13 minute read

Money Matters

by Focus

focus_contributor.

MONEY

MATTERS

with BARRY HOCKEY

ACCOUNTANTS

MORTGAGE VS SUPER

If you have a mortgage, should

you make extra repayments or would you be better off in the

long run boosting your super? The answer is, it depends. Your personal circumstances, interest rates, tax and the investment outlook all need to be taken into consideration. What to consider - Some of the things you should weigh up:Your age and years to retirement. The closer you are to retirement and the smaller your mortgage, the more sense it makes to prioritise super. Younger people with a big mortgage, dependent children, will need to wait until age 60 before accessing super. So better to pay down housing debt, perhaps building up investments outside super. Your mortgage interest rate. This will depend on whether you have a fixed or variable rate, but both are on the rise. As a guide, the average variable mortgage interest rate is currently around 4.5 per cent so any money directed to your mortgage earns an effective return of around 4.5 per cent. When interest rates were at historic lows, you could earn better returns from super and other investments; but with interest rates rising, the pendulum is swinging back towards repaying the mortgage. Super Fund Returns. In the 10 years to 30 June 2022, super funds returned 8.1 per cent a year on average but fell 3.3 per cent in the final 12 months. In the short-term, financial markets can be volatile but the longer your investment horizon, the more time there is to ride out market fluctuations. Tax. Super is a concessionally taxed retirement savings vehicle, with tax on investment earnings of 15 per cent compared with tax at your marginal rate on investments outside super. Contributions are taxed at 15 per cent going in, but this is likely to be less than your marginal tax rate if you salary sacrifice into super from your pre-tax income. Personal sense of security For many people there is an enormous sense of relief and security that comes with having a home fully paid for and being debt-free heading

Contributions are taxed at 15 into retirement. As per cent going in, but mortgage interest this is likely to be payments are not less than your tax deductible for marginal tax rate if the family home (as you salary sacrifice opposed to investment into super from your properties), younger pre-tax income. borrowers are often encouraged to pay off their mortgage as quickly as possible. But for those close to retirement, it may make sense to put extra savings into super and use their super to repay any outstanding mortgage debt after they retire. All things considered. As you can see, working out how to get the most out of your savings is rarely simple and the calculations will be different for everyone. The best course of action will ultimately depend on your personal and financial goals. Buying a home and saving for retirement are both long-term financial commitments that require regular review. This is general information so you should seek the assistance of a financial advisor to discuss your personal circumstances.

A SPECIAL FOCUS FEATURE

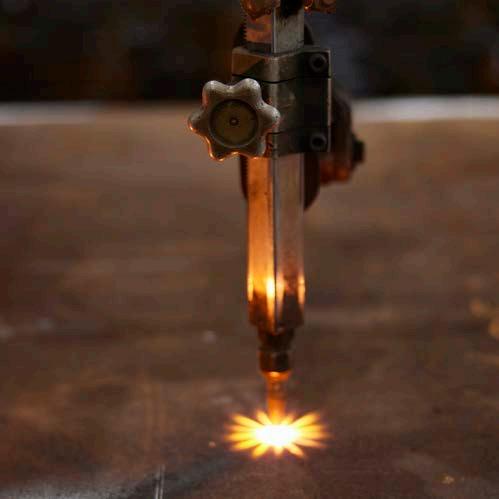

PACIFIC

ENGINEERING

United Pacific Engineering is a privately owned Australian Engineering Company providing innovative engineering solutions. The company moved to new premises in 2020 at Hamilton Drive Boambee NSW Australia. The move into these premises has greatly expanded the company’s capability to provide a greater range of engineering services. The facilities include over 7500 m² of workshop area serviced by high capacity cranes and 10,000 m² hardstand area.

Take us back to the beginning… What is the History of United Pacific Engineering and how have things changed since conception?

