8 minute read

Newcastle’s City Image:

Strengths:

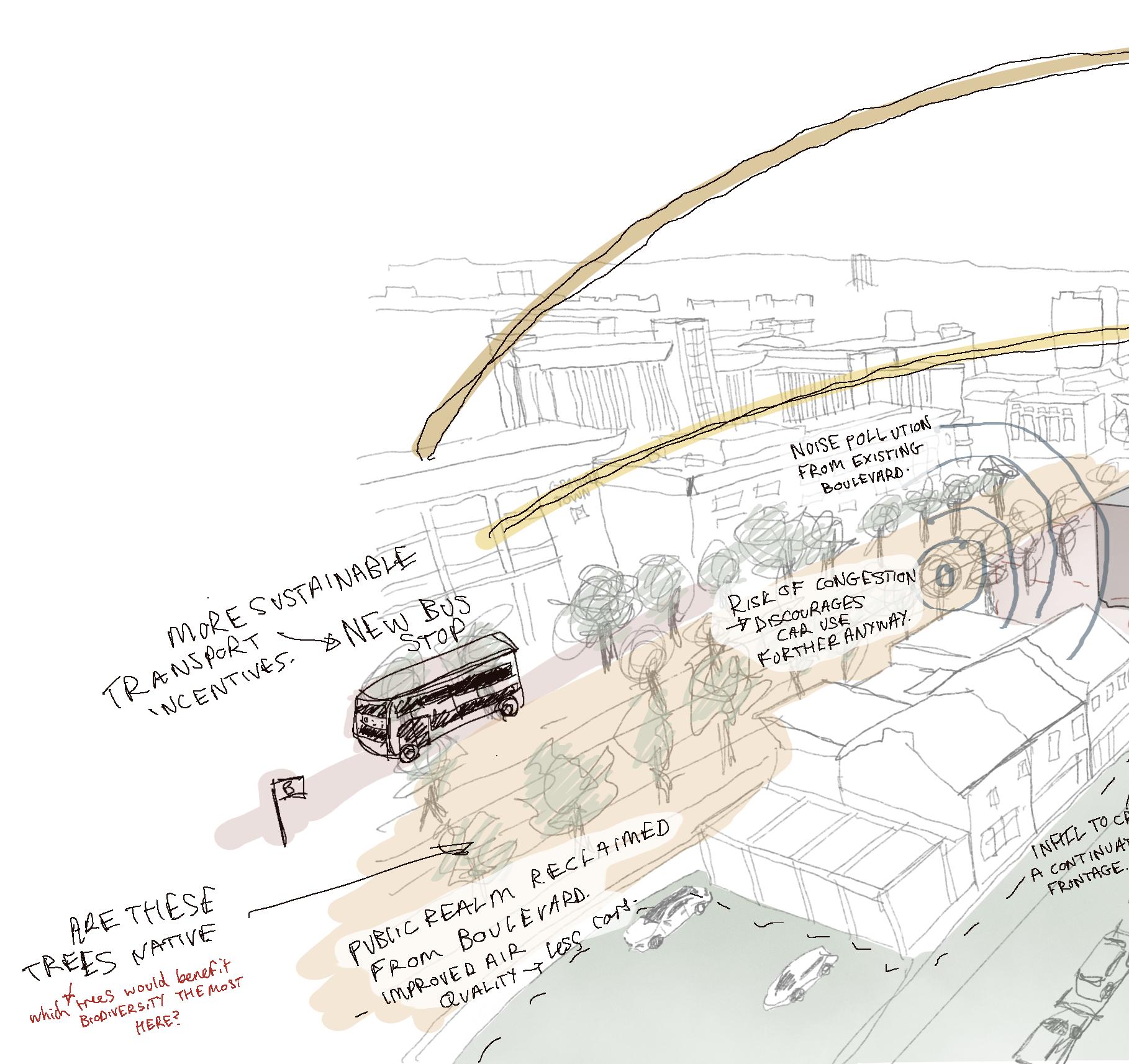

•There is a huge section of space that could become a new section of public realm

Advertisement

•There are multiple options for where to extend

•There is already a really strong cultural presence with the theatre and museum opposite

•The site is in the west of the city – a historically neglected part of the city

Weaknesses:

•St. James’ Boulevard is a huge urban edge cutting the site off from the city centre

•The boulevard creates lots of noise pollution and air pollution

•Too much hardscaping and not effective planting for biodiversity

•The existing fabric of the building will have to be upgraded in terms of thermal performance

