5 minute read

Are we endangering the lives of our firefighters?

Are we endangering the lives of our firefighters?

By Lenny Naidoo; contributor: Jackie De Billot

Firefighters consistently face life-threatening situations that put their health and safety at risk. In many industries, personal protective equipment (PPE) serves as the last line of defence against hazards.

While PPE is often considered the least effective method for controlling workplace risks according to the Hierarchy of Controls, for firefighters, eliminating or substituting hazards is typically not feasible. This makes PPE the most critical form of protection in an environment that is unpredictable and often chaotic.

The importance of firefighter PPE

Firefighter PPE is not as straightforward as it might seem. Several factors must be considered to ensure the safety and effectiveness of this gear, including:

What are the relevant international standards for firefighter PPE?

What training is necessary?

Is there an appropriate standard operating procedure (SOP) for the use of PPE?

Is there an SOP for the care and maintenance of PPE?

Are all stakeholders aware of the above, including the procurement team?

Is there a requirement for continuous physical and medical fitness for operational firefighters who are expected to use full firefighter PPE?

This article will focus on the first item: International firefighter PPE standards. Future articles will address items 2 to 6.

International standards for firefighter PPE

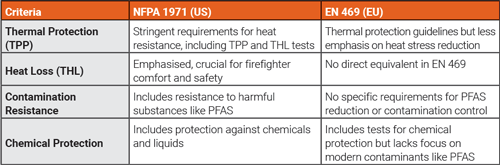

When it comes to firefighter PPE, there are two primary standards that govern the protective gear used in the field: NFPA 1971 (US) and EN 469 (Europe). These standards are designed to ensure the safety of firefighters by specifying rigorous testing protocols for the PPE they rely on. While both standards are meant to protect firefighters, they differ in certain areas.

NFPA 1971 - US Standard for Structural Firefighting PPE

The NFPA 1971 standard is recognised as one of the most comprehensive for firefighter PPE. It covers a broad range of protective measures, requiring rigorous testing in various areas, including:

Thermal Protective Performance (TPP) and Total Heat Loss (THL): These tests are essential for evaluating a garment's ability to protect against extreme heat. TPP measures how long it takes for heat to penetrate the fabric, while THL evaluates how well the PPE allows the body to release heat and moisture.

Protection against flames and heat: The standard includes tests for flame resistance, heat resistance and garment durability.

Contamination resistance: Recent updates to NFPA 1970 (part of the NFPA 1971 suite) include stronger mandates for contamination resistance and the inclusion of particulateblocking hoods.

A significant shift in NFPA 1971 is its focus on reducing PFAS (per- and polyfluoroalkyl substances) in firefighter gear. Manufacturers have been given until September 2024 to comply with these new regulations, though this timeline may be extended as testing protocols are finalised.

Key features of NFPA 1971

Thermal protective performance (TPP) and total heat loss (THL) ratings

Protection against heat, flame and liquids

Resistance to viral penetration

Contamination control measures in line with PFAS testing updates (NFPA 1970)

Advanced testing for durability, including seam strength and tear resistance

EN 469 - European Standard for Structural Firefighting PPE

The EN 469 standard, which is followed in Europe, also ensures firefighter safety but with notable differences:

Thermal protection: EN 469 has guidelines for heat resistance but does not mandate the same TPP or THL testing as the NFPA 1971, meaning it may not address firefighter heat stress as thoroughly.

Protection against chemicals: EN 469 covers protection against hazardous materials like chemicals but it lacks the detailed PFAS-specific tests found in NFPA 1971.

Focus on comfort and mobility: EN 469 places greater emphasis on comfort and ease of movement, which is crucial during prolonged operations, though this may slightly compromise some of the heat protection standards found in NFPA 1971.

Key features of EN 469

Guidelines for heat protection and resistance to flame

Tests for liquid penetration and chemical resistance

Focus on comfort and ergonomics for better mobility

No standardised PFAS testing or contamination control

The PFAS dilemma in firefighter PPE

A growing concern in recent years has been the presence of PFAS chemicals in firefighter PPE. These substances are used for their water- and stain-resistant properties but have been linked to serious health issues, including cancer and liver damage.

While NFPA 1971 has taken steps to address PFAS reduction, EN 469 does not yet have specific provisions for managing PFAS in PPE. This raises concerns for firefighters in European jurisdictions, who may be exposed to the risks of PFAS contamination without sufficient regulatory oversight.

As the NFPA 1971 standard continues to evolve, the NFPA 1970 (2025 edition) will place a greater emphasis on contamination resistance, especially regarding harmful chemicals like PFAS. However, because developing testing methods for PFAS reduction remains a challenge, the full compliance deadline could be extended until early 2026.

Conclusion: Firefighter safety first

Given the lack of PFAS-specific regulations which is surprising in EN 469, firefighters in regions following this standard may not be fully protected from the health risks posed by these chemicals. However, NFPA 1971 is actively addressing the issue and pushing for PFAS-free firefighter PPE. Until more comprehensive standards are in place, fire departments should continue to rely on NFPA 1971-certified gear.

Fire departments must also ensure that their PPE meets or exceeds NFPA 1971 or NFPA 1970 standards. The safety of our firefighters is paramount and adherence to these standards should be a top priority for procurement teams and decision-makers.

Stay tuned for the next article, where we will explore the changes from NFPA 1971 to NFPA 1970, focusing on the gear adjustments manufacturers are making to comply with these evolving standards.