2 • 2024

ARE YOU READY FOR DECT NR+?

REMOTE MONITORING CHANGES HEALTHCARE

2 • 2024

ARE YOU READY FOR DECT NR+?

REMOTE MONITORING CHANGES HEALTHCARE

FAIL-SAFE TIMING FOR AUTOMOTIVES

ELECTRONICS REPLACES HYDRAULICS

GALLIUM NITRIDE BRINGS RELIABILITY

SmallFootprintRadia�on-TolerantArm®Cortex®-M0+

Areyoulookingforasolutiontoenhanceyourspaceanddefenseprojects?Looknofurtherthanthe SAMD21RTasthismicrocontrolleroffersarangeofbenefits,tailoredtomeetyourdemands.

Capturingthepowerofa32-bitprocessorcore,itenablesdevelopmentinthemostconfinedspaces. Withacompactfootprintmeasuringonly10x10mm,theSAMD21RTMCUdeliversexceptional performance.Ourgoalistodesigncost-effective,smallpackageandpowerefficientproductsthatwill revolutionizeyourdevices.

OurSAMD21RTmicrocontrolleroffersvariousresourcesandtoolstobenefityou:

• Highlevelofradiation-tolerantwithTIDcapabilityupto50kRadandSELimmunityupto78MeV. cm2/mg

• MPLABXIntegratedDevelopmentEnvironment–expandable,highlyconfigurablesoftwareprogram

• MPLAB®PICkit™5in-circuitdebugger/programmer

• SAMD21CuriosityNanoEvaluationKit

The market for smart rings was worth 210 million USD, and it was dominated by the Finnish company Oura. Last month, the competition heated up as tech giant Samsung presented its first device, called the Galaxy Ring, of course. It takes on Oura's 4th-generation ring, which was launched just a few weeks earlier.

The smart ring is an intriguing embedded device with its many sensors, radios, battery, CPU, and storage for various smart measuring apps. Naturally, I wanted to compare the two leading designs on the market.

Four years ago, during Electronica, I spoke to the lead designer at Oura. Back then, they were eager to share all their component choices and design solutions. Now, it is a different ballgame. Oura published a very general blog post about adding sensors to the new design, but that was it. Any more detailed information would be "too valuable for competitors," the company said.

The same applies to Samsung, which also refused to provide any detailed information about the hardware of the Galaxy Ring. The device features two photodiodes for heart rate and fitness tracking, and one infrared sensor for SpO2 tracking.

Oura has advanced a few steps further. The new 4th-generation ring has more sensors and a new Smart Sensing algorithm that provides more accurate measurements and can adapt to the user's finger, or "physiological properties," as the company describes it.

Oura's caution is understandable. They have owned the market, and now the new competition arrives with a vast ecosystem of devices ranging from smartphones to tablets.

According to statements made by Oura, revenue will be close to 460 million euros this year, and the company is also profitable for the first time. The next few years will show how it can handle the mighty Korean challenge.

Veijo Ojanperä ETN, Editor-in-chief

ETNdigi

Editor-in-chief Veijo Ojanperä vo@etn.fi

+358-407072530

Sales manager Rainer Raitasuo

+46-734171099

rr@etn.se

Advertising prices: etn.fi/advertise

ETNdigi is a digital magazine specialised on IoT and embedded technology. It is published 2-3 times a year.

ETN (www.etn.fi) is a 24/7 news service focusing on electronics, telecommunications, nanotechnology and emerging applications. We publish indepth articles regularly, written by our cooperation companies and partners.

ETN organises the only independent embedded conference in Finland every year. More info on ECF can be found on the event website at www.embeddedconference.fi.

The easiest way to access our daily news service is to subscribe to our daily newsletter at etn.fi/tilaa.

Embedded Conference Finland is the only independent embedded conference in Finland. In 2025 we are planning to organise two seminars.

In September 2024 we organised the event for the 6th time. You can find all the ECF24 presentations on the event website at embeddedconference.fi. Recordings are online in the ECF Youtube channel. All vital information on future events will be posted on the event website.

ECF24 focused in embedded technology. We covered embedded hardware and software solutions. We also had presentations about embedded cybersecurity and new EU legislation.

For more information see www.embeddedconference.fi

To book a place or ask for sponsor packages please contact

ETN editor-in-chief

Veijo Ojanperä vo@etn.fi

+358-407072530 or Sales manager

Rainer Raitasuo

+46-734171099

rr@etn.se

AI will be trained in factories.

ECF24: Modules shine in embedded design.

Predicting the distribution is hard, says Graham Maggs of Mouser Electronics. 21 PREDICTINGISHARD

When will the market pick up? ETNdigi talked to Graham Maggs, the VP Marketing EMEA for Mouser Electronics 22

SiTime has introduced the industry’s first fully integrated clock system-on-a-chip (ClkSoC) with built-in fault monitoring mechanisms for the entire clock generation signal path.

Electrification of aerospace sector is driving transition from hydraulic actuators to power electronics drive.

Remote patient monitoring is intended to measure vital signs and other key parameters with non-invasive devices that wirelessly transmit patient information.

DECT NR+ fills a significant gap in wireless connectivity by providing a reliable, standardized communication protocol.