•The party wall of the building will have to be considered very carefully to eliminate thermal bridging

Opportunities:

•The boulevard could be closed down over time and this could create yet more public realm

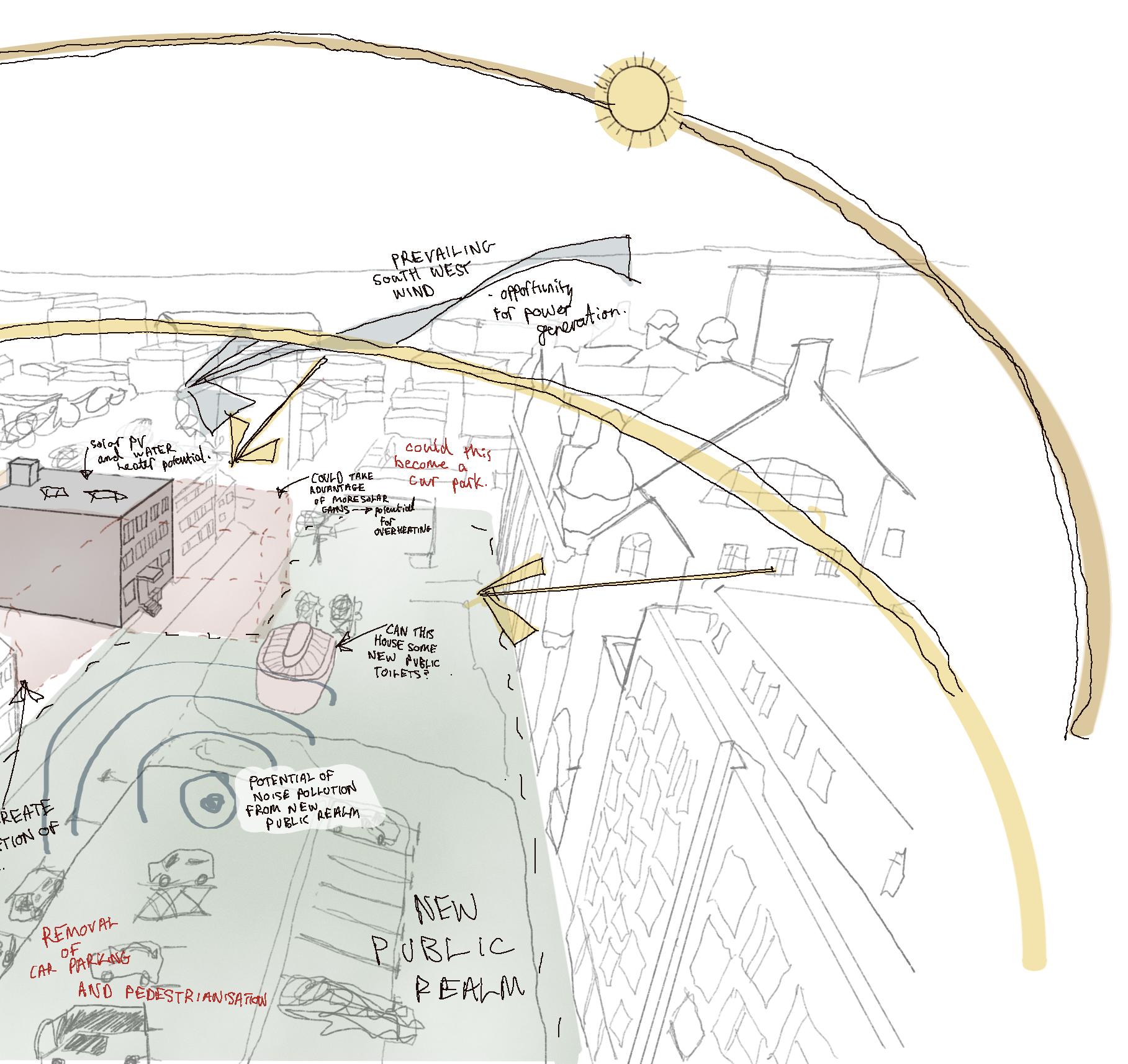

•Availability of sun and wind on site could be used to generate electricity and heat water

•If I extend to the north there is an opportunity to create a new sense of frontage for Blandford Square

•There is an opportunity to connect with the Newcastle Helix site and maybe be a small business hub

Threats:

•If the boulevard is closed down, there is a risk of city-wide congestion

•If the extension is to the west here is a risk of overheating in summer

•There is potential that the are could become gentrified – therefore the community will be the decision makers

•If the new landscaping is not carefully considered the impact of the new tree species etc could cause consequences later down the line

Web joists used to suspend panels finished with stil acoustic veneer in a nano-perforated, quartercut Douglas Fir finish. These panel act as acoustic baffles with in-built, direct downlighting and led backlighting strips

WiFi routers mounted to soffit and hidden behind acoustic baffles

Concrete frame of existing building exposed and floor plate cut through to create double height space – edge of slab reinforced with a new steel angle inside. Concrete left untreated

Repetition of 2x4 timber elements used to create railings and slats with 150mm centres

BASIS High table By e15 and Ergo Impact LeanRite Elite - Ergonomic Standing Chairs to enable a range of different ergonomic settings

Depth of columns used to create an alcove occupied with bespoke shelving and a place for printing and plotting.

Fixed in place computer workstations have ethernet connections as well as other data ports such as SD Card slots etc – essential for the creatives working here who maybe don’t have ready access to their own computer

Bauder Storm Sub BLUE roof with biosolar finish and native windflower blanket

Windows are openable for purge ventilation in a morning - required to extract the Carbon Dioxide generated from the internal green wall’s overnight respiration

Biotecture UK interior green wall provides air purification and a connection to nature from within the building.

Lime plaster finish – this is naturally white but not too stark that it is overpowering and it complements the muted and natural tones of the other wall finishes

Deep wall build -up allows for bespoke window seats and shelving

BASIS Workstation table By e15 Charles and Ray Eames Aluminium chair ea119 finished in chrome and black leather.

240 Volt, USB A and USB C ports built in to desks with all wires routed under tables in trays, down into the floor through service “channels” or “trays” in the raised access floors

Kingspan RMG600 raised access floor with 150mm pedestals allows for some ventilation ducts as well as all plumbing electrical and telecommunications cables to be routed through service channels in the floor.

