swing Yarder in action

180

www.tigercat.com

Loading lumber is quicker and way more efficient with a Combi-CSS

Located in the Appalachian foothills of Virginia, Meherrin River Forest Products produces over 40 million board feet of green and kiln dried lumber each year for its global customer base. Business is growing month by month across the five sites in Virginia and North Carolina and the company aims to double its exports within the next five years. The streamlined journey of products from sawmill to container and finally to ship is therefore a key issue for President Don Bright, who has found a piece of equipment that has dramatically increased efficiency when loading a consignment into a freight container.

Don came across the Combi-CSS Slip-Sheet during an event at the Virginia Forest Product Association when Combilift product Manager Patrick Keenan introduced him to this automated and very fast method of stuffing containers. “I had been planning to get some new forklifts in for this task, but realized the concept, design and performance of this device was far superior in terms of time and use of manpower and resources,” he said.

The Combi-CSS is a low level free-standing platform with a dual-directional motor-driven pulling mechanism, on which a steel sheet rests. This enables a full load of product to be prepared behind the container before the four hydraulic cylinders pull the sheet forward into the container. Once fully

loaded, a hydraulic rear barrier gate swings across the container opening and holds the load in place while the sheet is slipped out from underneath. The machine can load containers in lengths between 6.1m / 20 ‘ feet and 12.2m / 40 ‘ feet and has a capacity of 30,000kg/ 66,000 Lbs.

This has many advantages over the traditional “pushpull” method using forklifts, as Don has discovered since his Combi-CSS has been in operation. “What used to take a good half an hour per container and involve two forklifts and 2 operators can now be done in less than half the time, with half the resources – freeing up personnel and equipment for use elsewhere on site.” A further major advantage is the much lower risk of damage to the product as well as the container during loading. “This improves quality and therefore enhances customer service and is also a major advantage when you are dealing with very valuable lumber,” said Don.

Meherrin River is unique in that it is the only North American forest products company to have an onport facility, and having the Combi-CSS based within the Richmond Marine Terminal means that drayage charges are not applicable on each container that is loaded there. This represents substantial cost savings and also gives the company a competitive

edge as half of the current weekly tally of around 20 containers is loaded with lumber transported from other Meherrin sites. All personnel here are trained to use the

Combi-CSS and they find it very easy and straightforward to operate.

Don has been impressed with the build quality: “it’s a tough and heavy duty machine built for an industrial environment and what’s more it takes minimal service to keep it running smoothly. It’s cheaper to maintain than the second forklift I was originally thinking of getting too.” He is also full of praise for the people at Combilift who he believes are as good a team as he has ever come across. “They are passionate, capable and totally committed to getting things 100% right for the customer. Combilift’s drive for innovation is also incredible. I visited the global HQ and factory in Ireland a few weeks ago as part of a trip to Europe for a trade fair, and from the CEO

Patrick Keenan, Product Manager, Combilift

down, everyone is focussed on not just building trucks but on getting a better understanding of the challenges facing customers and the solutions they really need. At Meherrin we believe we are a great company built around good people and the same can be said of Combilift.”

By the end of the year the plan is to be loading 75% of containers within the on-port location and to offer this service to other exporters in the region. The first Combi-CSS has been an integral part of the company’s growth plan and Don is hoping that business will continue to expand to justify getting a second unit for Richmond so that 100% of Meherrin’s products can be conveniently and cost effectively loaded port-side.

10 International Forest Industries |

/ MARCH 2023

FEBRUARY

Wood-Mizer adds WIDE option to popular LT15CLASSIC Mobile Sawmill

The popular, versatile, and compact LT15 sawmill series expands with the introduction of the LT15CLASSIC WIDE Mobile, which combines the features of the mobile LT15 sawmill with a wider sawhead. “It makes an interesting offer for companies and individuals who need to cut larger logs away from their sawmilling workshops. The LT15CLASSIC WIDE Mobile sawmill has been built based on proven and reliable engineering designs from the proven LT15 models, which have earned worldwide recognition among users,” says Hubert Powietrzyński, Sales Manager at Wood-Mizer.

The LT15CLASSIC WIDE Mobile features a portable

chassis for transporting to any place, allowing you to start sawmilling immediately. To start sawmilling, the user only needs to remove the fenders, unlock the protection securing the sawhead during transportation, and level the bed against the ground.

The chassis design is based on the S3 type bed, consisting of 3 segments, each 1,95 m long. The sawmill bed is fitted with six standard side supports and three manual log clamps for securing the log. The standard bed configuration of the LT15CLASSIC WIDE Mobile sawmill allows you to cut logs up to a maximum of 5,2 m. For more efficient log loading, the sawmill can be equipped with

Safety Storage Efficiency

a set of loading ramps with a manual winch. A standard log wedge allows for efficient leveling and positioning of any tapered logs.

The LT15CLASSIC WIDE Mobile comes with a trailer package (up to 1500 kg), including an axle with wheels, a hitch with a support wheel,

eight adjustable outriggers, a light bar, side positioning lights, and fences. The sawmill bed sections have been redesigned and strengthened for increased integration with the chassis, while the electrical wires are secured under special covers.

To find out how Combilift can help you unlock every inch of your storage space Contact Us Today combilift.com Enhance the Safety, Storage and Efficiency of your forest product handling with Combilift Combilift is the perfect fit for the forest timber industry. Safely handle long loads in narrow aisles, and minimise double handling with our multidirectional forklifts, sideloaders and container loaders. forest timber industry 210x148 rev 1.3.indd 1 30/01/2023 17:39:15 LOGGING & BIOMASS NEWS

Positive winds at Rottne Canada - move to own premises & continued increased sales

Rottne Industri delivered 40 new forest machines to Canada last year.

And interest in the Swedish forwarders and harvesters continues to increase on the other side of the Atlantic.

‘The investment in the North American market continues. One step in this is that Rottne Canada is going from previously being tenants to now having acquired a property with modern premises’, says Tobias Johansson, CEO of Rottne Industri.

For Rottne Canada, having its own premises means that the company can more easily continue with the investment that began a couple of years ago. In recent years, the company has built a new network of dealers in the country with very good results.

In terms of sales, we see a clear rise in our machines, says Niklas Lefévre, sales and marketing manager at Rottne Industri.

Above all, it is about our large forwarders, Rottne F18D and Rottne F20D, which account for 60 percent of the orders. Interest has also skyrocketed in our harvesters, in particular the Rottne H21D.

Rottne Canada was formed as a subsidiary of Rottne Industri in February 2008, mostly to provide a spare parts warehouse for the machines. Since then, the company has leased its premises in Moncton, New Brunswick, on the Canadian east coast.

Until last fall when the opportunity arose to purchase premises from a former paver company, built in 2018.

Rottne Canada now has a permanent home in Moncton, NB. We are excited to now have premises that will contribute

to our success. This means that we can take care of our customers even better and also have room to grow, which is one of our goals, says Denis Surette, site manager at Rottne Canada.

Rottne Canada is a large company and since their market is growing, we want to own our premises, not rent. The contract is valid from January and since last autumn we have been on site in our new premises, continues Tobias Johansson.

The property is strategically located on the outskirts of Moncton with close proximity to the main routes around the city. The approximately 1,000 square meters have space for the machines, service, spare parts warehouse and office building for the approximately ten employees.

Our type of felling machines do well in this part of the world. Apart from the fact that they are good machines, other significant advantages are also environmental awareness, being able to absorb directly out in the forest and fuelefficient engines now that the fuel has skyrocketed even in North America, says Tobias Johansson.

The effort that Rottne Industri has made in Canada has borne good fruit. The order intake continues to be replenished, both for forwarders and harvesters, but that does not stop future plans.

We succeeded in our goal of delivering 40 new machines to the Canadian market in 2022. With new and own premises, as well as an established dealer network, we have significantly greater opportunities to continue growing and thus take the next step in the market. And that is our plan, says Niklas Lefévre.

In summary, 2022 was a successful year for Rottne Industri, which delivered a total of 192 machines, which is an all-time high. And this year the company aims even higher.

The order books are fully signed and the goal is to deliver 220 machines, which feels very fun and exciting, says Tobias Johansson.

12 International Forest Industries | FEBRUARY / MARCH 2023 LOGGING & BIOMASS NEWS

The Rottne F18D and Rottne F20D forwarders are both very popular in Canada

Tobias Johansson, CEO, Rottne Industri AB

Niklas Lefévre, Sales & Marketing Director, Rottne Industri AB

New order for Brazil!