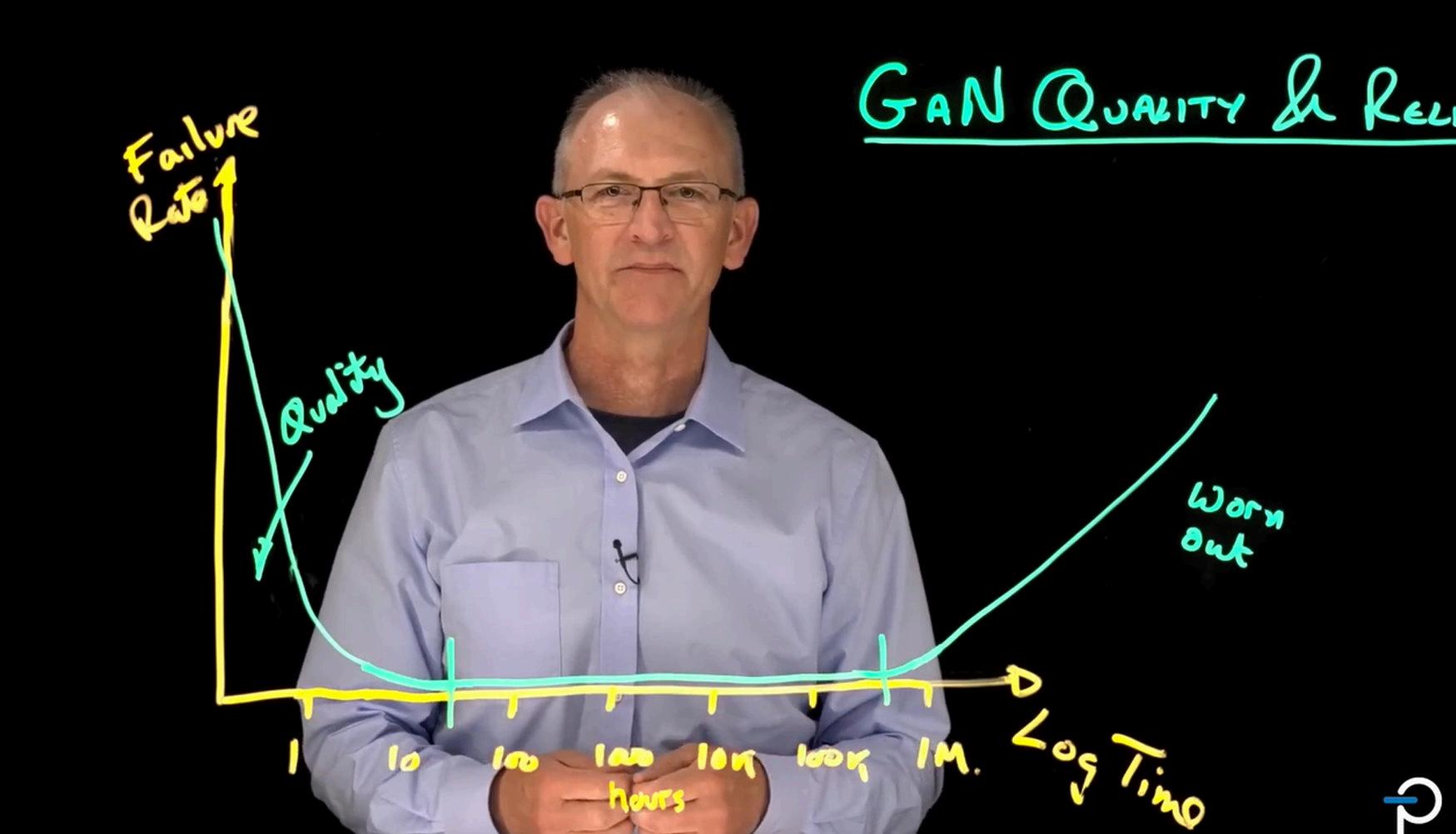

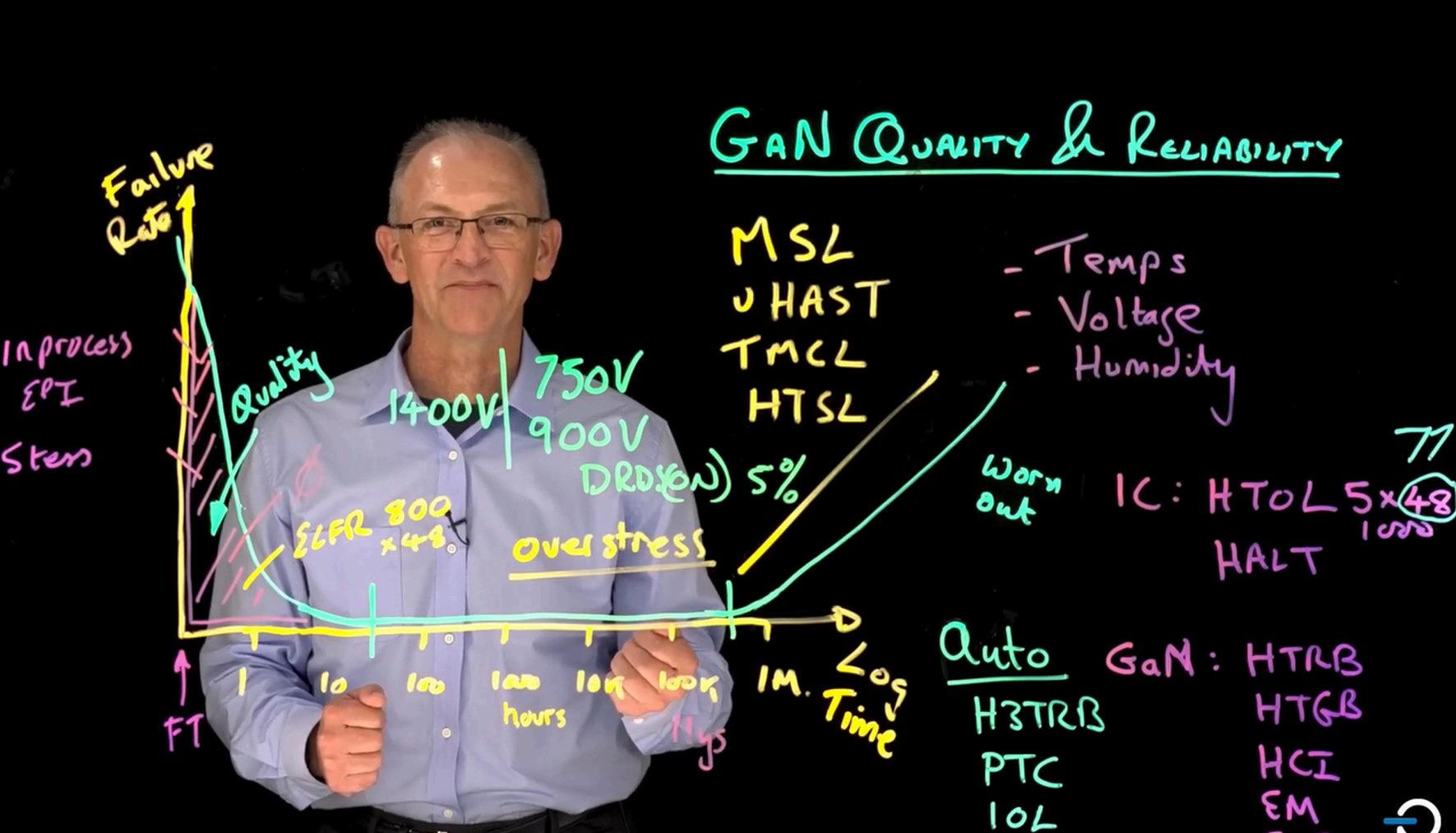

Gallium nitride (GaN) offers significant benefits of increased efficiency and power density, and allows designers to meet far more challenging power supply specifications.

Europe wants to stay in the AI race. That is why a number of AI factories will be built over the next couple of years. These factories will, in practice, be extremely powerful supercomputers. One of the factories is planned to be located in the northern Finnish town of Kajaani, which is currently home to the fastest European supercomputer, called LUMI.

The EuroHPC Joint Undertaking (EuroHPC JU) has launched two calls for expressions of interest to select hosting entities that will host and operate AIoptimized supercomputers, AI experimental platforms, and AI factories across Europe.

