7 minute read

Navigating the transition to sustainable firefighting foams: Key factors for system compatibility

Navigating the transition to sustainable firefighting foams: Key factors for system compatibility

The global firefighting industry is undergoing a significant transformation as regulatory and environmental pressures drive the transition from traditional aqueous film-forming foams (AFFF) to sustainable alternatives. For high-hazard industries reliant on Class B firefighting systems, this change represents a pivotal moment. It introduces the opportunity to adopt safer, environmentally friendly foams and the challenge of adapting existing systems to maintain performance and safety.

This shift away from fluorinated foams, including those containing Per- and Polyfluoroalkyl substances (PFAS), marks an important step in addressing environmental and health concerns.

Historically, firefighting foams contained long-chain PFAS compounds such as PerfluoroOctane Sulfonate (PFOS) and Perfluorooctanoic acid (PFOA), widely recognised for their environmental persistence and toxicological risks. These compounds, known as C8 foams due to their eightcarbon chain structure, were commonly used until concerns over bioaccumulation and water contamination led to restrictions.

In response, manufacturers transitioned to shorter-chain alternatives, such as PerfluoroHexanoic acid (PFHx) found in C6 foams. While these shorterchain compounds were marketed as safer options, they remain environmentally persistent and their potential long-term impacts continue to be studied. This has prompted a global shift toward synthetic Fluorine-free foams (SFFF), certified by frameworks such as Greenscreen.

The following sections provide a comprehensive guide to understanding the critical factors affecting the performance and compatibility of these new foams in existing fire suppression systems.

These considerations include foam expansion characteristics, viscosity and flow dynamics and application rate requirements. By addressing these factors, end-users can ensure a smooth transition to sustainable foams without compromising fire safety standards.

1. Expansion characteristics: adapting system design and discharge devices

Foam expansion, the ratio of foam volume after expansion to its original liquid volume, after mixing and aerating, is a fundamental property that influences the foam's ability to cover and suppress fires. Historically, AFFF was designed to produce high expansion ratios, which made it particularly effective in forming a stable, durable foam blanket over flammable liquids.

Impact on discharge devices

Discharge devices such as monitors, nozzles and pourers are designed to operate within specific expansion parameters. When transitioning to environmentally friendly foams, the expansion characteristics may differ significantly, necessitating adjustments to discharge equipment:

Device compatibility:Many Fluorine-free foams, such as SFFF, tend to produce lower expansion ratios than traditional AFFF. Existing discharge devices optimised for high-expansion foams may fail to deliver adequate coverage or a sufficiently thick and stable foam blanket.

Recalibration or replacement:To achieve optimal performance, discharge devices may require recalibration to match the properties of the new foam. In some cases, replacement with equipment specifically designed for low-expansion foams may be necessary, particularly in high-risk applications such as fuel storage facilities or chemical plants.

System-wide design adjustments

The expansion characteristics of environmentally friendly foams influence not just discharge devices but the overall system design:

Foam coverage:Systems designed for AFFF may deliver insufficient foam coverage with lower-expansion foams, potentially requiring increased foam volumes or reconfiguration of discharge layouts to maintain equivalent performance.

Water supply demands:Environmentally friendly foams may require more water to achieve similar expansion ratios, which can strain the system's water supply infrastructure. Upgrading water flow capacity, increasing storage tank sizes or installing booster pumps may be necessary to meet these higher demands.

Matching approvals:Systems designed and approved according to standards such as FM, UL, VdS, etc, means the individual components of the foam concentrate, foam discharge devices and proportioning system must match. Otherwise, the approval is void.

Considering the complete system design, an increase in expansion ratio means the complete system can potentially be addressed by changing to discharge devices providing better expansion rations, where possible, while ensuring any common standards are met, ie UL, FM etc. This potentially has the least impact on an overall system if addressed.

2. Viscosity and its influence on proportioning and flow dynamics

Viscosity or the thickness of a liquid plays a critical role in foam proportioning and system flow dynamics. Fluorine-free foams often have higher viscosities than AFFF, presenting unique challenges for proportioning equipment and system efficiency.

