26 minute read

Best Replacement Brushes for Rotary Broom Attachments

How to Select the Best Replacement Brushes Replacement Brushes for Rotary Broom for Rotary Broom Attachments Attachments

Here’s how to match wafers, strips and tube brushes to the job

REPLACING BROOMS AS they wear out is, with tires, the mostcommon maintenance task contract sweepers handle. Primary replacement options are one-piece tube brooms, flat or convoluted wafers, and strip brooms, and all have their specific applications, reasons for use, and advantages and disadvantages.

Interviews with three United Rotary Brush Corp. broom specialists -- Harry Vegter, director of engineering; salesman Perry Stenzel; and Tom Staab, contracts & product compliance -- offered insights into which replacement brooms contractors should consider and why one type might be considered over another. "The different styles of brooms are something not many people give much thought to," Vegter says. "If the sweeper comes with a tube broom they usually replace it with a tube broom and never give much thought to replacing that tube with a different type of broom.

Staab says that as a rule, sweepers in the construction market primarily use wafers, while the municipal market uses tubes and strips. "The type of broom is often tied to the machine, tied to the application, and tied to the broom that was initially sold with the machine," Staab says. "Most contractors put on what they take off."

But he says contractors should consider other types of replacement brooms because they can offer advantages. "When our salesmen are in the field talking with contractors about their sweeping requirements they can help them decide what style broom works best," Staab says. "We're not just in the business of selling brooms. We want to make them aware of what's available to help them meet their needs."

brooms contractors should consider and why one type

As a rule, sweepers in the construction market primarily use wafers, while the municipal market uses tubes and strips, says Tom Staab, contracts & product compliance for United Rotary Brush.

Perry Stenzel, salesman for United Rotary Brush says the most common wafer configuration on says the most common wafer configuration on a broom is to alternate wire wafers with a broom is to alternate wire wafers with polypropylene wafers. "For general polypropylene wafers. "For general purposes, most contractors use purposes, most contractors use either a combination of poly either a combination of poly and wire or all poly." and wire or all poly."

Wire and

Polypropylene Polypropylene Wafers Wafers

Vegter says the mostcommonly used replacement commonly used replacement brooms are wafers, available in both flat and convoluted styles. Flat wafers come with spacers that create a 1-in. space between each wafer on the broom core. Convoluted wavers create their own space due to their convoluted shape. Typically there are 7 convoluted wafers or flat wafers per foot. Wafers are available in either polypropylene or wire bristles (filaments) and are available in diameters to fit a variety of sweeping equipment.

Vegter says construction companies, sweeping contractors and paving contractors replace existing brooms with wafers to customize their broom. "They can make dense heavy-duty brooms with smaller or fewer spaces, and they can also mix wire and polypropylene," he says.

Stenzel says wafers are common in construction sweeping partly because there are more options of mixing poly and wire. "Polypropylene does more sweeping than wire does," he says. "Wire is the cutting action and poly is the flick." He says the type of broom and bristle often depends on what the contractor is sweeping. Airport runways, for example, require a wire broom to cut the rubber left on the runway from airplane tires.

Stenzel says the most common wafer configuration on a broom is to alternate wire wafers with polypropylene wafers. "Sometimes you see two wire and two poly because that will give you more

With interchangeable rows of bristle, the strip broom provides efficient sweeping, simple storage and simplified broom changeovers.

Supplied by United Rotary Brush Corp.

wire throughout the broom and make for a more aggressive broom," he says. "For general purposes, though, most contractors use either a combination of poly and wire or all poly."

Staab says that depending on how you position the convoluted wafers an operator can make a broom more or less dense. He says convoluted wafers "are shipped stacked like Pringles potato chips. They're nested together when shipped and you just locate every other wafer from a 12 o'clock to a 6 o'clock position on the wafer core in order to create a space between each wafer. Or you can make the broom denser by decreasing the space between the wafers by reducing the distance of the two clock positions."

Wafers offer greater versatility to contractors with a variety of sweeping equipment in their fleets. "Strip and tube brooms have to be made specific to the length of the broom core on a specific piece of equipment," says Stenzel.