The first cut-off deadline was at the beginning of November. CSC, the IT Center for Research, and the panEuropean LUMI consortium applied for a factory in the first round. LUMI's replacement system would be a nobrainer choice for one AI factory, as the current LUMI system is, in many ways, a poster child for carbon-free supercomputing.

CSC already has plans for their nextgeneration supercomputer, which will also be housed in the same old paper machine hall. In the Finnish government's budget for next year, 50 million euros have been allocated for the purchase of LUMI's "replacement machine."

Pekka Manninen, CSC's director of science and technology for scientific computing, was responsible for LUMI's architectural design. He believes that Kajaani would be an excellent location for one of the EU's artificial intelligence factories.

Supercomputers do not age very well. The systems are expensive, extremely demanding to design, and costly to

operate. According to current plans, the original LUMI might be unplugged as early as October 2027.

According to Pekka Manninen, LUMI might outlive the October 2027 deadline, but its extension will not last very long.

- Each cabinet weighs four tons; it is not very easy to move the equipment anywhere. Some parts can also be used in the future LUMI successor, he says.

EU-level decisions always involve politics, but it would seem downright absurd if one of the EU's future artificial intelligence factories were not located in Kajaani. The current LUMI is clearly the world's greenest supercomputer in terms of carbon footprint. The typical 5-6 megawatts of power it requires are produced by hydropower, meaning no CO2 emissions are generated. Additionally, the heat produced by the machines is used in Kajaani Voima's heating network—around 10 percent of heating energy is produced by the CPUs and GPUs in the LUMI system.

The EU's artificial intelligence factories will be "GPU-intensive" centers. The definition is somewhat vague, given that LUMI is already a vast system in terms of GPU power. The machine's GPU section has 11,900 AMD Instinct series MI250X processors. These have been used to train, for example, the Poro and Viking

language models of the University of Turku and Silo AI. According to CSC, no issues with GPU power or memory capacity have been found in LLM training that would slow down the training process in any way. The Poro 34B model contains 34.2 billion parameters.

However, the size of these models continues to grow. Fortunately, the hardware used for calculations is also improving. AMD is already beginning deliveries of the MI325X series of Instinct GPU chips, which would increase power eightfold compared to the GPU circuits currently used by LUMI. Next year, the MI350 circuit produced using a 3nanometer process is expected to be available, which would increase performance 32 times. As the project timeline becomes clearer, the architecture of the new machine can be better planned.

The maximum funding for the AI Factory project is just under two billion euros, with the EU responsible for half and member states covering the rest. For Finland, 50 million euros has been planned for financing the "LUMI2" machine next year, with 75 million euros in each of the following two years, and 50 million euros in 2028.

LUMI is currently the fastest European supercomputer. On the June 2024 TOP500 list, its performance was measured at

379.90 petaflops. Its hardware architecture is based on a similar HPE Cray and AMD system as the fastest system, Frontier, at the Oak Ridge National Laboratory in the United States.

Europe had four systems in the last top ten of the TOP500 list. The Alps system at the Swiss National Supercomputing Centre (CSCS) produces 270 petaflops with its 1.3 million Nvidia Grace 72C and GH200 processors. Leonardo in Bologna, Italy, scored 241.2 petaflops with Intel and Nvidia hardware, while MareNostrum in Barcelona, Spain, achieved 175.30 petaflops with an Intel/Nvidia combo.

AI factories will be used, for example, to train the next generation of large language models. LLM training is very demanding in terms of parallel computing. The first LUMI machine has 2,978 GPU nodes, each with four AMD Instinct MI250X processors. Since the processors are dual-core, there are a total of 24,000 GPU processors in use.

The first Finnish language model trained by the LUMI machine was TurkuNLP's FINGPT3, which was completed in January 2023. It was trained entirely with Finnish material, according to Aleksi Kallio, who is responsible for AI services at CSC. According to Kallio, FINGPT3 was trained with practically all available Finnish text. Meanwhile, Poro, developed in cooperation with Silo AI, was mainly

- There is much more text available in English, which allowed the model to be built by combining both languages. In fact, using English improved Poro because there is more understanding in English of how concepts work and how the world works, Kallio explains.

Next in line is the Viking model, which understands all five Nordic languages, English, and software code. Different versions of the model have been trained (7, 13, and 33 billion parameters), according to Kallio.

The OLMo language model from the American Allen Institute has also been trained using the LUMI supercomputer; it is a 7-billion-parameter model mainly for analyzing scientific texts.

So, how are LLM models trained? These models are trained to predict the desired output from the input or prompt given by the user. During pre-training, trillions of tokens—roughly equivalent to words—are fed into the neural network, which contains a few billion to hundreds of billions of parameters, Kallio notes.

The model also understands concepts such as time and space.- You can't say that the model fully understands the world, but it has some kind of model of it

at its disposal, he says.

This pre-training is such a computationally intensive process that it can only be done on a supercomputer. The model obtained through pre-training is then fine-tuned with a smaller set of data so that it learns to follow rules created for it—this step is also typically carried out on supercomputers.

To train the Poro model, 32 billion Finnish words (tokens), 500 billion English tokens, and 200 billion tokens of software code were used. The data was sampled to ensure that the role of Finnish-language tokens was emphasized.

The results are impressive. In Finnish, Poro 34B performs clearly better than Llama 33B of approximately the same size and is better than other open models. In English, Poro also performs reasonably well, although it lags behind Llama and a couple of others.

- Poro also performs well in program code, better than Llama and almost as well as the Starcoder model, which was specifically developed for programming," says Kallio.

Poro performs particularly well in translations from English to Finnish— even better than OpenAI's GPT-4.

The 6th Annual Embedded Conference Finland showcased the latest trends in embedded design. Increasingly, designers are turning to modules, single-board computers (SBCs), and new integrated solutions to bring their designs to market faster. This approach also helps in meeting the requirements of new cybersecurity legislation.

Over one hundred professionals registered for the ECF24 in Helsinki. Presentations showcased new solutions and sparked lively discussions. The debate between standard versus custom designs remains a talking point in embedded development.

Timo Poikonen of congatec presented the company's module offerings, particularly the new aReady platform, which aims to address the growing challenges faced by designers. Designs are becoming increasingly complex, the number of cyberattacks is rising, interfaces are expanding, and IoT devices are generating exponentially more data to process.

aReady responds to these challenges in various ways. It enables the virtualization of resources, especially through the hypervisor aReady.vt. aReady.com, meanwhile, is a ready-to-use comprehensive solution that includes both hardware and software, while aReady.iot is a connectivity solution for data transfer and automation.

