2 minute read

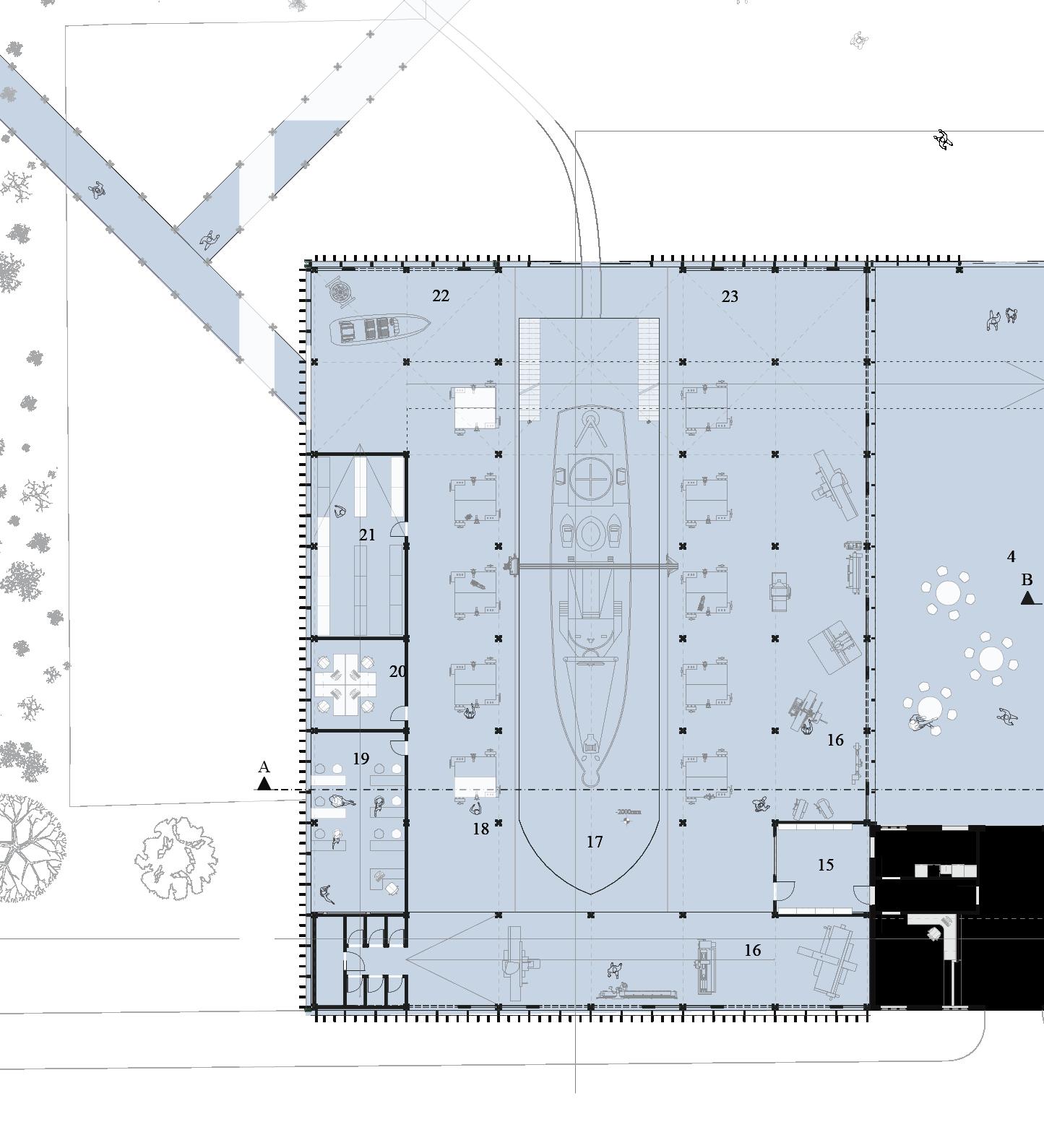

THE HAWTHORN LESLIE CENTRE, HEBBURN

BA Hons, Year 3, Project 2

The main aim of this scheme is to regenerate the sense of Pride that was once so prevalent in Hebburn and the wider industrial landscape along the banks of the Tyne. The industrial nature of the place means that there has inherently been an impact on the ecology in the area. Therefore, I aim to regenerate and conserve the delicate riparian ecosystem, preserve the memory of the industry that gave rise to the neighbourhoods of Tyneside and create a place that instils a new sense of pride in the community