He says wafers also are not sensitive to makes or models of sweeper. "Some municipal machines have a 10-in. core and 36-in. diameter broom. Tube brooms are built to a particular width of sweeper. If you use a tube broom you're stuck with buying a specific broom, a 66-in. for Pelican, for example, or a 60-in. broom for an Eagle. You have to buy separate tube brooms for each unit. But if you use wafers you can just keep them in stock and replace the broom as needed. It saves a lot of storage space and money."

Altering Density with Wafers

"A wafer broom is really no different from a tube broom, but the advantage is that with wafers you can alter the density of the broom," Vegter says. "Some contractors see a lot of success by altering the broom to their own density, wider spaces or no spaces."

He says that contractors involved in

construction sweeping face problems such as clay and mud baked onto the pavement. "Some of those contractors want a heavy-duty broom," Vegter says. "They might need wire to break up the debris and the poly for the sweeping." Vegter says some contractors want a more dense broom because they can get more hours out of a more dense broom. "If you make it denser it doesn't wear as quickly, and some people say a denser broom just works better," he says. This is not always the case because in other applications a lighter broom can flick debris much better than a denser broom." A dense broom can be effective for certain applications, but to obtain the best result contractors need to be careful how dense a broom they are using. "You have to have space between the wafers for it to be effective," Staab says. "If you don't have that space to get the flicking action it won't sweep efficiently. It depends on the application as to how dense you make it." He says that if a broom is too dense it can result in problems for the equipment. Strip brooms can be used on a variety "Machines are designed of applications but have become to use a certain weight the broom of choice for contractors and density of broom. sweeping up pavement millings. With a more dense broom the sweeper equipment might not be designed to power that broom and might actually wear out sweeper drive components because there's so much more friction" In addition to making brooms denser, some contractors like to "double up" on the broom ends, increasing the density on the ends. "This eliminates trailing for those machines that tend to trail," Vegter says. He says conveyor-style sweepers with rear-mounted brooms often experience trailing on tight turns. "Some contractors really dense up the ends of the brooms so they don't trail," Vegter says, adding that some tube brooms also are tight wrapped on the ends to obtain the same effect as adding wafers to reduce trailing.

This broom is a combination of poly and wire wafers which gives the operator flick action and abrasive power all in one.

Supplied by United Rotary Brush Corp.

Replacement Strip Brooms

Unlike wafers, replacement strip brooms are available only with polypropylene bristles. Strip brooms are shipped in pairs (36 pair measuring 48-in. long, for example, to use on a 96-in.-wide broom). "They are shipped in pairs because they are much easier to handle," Stenzel says. "Handling one long 96-in. strip is like handling a wet noodle."

With strip brooms a mandrel slides on over the equipment wafer core and the strips slide into slots in the mandrel. Many contractors say strips are easier to replace than wafers or tube brooms, as Stenzel says 18 rows of strips can be replaced in 20 minutes. "When changing tube brooms, you have to remove the entire tube broom from the sweeper," Staab says. "But with strip brooms you just drop the end plate, slide the used strips out and replace them with new strips."

Vegter says that while strip brooms can be used on a variety of applications, they have become the broom of choice for contractors sweeping up pavement millings. "Some contractors, especially those who do milling, seem to like strips because they pick up millings very well - there's a pedaling effect," Vegter says. "Because of the spaces in between, the strips seem to flick debris better onto the conveyor. We've had a lot of success with strip brooms with milling sweepers and also with sweepers who do fall sweeping where there are a lot of leaves."

Staab says another strip broom advantage is that they tend to load a hopper more evenly than other types of brooms. "The channels that the strips slide into are crescent-shaped, so both ends of each strip section are lower than the center and when the broom rotates the outer edges of the strips sweep the pavement first. As they spin, the debris moves toward the center of the broom before it is transferred on to the sweeper elevator belt," Staab says. "As a tube broom loads a hopper, for example, the tube broom flicks debris onto the elevator and up into the hopper and it usually fills the hopper from one side or the other. This can create an unbalanced hopper which can result in coning of the broom. That doesn't happen with strips because strips move material from the outside edges toward the center of the elevator so the hopper is loaded from the center resulting in a more evenly distributed load."