Following successful trials in Brazil PlantMax have announced that they have signed a deal with their South American partner Timber in Curitiba, Brazil, for 3 machines to be delivered during 2023!

Thanks to the flexibility of the concept and the great support of the Timber crew they have shown that they are able to handle different kinds of seedlings and adjust the ground preparation for different ground conditions and requests, and they have now confirmed that they have the ability to plant both Pine and Eucalyptus seedlings with good results in Brazilian soil.

PlantMax see a great future in the Brazilian market. Vamos!

Mechanized planting of seedlings with PlantMax X2

Planting the forests of the future has evolved. Meet the PlantMax X2, seedling planter that mechanizes forestry. The equipment is produced by the Swedish manufacturer Plantma Forestry and distributed in

Brazil by Timber. The initiative also had the support of Aperam.

The planter is coupled to a forwarder and plants automatically, according to the desired setup, by two autonomous arms. It has a pair of scarifiers that can operate in 3 modes: 1. Continuous, 2. Intermittent 3. Light removal. Planting can be done in the hole, on the hill or intermittently. Everything can be adjusted in real time while the planter is in motion. It delivers an average productivity of 2,500/h of planted seedlings.

The seedling container has a capacity for 18,000 to 30,000 seedlings, depending on the size of the units. The planter’s arms have sensors that identify obstacles such as stones and stumps that could make planting the seedling unfeasible. The equipment automatically recalculates the spacing and maintains the planting schedule.

Watch out for our special report on Mechanical forest Regeneration & Afforestation: in April May issue.

Mechanical forest

Regeneration & Afforestation: We look at manufacturers who supply forest contractors and forest owners with mechanical forest management equipment and solutions. To include those who companies who design, manufacture and deliver proven efficient forest machines for the phases of forest construction and seedling management, not forgetting the digitization of work tracking.

Fast facts

• In July 2019 Ethiopia planted more than 353 million trees in 12 hours, which is believed to be an afforestation world record

• There are 7 billion hectares of treeless land on earth, where 1.2 trillion native tree saplings could naturally grow through afforestation

Source:Drax.com

International Forest Industries | FEBRUARY / MARCH 2023 13 FAE RCU s REMOTE CONTROLLED PRODUCTIVITY Broaden your concept of productivity with the RCU-55 and the RCU-75 , the line of FAE compact remote controlled tracked carriers. Powerful, robust , and agile. Everything you need to take advantage of FAE’s efficient forestry mulchers, even in steep and hard-to-reach places. fae-group.com Contact us to find the right FAE product for you: info@fae-group.com

dynaCERT breaks into the Forestry Sector in Western Canada

dynaCERT Inc. has announced that it will be installing its HydraGEN™ Technology Units on logging equipment and heavy-duty trucks owned by Fiorentino Bros.

Contracting Ltd.

FBC owns over 100 units of heavy equipment and a fleet of over 70 motor vehicles. The proprietary HydraGEN™ Technology of dynaCERT will be installed on Caterpillar Graders and a Freightliner lowbed truck servicing the forestry industry in British Columbia. The HydraGEN™ Technology is designed to reduce emissions and save fuel and maintenance costs.

Jim Fiorentino, General Manager of FBC, stated, “At FBC, we are committed to helping our clients complete their projects in a safe, profitable, and environmentally sustainable manner. We are pleased to support our clients in providing the products and infrastructure that people need, while reducing our environmental footprint, and costs for fuel equipment

maintenance. The HydraGEN™ Technology of dynaCERT helps us meet our ESG goals and will contribute as a major step forward in reducing GHG’s.”

Jim Payne, President and CEO of dynaCERT, stated, “As global diesel prices soar, dynaCERT continues to serve the private sector in Canada and internationally, including the forestry industry as well as private sector users of internal combustion engines in the logging industry. Our products help users to achieve sustainability and reduce global Greenhouse Gas Emissions. I applaud Fiorentino Bros. Construction Ltd. for their vision and commitment to contributing to a greener planet by reducing emissions.”

About Fiorentino Bros. Contracting Ltd.

FBC is a full-service provider of heavy construction equipment to the logging, mining, earthmoving, and land development industry in the Kootenay region of southeastern British Columbia. This includes communities such as Cranbrook, Creston, Canal Flats, Invermere, Radium, Parson, Golden, Elkford, Fernie, and Sparwood.

Established in 1966, this second-generation, familyowned and operated company owns over 100 units of heavy

equipment and a fleet of over 70 motor vehicles. Canfor, formerly Tembec Industries Inc., and earlier Crestbrook Forest Industries, has been one of the company’s major customers since the 1960s.

About dynaCERT Inc. dynaCERT Inc. manufactures and distributes Carbon Emission Reduction Technology along with its proprietary

HydraLytica™ Telematics, a means of monitoring fuel consumption and calculating GHG emissions savings designed for the tracking of possible future Carbon Credits for use with internal combustion engines. As part of the growing global hydrogen economy, their patented technology creates hydrogen and oxygen on-demand through a unique electrolysis system and supplies these gases through the air intake to enhance combustion, which has shown to lower carbon emissions and improve fuel efficiency. Their technology is designed for use with many types and sizes of diesel engines used in on-road vehicles, reefer trailers, off-road construction, power generation, mining and forestry equipment.

14 International Forest Industries | FEBRUARY / MARCH 2023

Jim Fiorentino, General Manager of FBC

Jim Payne, President and CEO of dynaCERT

Pfeifer acquires Finnish wood processing company Pölkky

The Austrian Pfeifer Holding GmbH has signed an agreement on acquiring the Finnish wood processing company Pölkky Oy. The transaction strengthens Pfeifer’s position as one of the leading European timber industry companies and prepares the producer to face global competition. The Pölkky brand, management and operations will remain untouched.

Since its inception in 1968, Pölkky has been owned by the Virranniemi family. As the largest wood processing company in private ownership in Northern Finland, Pölkky employs 420 people and most recently recorded an annual turnover of 200 million Euros. After Pölkky integration into the Pfeifer Group, it intends to continue with its investment programme as planned during years 2022–2024.

Michael Pfeifer, CEO of Pfeifer Holding GmbH, said:

“We are excited about the opportunities this acquisition brings. Pölkky is a wellmanaged family company with a competent management and staff, a unique location in the heavily forested area of Northern Finland and a valuable market position. This is why Pölkky fits perfectly into our strategy of synergistic growth. The Pfeifer Holding’s three-man management team is comprised of CEO Michael Pfeifer, CTO Clemens Pfeifer and CFO Ewald Franzoi.

Thorough analysis resulted in Pölkky being the best option

In a well-founded analysis process, the Holding’s Managing Directors thoroughly examined all acquisition options over the course of the last few years. In the end, Pölkky emerged as the best option. When signing the contracts, the leadership trio announced that they intend to continue Pölkky’s ambitious investment projects and

operations with full force and expand the Pfeifer Group’s role as a strong partner in the global sawn timber market.

Petteri Virranniemi, CEO of Pölkky Oy, also emphasises the benefits of the deal: “For me and my family, this step strengthens our development potential, allowing Pölkky to continue to grow and make profits. I am confident that we will be able to create new synergies and additional market potential.”

New perspectives for Pfeifer

Thanks to the acquisition, the Pfeifer Group’s number

Continued on p48

International Forest Industries | FEBRUARY / MARCH 2023 15

Petteri Virranniemi, CEO, Pölkky

Alberta renews forest management agreement

The Government of Alberta has renewed the forest management agreement (FMA) jointly held by Tolko Industries Ltd., Norbord Inc. and La Crete Sawmills Ltd. for the next 20 years in exchange for important stewardship responsibilities.

This agreement establishes the companies’ right to grow and harvest Crown timber from a forest management unit in the northwestern corner of the province, surrounding High Level.

Over its lifespan, this FMA is expected to maintain more than 1,700 full-time, contract and seasonal positions and will potentially contribute:

• $48.7 million in holding and protection charge payments

• $433 million in timber dues payments

• $6.1 billion to Alberta’s gross domestic product

“The decision to renew this joint FMA helps maintain hundreds of good jobs for Albertans, provides our forest sector with sure footing for their long-term investments and ensures sustainable management practices for Alberta’s forests. Supporting the competitiveness of our wood fibre products grows our province’s forest sector and advances Alberta’s Recovery Plan.”

Nate Horner, Minister of Agriculture, Forestry and Rural Economic Development

“We’re very pleased with the decision to renew. Reliable

collaboration with government is foundational to the security of our employees and partners across the region, including Indigenous communities. The long-term fibre access provided through an FMA is crucial for our ability to do business in northern Alberta.”