Advertisement

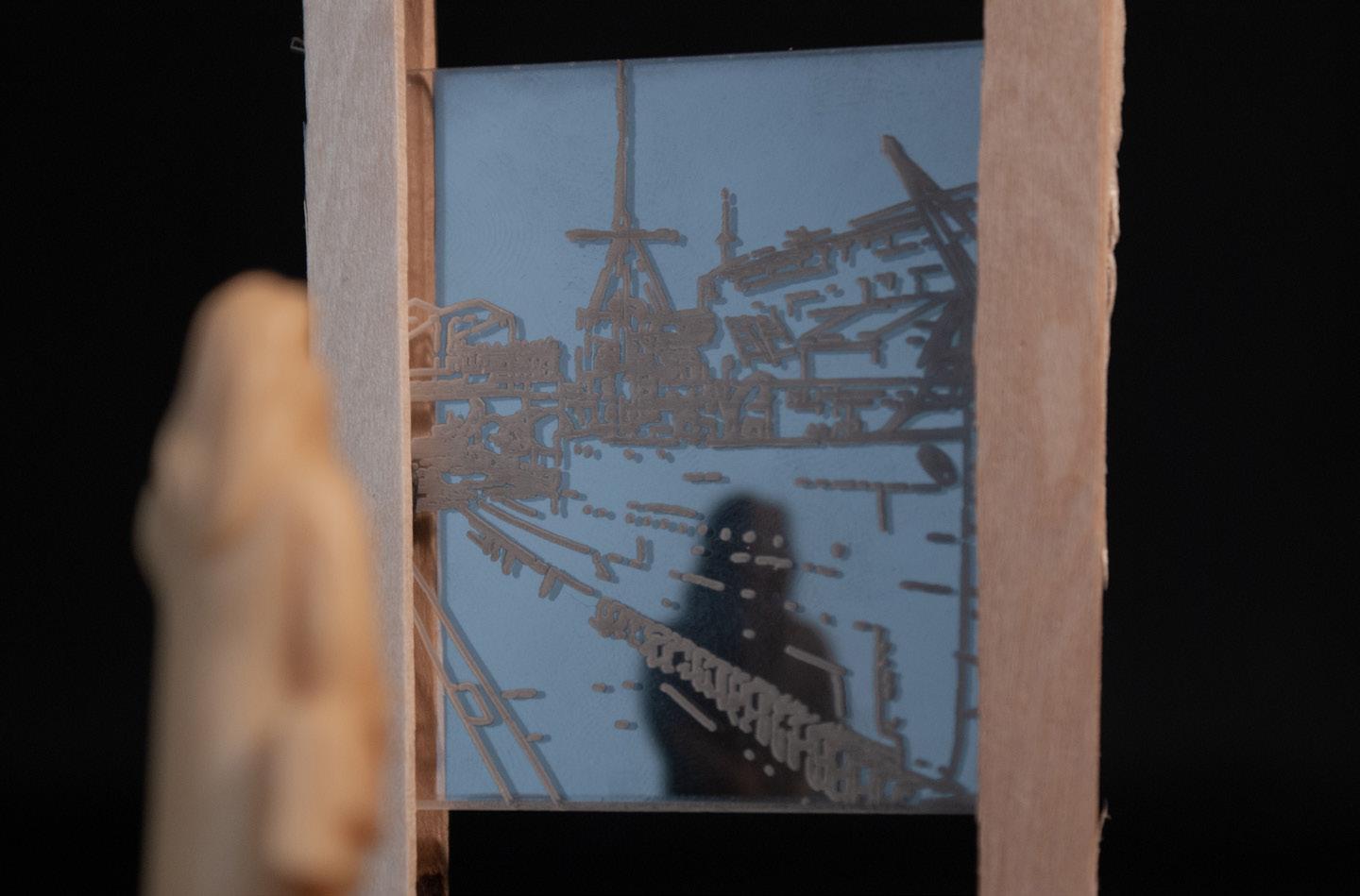

The introduction of viewing portals with line drawings of historic photographs transport visitors back to the industrial days of The Hawthorn Leslie shipyard - these augmented views are generated from historic photographs of the site meaning that the visitor is stood eactly where the photo was taken giving the ma feel for what the activity on site was like