United Pacific Engineering was founded in 2009 as a new enterprise. The original site was in Englands Road Boambee and the factory and workshop facilities had been established by “Isles Forge and Engineering “ who relocated to the site after moving from the location now known as the Bailey Centre. Isles Forge had a strong history of servicing the local timber, mining and agricultural industries throughout the region. Their products included cranes, earthmoving equipment, timber milling plants and a whole host of specialist equipment which helped build the region. Initially UPE had only a handful of staff, but has grown steadily and now boasts a strong and skilful workforce that includes not only highly skilled tradesmen and apprentices but a Project Management and Engineering Team that boasts a diverse array of skills and experience.

Can you tell us a little bit about your background and experience in this industry?

The Managing Director of United Pacific Engineering is John Fuller. John began his career as a Metallurgist at the BHP Newcastle Steelworks, before moving to Goninan where he held several roles in the Laboratory, Iron Foundry, Heavy Fabrication shop and Engineering office before settling into the role of “Welding Engineer”. Moving around during his early career John has gained experience in a wide variety of technical, project and management roles across a broad range of heavy industry. Originally John moved to Coffs Harbour to work for W.E. Smith Engineering as a Welding Engineer, during this time he and his family fell

in love with the area. John then returned to Newcastle to continue his career moving into the frontline management in heavy engineering and fabrication. The call of the beautiful Coffs Harbour region was too strong and after a couple of years John took an opportunity to return to the area with Boral Asphalt working in Senior Management roles for over 10 years. John also has a unique understanding and passion for welding. Being somewhat of a welding geek, he holds significant qualifications in this field including International Welding Specialist, International Welding Inspector, Certified Pressure Equipment, Welding Supervisor, Certified Structural Steel Welding Supervisor. John’s love of Welding and Engineering Fabrication finally drew him to establish United Pacific Engineering in 2009.

Who makes up your team and what are their roles?

Today the UPE Team has grown to include many talented individuals who work together to ensure that effective solutions are delivered to our customers. Instrumental in the development of our team is Rob McComas who has been with us for approximately 10 years and brings a vast array of practical experience and problem solving skills to the team. His particular expertise is in the machining and fitting areas courtesy of his trade background which began as an apprentice with Isles Forge and Engineering and includes many years in a supervisory role with WE Smith Engineering. Bob’s experience is invaluable, his wealth of supervisory and hands-on experience in complex set out, high quality machining, fitting and testing make him a guiding light in our workshop. Our office and financial activities are managed by Kerrie who came to us shortly after we commenced operation and told John that “she thought she could help us run a pretty efficient office“ she was correct! Kerrie ensures that all the little things get done at the right times as well as sorting a lot of life’s little dramas for the boys in the shop. Our Project Management team includes the following key staff:Jordan Helgeton who has a range of mechanical design experience in the mining industry including both below ground and mill projects. He also has experience in the Canadian Oilfields installing tanks and piping for oil leases as well as repair and servicing of bulk materials handling systems. Jordan has been in our team for several years and has been instrumental in the operating, maintenance and repair of

Moving around during his early career John has the CNC Plasma Cutting Machines as well as his gained experience in normal roles in project a wide variety of management, design and technical, project and drafting. management roles Tyler Kemp, with formal across a broad range qualifications as a of heavy industry. Mechatronics Engineer has been with us for approximately 1 year and his initial role was as Quality Manager for large projects. He has quickly moved into project management and is adding a valuable skill set to the team. He provides expertise to the adaptation and manufacture of equipment for both internal and client use. James Morrison a formally qualified Mechanical Engineer with several years experience in project management. His special skill set is vehicle modification and structures design. He has recently joined us and adds strength to the overall project team. Ben Price who is formally qualified as an International Welding Specialist and Also as Pressure Vessel Welding Supervisor has joined us this year, he adds further strength to our Welding Technical Credentials We also have a small group of independent experienced engineers who provide mentoring and guidance for our team and are available to assist with challenges as they arise.

Continued over...

