3 minute read

All about products

Transforming Lives Together

When we work together as an industry, we can deliver products and expertise that truly transform patients’ lives.

Advertisement

Full Range of Materials Led by industry insights, Contamac offers a complete range of contact lens materials to suit all indications. From our signature Optimum family of gas permeable materials, to Definitive silicone hydrogel materials and Contaflex hydrophilic soft lens materials, each with their own unique properties to benefit machinability, comfort and corneal health.

Educational Initiatives We also believe that by investing in the professionals of our future, we can ensure they are fully equipped to transform the lives of patients. Whether it is through publications, videos or industry events, Contamac is proud to support an exchange of knowledge with the industry. Find out more: www.contamac.com, sales@contamac.co.uk

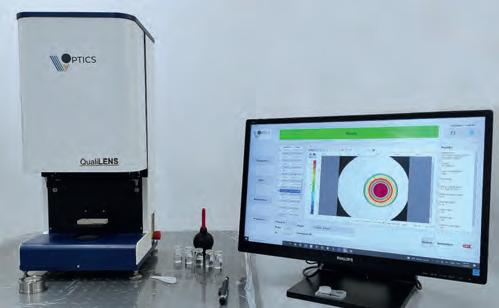

QualiLENS®100 for Automation

The new QualiLENS®100 for automation is a global and option-based solution, for R&D and production inspection machines, with a built-in fanless computer and PLC for Cleanrooms. At V-OPTICS, we believe that handling lenses is tricky, risky, and burdensome. That’s why we have reflected on an all-in-one machine, able to embed any line of production, to be duplicated at will, for any type of inspection machines (contact lenses, IOL, ICL or semi-finished). In 2021, we launched add-ons of new increasingly optic controls such as 2D dimensions, engraving reading and QC, automated cosmetic inspection, and advanced optical power. Machine-side, high resolution cameras and illumination are used to complement our patented technology: the “Phase shift Deflectometry and computations”. Software-side, we developed software package according to manufacturers and current equipment’s requirements. More is to come. V-OPTICS, your partner “outside of the box”. info@v-optics. fr, www.v-optics.fr/en/automatic-lens-defect-control/

Optimizations for IOL production testing

OptiSpheric® IOL PRO 2 is TRIOPTICS’ fully automated optical IOL test stand. Developed for use in production, it provides a throughput of up to 100 lenses per batch. The ISO-compliant measurement of hydrophobic and hydrophilic lenses in air or in-situ can be performed with an accuracy of 0.3 % (power) for all types of intraocular lenses (incl. EDOF, multifocal and trifocal). With the latest software module, the system can be connected to your database in accordance to FDA 21 CFR PART 11. This allows you to retrieve sample-specific data and measurement scripts from the server as well as to archive your measurement results in conformity with the standards. www.trioptics.com, info@trioptics.com

The Non-Paraxial Model Eye opens the doors of EDoF IOL metrology

As the complexity of IOL designs increases, metrology tools must become more powerful and effective to overcome new challenges, especially with the rise of Extended Depth of Focus (EDoF) IOL. Until recently, the Model Eye historically available in NIMO (mathematical model base on the summing of the wavefront of the IOL and the wavefront of a synthetic cornea) was perfectly appropriate. However, this method faces limitations for larger apertures and when the IOL and synthetic cornea show aberrations. LambdaX’s new Non-Paraxial Model Eye overcomes these issues by accounting for the focusing effect of the model eye and therefore the incident light entering the IOL not being collimated. The patent pending Non-Paraxial Model Eye implemented in IOL-MENTOR® opens way to more efficient measurements of complex refractive optics with wavefront sensors in IOL metrology for both R&D studies and production quality check. Since the model has been fully validated for measurements of lenses in-air and in-situ, the operation is simpler, more consistent, beneficial to IOL manufacturers and ultimately contributes to a better vision for the patient. www.lambda-x.com , sales-ophthalmics@lambda-x.com

Advertisement

Complete Metrology Solutions

for contact lenses and IOL's