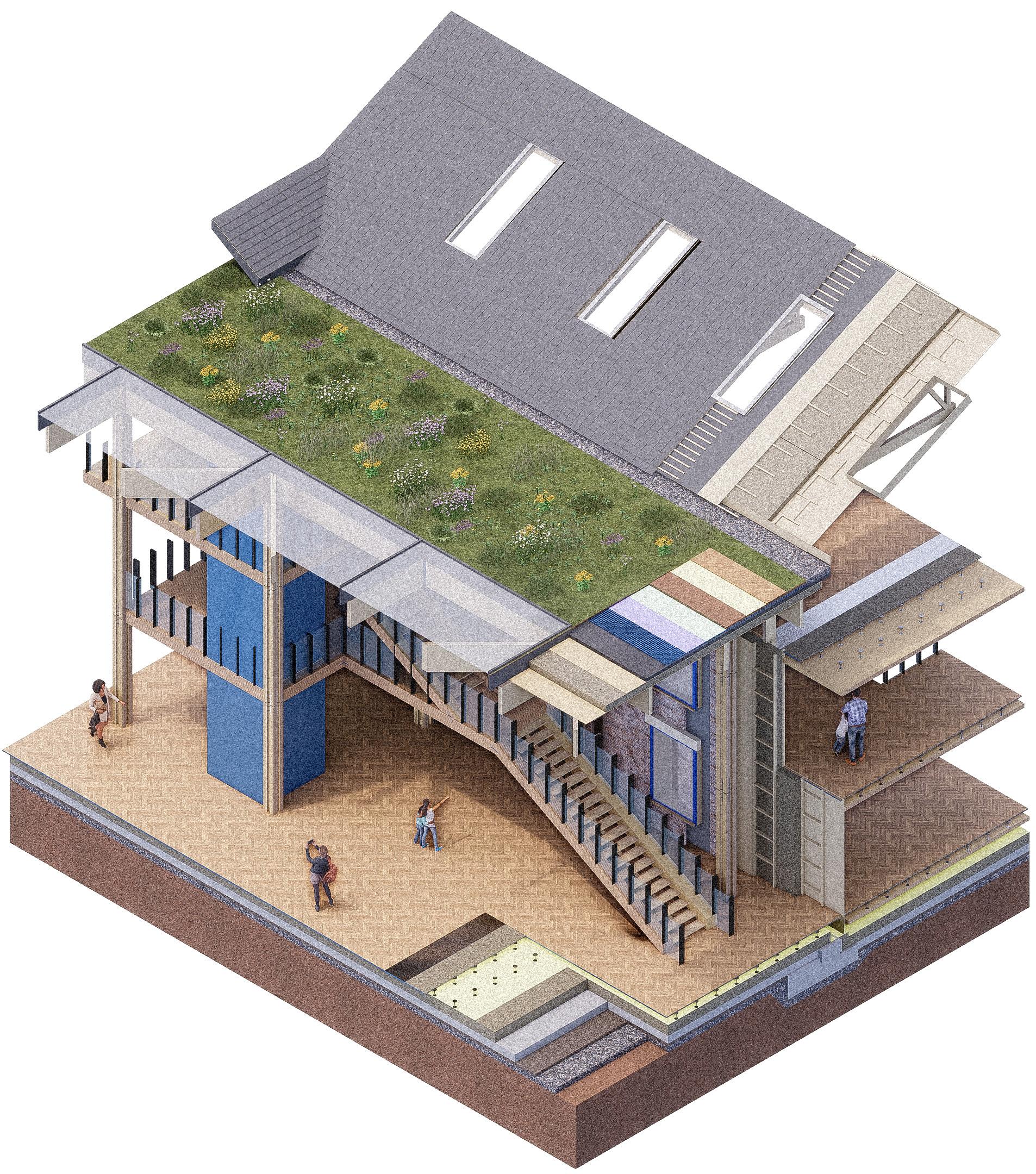

1 - Ground floor build up (Bottom to Top):

• Compacted earth

• 150mm recycled concrete aggregate hardcore (from existing floor plate that was removed)

• 75mm sand

• Original reinforced concrete strip foundation

• New underpinning reinforced concrete foundation using 40% Seratech cement.

• 200mm reinforced concrete slab using 40% Seratech cement.

• Dörken Italia – Delta DPC Tagliamuro

• 280mm rigid insulation

• Pro Clima Intello Plus Intelligent vapour check and airtight membrane with Pro Clima Airtightness tape at the seams and over any holes from screws etc

• Steel footplate with self-tapping concrete anchor bolts

• Kingspan RMG600+ raised access floor with 150mm pedestals with power and data cables fed through the floor in service channels with Attiro flooring in a Bianco pallido finish.