What type of services do you provide?

We make and repair almost anything!. Heavy fabrication and conventional machining are our bread and butter. We have equipment capacity rarely seen outside of large cities and industrial areas, but we also are able to do finer intricate works. No job is too big or too small.

Tell us about the advantages of the unique machinery you use.

With a maximum lift capacity of 125t within the workshop and multiple gantry cranes we can undertake quite large works. The range and capacity of our equipment and the fact that it is all under one roof lets us efficiently undertake a full engineering adventure. We can cut, form and weld steel plate 100mm thick, we can machine round components up to 3000 mm diameter and straight items many metres long.

What makes United Pacific Engineering different from other companies in the local area?

The strength and diversity of our team, our unique array of equipment, and our understanding of materials and welding technology, combine to give us a problem solving ability second to none. We are not a simple fabrication shop, but a truly one stop engineering service, here in Coffs Harbour..

What is the best advice you can give to a prospective customer?

Get professional advice, ask all the “stupid” questions before you start the physical work, it’s much easier to fix things on paper! And the collective experience of a professional and experienced team can be a huge benefit!

Do you offer solutions for budgets of different sizes?

Certainly, we understand the value of things and will often advise and assist people to do a lot of work themselves in order to save money. We also take care of the whole service, ensuring that correct parts, materials and expertise are used to provide a complete solution. If something is better provided by others we will recommend them. Get professional Our normal workload advice, ask all the includes simple items “stupid” questions from cutting and selling before you start the small pieces of material physical work, it’s for customers own much easier to fix projects, straightening things on paper! bent beams or guards through to the manufacture of high quality process plant and equipment for large industry.

How has the local building and construction industry changed over the last few years?

The whole area has really developed and the traditional family based companies are being replaced with larger corporations

often based in major centres and attracted by the size of individual projects. The internet has also seen wider access to services from outside the area meaning that we no longer have to compete in a local sense but in a much wider field. We have also benefited from this and our client base has grown and we now manufacture equipment for clients all over the country. The upcoming Pacific Highway Project is one where we are capable of performing a large volume of the work but will need to compete with others from far and wide.

Tell us about the most challenging engineering projects you’ve worked on

Over the years we have undertaken a wide variety of challenges and each week there is something to test our

The upcoming skills, be it a broken

Pacific Highway machinery part or a Project is one where piece of artwork there we are capable of is always something performing a large new. volume of the work Currently we are but will need to nearing completion compete with others of a very challenging from far and wide. Project. It involves some very complex fabrication work to build a set of 12 identical units which are basically very large steel “Dyson” type air filters for a mineral processing plant. There are many parts to be cut and formed to complex shapes from 10 and 12mm thick steel plates. This project was quoted during the COVID period and we decided to undertake 95% of the cutting and forming works in-house. The workmanship from our team has been exceptional and this project is one of the most interesting that we have undertaken as a team.

What are your plans for the future of United Pacific Engineering?

The future plans are to continue to grow steadily and to ensure that the current facilities and expertise available are built upon to allow stable employment and locally available engineering skills and services well into the future.

How important is it to you to support local?

We are very much part of this community and want to continue to employ and train local staff but also provide opportunities for those with experience from other areas to settle here and increase our knowledge and skills base as we grow with the region.

How can we get in touch?

www.unitedpacificeng.com 02 6652 2066

The manufacturing plant and equipment are capable of handling large pressure vessel manufacturing, rolling of heavy wall barrels & fabrication of custom made welded beams. These manufacturing capabilities are only generally found in major cities or International corporations.

Our workshop team includes a healthy balance of highly skilled Craftsmen and Apprentices who provide the skills and enthusiasm to provide a “one stop” engineering service for our clients.

UNITED PACIFIC ENGINEERING IS A PRIVATELY OWNED AUSTRALIAN ENGINEERING COMPANY PROVIDING INNOVATIVE ENGINEERING SOLUTIONS.