Brad Thorlakson, president and CEO, Tolko Industries Ltd.

“West Fraser understands the responsibility entrusted to us by Albertans in managing public forested land. We work with Indigenous communities and the public to balance a range of values, from job creation to biodiversity. With a focus on long-term sustainable resource management, we look forward to doing business in Alberta for years to come.”

D’Arcy Henderson, vice-president, Canadian Woodlands, West Fraser Timber Co. Ltd. (Norbord Inc.)

“I am always excited to see job creation in our communities within anchor industries like forestry. Our government’s decision to renew this FMA supports Alberta’s Recovery Plan, and the 1700 jobs that this agreement is expected to maintain is a huge contribution to our region.”

Dan Williams, MLA for Peace River

“La Crete Sawmills is proud of the strong local working relationships that support our operations in the High Level area. We’re a local business, and we feel a deep commitment to providing responsible resource management in our region. With

the renewal of our joint FMA, we’re able to continue providing benefits for our community, Indigenous communities and forests well into the future.”

John Unger, president and CEO, La Crete Sawmills Ltd.

Forest management agreements

An FMA is the most secure type of forest tenure, providing companies with rights to establish, grow and harvest timber on Crown land consistent with sustainable forest management principles and practices. FMAs also establish numerous legal obligations for companies, including developing forest management plans that help protect biodiversity, increase forest resilience and reduce the risk of catastrophic wildfires and insect and disease outbreaks, like mountain pine beetle.

Forest Jobs Action Plan

Approval of this joint FMA supports the Forest Jobs Action Plan initiative to provide forest companies with long-term fibre access, ensuring that Alberta’s forests continue to provide ecological, economic, social and cultural benefits for future generations.

Quick facts

The companies directly employ 688 full-time employees and

about 1,080 contract employees in logging, transportation, and other forestry support services. Tolko directly employs about 376 employees and 400 contract employees.

Norbord directly employs 160 full-time employees with about 600 contract employees.

La Crete Sawmills directly employs about 152 full-time employees and about 80 contract employees.

FMA holders are subject to legal requirements to reforest harvested areas within two years. On average, forest companies plant two trees for every three harvested, establishing young, healthy forests that provide environmental benefits such as habitat for wildlife.

To date, almost 211 million seedlings have been planted under this joint FMA

16 International Forest Industries | FEBRUARY / MARCH 2023 LUMBER PROCESSING NEWS

Nate Horner, Minister of Agriculture, Forestry and Rural Economic Development

Dan Williams, MLA for Peace River

John Unger, president and CEO, La Crete Sawmills Ltd.

Brad Thorlakson, president and CEO, Tolko Industries Ltd.

D’Arcy Henderson, Vice President, Canadian Woodlands, West Fraser

Setra first in Sweden with moisture protection for cross-laminated timber (CLT)

about using traditional weather protection such as tents, which cost both time and money to install,” says Theres Jansson.

The timber industry company Setra is the first business in Sweden to offer a new moisture protection for frames made from cross-laminated timber. The protection is applied directly in the production facility and simplifies the construction process.

“Having to take into account the weather and humidity is a constant issue in the construction industry, regardless of the material being used. We are very pleased to be able to offer an effective solution that makes work easier at construction sites and makes it even easier to build with wooden frames,” says Theres Jansson, CLT salesperson at Setra.

The Wetguard200SA moisture protection is manufactured by the Swiss company Siga Cover AG. It consists of an advanced membrane that allows the wooden frame to breathe and releases moisture in the vapor phase, while at the same time protecting against the penetration of water and other dirt. The protection is applied to surfaces such as floor structures and end-grain wood when the frames are being manufactured in Setra’s cross-laminated timber production facility.

“Wetguard allows construction to continue regardless of the weather, and construction companies do not have to think

The method has been tested by Setra, ByggPartner and Siga on a large scale during different seasons. All the measurements show that the protected wood complies with the limit values for moisture by a large margin, even when the frames have been exposed to severe weather.

“Wetguard200SA is initially intended for CLT floors as weather protection during the construction phase. We are pleased that Setra, which has tested the product for a long time in collaboration with us, is now offering all its customers pre-applied Wetguard directly from their production facility,” says Mattias Rudin, product advisor at Siga.

“By increasing the industry’s expertise regarding wood construction and developing new methods such as this, we want to make it easier to choose to use wooden frames. We already

know that wooden frames both shorten the construction time and have a significantly lower climate impact than conventional building materials,” says Theres Jansson.

About Wetguard

The membrane has been developed especially to protect CLT floors against various weather conditions in the construction phase. The protective film is open to diffusion, as well as being wear-resistant and waterproof. It provides effective protection against moisture, construction dirt, footprints and other wear that can occur during frame assembly.

About Setra’s production facility for cross-laminated timber

The production facility for crosslaminated timber is part of the Setra Timber Industry Centre in Långshyttan, southern Dalarna. Glulam and components for the door and window industry are also manufactured there.

E-LOADER

SPRINGER’s latest innovative product development – A new high speed feeder solution for lumber sorting

Your Advantages:

> Can handle a wide range of sizes

> Operates superbly with different sizes

> Lumber can be placed directly into the scraper bar partitions

> Performance is consistently high

> Can be adjusted perfectly to any lumber width

> Layers are accumulated reliably without being pushed back

> It’s maintenance friendly because maintenance lids can be walked on (crossover option)

The E-Loader is used to separate pieces of lumber. Boards are gathered at the E-Loader’s retainer by an accumulation conveyor. The feeder lever takes the board and lifts it into the subsequent measurement conveyor’s scraper bar partitions.

www.springer-usa.com

International Forest Industries | FEBRUARY / MARCH 2023 17

Stenner looking forward to Ligna 2023

Stenner staff are all looking forward to the return of Ligna for the first time since 2019. “ It’s been a long time coming and it’s been a huge miss” says Stenner MD, Syd Mather.

Shows give us manufacturers the opportunity to introduce our products to a wide audience but, more importantly, we are able to sit down in a focussed environment and discuss projects with clients in fine detail, face to face and reach some conclusions. Remote meetings via modern media will never replace this in my opinion” he adds.

Stenner machines on the stand are as follows;

VHET100

This is the latest design in our very successful range of Centre Cutting Resaws. Based on 36 inch pulleys the machine has a new, but proven, servo motor based positioning system for the sawblades and feedboxes making operation very simple and user friendly.

All controls are via a high-definition touch screen. Options included are Remachineable Sawguides, Spray Lubrication Systems and Remote Tracking. We are really looking forward to “showing off“ the VHET100 as it represents what modern

Stenner is all about and is a credit to the Electrical and Mechanical Design Team in particular but also influenced by significant input from our Shopfloor Technicians.

The VHET100 can operate as a stand alone hand fed machine or as part of an automated system in combination with other machine centres such as Moulders and Cross Cut Saws. Stenner can offer such handling systems as part of a “turnkey” package.

ST100R

This is the latest design in the 36 inch stand alone range which has been core to the Stenner business since the 1950’s and is probably what they are best known for throughout the world. This machine will be unsold and

will come with a special show “package” of goodies.

We will have videos representing other machines in the range with particular emphasis on the very successful MHS multi head resaws with over 900 of these models sold all over the world from Iceland to New Zealand.

All Sales Staff will be available as well as installation and production staff to give practical advice on service and operation of the resaws.

18 International Forest Industries | FEBRUARY / MARCH 2023

“

LIGNA HANNOVER GERMANY, 15th to 19th MAY 2023.

STENNER STAND IN HALL 25 STAND NUMBER L46.

Stenner MHS9 4 head

Stenner ST Range

SAWLINES

VHET 100

Hekotek delivers sawmill equipment to France

Hekotek supplied equipment for processing logs with collecting conveyors for sawing leftovers to Etablissements

GAIFFE SARL. The client is a local sawmilling family business in the northeastern region of France. The new sawmill complex includes a variety of Hekotek-made equipment, including conveyors for gathering, sorting, and removing sawing wastes, a log sorting line, and equipment for feeding logs into the sawing line.

The Veisto OY HewSaw sawing line serves as the centre of the complex (bark, chips, sawdust). High-speed in-feed of short (2,5 m) logs is a unique feature of this project. Hekotek will be delivering all of their equipment and installing it locally.