Impact on proportioning equipment

Proportioning systems mix foam concentrate with water at a precise ratio to ensure consistent foam performance. The higher viscosity of environmentally friendly foams can affect this process:

Pump performance:Many existing systems use pumps designed for low-viscosity AFFF, which may struggle to handle thicker fluorinefree foams. This can lead to inconsistent proportioning, requiring pump upgrades or adjustments to maintain proper performance.

Eductor compatibility:In-line eductors, commonly used for foam proportioning, may not function effectively with highviscosity foams. Larger or specifically calibrated eductors may be needed to achieve the correct foam-to-water ratio, necessitating consultation with system manufacturers.

System flow dynamics

The increased viscosity of fluorine-free foams affects how they flow through pipes and hoses:

Pressure loss:High-viscosity foams create greater friction within pipes, leading to pressure drops and slower foam delivery. Systems originally designed for lowviscosity AFFF may require reconfiguration, such as increased pipe diameters or the addition of booster pumps, to ensure efficient foam delivery.

Testing and calibration:After transitioning to Fluorinefree foams, system testing is essential to identify flow inconsistencies, pressure variations or bottlenecks that could compromise firefighting effectiveness. Testing with a wide-range proportioner not affected by flow or pressure can provide both peace of mind and a cost-effective solution to increasing costs of foam concentrate.

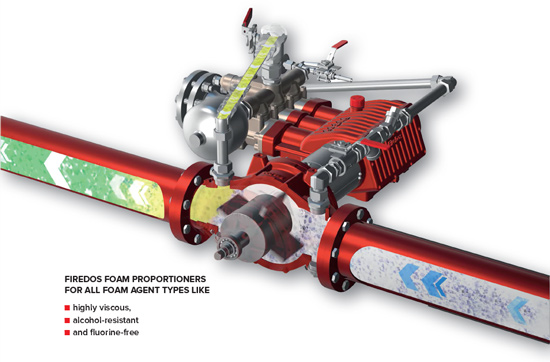

The viscosity of foam concentrate affects the proportioning element of the system. This can be addressed using water-driven foam proportioners, such as those manufactured by FireDos, due to their adaptability to different foam types. Educted systems relying on a Venturi for accurate proportioning are sensitive to flow or pressure fluctuations, leading to inconsistent foam quality. Although historically effective, Venturi-based systems may present problems with correct proportioning rates.

Where a single foam system protects multiple hazards, this change in viscosity primarily affects the foam proportioning element of a foam system. FireDos waterdriven foam proportioners provide the advantage of a centralised foam system due to their inherent adaptability to multiple foam types with multiple viscosities, such as the non-Newtonian, shearthinning and pseudoplastic foam concentrates, sometimes typical properties of SFFF concentrates.

Additionally, as the system automatically proportions at the correct percentage across a broad flow rate range, commissioning and maintenance are inherently very simple, as no calibration is required.

3. Application rate: ensuring effective fire suppression

The application rate, measured in litres per minute per square metre (l/min.m2) or gallons per minute per square foot (gpm/ sq.ft), defines the amount of foam concentrate needed to extinguish a fire effectively while maintaining coverage.

With environmentally friendly foams, application rates often differ from those of AFFF, requiring adjustments to meet performance standards. As AFFF and alcohol resistant-AFFF (ARAFFF) have been used to great effect on multiple petrochemicals and crude oil, the same cannot be said for SFFF as a ‘one size fits all’ solution. This means the onus is on the end user/foam manufacturer to provide test results for specific compounds.

Adjusting discharge systems

Environmentally friendly foams may require higher application rates to achieve the same level of fire suppression:

Increased discharge capacity:Discharge devices, such as monitors and sprinklers, may need recalibration or replacement to meet the higher flow demands of sustainable foams. Additional discharge points or devices with higher output capacities may also be required.

Foam blanket stability:Maintaining a stable foam blanket is critical for suppressing fires involving flammable liquids. Testing is essential to determine the correct application rate and ensure the foam type can sustain fire suppression over time.

Water supply and system automation

Higher application rates have broader implications for system infrastructure:

Water supply enhancements:Increased water demands may necessitate larger storage tanks, higher-capacity pumps or backup water sources to sustain prolonged firefighting operations.

Real-time monitoring:Advanced control and monitoring systems can help manage application rates dynamically, ensuring optimal foam output during firefighting operations.