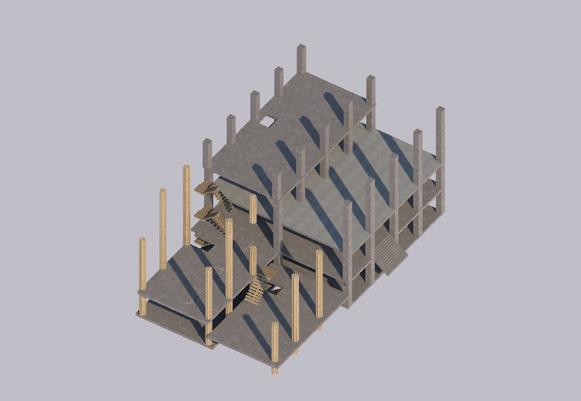

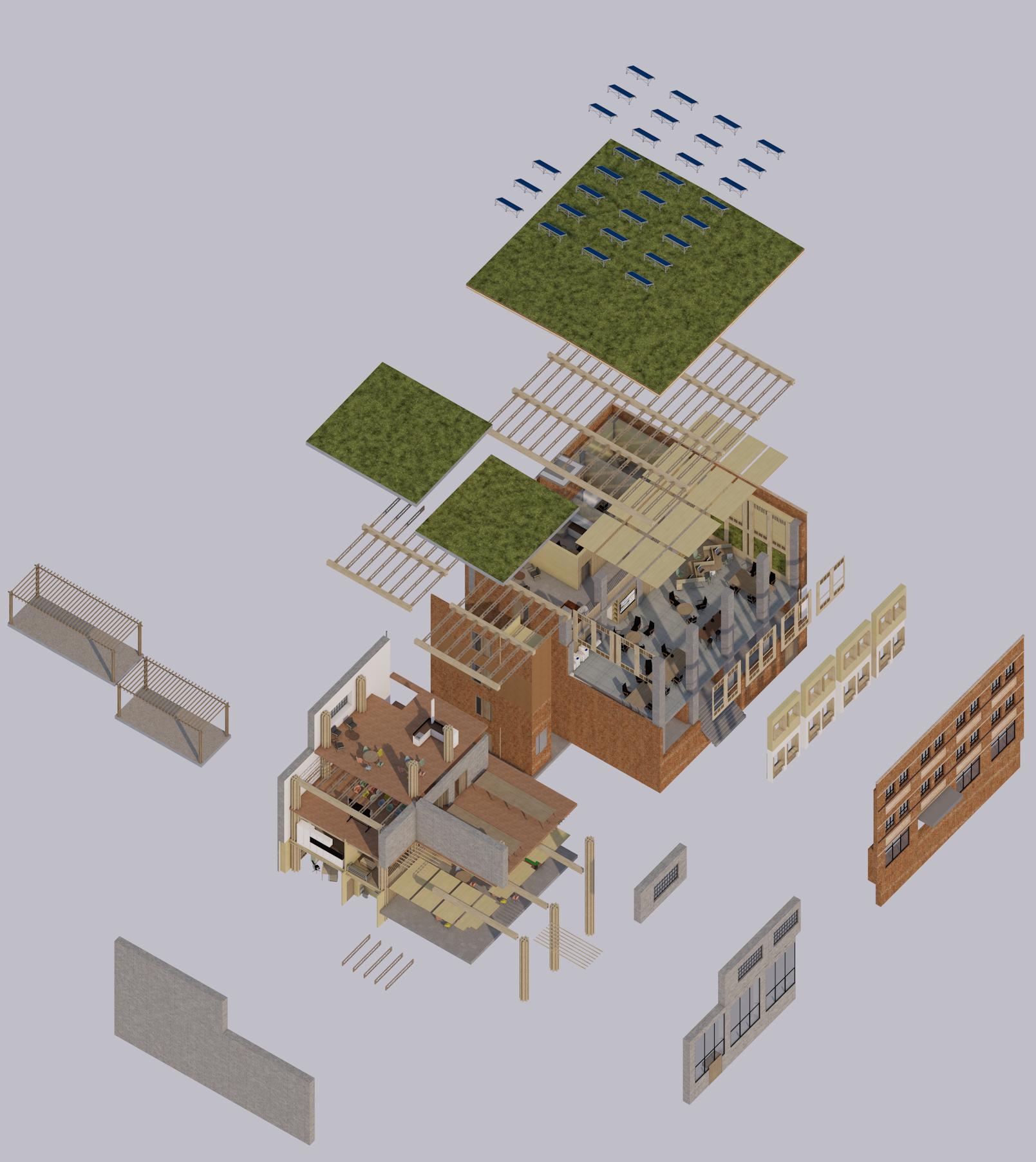

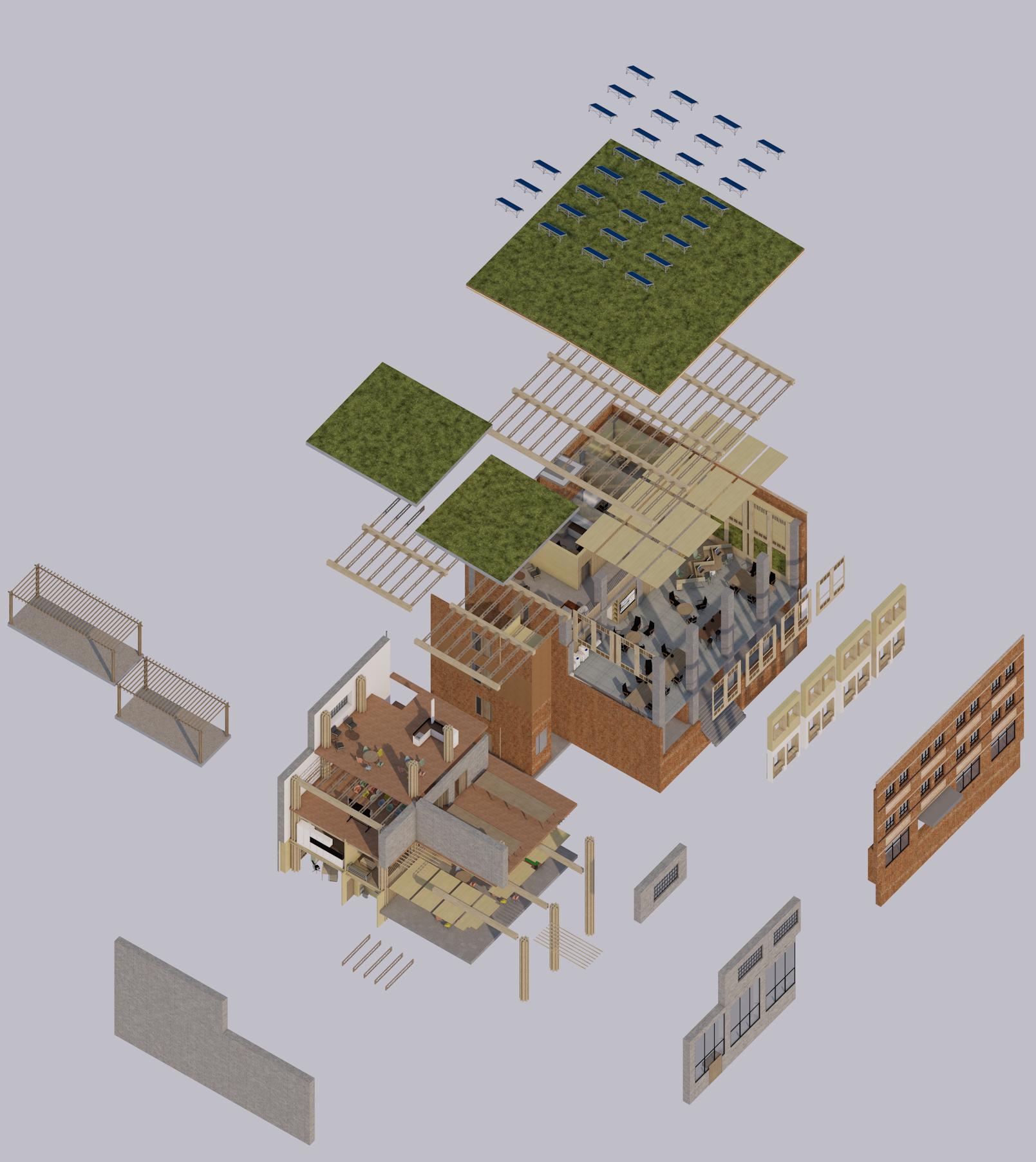

Existing building:

1. Solar PV Panels as a part of the BioSolar blue roof from Bauder

2. Bauder BioSolar StormSub BLUE roof

3. New supporting roof structure composed of Baubuche beams and web joists

4. Acoustic baffles with integrated lighting

5. Existing reinforced concrete frame

6. Acoustic surface treatment

7. SIP Cassettes with integrated bespoke window seating

8. Existing Alphabetti façade with upgraded Velfac V200e windows

Building extension:

9. Technal tental 50 feature cap curtain wall

10. SIP Cassette façade

11. Timber battens for floor

12. Primary Baubuche profiled columns

13. Web joists pedestals – unfinished and sealed with Solid StepCote Clear DIY Abrasive Anti-Slip

14.

15.

16.

17.

18.