The sawmill will handle logs with a wider diameter

Currently, mechanical installation was finalised at the end of 2022. The equipment is expected to start up in the spring of 2023. The equipment provided as part of the project framework has a fairly conventional range, but the project also has a relatively unique feature—the log in-feed line can handle both round logs and so-called “square” logs. It is a fact that the mill will handle logs with a wider diameter. In order to remove the slabs, these logs must first pass through a band saw. Only then can they go to the in-feed line supplied by Hekotek and then to the saw line.

One of the largest machine construction companies in the Baltics today, AS Hekotek was established in Estonia in 1992

and specialises in the technical design and production of technological equipment for sawmills and the bioenergy industry.

Hekotek adheres to the idea that quality must be guaranteed at all times. By reducing the number of errors, it ensures right methodology and superior results. Hekotek is also collaborating with the French sawmill Société Européenne des Bois S.A.S, located in Saint-Amans-Soult commune, to modernise its

wood pellet production. About two years ago, Hekotek finished the first phase of modernising the customer’s production facility in France. The majority of the auxiliary equipment was then replaced, and a new pellet granulator was also provided.

International Forest Industries | FEBRUARY / MARCH 2023 19 SAWLINES Stenner Ltd Hartnoll Business Centre, Post Hill, Tiverton EX16 4NG, United Kingdom Tel: + 44 (0) 1884 255700 Fax: + 44 (0) 1884 257794 Email: sales@stenner.co.uk Website: www.stenner.co.uk STENNER HORIZONTAL RESAWS MHS10 machines in-line producing finished components at speeds up to 200 feet per minute Contact: Stenner Ltd, 0044 1884255700 or sales@stenner.co.uk for details. Visit us at Ligna 2023 Hall 25, Stand L46

Opticom Cameras Last Longer in Sawmills

Even when hit by a log

Video monitoring is vital for sawmill operations. It keeps operators safe and helps identify issues immediately before they spiral into major problems.

But many sawmills purchase off-the-shelf consumer or commercial cameras, which aren’t able to handle the dusty, highvibration environment of a sawmill.

When sawmills implement generic camera technology, they end up replacing cameras constantly—sometimes weekly or monthly. Every camera replacement costs money and, more impactfully, mill downtime. The uncertainty leaves mill managers and electrical supervisors with constant worry: they never know when the feed is going to cut out and operations will be down for who knows how long. The right video monitoring equipment—specifically designed for sawmills—can keep operations up and running.

Cameras That Last Years

Dust and vibration cause camera components to come apart inside the camera and break down. Opticom’s cameras and accessories are designed specifically for dusty, high-vibration environments like sawmills. Opticom’s cameras have survived the harshest sawmill and industrial environments. They’re specifically designed to help sawmills monitor operations to improve safety and efficiency. The cameras offer durability and reliability to keep mills up and running thanks to:

• High-quality components

• Durable camera housing that ensures long camera life by protecting the imaging components from vibration

• Special camera mounts that stabilize and protect the camera, no matter where it’s placed in the mill

• A satisfaction guarantee and equipment warranty

When sawmills invest in the right sawmill video equipment, they can stop replacing sawmill cameras every few months. Choosing rugged cameras specifically designed for sawmills means:

• Fewer surprise expenses (like replacing the cameras often)

The complete sorting plant for Pölkky can continue

Jartek Invest Oy delivers a modern sorting facility to Pölkky Oy’s Kajaani production facility. The delivery is a continuation of Pölkky Oy’s renewal of sawing technology that began in 2021 The delivery includes the degreasing and dry sorting facilities with peripheral equipment. Automation for sorting systems is supplied by Jartek AI Oy. The dry sorting line is the largest complex that has ever been built in Finland, including e.g. automatic bar and load handling.

It’s really great that Pölkky Oy wants to continue cooperating with us and that they trust Finnish expertise.

Jartek thanks you for the trust

wants to continue cooperating with us and that they trust Finnish expertise. Jartek thanks you for the trust,” says sales and development director Kari Puustinen.

“We wanted to continue the cooperation we started with Jartek on this project as well. A lot of joint time was used to refine the plant’s concept, as the new line will be installed on the current site with the shortest production stoppage possible. We felt that a local partner would best serve our needs,” states Pölkky Oy’s technical director Tero Dillström.

The Kajaani dry sorting project has been prepared for a long time by both parties and is a continuation of the delivery of the fresh sorting line, which is currently being commissioned.

“It’s really great that Pölkky Oy

The investment is a continuation of the well-started cooperation between Jartek and Pölky. Jartek AI Oy has recently delivered automation solutions to other Pölky plants as well.

The preparatory work for the Kajaani project is already underway. Equipment

A lot of joint time was used to refine the plant’s concept, as the new line will be installed on the current site with the shortest production stoppage possible Pölkky Oy’s technical director Tero Dillström

installations will begin in the spring of 2024 and production trial use will begin in the summer of 2024.

20 International Forest Industries | FEBRUARY / MARCH 2023

Jartek sales & development director Kari Puustinen

SAWLINES OPTICOM

• Zero gaps in safety and security procedures

• Better protection for workers

• Consistent image quality

applications and helps extend the life of the already-rugged camera equipment.

One of Opticom’s customers, a sawmill in Mississippi, was using an off-the-shelf camera to monitor its log debarker. In doing so, they were having to replace the camera almost weekly. Once the mill switched to Opticom’s CC02 camera, mounted onto the debarker with the VM-1 vibration resistant mount, the need for replacement stopped. The same cameras have been in use for more than six years, and are still going strong.

Opticom’s

Mount Cameras Directly on a Debarker

One of the hardest places in a sawmill to monitor is the log debarker. The camera and mount are constantly vibrating; are surrounded by dust and debris; and get hit with wood chips, rocks, glass, and more. Most cameras and video systems can’t last in those conditions, but Opticom’s cameras can last for years even when directly mounted onto a log debarker.

Vibration-resistant camera mounts are key components for reducing the impacts of noise and vibration on electrical equipment in environments where heavy machinery is used. The VM-1 mount for Opticom’s CC02 camera is designed for extreme vibration

Opticom’s

Hit By a Log

Opticom cameras work even through temperature changes, dust, high levels of vibration, and sometimes they work even after they’ve been hit by a log.

One of Opticom’s sawmill customers in Mississippi had one of its CC04 cameras take a direct hit by a log—and the camera survived. It still works flawlessly, and the client only needed to replace the mounting bracket around

it. This is what happens when sawmills choose the right type of camera for their applications.

Proven in the Industry

This year, Opticom Technologies is celebrating 50 years in business.

David Boyd founded the company in 1973 to serve the video monitoring needs of industrial organizations. Industrial facilities that have implemented their video monitoring systems have high praise.

“Opticom has been a responsive and innovative driving force in the industrial arena over the years and their continued success will surely last for another 50 years in the making,” said Scott Agen, IC / IT solutions specialist at Rexel

U.S.A, Florida Region.

“50 years of hard work by Opticom has made a great company with enjoyable people and incredible products. Looking forward to the next project I get to use their products on,” said Todd Richardt, datacomm and video surveillance specialist at Platt Electrical Supply.

1-800-578-1853

www.opticomtech.com

Opticom Technologies, a leader in sawmill video monitoring equipment for 50 years

International Forest Industries | FEBRUARY / MARCH 2023 21

CC02 camera, built to withstand dusty, high-vibration environments like sawmills

VM-1 vibration resistant mount to further protect CC02 cameras in extreme vibration applications

An Opticom Technologies CC04 camera and mount after being hit by a log in a sawmill in Mississippi. The camera still worked perfectly; just the mount needed replaced

P T Z & Bullet Cameras / Cámaras tipo bala y PT Z AL SO AVAIL ABLE / TAMBIÉN DISPONIBLE CC02 & CC04 Cameras / Cámaras Funciona con redes IP PoE , HDT VI y coaxial analógico Work s wi th IP PoE Ne t working, HDT VI and Coax Analog VIBR ATION RE SISTANT / HIGH IMPAC T RESISTENTE A VIBR ACIONES / ALTO IMPACTO