Strip brooms will streak or trail when the unit turns, and strips lack a wire option for more aggressive sweeping, so some contractors consider their use to be limited. "Everybody has their own preferences as to what type of broom they like and what they like to use on a particular job, and a lot of people like strip brooms," Stenzel says.

"The decision on what type of broom to use needs to be based on what you're comfortable with and what operation you're used to. With strip and tube brooms you can adjust the down presthe conveyor. sure and it takes a little more finesse to We've had a lot of get them to sweep for you the way that success with strip brooms you want. If you put too much down with milling sweepers and pressure on a strip broom, for example, also with sweepers who do the machine will really bounce and fall sweeping where there are a lot of vibrate so you have to adjust it. leaves." "A big part is operator preference

Staab says another strip broom and what the operator likes and what the customer is comfortable with," Stenzel says. "It can often come down to what they like the best and what works best for them. In the end they all end up sweeping and getting the job done."

Tube Brooms

Tube brooms are one-piece brooms available in either all polypropylene or a poly/wire mix. Where wafers are manufactured in a variety of diameters and can fit any sweeper, tube brooms are manufactured for specific models of sweepers and can't be used on other models. Tube brooms are also more difficult to store and ship and are more costly to ship.

And where wafers and strip brooms can be replaced in the field, tube brooms are usually changed in the shop. "Our contractor Tube brooms are one piece and are between 89 to 96 in. long and they're heavy," Stenzel says. "An all-poly 8-ft. broom weighs 300 lbs. and a poly/wire weighs 385 lbs., so it's just easier to change them out in the shop."

But Staab says replacing tube brooms is quicker than stacking wafers.

Poly wafers will have maximum flick action, while wire wafers will have more abrasive power, and the combo wafer gives you the best of both.

Supplied by United Rotary Brush Corp.

"Once you have the tube broom lined up you just slide it on and you're done," Staab says. "So it is much quicker than loading wafers."

Staab says tube brooms and wafer brooms are not as stiff as strip brooms. "If you put your hand on a tube or wafer broom and push the filament back there is less resistance than doing the same thing with a strip broom because the filaments in a strip broom are packed together in a channel so they are a lot stiffer, a lot more resistant. So if you need a really aggressive broom that really gets in there and digs you would look at a strip broom."

Recruitment Woes Hit the Sweeping Industry

It seems like everywhere I hear of power sweepers who are struggling to get bodies behind the wheels. It is not only this industry but many industries. Many companies are asking what they can do to attract and retain employees. One way that seems to be adding value and helping with retention is employee training. There is a perception of value when an employer invests in the training of their employees. Training employees to do their job correctly trickles down into pride in their career as well as enhanced professionalism for the company. So where can you find professional training for the power sweeping industry?

Years of blood sweat and tears for dozens of NAPSA members and beta testers have culminated in the release of multiple powerful training tools. Certified Sweeping Operator (CSO) programs have come online for Parking Lot and Construction sweeping. Municipality is slated for the future. These operator training programs create a great baseline of training for improved professionalism in your drivers. These can be found at www. SweeperSchool.com. Upon completion of CSO, the owner will give the driver a verbal test and then certify that they have at least 1,000 hours of incident free sweeper driving. NAPSA will then issue the driver a certificate, hat pin and uniform patch recognizing their effort.

The second training option available at www.SweeperSchool. com is our Certified Sweeping Manager series. This training track teaches about the Power Sweeping Standard. Managers gain valuable insight to the standard which translates to better management in your operation. Lastly, there is a course called Fleet Basics. This course covers general topics for anyone who isn’t behind a wheel but may need to speak the lingo. It is worth the $20 hands down.

The education found at SweeperSchool is invaluable. NAPSA members receive deep discounts on the training at SweeperSchool. For more information, contact the North American Power Sweeping Association at info@ powersweeping.org or 888-7570130.