Virtualization essentially means integrating a hypervisor into the modules. It is included in the firmware, like a bootloader. The most common use of a hypervisor is to run one operating system inside another in a virtual machine, such as Linux on Windows. The hypervisor also allows several parallel operating systems to run on the same hardware. Congatec's hypervisor supports virtually all the most popular operating systems, including RTOSs.

aReady.iot is software that congatec previously offered as a separate device for connectivity. Now, it is being developed as a complete software solution, with the official announcement planned for early next year. The idea is simple: make devices accessible from anywhere and enable easy maintenance.

aReady.com itself is a combination of all these components. It includes connectivity, memory, and storage required by hypervisors to run pre-tested and licensed operating systems, readymade functional software components,

and, finally, the customer’s own applications.

One of the operating systems offered for aReady is Bosch Rexroth's CtrlX, which allows, among other things, secure updates for device management. Bosch also has an application store with a wide selection of ready-made applications.

A large portion of embedded designs is based on COM modules. One of the newest standards is OSM, or Open Standard Module. Adlink Technology's Henrik Petersen presented the new module, which differs in several ways from other modules. It is compact, about half the size of an L-sized SMARC module. One of the most important differences is that OSM can be soldered directly onto the PCB, allowing it to be treated like any other BGA component in production, Petersen emphasized.

OSM is hardware-architecture independent, meaning it can support both x86 and Arm processors. Additionally, OSM contains 662 pins,

giving access to all pins of the SoC.- The idea is that all you need is memory and an SSD drive in addition to the module, Petersen explained.

Adlink has already announced three OSM-based products, with more to come this year. According to Petersen, future products will be brought to the OSM platform faster than with other COM cards.

The OSM standard includes four different sizes, with Adlink focusing only on the Large version, which is 45 x 45 millimeters and contains the full number of pins (662). The smaller versions (Zero, Small, and Medium) are more suited for microcontroller-based designs, which are not Adlink's focus.

Despite its small size, OSM is suitable for many demanding applications. The power budget is up to 40 watts, and the module supports a wide range of connections. "Using the OSM module can simplify the system circuit board since fewer layers are needed, which helps to reduce system costs," Petersen said.

Is there still room for custom hardware? Yes, according to Tomi Engdahl of CVG Convergens. Customized solutions give full control over the product and IP rights. "If you want to design a product to exact dimensions, replace a component in an old product, or use specific connections or connectors, a custom solution is the answer," Engdahl said. A long product life cycle often also requires customized device design.

Of course, designers face several decisions when creating custom hardware."Should you choose a microcontroller or an application processor, or both? What operating system should you use? If you choose Linux, you'll need megabytes of memory, while RTOS with a microcontroller may need only a few hundred kilobytes."

The intended life cycle of the product, production volumes, and choice of components are also critical factors.

Several trends are driving growth in embedded application design. Connectivity is a key factor—most devices are connected via some form of radio. Another trend is achieving "more with less"—products should cost less to manufacture, consume less energy, and be designed for reliable production and component availability.

- In addition, people are accustomed to smartphone-style user interfaces, which

means that industrial applications are now also looking for colorful graphical user interfaces, Engdahl added.

Many believe in the power of opensource code, but it doesn't always provide the complete solution.- With open-source code, a lot can be achieved, but maintaining the system can be challenging. For example, patching vulnerabilities can be a significant challenge.

Data security is also an issue. The U.S. government wants to move away from C and C++, as memory-related problems in these languages are often the cause of data breaches. Instead, they aim to switch to memory-safe languages like Rust.

This is, of course, a significant challenge, given that C and C++ dominate the embedded programming market, with a combined market share of over 90% (C around 70%, C++ around 23%). Python holds a 5% share, while Assembly has a 2% share, mainly used in bootloaders and low-resource microcontrollers.

All the ECF24 videos can be found at the ECF Youtube channel. All the presentation slides can be found on the event website at www. embeddedconference.fi

Samsung Electronics has begun mass production of its one-terabit (Tb) quadlevel cell (QLC) 9th-generation vertical NAND (V-NAND).

With the industry’s first mass production of QLC 9th-generation V-NAND, following the industry’s first triple-level cell (TLC) 9th-generation V-NAND production in April this year, Samsung is reinforcing its leadership in the high-capacity, highperformance NAND flash market.

Samsung plans to expand applications of the QLC 9th-generation V-NAND, starting with branded consumer products and extending into mobile Universal Flash Storage (UFS), PCs, and server SSDs for customers including cloud service providers.

The new chips utilize Samsung’s

proprietary Channel Hole Etching technology, which enabled them to achieve the highest layer count in the industry with a double-stack structure. Leveraging the technological expertise developed from the TLC 9th-generation V-NAND, the cell area and peripheral circuits have been optimized, resulting in an industry-leading bit density approximately 86% higher than that of

the previous generation QLC V-NAND.

Designed Mold technology adjusts the spacing of Word Lines (WL), which operate the cells, to ensure uniformity and optimization of cell characteristics across and within layers. These traits have become increasingly important as VNAND layer counts increase. By adopting Designed Mold technology, data retention performance has been improved by roughly 20% compared to previous versions, leading to enhanced product reliability.

Data read and write power consumption has decreased by approximately 30% and 50%, respectively, thanks to Low-Power Design technology. This approach reduces the voltage required to drive NAND cells and minimizes power consumption by sensing only the necessary bit lines (BL).

The third System-on-Chip (SoC) named "Headsail," developed by the SoC Hub consortium, which consists of Tampere University and seven partner companies, is currently being tested at Tampere University.

The SoC was manufactured by TSMC and is the most complex one created by SoC Hub to date. It contains 330 million transistors and complex IPs, such as a 4-core 64-bit RISC-V sub-system, a deep learning accelerator, and numerous company-specific IPs.

- Headsail represents an important milestone for SoC Hub, showcasing our powerful SoC development capabilities, where complex SoCs are built by adding content to previous designs and reusing blocks that are most suitable for the new chip, says Timo Hämäläinen, Professor of Computer Engineering at Tampere University.

Designing and preparing a System-on-Chip all the way to a physical chip is a lengthy process. The design of Headsail began at the end of 2022, concurrently with the completion of the project’s second chip. The design phase was completed in August 2023, and the chip was then sent for tape-out. Approximately three months later, the manufactured unpackaged chip dies arrived at Tampere University and were sent for packaging. A custom 624-pin FCBGA package was designed for Headsail, making the packaging phase particularly significant. The packaging process took approximately six months, and the consortium received the packaged chips in July 2024. After this, the chips were mounted on development boards before testing could begin.

- During the initial phase of testing, it was discovered that the chip is electrically functional. All subsystems can be

switched on and are connectable, and the RISC-V processor subsystem successfully executed the first ‘Hello World’ program on each of its cores, describes Arto Oinonen, who leads the testing process at Tampere University. In addition to functioning processor cores, this also requires the interconnect between the subsystems, programming and data interfaces, and the software development environment to be operational.

