Sea lice – Steinsvik

Now – the Thermolicer boat Norwegian firm building vessel to ‘perfect’ thermal delicer

S

TEINSVIK has designed and is planning to build integrated Thermolicer vessels. The company has had major successes with its Thermolicer machine, an environmentally friendly and highly effective way to treat salmon and trout for sea lice. The Thermolicer is a commercially available method for the industrial scale dip treatment of salmon and trout - the brilliance of it is that the only treating agent is heated seawater. So far, about two million tonnes of fish have been deliced with the Thermolicer in the regular containerised units – which have been sold to customers in Norway, Chile, the UK and the Faroes. The Thermolicer principle Elliot et al (1981) showed that salmonids can withstand temperatures of 30-34 °C for a short time. (30 minutes for trout, S. trutta). The same levels are not established for sea lice but their tolerance is naturally lower due to their comparable small size. The Thermolicer utilises the fact that sea lice have a large surface area compared to their volume, which makes the lice immediately sensitive to sudden temperature changes. By suddenly heating the lice, they fall off the fish. All lice in the system are then filtered and safely disposed of by filters at 150 microns. No compromises Sales manager for the Thermolicer in Steinsvik, Tore Laastad, explains that so far all installations have been done on boats and barges chartered or bought for use with the Thermolicer. However, fitting a complex system on an existing vessel more often than not means that compromises have to be made. ‘The placement of various components is not exactly where we wanted them to be,’ said Laastad. ‘Extra space for technicians and other personnel was sacrificed for fish health purposes.

52

Steinsvek PED.indd 52

‘In short, we knew we could make the perfect Thermolicer vessel but then we would need to design the boat around the Thermolicer and not the Thermolicer installation to fit the boat. So that’s what we did. ‘In 2016 we started the process of designing the perfect delicing vessel. Not only did we have the design done from scratch, we also redesigned the Thermolicer unit itself. ‘The goal was to optimise fish health and simplify the delicing process for the farmers: our answer is the Integrated Thermolicer vessel.’

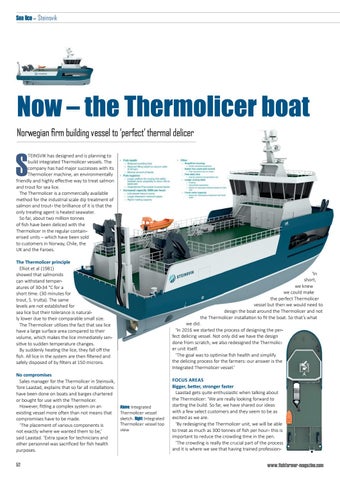

Above: Integrated Thermolicer vessel sketch. Right: Integrated Thermolicer vessel top view

FOCUS AREAS Bigger, better, stronger faster Laastad gets quite enthusiastic when talking about the Thermolicer: ‘We are really looking forward to starting the build. So far, we have shared our ideas with a few select customers and they seem to be as excited as we are. ‘By redesigning the Thermolicer unit, we will be able to treat as much as 300 tonnes of fish per hour - this is important to reduce the crowding time in the pen. ‘The crowding is really the crucial part of the process and it is where we see that having trained profession-

www.fishfarmer-magazine.com

07/02/2017 15:19:22