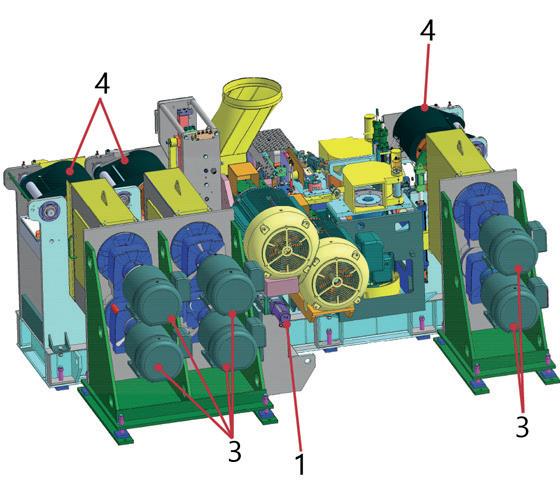

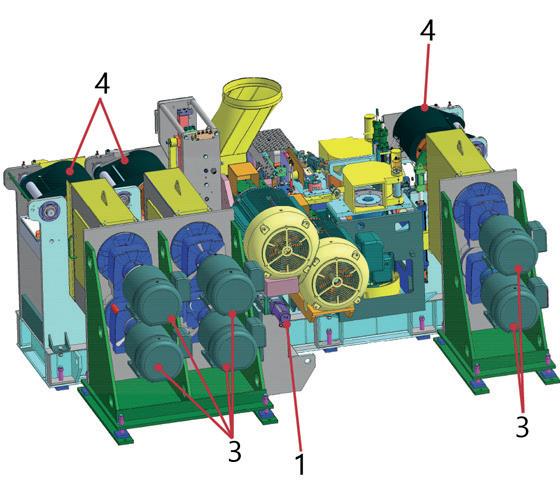

Planer upgrades

LOW COST UPGRADES ADD YEARS OF SERVICE LIFE

Upgrading your planer system is a worthwhile investment that can greatly increase its efficiency, and offers an attractive return on investment particularly when productivity is an issue.

Many of the upgrades USNR has developed for planer machines are applicable to other brands besides USNR designs. Even after years of brute-force service, technology advances can breathe new life into this steadfast system.

Some of these upgrades can be installed over a weekend and may be applicable for USNR, Coastal, or other brands of planers. Contact USNR to learn about all of the upgrades they’ve developed.

1. Planer setworks upgrade

Upgrading the setworks on your planer with electric servo motors increases accuracy and saves significant setup time. Remote HMI adjustments and a recipe-driven setup improves operating efficiency and reduces downtime.

2. Auto-jointer upgrade

USNR’s Auto-Jointer utilizes your PLC control system to joint planer knives from the safety of outside the planer room. This provides safe, efficient, uniform, and remote jointing of your planer knives through your HMI. The Auto-Jointer is a proven system that works to precisely configurable measurements, and works for all 4 cutterheads.

3. Motor driveline upgrades

Electric drives are now available for both the planer and the infeed. The powered hold-down and electric drive ensures better speed regulation and a constant, smooth flow of material. Electric motors and gear ratios can be easily tailored to suit any application. The conversion can be further customized with VFD’s, HMI’s and control systems integration. Factory assembled drive modules make installation easy.

4. Top roll tension & position upgrade

This upgrade enables electronically-stored presets for quick roll height positioning and tension pressure adjustments, for ease of changing product thicknesses. This upgrade uses tension

cylinders with pressure control valving to control the force, and a position cylinder with a feedback device for precise positioning of the roll. The operator interface is used to recall the appropriate position and tension values for each product. Fine tuning the position and tension can help smooth the feeding of boards through the planer. The upgrade can be applied to the top rolls of the infeed and/or the planer.

5. Planer live shear upgrade

The planer shear drive assembly upgrade improves lumber flow and uptime, and increases your planer throughput. USNR’s shear drive assembly is designed to resolve critical planer feeding issues that can cause large gaps, break-ups and jam-ups

22 International Forest Industries | FEBRUARY / MARCH 2023 SAWLINES

1. Planer setworks upgrade

in your planing process, and get you back to full-speed production with maximum uptime. It is offered with hydraulic or electric actuation.

6. Powered hold down assembly

Hold down rolls driven by an electric motor are installed to assist the bridge in feeding

the planer. This provides more powered feed rolls after the pineapple rolls and assists critical lumber feed when accelerating boards. It produces consistent board feeding, reduced board gaps, and more production.

7. Infeed table upgrade USNR has updated the planer

infeed and bridge system with 16” diameter pineapple rolls that have an aggressive tooth pattern and an open profile to facilitate picking up the boards. It also features a closed-loop tensioning and positioning system so one push of a button sets all the feed rolls and pressures. This results in better

pressure control, product feeding and recipe setting options for different product widths and thicknesses. It features automatic thin board control, whereby the system automatically senses a thin board and drops the pineapples to grab the board and shoot it off to the planer.

Lampe & Malphrus Lumber to receive new End Dogging Carriage line

USNR is replacing the Headrig system at Lampe & Malphrus Lumber Company with a new End Dogging Carriage line, including several new machines such as:

• Log infeed using belts, chains, and ending screws

• Pinnacle feeder

• USNR carriage optimization with LASAR

• Reciprocating EDC with rotation

• Conical chip-heads with board and cant separators

• A single pass resaw

• An inertial separator to separate the split cants

• Numerous belted and chain transfers

This comes on the heels of another significant investment for Lampe & Malphrus, a new Optimized Edger line slated for installation in early 2023. A strong business needs

constant updating and revitalization, and that’s exactly what a new carriage line will do. Once the new systems are installed, logs will move through faster and with a higher-quality end result.

“The new primary breakdown will allow us to meet our customer’s growing demand for quality lumber while improving recovery and the health and safety of our team members.” - Will Lampe, President & CEO, Lampe & Malphrus Lumber Company

USNR enjoys working with Lampe & Malphrus Lumber on all of their upgrades and expansion projects.