The project team will now continue with more thorough testing and building demos. There are multiple planned use cases for Headsail, including AI applications, audio processing, and real-time critical communication applications.

Rutronik has introduced the new Rutronik System Solutions Adapter Board RAB5. This development board is specifically designed for LED applications in the automotive industry and Industry 4.0. The adapter board uses high-performance LEDs from the OSIRE series by ams Osram.

The OSIRE LEDs are designed for dynamic ambient lighting and offer individually addressable chips for maximum flexibility in color and driver selection. The userfriendly GUI from ams Osram also allows for easy programming of each LED, providing unparalleled customization and control options.

With integrated algorithms and a built-in temperature sensor, the high quality of the LEDs is maintained regardless of temperature changes. Impressively, up to

1,000 LEDs can be connected to a single bus, ensuring scalability for various applications.

Thanks to the Arduino interface, the adapter board can also be easily combined with other base boards and adapter boards from Rutronik System Solutions. This modular concept allows for a variety of approaches to quickly, cost-effectively, and easily realize development projects while maintaining technical sophistication.

For example, combining the Adapter Board RAB5 with the Base Board RDK4 is particularly promising for motor control applications. This combination leverages the strengths of both boards, providing a comprehensive platform for the development and testing of automotive applications.

Renesas Electronics has introduced the RX261 and RX260 microcontroller (MCU) groups. The new 64 MHz MCUs deliver outstanding power efficiency, consuming only 69 µA/MHz during active operation and just 1 µA in standby mode. They also allow designers to easily implement water-resistant capacitive touch sensors and provide robust security features.

This combination of performance and features positions the RX261/RX260 Group MCUs for use in applications such as home appliances, building automation, and factory automation devices.

The new MCUs are based on Renesas' RXv3 CPU core, achieving 355 CoreMark at 64 MHz. This score is 2.5 times higher

than that of competing 64 MHz-class MCUs. Compared to other MCUs in the same class, the RX261/RX260 also delivers 25% lower active current and 87% lower standby current.

Renesas' third-generation capacitive touch IP (CTSU2SL) delivers high noise immunity and water resistance, allowing users to implement touch sensors in kitchen appliances and outdoor equipment, such as smart locks. The automatic judgment function reduces current consumption during intermittent operation by enabling touch detection even in standby mode.

The QE for Capacitive Touch tuning tool, along with design guides and sample code, further eases implementation.

Bittium of Oulu, Finland has implemented the quantum-safe ML-KEM algorithm (previously known as CRYSTALS-Kyber), standardized by NIST, into its Bittium SafeMove Mobile VPN software used for encrypting network traffic. With the implementation of this algorithm, the mobile VPN software now offers quantumsafe connectivity between a mobile device and an organization’s services, protecting the organization’s sensitive data from the threat of quantum computing.

-> etn.fi/16768

The TIOBE index ranks programming languages based on their popularity on the web. Python has long occupied the first spot, followed by C derivatives and Java. Now, Rust, thanks to its emphasis on security and speed, is making its way into the top 10 of the TIOBE index.-> etn.fi/16764

Microchip Technology has announced the PIC64HX family of microprocessors, which

addresses the unique demands of intelligent edge designs. The expected arrival of quantum computers will render current security measures ineffective. Addressing current and future security needs, the PIC64HX is one of the first MPUs on the market to support comprehensive defense-grade security, including the recently NIST-standardized FIPS 203 (MLKEM) and FIPS 204 (ML-DSA) post-quantum cryptographic algorithms. -> etn.fi/16764

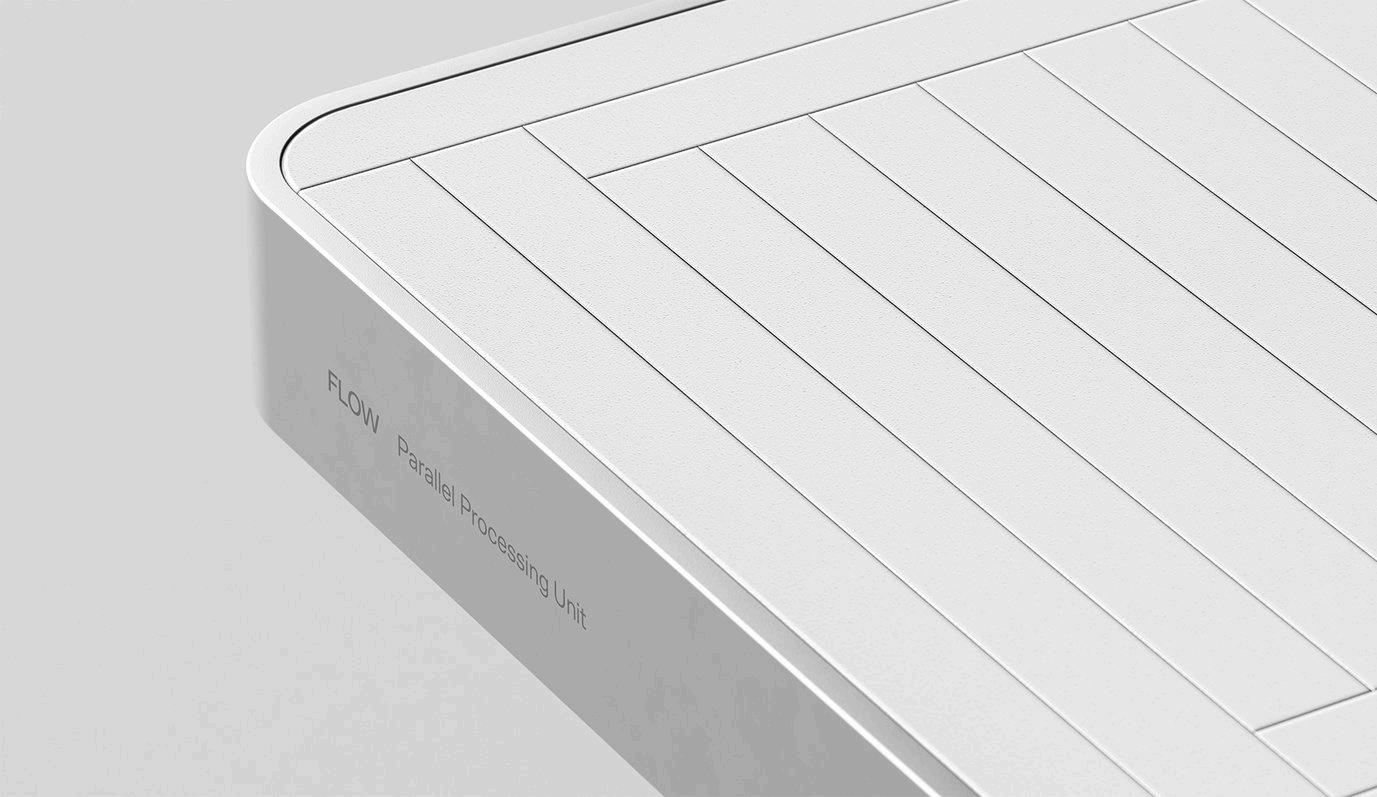

The Finnish startup Flow Computing attracted a lot of attention during the summer by claiming that its PPU architecture for parallel computing significantly improves the performance of all modern processors. Now, Flow has joined RISC-V International and promises a 100x power increase in all current RISCV designs.