The North American Power Sweeping Association (NAPSA) is a nonprofit association made up of 200+ contract sweepers, service providers and sweeping equipment dealers, manufacturers and suppliers. NAPSA is dedicated to providing beneficial support to the membership and enhancing services to the sweeping industry. NAPSA is committed to promoting and educating the power sweeping community while enhancing the environment. For more information on NAPSA membership, please visit www.powersweeping.org or call (888) 757-0130.

Keeping Your Company 'Safe' From Potential Purchasers

If you receive a call from a private equity firm be sure to protect your business' confidentiality

by Ranger Kidwell-Ross

Because of the apparent success of the private equity company behind the continuing expansion of Sweeping Corporation of America (SCA) — which now boasts being in 40+ markets — larger sweeping contractors have reported numerous contacts from SCA and other private equity (PE) firms. If you receive a call from one and want to find out more, be sure to protect your business’ interests.

Before providing a PE or anyone else with confidential information about your company, make sure to have a non-disclosure agreement in place. Also find out if the PE already owns any other sweeping companies. If so, see what you can find out about those previous purchases.

Perhaps the most important factor for the PE will be confirming there is an excellent management team in place, since they often will not be involved in day-to-day operations after purchase.

Essentially, PE purchasers view your business from a mathematical perspective. They are all about increasing your growth after sale, so to increase your value to them show how your company is positioned for that possibility. In order to maximize the multiple of EBITDA (Earnings Before Interest, Taxes, Depreciation and Amortization) you end up receiving, show in as mathematical a manner as possible why your company is a good purchase prospect.

PE firms tend to purchase companies that require little initial additional investment. They are also calculating their potential exit strategies as they negotiate any sale. The advantages of selling to a PE firm can be many, including obtaining additional capitalization needed for growth. However, before you open your books to a PE firm or anyone else interested in buying your company, it’s vitally important that you do some research about the best protocol to follow.

WSA contributor Ranger Kidwell-Ross has been providing information to the power sweeping industry since 1988. He is editor of WorldSweeper.com, an information resource for power sweeping, as well as founder and executive director of the World Sweeping Association. For more information about WSA visit www. WorldSweepingPros.org or contact Kidwell-Ross at director@ worldsweepingpros.org.

PCTC Keeps Close Eye on Trends in the Post-Pandemic Era

There are challenging trends starting to emerge

The post-pandemic era will bring with it many challenges to the skilled and unskilled labor market, with an unusual impact on the construction industry. According to a recent report by McKinsey titled, The Future of Work after COVID-19, the most immediate and lasting impact will be felt by organizations that will grapple with an ongoing remote or hybrid workforce.

This presents its own set of challenges for firms with their entire workforce under one roof with employees who perform most tasks via computer or at their desks. However, things aren’t quite as clear within the construction industry where the workforce is often split between inside and field employees and at times divided even further within the office. In the pavement coatings industry, we are seeing a few challenging trends emerge.

As our members continue to keep a close eye on trends within their centers, we’re seeing a few key trends emerge. When asked if they were having difficulty in recruiting new employees, 100% of members polled replied yes. “We’re finding it difficult to fill labor positions and full-time office positions on campus,” replied one PCTC member. “This is forcing us to fight two distinct battles with two very different consequence, both of which have the potential to simultaneously disrupt production, our culture and internal engagement.”

Conversely, and perhaps the silver lining in the post-pandemic era, 100% of respondents

For more about PCTC visit www.pavementcouncil.org.

stated that retaining current employees was not a challenge. However, there’s no telling how long that will last. “There is an expectation of working from home instead of on site. This may force more automation moving forward for manufacturing and certain aspects of contracting/accounting/sales will undoubtedly begin to look very different.”

In the pre-pandemic era, leaders within the pavement coatings industry, like many other related industries, fought their own set of battles. These same leaders will undoubtedly and quickly develop a new set of skills to help them navigate their companies and their teams through a new environment.

PATENTED & PATENTS PENDING

CURB CLEANING SYSTEM

- Curb Cleaning - Gum Removal - Crack Cleaning - Pressure Washing - - remove striping paint - Water broom - And more! -

Water recovery options

Features 2 adjustable nozzles to fit any curb!

Multi-tool

Attaches to your mw30 to remove gum, crack clean, and more!

