McALESTER ARMY AMMUNITION PLANT McAlester, Oklahoma Mission McAlester Army Ammunition Plant (MCAAP) receives, stores, ships, produces, renovates, and demilitarizes conventional ammunition. MCAAP provides centralized ammunition management for training ammunition and contingency stocks for Army units in the Southwest region. Capabilities • Manufacturing • Logistics support • Demilitarization/disposal • Mobile Ammunition Renovation Inspection, and Demil (MARID) Team • Safety and environmental protection • Assists with research and development • Renovation • Mobile Rail Maintenance Team

Statistics For fiscal year 2014, MCAAP has an operating budget of $158.1 million and a payroll of $98 million. There are 1,271 Department of the Army civilians and one Soldier. Facilities MCAAP is housed on 44,964 acres with 2,826 buildings including 2,263 igloos, and a storage capacity of 8,840,559 square feet.

94

Photo by Sgt. Ferdinand Thomas

History MCAAP was established May 20, 1943, as the McAlester Naval Ammunition Depot. It became part of the Army’s Single Manager for Conventional Ammunition in 1977. Under Base Realignment and Closure 2005, MCAAP acquired additional workload from Red River Munitions Center. From Kansas Army Ammunition Plant, it acquired the Sensor Fuzed Weapon and missile warhead production, and from Red River Munitions Center, Lone Star Army Ammunition Plant, and Sierra Army Depot, it acquired demilitarization, storage, and maintenance functions.

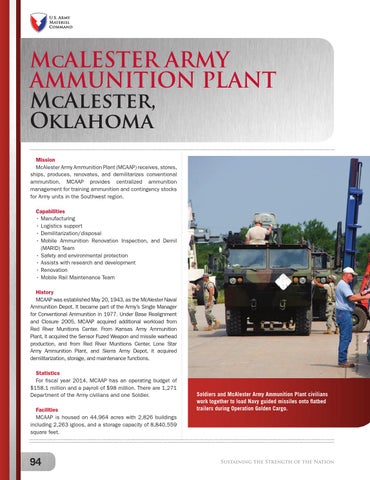

Soldiers and McAlester Army Ammunition Plant civilians work together to load Navy guided missiles onto flatbed trailers during Operation Golden Cargo.

Sustaining the Strength of the Nation