RISC-V is now the first CPU architecture officially supported by Flow Computing's PPU technology. According to the company, PPU-enhanced RISC-V designs are fully compatible with all existing RISCV CPU architecture software applications.

Flow's IP can be easily integrated into any CPU design, regardless of architecture, instruction set, or process geometry. The more PPU cores integrated into the processor chip, the greater the performance increase achieved. PPUs can be optimized for different tiers and use cases of the CPU market, including mobile devices, PCs, and supercomputers.

The PPU architecture not only enhances the performance of the device's host processor, but Flow's technology also complements the device's motherboard and peripheral cards. As a result, all other attached units—such as matrix units, vector units, NPUs, and GPUs—benefit holistically from a PPU-enhanced processor.

The father of PPU architecture is Martti Forsell. Research on parallel computing started at the University of Joensuu as early as the early 1990s. It was discovered quite soon that efficient parallel computing was not possible without significant architectural changes to existing machines.

- For this purpose, I began developing new types of processor architectures for both parallel and sequential computing. At VTT in the early 2000s, I demonstrated that the optimal architecture for parallel computing is fundamentally different from the optimal architecture for sequential computing. We developed a suitable computational model, methodology, two-part architecture, and special techniques for this, Forsell told ETN last summer.

The company has promised to fully reveal the details of its technology by the end of the year. Some specifics have already been disclosed. For instance, implementing 64 PPU cores in a 3nanometer process would occupy 21.7 square millimeters of silicon space. A 256core additional processor would take up 103.8 square millimeters of silicon area, roughly equivalent to a one-centimeter edge.

The size increase with more cores is marginal, while the performance boost is impressive. A PPU unit with 64 cores could speed up parallel computing by 38 to 107 times. With 256 cores, the performance of parallel computing could improve up to 148 to 421 times.

But why RISC-V? CEO Timo Valtonen notes that the open ISA will accelerate development.- There are libraries and other components ready, and we are in discussions with different RISC-V CPU manufacturers, Valtonen says.

A Finnish parallel processing unit for Arm or x86 chips could also be developed quickly.- All it really takes is a call from the big processor companies, Valtonen concludes.

NXP Semiconductors announced that its Trimension NCJ29Dx family of UWB products is the technological foundation for Audi’s advanced new UWB platform, delivering the precise and secure real-time localization required by leading premium car manufacturers to enable handsfree secure car access via smart mobile devices and other UWBbased features. Cars featuring NXP’s Trimension UWB devices, including the Audi Q6 e-tron, will hit the road in 2024. The Trimension NCJ29Dx family enables UWB-based fine-ranging capabilities and is compliant with IEEE 802.15.4, CCC, and FiRa standards. It delivers high localization resolution and power optimization for batterypowered devices, such as key fobs, while also minimizing BOM costs.-> etn.fi/16752

EX-VARJO FOUNDERS WANT TO REVOLUTIONISE VR

Urho Konttori and Jussi Mäkinen were part of the founding team at Varjo Technologies almost ten years ago. Now, their new company, Distance Technologies, plans to revolutionize XT technology, or augmented reality technology. Distance develops technology that turns any transparent surface into an augmented industrial surface, where digital content can be mixed with reality. This represents a significant step forward, as it would be possible for the first time to mix digital content with the surrounding world without the need for glasses.-> etn.fi/16744

THE FASTEST SNAPDRAGON

Qualcomm Technologies has unveiled the Snapdragon 8 Elite Mobile Platform, which the company claims is the most powerful and fastest mobile system-on-a-chip ever. This platform debuts industry-leading technologies, such as the second-generation custom-built Qualcomm Oryon CPU, Qualcomm Adreno GPU, and an enhanced Qualcomm Hexagon NPU, all of which deliver gamechanging performance improvements. -> etn.fi/16737