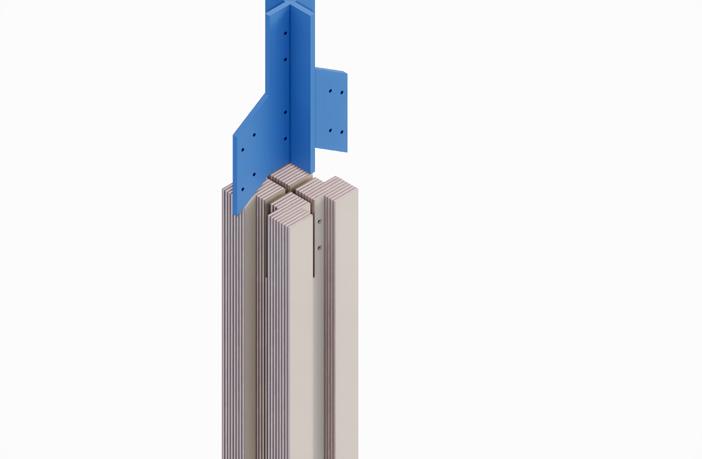

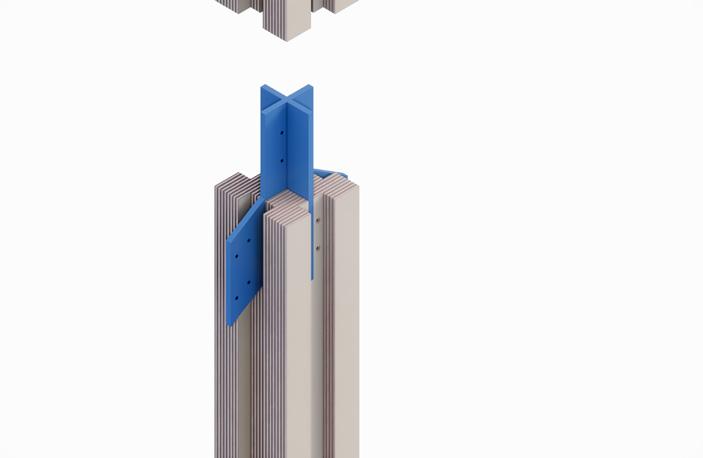

• Pollimier Baubuche profiled column (300x300mm)

2 - Atrium roof build up (Bottom to Top):

• 700x100mm Baubuche roof beams

• 300mm Brettstapel (dowel-laminated timber) deck

• Indinature, Inditherm hemp insulation 100mm

• 35mm smartply propassiv plywood deck

• BauderBLUE adjustable flow restrictor

• Bauder waterproofing system

• Bauder FMS600 protection layer

• Bauder Re 40

• Bauder RE substrate

• Bauder filter fleece

• Bauder biodiverse substrate

• Vegetation with WB native wildflower blanket

• Gravel Drainage channel

3 - Existing wall and thermal performance upgrades (Atrium to Exhibition Hall):

• Bespoke LVL Staircase

• Bespoke balustrades – Yakisugi treated timber, Corten steel fixtures and glass panels.

• Existing brick cavity wall (no insulation)

• Velfac v200e windows

• Recessed insulated, lockable shutter.

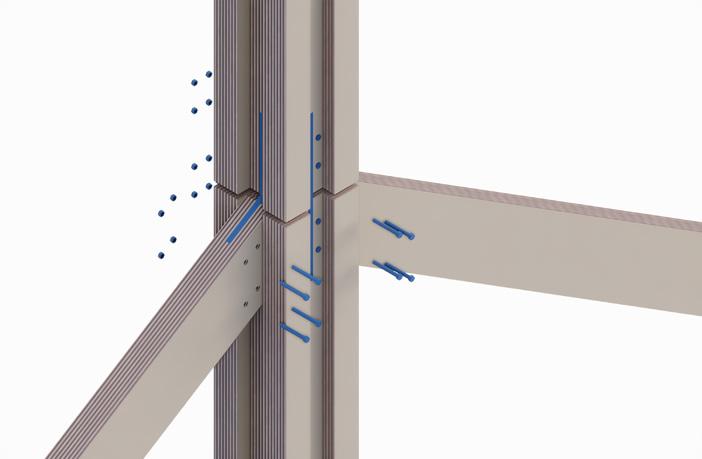

• Ecosystems technologies A.T.O.M.S (Adaptable Timber Offsite Manufacturing System) insertion

• LVL portal frames (300x100mm at 4500mm centres)

• 12mm Smartply Propassiv plywood

• Timber cassette frame (Larsen Truss) made up of 38mmx75mm timber battens at 600mm centres.

• 100mm Brettstapel (dowel-laminated timber) deck

• Indinature, Inditherm hemp insulation 250mm

4 - Intermediate floor build up (Bottom to Top):

• 100mm Brettstapel (dowel-laminated timber) deck

• Kingspan RMG600+ raised access floor with 150mm pedestals with power and data cables fed through the floor in service channels with Attiro flooring in a Bianco pallido finish

5 - Sloped roof build up (Bottom to Top):

• 35mm smartply propassiv plywood deck

• Timber cassette frame (Larsen Truss) made up of 38mmx75mm timber battens at 600mm centres.

• Indinature, Inditherm hemp insulation 250mm

• Timber cassette frame (Larsen Truss) made up of 38mmx75mm timber battens at 600mm centres.

• 35mm smartply propassiv plywood deck

• Water proof membrane

• Reclaimed slate shingles fixed back to timber purlins.