International Forest Industries | FEBRUARY / MARCH 2023 23

Will Lampe, President & CEO, Lampe & Malphrus Lumber

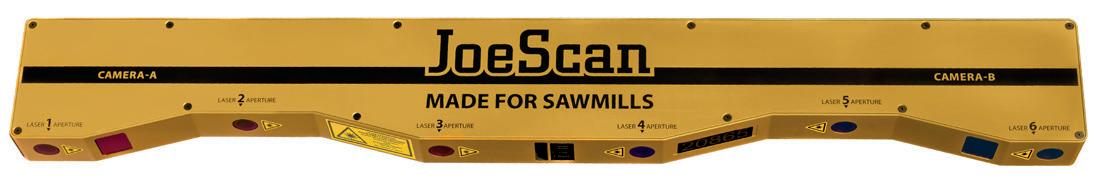

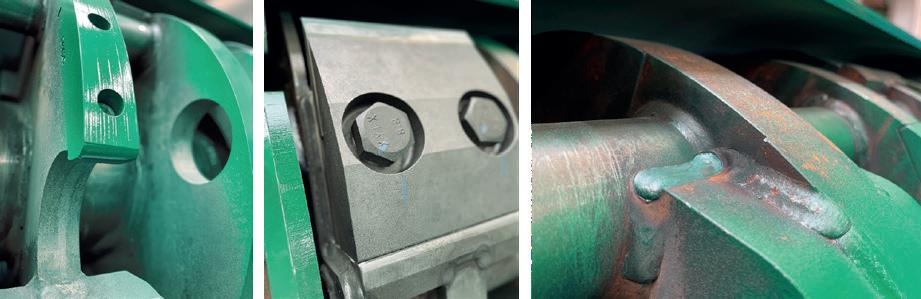

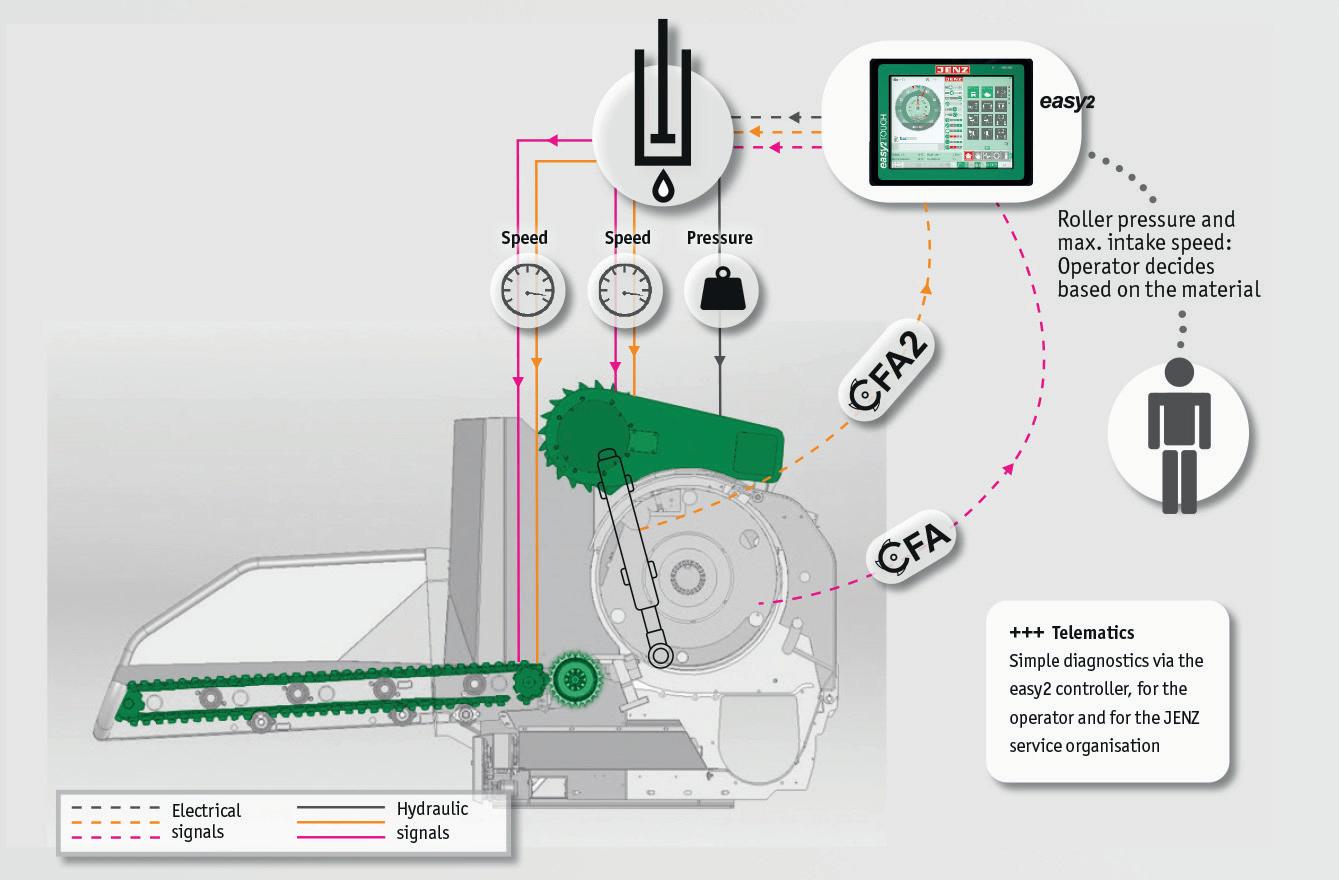

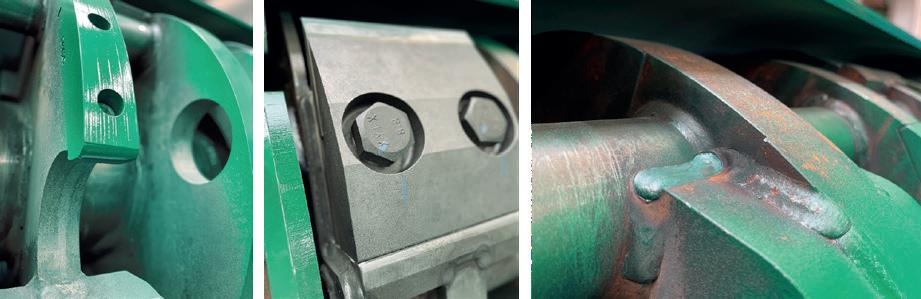

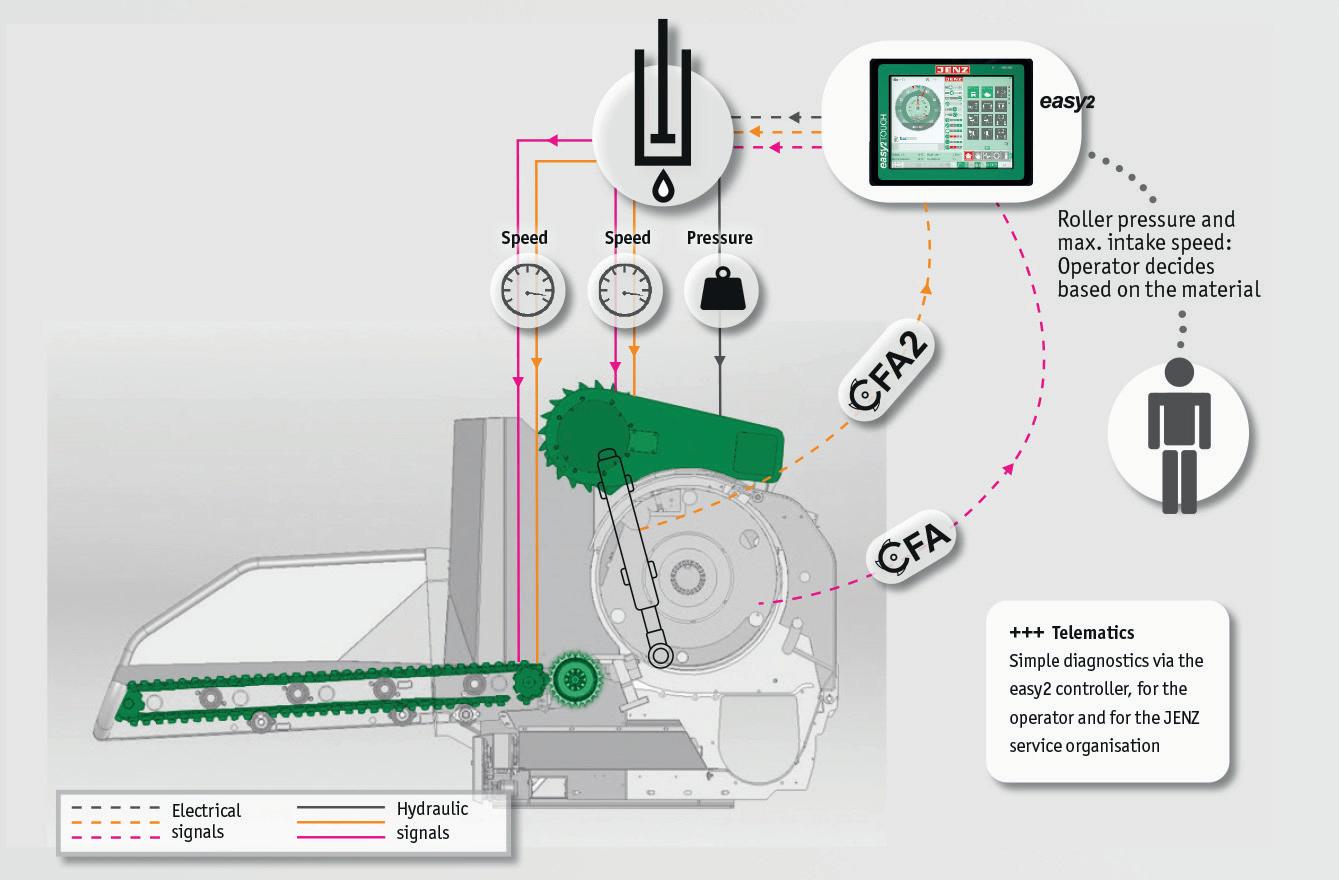

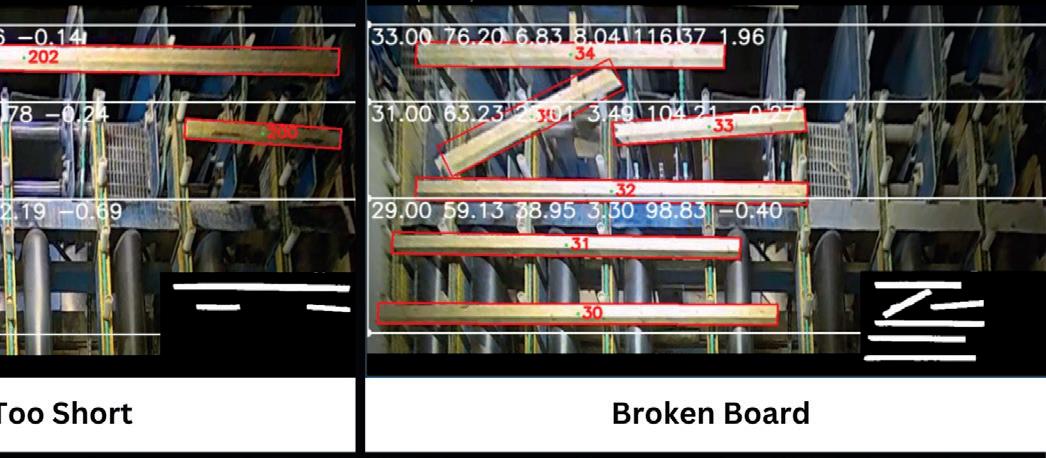

BID Group’s New AI-Powered Smart Vision for Sawmills and Planer Mills

Artificial Intelligence & the Wood Processing Industry

Artificial Intelligence (AI) has triggered the start of a major revolution in the wood processing industry. AI is here to stay, and we can already notice its presence more often in various areas of sawmills and planer mills.

