ANNISTON ARMY DEPOT ANNISTON, ALABAMA

HISTORY Anniston Ordnance Depot (AOD) was constructed in 1941 with storage igloos, ammunition magazines, warehouses, and several administrative buildings. Nearly a decade later, AOD began an assignment to overhaul and repair combat vehicles. The maintenance and storage missions began in 1963 under the name Anniston Army Depot. ANAD began repair and overhaul of the M1 Abrams Main Battle Tank in the mid-1980s and was the recipient of towed and self-propelled artillery and light combat vehicle missions as a result of the Base Realignment and Closure Commission 1995. Production of Stryker vehicles began in 2001 with commercial partner General Dynamics. ANAD is transforming with the Army and utilizing innovative initiatives including but not limited to workforce revitalization, Lean Six Sigma, and partnering with industry. In September 2006, the secretary of the Army designated ANAD as the CITE for combat vehicles (wheeled and track except Bradleys) including assault bridging, artillery, and small-caliber weapons. In July 2014, the depot became the CITE for locomotives, rail equipment, and non-tactical generators. INSTALLATION OVERVIEW ANAD is located on 15,319 acres in Calhoun County. ANAD has a building and plant replacement value of approximately $2.5 billion. To the north, the installation is bordered by Pelham Range, which is a 20,000acre training range operated by the Alabama Army National Guard. There are no encroachment issues for

104

U.S. Army photo

MISSION Provide industrial and technical support to joint services for repair and overhaul of combat vehicles, artillery systems, bridge systems, small arms, secondary components, locomotives, rail equipment, and non-tactical generators. Anniston Army Depot (ANAD) is the premier Department of Defense Center for Industrial and Technical Excellence (CITE) and is capable of overhaul and refurbishment of all the aforementioned systems. Major tenants of the installation include Anniston Munitions Center and the Defense Logistics Agency Distribution Anniston, Alabama.

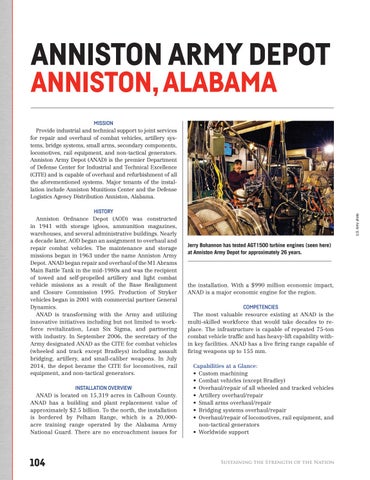

Jerry Bohannon has tested AGT1500 turbine engines (seen here) at Anniston Army Depot for approximately 26 years.

the installation. With a $990 million economic impact, ANAD is a major economic engine for the region. COMPETENCIES The most valuable resource existing at ANAD is the multi-skilled workforce that would take decades to replace. The infrastructure is capable of repeated 75-ton combat vehicle traffic and has heavy-lift capability within key facilities. ANAD has a live firing range capable of firing weapons up to 155 mm. Capabilities at a Glance: • Custom machining • Combat vehicles (except Bradley) • Overhaul/repair of all wheeled and tracked vehicles • Artillery overhaul/repair • Small arms overhaul/repair • Bridging systems overhaul/repair • Overhaul/repair of locomotives, rail equipment, and non-tactical generators • Worldwide support

Sustaining the Strength of the Nation