12. Power and data cable tray

13. Plywood window reveal

14. 600mm reinforced concrete perimeter ring-beam

15. Technal Tental50 feature cap Curtain wall system

16. Pollimier Baubuche profiled columns

17. Steel drainage channel

18. Gravel and French drain

19. 50mm coarse sand

20. Geotextile water permeable membrane

21. 600x600mm Northumberland Buff stone paving slabs

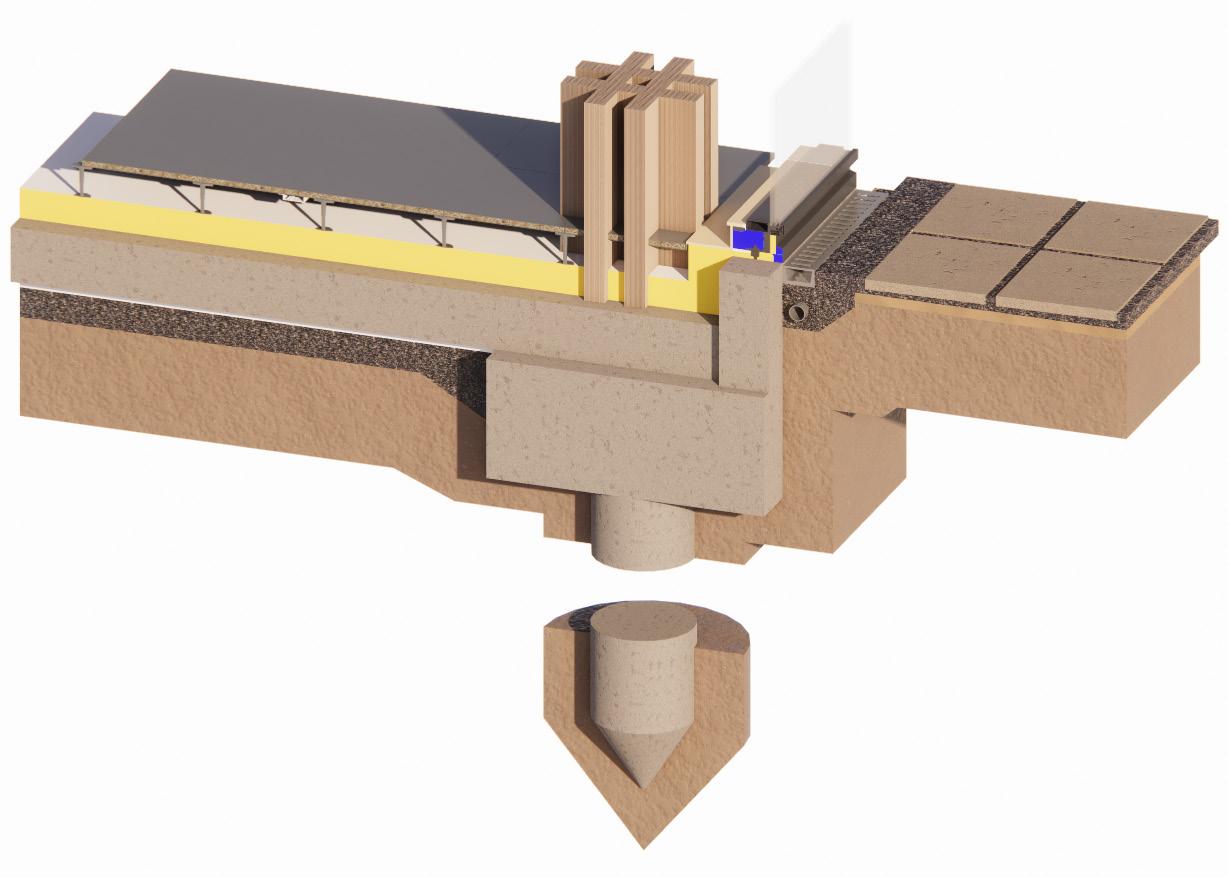

Wall To Roof Junction:

1. Pollemeier Baubuche Profile column 675x675mm

2. Pollemeier Baubuche Beam with shadow gap and led strip fixture

3. Web joist (420mm depth)

4. 38x75mm Timber battens (300mm Centres)

5. Velfac V200e energy windows

6. Plywood reveal

7. Insulation around window reveal

8. Pro Clima Intello Plus Intelligent vapour check and airtight membrane with Pro Clima TESCON No.1 Airtightness tape at the seams and over any holes from screws etc

9. Metsawood Kerto Ripa System SIP Cassette made up of KERTO LVL Q panels and S studs

10. 4 200X100MM Timber sections acting as a lintel and SIP Cassette termination

11. 400mm Hemp fleece insulation

12. Lime-stabilised earth, dry-stacking brick

13. Steel reinforcement bar

14. Weatherproof membrane

15. Wall tie

16. Mesh to prevent bees and wasps nesting in the cavity

17. Timber lintel

18. 2 200X100MM Timber firrings

19. Aluminium parapet cap

20. BauderBLUE adjustable flow restrictor

21. Bauder waterproofing system

22. Bauder FMS600 protection layer

23. Bauder Re 40

24. Bauder RE substrate

25. Bauder filter fleece

26. Bauder biodiverse substrate

27. Vegetation with WB native wildflower blanket

28. Gravel Drainage channel

29. 200mm Hemp fleece insulation

This scheme would be comprised of 2 major packages of works – a public realm improvement, phased over 24 months and a building development as an extension to the existing Alphabetti theatre. This pre-construction plan is for the latter half of the works and focuses specifically on the extension build rather than the paving etc that would already be complete by this stage.

KEY:

1 - Changing rooms and showers

2 - PPE Storage

3 - Toilet Block

4 - Canteen/ Mess

5 - HSE Office

6 - Meeting room

7 - Plant

8 - Secure lock up

TCR - Tower Crane - 35 boom

TH - Turning head

CP - Car park

W - Water mains connection

P - Power mains connection

A - Carpentry workstation

B - SIP storage/ prepartion area

C - Stick system curtain wall station

Proposed build area

Temporary units

Double stacked units

Ancillary units

Workstations

Scaffolding

Turning head

Car Park

12 Yard skips for removal of waste

10mph speed limit sign

On-site Health and safety principles:

• Every worker on site must be provided with the adequate PPE before commencing work, this will be provided in the PPE store on site and the workers will have a changing facility on site.