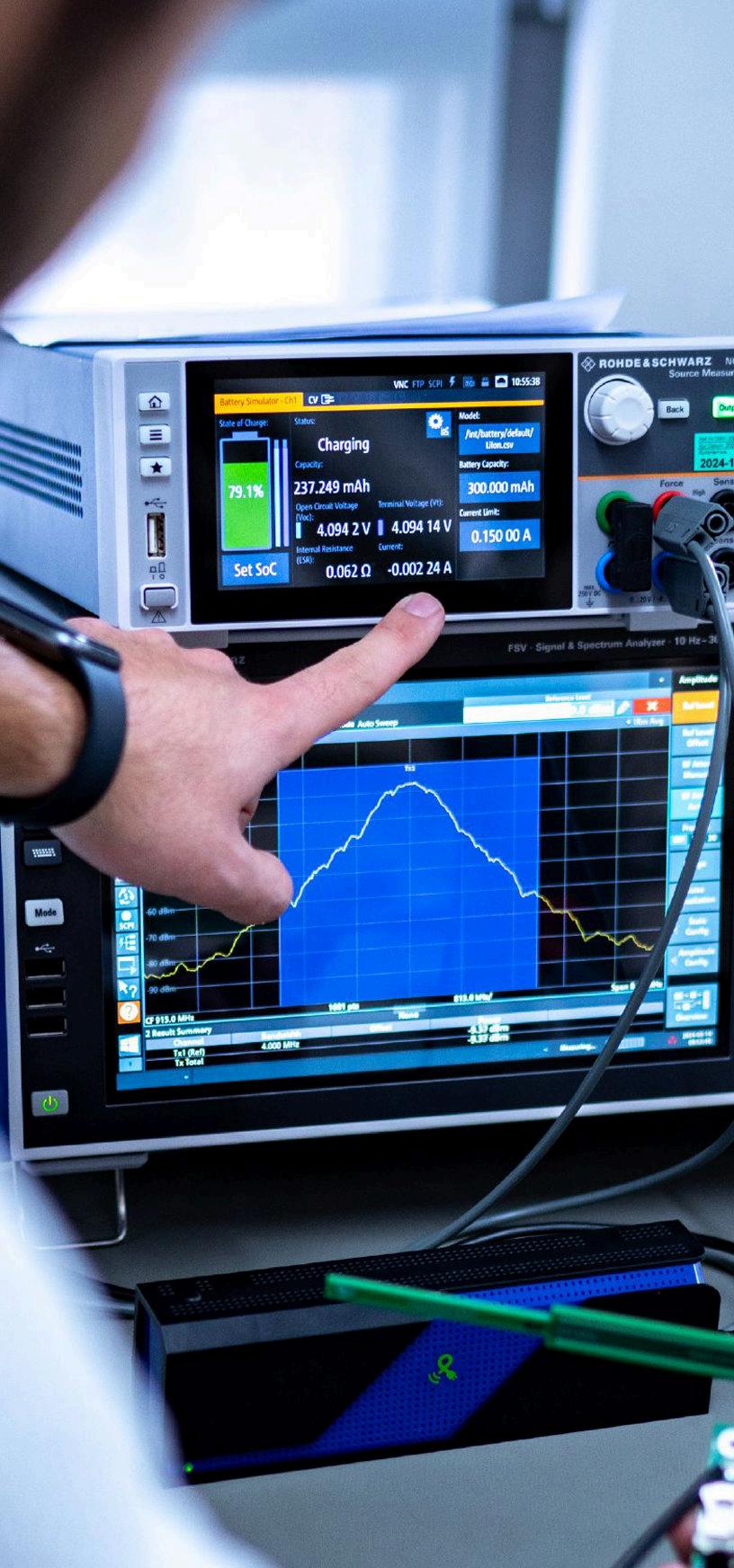

While Qi technology generally requires the wirelessly charged device to lie directly on top of the charging pad, AirFuel technology allows charging from up to several meters away. Rohde & Schwarz has now introduced the first testing solution for the development of these wireless links.

Rohde & Schwarz presented their concept at the IEEE Wireless Power Technology Conference and Expo in Kyoto, Japan. The testing solution uses the company's testing and measurement equipment, as well as the wireless charging development kits available on the market. It also includes test automation and a user-friendly interface.

The AirFuel Alliance officially introduced the AirFuel RF standard in 2019. The RF standard was designed to complement the AirFuel Resonant standard and expand the range of wireless charging options offered by the AirFuel Alliance. AirFuel aims to bring wireless charging capabilities to IoT devices, wearables, and

other gadgets that require a more flexible approach, allowing greater distance and freedom compared to traditional inductive methods like the Qi standard.

Charging with an RF connection involves contactless power transfer technology, which enables multiple devices to be charged simultaneously within a radius of several meters from the power source. This approach eliminates the need for wires and minimizes the hassle of battery maintenance. The wireless RF power supply has a wide range of applications, particularly for low-power IoT devices. For example, in a smart building or a smart car, this technology could provide power to multiple sensors without manual charging or battery replacement.

The goal of Rohde & Schwarz's WPT project is to develop a comprehensive testing solution for wireless power transmitters and receivers. Rohde & Schwarz is an active member of the AirFuel Alliance.

EU is introducing several new directives related to device information security and artificial intelligence. According to Antti Tolvanen, Sales Director at Etteplan, these changes are significant.- In the next three years, most of the current hardware and software products will become illegal, Tolvanen said during his presentation at the ECF24 event.

This development has already begun, starting with cars. Many car manufacturers have announced they are discontinuing certain car models because making them compliant with the new directives would cost up to half as much as developing a completely new model.

Tolvanen was referring to the requirement that cars—and other devices—must now be "secure by design." - It is currently expected that the CRA, or Cyber Resilience Act, will enter into force sometime at the end of 2027, he continued.

The EU's upcoming and partially finalized regulations will have significant implications for anyone designing electronics. In addition to the CRA, a new Radio Equipment Directive (RED) update will require all radio equipment to

support new safety standards by 2025. Most devices sold in the EU will need to meet cybersecurity requirements to receive the CE mark. These requirements apply to the development and documentation of both hardware and software. In practice, designers must adapt their development processes to comply with these new safety standards and ensure product accessibility.

There is also considerable uncertainty

among companies regarding these changes. Tolvanen noted that "launching" refers to the moment when a new product is made available for sale in Europe with CE approval. For physical devices, this limit is clear, but the regulations also apply to software products, which are increasingly being sold as licensed SaaS solutions.

- Every new sales contract represents a new product that must comply with the regulations, Tolvanen emphasized.

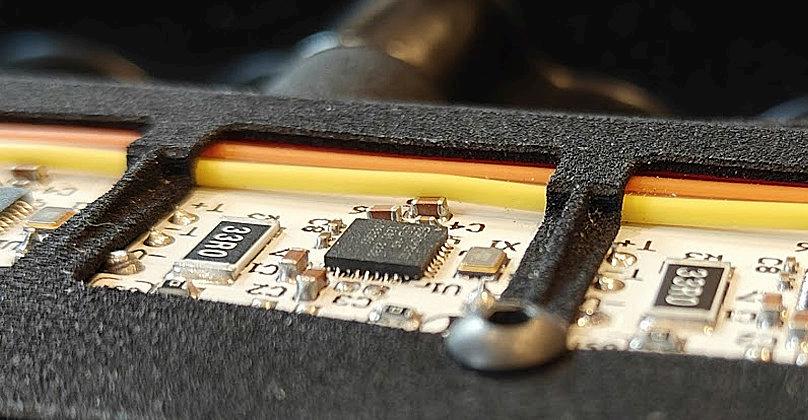

Dukosi from Edinburgh aims to revolutionize battery system monitoring with its new wireless solution. The company now says that its circuits are ready for volume production. The technology is expected to enter the market next year in an "Asian electric car," which presumably refers to a new model from a Chinese EV manufacturer.

The technology developed by Dukosi increases battery performance and lifespan while enabling battery reuse at the end of its life, as the condition of all cells can be tracked throughout their entire lifecycle. The solution involves a circuit installed on top of each cell, which measures various parameters related to the cell's condition. The image shows a 5x5 DK8102 circuit in a protocell.

According to Dukosi, the technology it has developed addresses all three key challenges of electric vehicle batteries: improving performance, reducing cost, and enabling reuse through accurate monitoring, which supports sustainable battery development.

Dukosi has developed its own local radio technology, with measurement data transferred over the link using its proprietary C-SynQ protocol. This protocol synchronizes measurements from the cells, and the link operates at a 2.4 GHz frequency. The solution is also cellagnostic, meaning it can work with any available battery chemistry.

The DK8102 chip is manufactured using GlobalFoundries' 55-nanometer process. According to tests, the Dukosi circuit measures the state and health of the cell more accurately than any other sensor currently available. This precise information can be used to increase the amount of usable energy extracted from the battery by more than 20%.

Professor Bantval Jayant Baliga of North Carolina State University, United States, has won the 2024 Millennium Technology Prize for his innovation that has enabled a dramatic reduction in worldwide electrical energy and gasoline consumption.