MysticWasher® Cleaning System MW30 4.0 GPM 4200 PSI

Winning More Bids With Drone TECHNOLOGY

How one contractor started using drones on his jobs and how it is moving his business forward.

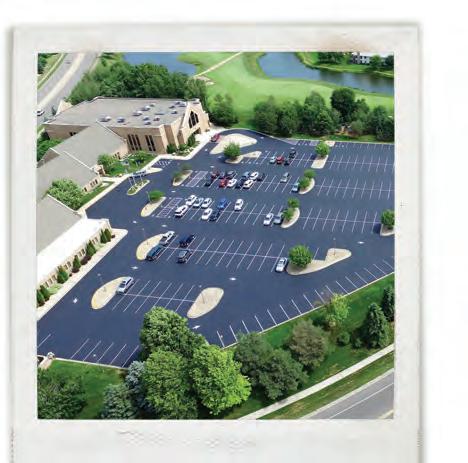

RANDY NUGENT, owner of Nugent Sealcoating & Paving, Minneapolis/St. Paul, is a firm believer in aerial photos for impressive projects. So he has taken a step that he says "provides greater control over the photos, better pictures and at times, has won more bids for the company."

“It’s actually gotten me some jobs I probably wouldn’t have gotten otherwise,” said Nugent. “Some people get really excited about aerial views of their parking lots and property.”

How it All Began

Nugent started his company in 1991 with a plastic tank attached to his rusty 1984 pickup truck.

Today all his work is mostly commercial, but does offer some residential services like driveway sealcoating, seam filling and garage door apron replacement. Nugent and his crews pride themselves on professional attention, in particular they use the standard MNDOT method to crackseal. "Many of our competitors do not follow this method," said Nugent. "It begins with routing the cracks to a width and depth of approximately 3/4-in. The cracks are then thoroughly cleaned. The cleaned cracks are filled with crack sealer brand Deery 3723, which exceeds all MNDOT requirements of 3405. As a final step, paper is applied as a bond breaker to allow for immediate traffic use, unless sealcoating is to immediately follow."

This attention to detail in the finished work propelled Nugent to offer before and after photos for his customers. "I started because I was interested in the picture aspect I could get by flying drones."

Hone in the Drone Skills

Self-taught, Nugent started using drones because he was interested in the pictures he could get by flying over jobsites, getting a bird's eye view perspective. He purchased his first drone in 2013, one that he had to attach a GoPro camera to because the first generation drone did not have a built-in camera. He would operate it around his house, under trees and wires to practice his flying techniques because he knew he would have to maneuver those types of obstacles. "Practicing really helped me get comfortable with flying" said Nugent. "When I first started out, I may or may not have gotten it stuck in a tree or two. There will be a few crashes along the way but drones are very durable. The worst thing I have had to do is replace the rotors."

Technology advancements in the drone sector has grown in many aspects. Drone manufacturers are offering customizable flight path options, enhanced photo and video quality, and even collision avoidance.

"The best advancement, in my opinion, is the ability to do everything through your phone," said Nugent. "I can watch through my phone and decide exactly which photos to take. In fact, I don't even watch the drone anymore when I fly. There is GPS built in so I know exactly where it is at all times and I can have it fly back to within a few feet of takeoff and land itself."

For Nugent, he utilizes his drones on a daily basis for photos and videos of jobs to gain a competition advantage. "If there is a job that I know there will be a fair amount of competition on, I use the drone to my advantage," said Nugent. "Prospective and existing customers love the fact that we will send them aerial photos of their property for free with a contract. I use it for larger jobs or sites, greater than 80,000 square feet, that I know will be great for before and after photos."

Randy Nugent of Nugent Sealcoating & Paving is a firm believer in aerial photos for impressive projects. Randy Nugent uses before and after photos and videos to gain a competitive edge against his competition.

SQUEEGEES, SEALCOAT TRAILERS, SEALCOAT SKIDS, HOT TACK SKIDS

200 GALLON HOT TACK 500-700 SEALCOAT TRAILERS 350 GALLON SKID

DISTRIBUTORSHIPS AVAILABLE VISIT SEALMATE.COM

Advertiser Index

Astec Inc.