• Before setting foot on site, each worker must have the relevant training and be signed off by an examiner – for a example a relevant CSCS Card for the activity they will be undertaking etc (Construction Builder Support [CBS], 2021)

• The removal of the existing windows and the floor plate as well as the extension build means that there will be a number of workers working at height i.e. 2m or more. These workers will be equipped with the appropriate fall protection – i.e. harnesses, fall nets, tool retention lanyards etc.

• Repetitive strain injuries can have a big effect on a workforce, yet they are some of the easiest injuries to avoid. Therefore, the handling of heavy components on site will be carefully monitored – no person should be lifting more than 10kg worth of weight at once. This applies to loads over 10kg too, for example a 30kg weight would require 3 workers.

• Construction is generally a dangerous industry and there are inherent risks attached to that fact. Therefore, there will be some hazards that can’t be fully eliminated. However, the risk can be mitigated and should be carefully considered to minimise the potential for harm as much as possible.

Risks that cant be fully eliminated will be mitigated by providing sufficient safety measures to reduce the likelihood of accidents. For example: provision of break spaces to prevent fatigue, implementing the relevant health and safety signs, and having a HSE on site that will ensure operations are running safely and in line with the health and safety principles outlined above.

PPE Provision:

The provision of the correct PPE is of paramount imporatnce for protecting workers. All of the following standards (below) are derived from SHE PPE: Complete guide to Personal Protective Equipment unless stated otherwise (SHP, 2022)

• Hard hats - The relevant standards are BS EN 397 and BS EN 14052

• Steel toe caps - The relevant standard for safety footwear is BS EN ISO 20345.

• Hi-vis clothing – The relevant standard for hi vis clothing is BS EN 471 + A1.

• Ear defenders - The relevant standard for the ear protectors is BS EN 352 Part 1.

• Safety goggles - The relevant standards are BS 7028 (Guide to Selection of Eye Protection for Industrial and Other Uses) and BS EN 166 (Specification for Eye Protectors).

• Gloves - BS EN 388 covers the specification

Fall Nets:

Due to the fact tha tthe proposal removes a part of a floor plate top open up a space in the existing building, there would have to be a sufficient net installed to prevent not only falling workers being injured, but materials and tools wouldn’t fall on others below.

Site compound: of gloves against mechanical hazards.

The Portakabins comprising the site compound have been arranged in a stacked configuration in order to reduce the overall footprint without comprising the facilities.

• Dust mask – there will be different standards of respiratory protection required for different tasks.

• Knee pads – knee pads and other body protection carry different standards and aren’t necessarily required – therefore workers may choose to not wear them however they would be provided on site.

• Safety harness – the different fall retention equipment will have different associated standards and will have to be thoroughly checked on a regular basis to ensure it is in working order.

HGV Drop off Point:

Access for HGVs is construction process. it is in the centre of connection to the long boom arm so HGVs to a designated them directly into

Hammerhead tower crane (30m Boom):

The tower crane has a large enough boom to be able to reach ver the extension and existing building. It is also large enough to swing over the new public realm and site compound to move elements directly from HGVs or from the floor.

Point: is essential for a smooth and seamless process. This has been positioned so that of the site as well as having a good road. The crane has a suffieciently that it can move components from the designated part of the site compound or lift the building.

Scaffolding:

Scaffolding is a key part of any construction project - this will allow for a temporary platorm for the removal of the existing windows as well as making the installation of the new windows and SIPs easier.

Temporary

balustrade:

The partial removal of the existing floorplate would mean that there would need to be a temporary balustrade installed prior to the construction and installation of the new railing. This would be installedas soon as the floorplate has been removed along with the fall nets.

All information reffered to in the diagram to the right is taken from Approved Document B Volume 2 unless otherwise stated. (HM Government, 2022)

The size and complexity of the floor plans of this building means that it will require an automatic fire detection system. This system will be primarily concerned with the protection of life as opposed to property. Despite the public nature of this building, a phased exit strategy would not be appropriate. The installation of an automated system would also eliminate the reliance on manual systems or staff operated systems. This would vary across the different types of spaces in the building so as to best prepare for the consequences of a fire in each specific space.