BID is spearheading this revolution with the most recognized solutions in the industry. In fact, BID’s AI-enhanced technologies, combined with its industry-

leading optimization software, have proven to be the most powerful and reliable solutions on the market, bringing sawmills to higher productivity levels.

BID’s AI-Powered Smart Vision

Being dedicated to constant innovation to better serve its customers, BID Group is expanding its digital transformation offering with its new AI-Powered Smart Vision.

The different applications of Smart Vision can be deployed at all stages of the primary wood processing and uses Artificial Intelligence to analyze images from the cameras to constantly monitor the process and identify production anomalies, leading to an increase in productivity and reduction in downtime.

BID’s Smart Vision and its applications optimize wood processing operations by providing the following benefits and technologies:

• Alerts when a problem occurs so that action is taken

• Identification of production anomalies that normally require mechanical and/or human intervention

24 International Forest Industries | FEBRUARY / MARCH 2023 SAWLINES

• Reduction of major production stoppages and equipment breakdowns

• Continuous management and monitoring of one or more stages of the wood transformation process with a large surface area vision

• Ongoing measurement of quality control and optimization of equipment maintenance

• Less relying on photocells for a better flow of operations

BID’s Smart Vision is user friendly, there is no need for AI-specific knowledge. The startup is seamless with BID’s large team of wood specialists and data scientists who run an extensive series of pre-startup tests and quality control checks to ensure the process is fast and effortless.

BID’s Smart Vision is only the beginning; a series of applications available for different stages of the processes, for sawmills and planer mills, is to be developed.

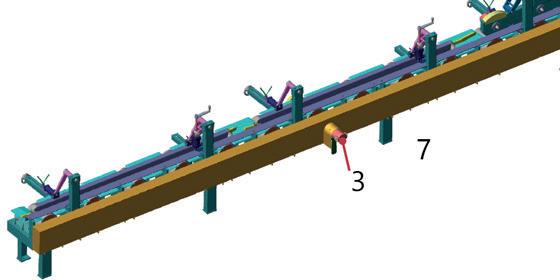

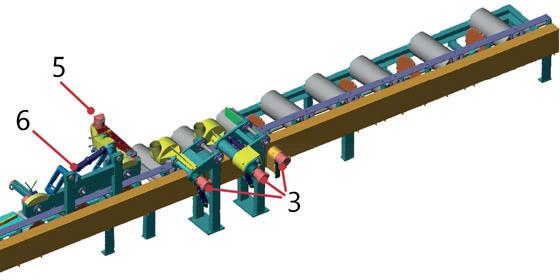

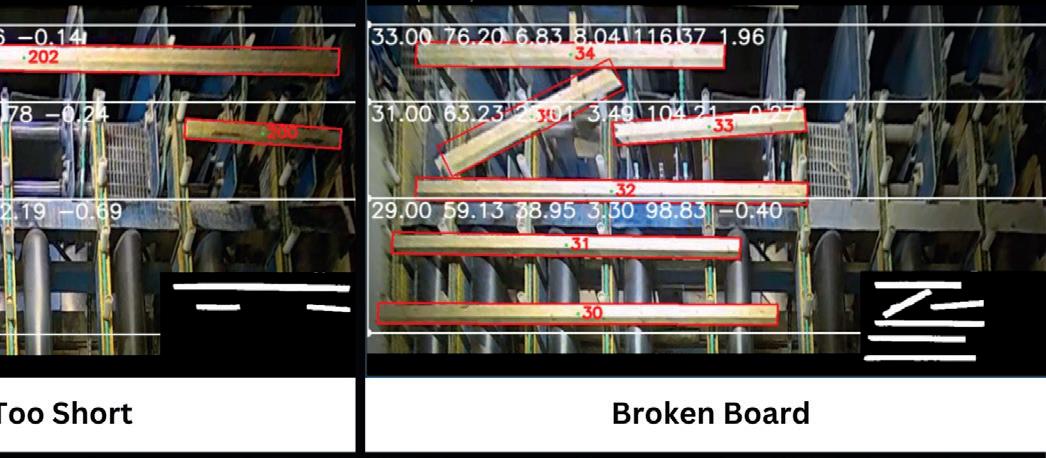

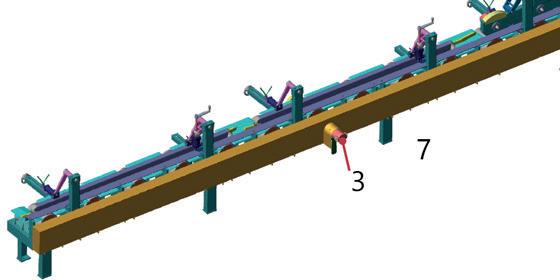

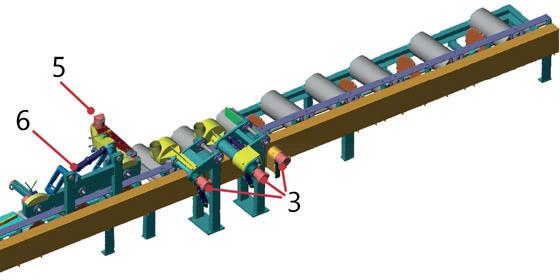

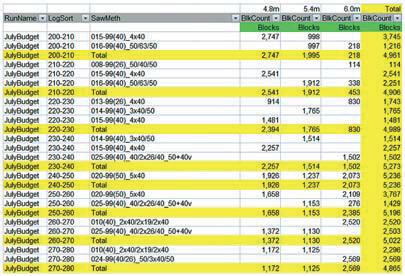

BID’s Smart Vision for the Trimming Line

From the trimmer unscrambler to the trimmer outfeed, boards can get stacked and cause problematic situations such as jams and blockages. With BID’s Smart Vision and its application for the trimming line, these challenges can easily be mitigated.

For the trimmer unscrambler, Smart Vision can detect stacked boards and distinguish it from timber or single boards. The information is sent to the PLC to trigger a mechanical action such as fast jogging to unscramble the boards stacks, avoid crossed boards before the lug loader, reduce human intervention and increase

production flow. The detection of this production anomaly is not possible with photocell sensors alone.

Integrated to the trimmer lug loader, Smart Vision will help to better control problematic boards that can cause downtime due to improper loading. The problematic situations will be identified before the boards are loaded so that parameters such as the loading speed or board feeding are adjusted to better load the boards.

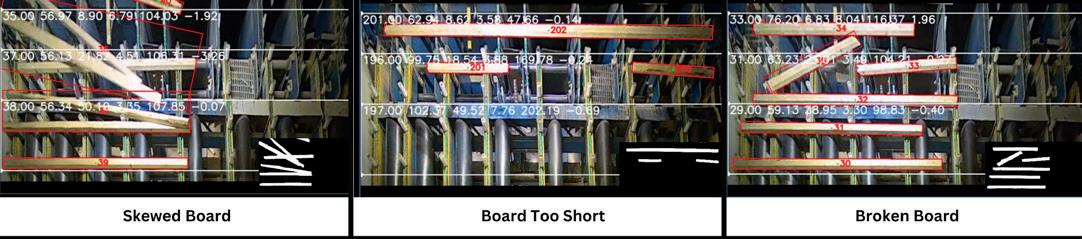

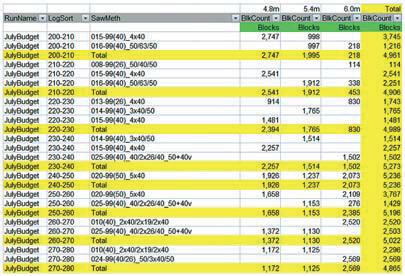

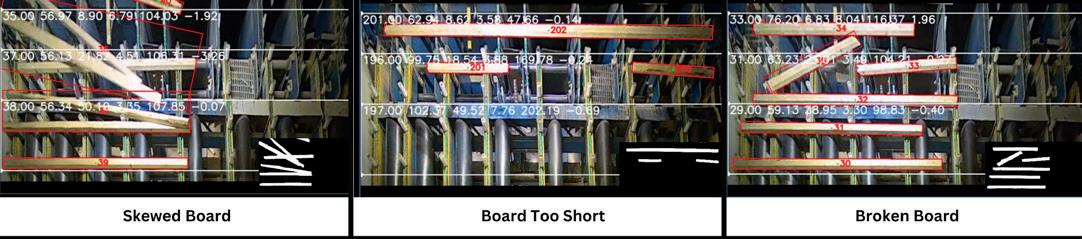

BID’s Smart Vision can also be added to the trimmer infeed to detect anomalies after the lug loader and before the trimmer optimizer. The anomalies to be detected in this zone are skewed boards, broken boards split in two, boards between lugs and double boards in the same lug. The current system of detection with photocells can be replaced with this application, as well as the operator having to press on a pedal to notify an issue.

