SCRANTON ARMY AMMUNITION PLANT Scranton, Pennsylvania Mission Scranton Army Ammunition Plant (SCAAP) manufactures large-caliber metal projectiles and mortar projectiles. Capabilities • Manufacturing source for 155 mm, M795 projectile • Multiple long-stroke vertical hydraulic forge press lines • Capability to produce large mortar projectiles • In-house metallurgical testing • Over 120 hydraulic tracer and CNC lathes • Machining capability exceeding current ammunition manufacturing requirements • In-house end-to-end production processes, no outsourcing requirements • Multiple automated paint lines • Multiple heat treat furnaces that austenitize, quench, and temper History The installation was originally constructed as a steam locomotive erecting and repair facility in 1908. SCAAP was established in 1953 and operated by U.S. Hoffman until 1963 when Chamberlain Manufacturing Corporation became the operating contractor. General Dynamics Ordnance and Tactical Systems assumed operation of the facility from Chamberlain in 2006 and is the current operating contractor.

Photo by Tim Tuttle

Statistics SCAAP has a government staff of nine Department of the Army civilians to provide installation management contract oversight. The government staff has a payroll budget of $910,000. Contractor statistics are considered proprietary and therefore are unavailable. Facilities SCAAP is housed on 15.3 acres with seven buildings and a storage capacity of 509,000 square feet.

Sustaining the Strength of the Nation

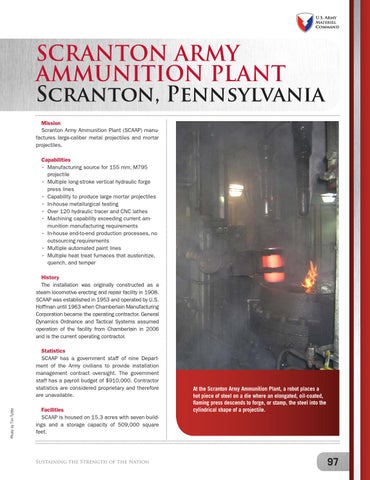

At the Scranton Army Ammunition Plant, a robot places a hot piece of steel on a die where an elongated, oil-coated, flaming press descends to forge, or stamp, the steel into the cylindrical shape of a projectile.

97