Bomag Americas

Buffalo Turbine LLC

Crafco Inc.

Dispensing Technology Corp.

Dynapac North America

Elgin Sweeper

EZ-Liner Industries

IGNITE Construction Summit

Keystone Plastics

KM International

Laserline Manufacturing Inc.

LeeBoy, Inc.

MRL Equipment Company

N I Wilson Mfg 67

11

44

5

42

15

2

42

59

40

21

45

31

39

44 PAGE

Advertiser Index

NEAL, A Div. of Blastcrete Equipment

Neyra Industries of Ohio

Odra Road Sweepers

Old Dominion Brush Co.

Pecora Corp.

Perma-Patch

RAE Products & Chemicals Corp.

Schwarze Industries, Inc.

SealMaster

Star Inc.

Unique Paving Materials

Weiler Products

Wirtgen America Inc.

Index

7

43

40

45

20

45

44

13

68

25

41

35

19 PAGE

Trading Expediency for SAFETY

OVER THE PAST few months of increased scheduling of projects, I’ve witnessed first-hand many poor decisions, many that were even risky decisions, impacted by the need to be fast in completing projects. When too much speed and workers collide, it often ends in a not so positive result.

With the huge release of work that has now permeated almost every state in the United States, contractors can’t find enough workers, and time, to complete the amount of work that customers are crying to complete. And when such demands are scheduled, with little room to breath between projects, it is almost a given that field leaders can and will shorten or eliminate some precautions for safety. Let me give you one example that probably fits every reader of this article.

The presence and use of what most contractors call the “quickie saw,” has become a normal part of most contractor’s equipment and tool resources. Used by both asphalt and concrete contractors, it is the “quickie saw” that allows a crew to quickly trim off an area or to cut a small square footage of concrete that can then be torn out by the skid steer with the appropriate attachment. If this process is performed safely, the use of such a tool is great…doing exactly what it is designed to perform. However, because so many foremen feel hurried to complete their work, a crew worker will quickly be instructed to grab the “quickie saw” and start cutting. However, here is what most foremen often forget to remind their sawcutter to wear…their PPE including: • No watering system (directly or manually applied) to help reduce dust from the cutting effort • Lack of face shield and/or face mask to reduce both any flying debris or dust inhalation • Ear plugs to reduce the decibels put off from the saw • Hard hat to keep any accidental material from

hitting the head (at an accelerated mph) • Gloves that can prevent material debris from scratching or cutting their hands, wrist, etc. • Long-sleeve shirt that can protect any debris from scraping or cutting their arms • Safety glasses which are perhaps THE MOST critical piece of PPE

As contractors, we must protect our workers and we cannot trade expediency of getting jobs done more quickly for the safety hazards that await such trade-offs. I’ve seen the invaluable “quickie-saw,” with a guard properly in place, still send material out the rear and bounce off a curb or other item that finds it way into the eyes of a worker not wearing safety glasses. Fortunately, it was nothing more than an irritation for the worker, but accidents are reported every year as to the serious injuries that can occur to those using the saws or those working close by that do not have on the appropriate PPE.

Hey contractor and construction leader, unless your foreman is especially disciplined to always ensure that their workers are safely prepared, it is only normal to think that they might forego all the proper PPE at the moment of having to use the saw. Our role is to influence them to the point where they instinctively choose safety over expediency.

Just think about this point, in less than 60-90 seconds the worker can put in place all of the needed PPE to safely operate the saw. Isn’t the safety of our workers, no matter how tight the schedule, more important to our long-term success?

Here’s to slowing down the decision-making process just a few seconds to strengthen employee safety.

Brad Humphrey is Vice President of HR & Employee Development for Pavecon, a pavement maintenance leader in the industry. Brad is also known as The Contractor’s Best Friend. You can listen to Brad on the The Contractor’s Best Friend Podcasts, sponsored by Caterpillar and A.C. Business Media. Be sure to sign up for Brad’s workshops at the 2022 National Pavement Expo in Charlotte NC, February 23-25.