Once the boards have arrived at the trimmer outfeed/ sorter infeed, Smart Vision will detect problematic situations at the exit of the trimmer and before entering the sorter infeed. This system would replace the current photocell

row detection system. The problematic situations to detect in this area are skewed boards, broken boards split in two, boards between lugs, boards that are too short and remain on the chains after being cut in half with the trimmer, and boards that are too far from the line bar after the transition rollers.

BID’s Smart Vision can also be added to the stacker infeed/ outfeed to detect the rank of boards before the stacker and identify the presence of the following anomalies: gaps between boards, boards under and overlength, stacked boards and broken boards. The number of boards can also be counted in the stacker to report if any are missing or have fallen.

All applications are linked to the PLC, so alarms are sent to notify issues and avoid stoppages and breakages of equipment. In some cases, the line will be stopped to avoid critically problematic situations.

BID’s Artificial Intelligence

Artificial Intelligence is the easiest way to improve production flow and increase profitability. Choosing BID’s AI-powered Smart Vision

results in the fastest ROI in the industry regardless of volume, peace of mind thanks to its integrated solutions and reliable service team, and consistent production quality to ensure customer satisfaction.

Stay tuned because our teams are relentlessly pushing the limits of what is possible to offer evolving technologies, ensuring the best results during the operational lifecycle.

Other BID AI-Enhanced Solutions

Upgrade your mill with BID’s AI-enhanced solutions:

• Defect detection for grading, trimming, and edging

• Residual bark detection

• Split detection on logs

• Wood species identification

• Green-board density separation for optimized wood drying

• And more in development

Curious to know how Smart Vision can help uptime and the flow of your operations? Contact BID now or visit www.bidgroup.ca

International Forest Industries | FEBRUARY / MARCH 2023 25

BSW group strengthens its position with several major investments and acquisitions during 2022

Binderholz GmbH, which acquired BSW Group in 2021, has reaffirmed its commitment to its UK operations after supporting several major investments into the company over the course of 2022.

The investments have strengthened the positioning of BSW Group, helping to place the company in a strong position for when the forestry and timber industry is able to bounce back from the current challenges.

Within its stable of timber and forestry companies, BSW Group has invested £4 million into a new 25,000 m2 miniplug production facility at Maelor Forest Nurseries.

Designed especially for growing forestry species, the investment will help to secure the future supply of highquality trees for the industry. The facility allows seeds to be sown directly into trays, with germination in a controlled environment helping to improve growth, efficiency and resilience in seedlings.

As part of BSW Group’s ongoing commitment to investment into sustainability and development of trees species suitable for the UK’s changing climate, plans are also in place to use the facility to cultivate alternative tree species that will be available to customers.

Another member of BSW Group, Dick Brothers finished the year in a very strong position after winning several new high value contracts with Forestry and Land Scotland. To better service these contracts, BSW Group is investing over £5 million in several new machines to strengthen their fleet of harvesters and forwarders.

BSW Group’s manufacturing sites have also received significant investment, with

Bayram Timber acquiring a £300,000 Hundegger machine. The new machine will help meet the demand of the industrial markets as it provides the ability to process timber in several ways, all in one operation. It has also allowed the company to streamline its caravan kit supply to improve customer quality and service. It is an exciting time for Bayram as they look to venture into new markets and make sizeable improvements to the automation around their site.

BSW Timber Solutions in Melton, Hull, has also had a new £400,000 H23 Planer installed to strengthen the existing stock of planers. The new machine brings an extra capacity in excess of 10,000m3 per year, as well as greater flexibility across existing workloads. Extra features include automated packaging stations for wood bundling and to be able to produce mini packs for customers moving forward.

BSW Timber Solutions has had further investment at its Stoke site, which has had a state-of-the-art showroom built to better showcase the full range of products produced by all BSW Group members, covering both internal and external timber products.

BSW Timber’s sawmill at Fort William, meanwhile, received a £1.4 million investment in in the form of VK Debarker. The new VK Debarker features a 680mm ring, allowing for a significantly increased output of 140m3 per hour. The site, based in Corpach. was also completely resurfaced, with an area of approximately 31,000m2 being filled in.

Tony Hackney, CEO at BSW Group, said: “The forestry and timber industries faced many

challenges in 2022, and further challenges will no doubt present themselves as we move into 2023.

“These challenges came in the form of the pandemic, the conflict in Ukraine, increasing energy costs and a 40-year high in cost-of-living expenses. The result of this was a global downturn across the timber industry, which unfortunately led to the closure of our Boat of Garten sawmill.

“However, the BSW Group and Binderholz GmbH board’s strategic review of the business has presented opportunities where investment would strengthen our offering.

“The decision to make these investments in 2022, with more planned throughout 2023, will allow us to drive efficiencies across all sites and place us in a great position to serve customers with an even stronger offering going forward.”

BSW Group also acquired Scott Group in December 2022. Based near Dunfermline in Scotland, with an annual turnover in excess of £250m and 1,300 employees, Scott Group is an award-winning, sustainable manufacturer

of new, bespoke, and reconditioned timber pallets, producing over 30 million pallets per year.

26 International Forest Industries | FEBRUARY / MARCH 2023

Tony Hackney, CEO, BSW Timber

After 23 years, Snider Industries welcomes a new plant manager

Snider Industries, LLC announced this month the transition of Plant Manager after 23 years of Jimmy Brewer at the helm. Wayne Fleming has assumed the Plant Manager role, bringing over 30 years of Forest Products Industry experience. With this transition, Snider Industries is building on existing expertise, as Jimmy remains firmly involved with the strategic planning for the operations of the company, while Wayne introduces his domestic and international experience as an Automation and Controls professional. As Plant Manager, Wayne Fleming’s official responsibilities will include management of the plant operations covering lumber production, and operations of the log yard, planer mill, and power plant; as well as maintenance, lumber shipping and shavings plant to name a few.

“We expect Snider Industries to benefit from the exceptional managerial and technical expertise that Wayne brings to our company. He has consulted with Snider on various projects and installations going back over 20 years and has an excellent understanding of our operations. To boot, he has been involved in many projects across the spectrum of wood fiber operations and production and we are fortunate to have him,” said Jill Snider Brewer, third-generation Owner.

With 30 years as an Automation and Controls professional, Wayne assisted various industries in increasing productivity and reducing downtime through facility modernization and control upgrades. He began his career as an electrician in a sawmill located in South Alabama. This position led him through the US and internationally, providing

automation and controls solutions over the years. He was then managing partner of an automation and controls engineering business for over 25 of those years, and also served as managing partner in several other businesses including mechanical design and machine fabrication. Throughout his career, he partnered with customers to work through some of the most sophisticated projects in sawmills, plywood/OSB, and pellet plant facilities throughout the US. His career has afforded him the privilege of meeting and developing professional relationships with some of the most revered people in the industry.

Family-owned and operated, Snider Industries has proven that small business, family values can reside in even the largest of industries and is reflected in over 85 years of

customer-centric operation within the industry. Upholding a long-standing commitment to superior quality and the satisfaction of their customers, this exclusively one-inch SYP lumber manufacturer has been labeled an industry leader in all facets: service, product offerings and overall operation. The people who make Snider Industries what it is, both those from within and without, continue to shout their praises of the company’s operational values and resulting product offerings.

International Forest Industries | FEBRUARY / MARCH 2023 27 LUMBER PROCESSING NEWS

Optimise your production plan... Optimise your operations www.halcosoftware.com Whatever your mill... Maximize profit by resolving trade-offs between recovery, production rate, and value HALCO Software Systems Vancouver, Canada• Tel: 1 604 731 9311 HALCO AD:Layout 3 3/8/10 17:22 Page 1 OVER 25 SYSTEMS SOLD

Wayne Fleming