The award recognizes Baliga’s leadership in the invention, development, and commercialization of the Insulated Gate Bipolar Transistor (IGBT). Since its development in the 1980s, the IGBT has been the most important semiconductor device for making electrical energy use and gasoline consumption more efficient and less polluting over the last 40 years.

use of renewable energy both efficient and profitable.

The technology has reduced global carbon dioxide emissions by over 82 gigatons (180 trillion pounds) in the past 30 years. This reduction is equivalent to offsetting carbon dioxide emissions from all human activity for three years, based on the average emissions of the past 30 years.

CONGATEC BRINGS AI TO THE EDGE

Congatec has introduced new COM Express Compact Computer-on-Modules with AMD Ryzen Embedded 8000 Series processors. Leveraging the dedicated computing cores of the new Ryzen processors, which feature up to eight ‘Zen 4’ cores, an innovative XDNA NPU, and powerful Radeon RDNA 3 graphics, the new modules deliver impressive performance of up to 39 tera operations per second (TOPS) for AI inference. This makes the new conga-TCR8 Type 6 modules particularly appealing for high-volume, price-sensitive applications.

-> etn.fi/16736

24GB GRAPHICS DRAM IS THE FASTEST SO FAR

Samsung Electronics has developed the industry’s first 24gigabit GDDR7 DRAM. In addition to offering the highest capacity in the industry, the GDDR7 features the fastest speed, positioning it as the optimum solution for next-generation applications. The 24Gb GDDR7 will be widely utilized in various fields that require highperformance memory solutions, such as data centers and AI workstations, extending beyond traditional graphics DRAM applications in graphics cards, gaming consoles, and autonomous driving.

-> etn.fi/16734

AVNET EMBEDDED IS NOW TRIA

The efficiency improvements and reductions in fossil fuel consumption and cost brought by the IGBT have revolutionized the power industry. This innovation has enabled the worldwide green transition and mitigation of global warming by making electrification and the

Baliga's innovation is used worldwide in various applications, including wind and solar power installations, electric and hybrid-electric cars, medical diagnostic machines like X-ray machines, CAT scanners, and MRI units, microwave ovens, induction stoves, air-conditioning and refrigeration systems, and portable defibrillators. Today, IGBT-based power converters and inverters dominate nearly every major application with a power rating between 1 kW and 10 MW.

This summer, Avnet rebranded its embedded products business under the name Tria Technologies. Now, Tria has introduced a new COM Express motherboard for rapid prototyping, technology evaluation, system design, and application software development. Named MSC C6MB-EV4, this Type 6 motherboard allows engineers to evaluate and prototype system electronics and software before an applicationspecific board is available for the designer. It utilizes the features of Tria's COM Express product range and accelerates product development.

-> etn.fi/16725

New Omdia insights into 5G technology forecast that 5G RedCap (Reduced Capability) will surge by 66% CAGR to reach 963.5 million connections by 2030.

These findings highlight the growing influence of 5G technology on IoT (Internet of Things) use cases, as well as the industry’s increasing readiness for RedCap and eRedCap solutions.

As 4G networks begin their gradual phase-out over the next decade, RedCap and its enhanced counterpart, eRedCap (enhanced Reduced Capability), are poised to replace current LTE Cat-1 to Cat-4 devices. The latest 3GPP Release 18 introduces eRedCap, which is designed to offer further reduced capabilities and lower data rate requirements, making it an ideal choice for cost-effective IoT applications. Omdia predicts that eRedCap will follow the path of RedCap, though

with a slight delay of a year or two, bridging the gap as industries transition from 4G to 5G technologies.

Alexander Thompson, Senior Analyst for IoT, stated, that 5G RedCap was specifically designed for IoT applications.- In just a year since the first module launches, we've already seen small-scale deployments and trials begin to take shape, he continued.

- We expect 5G eRedCap to follow a similar path, addressing use cases that demand reduced complexity and lower performance thresholds, Thompsons thinks.

The Omdia report examines ongoing hardware launches and global trials, reflecting the growing interest in 5G RedCap. Companies across various sectors are beginning to deploy RedCap anticipating its wide-scale adoption in the future.

Qorvo has introduced a new System-onChip (SoC) solution for smart home devices, which is currently being sampled with key customers.

This next-generation IoT solution features Qorvo’s proprietary ConcurrentConnect technology, combining multi-network support for Matter, Zigbee, and Bluetooth Low Energy with unrivaled energy efficiency in a scalable turnkey solution.

The QPG6200L is the first product based on a new low-power wireless connectivity platform from Qorvo, designed to address the challenges of today’s rapidly evolving smart home environment by ensuring seamless communication and interoperability across multiple wireless standards. The QPG6200L supports multiple protocols on separate channels simultaneously, delivering the highest RF

performance and reliability for a wide range of consumer IoT applications, including smart lighting, sensors, and home hubs. It also incorporates a built-in secure element and is PSA Certified Level 2 for enhanced IoT security.

Qorvo claims that the QPG6200L sets a new benchmark in energy efficiency for multi-standard SoCs, with an industryleading sleep current of less than 1 µA— 30% lower than competing solutions. It is an ideal choice for low-power applications, such as battery-operated sensors and energy-harvesting devices.

The QPG6200L’s ultra-low power consumption extends battery life, supporting more sustainable smart home solutions.

As the global market for smart home devices continues to grow—with IDC projecting global sales to reach 1.2 billion units by 2028—the QPG6200L is poised to play a crucial role in supporting the next wave of connected devices. Qorvo offers smart home OEMs a turnkey solution for Matter over Thread, simplifying the design process while ensuring robust security and performance across the network. Its PSA Level 2 certification ensures that the QPG6200L solution meets security standards to protect against common software attacks.

QPG6200L SoC samples and development kits are available now, with full production planned for early next year.

The new u-blox X20 platform brings centimeter-level accuracy to mass markets and expands geographical reach and service availability on a global scale. It follows the widely used u-blox F9.

u-blox has announced its new X20 allband high-precision GNSS platform, which raises the bar for accuracy, performance, and security. Building on the success of the company’s popular F9 highprecision GNSS platform, this new generation addresses the current needs of high-precision GNSS around the world, and its future-proof design is also equipped to handle new and emerging technologies and standards.

he platform is designed for industrial automation, automotive, and other applications that require centimeter-level positioning accuracy in challenging environments, as well as for time synchronization in critical infrastructure systems.

The X20 is an all-band (L1/L2/L5/L6) platform with an integrated L-band receiver. Including all available GNSS satellite signals, it provides the highest precision positioning, even in challenging signal environments. It supports the basic L1 and L2 frequencies, along with the L5 band, which operates at lower frequencies than L1 and L2, benefiting from im-

proved signal properties that make L5 signals inherently more robust. The ublox X20 also adds support for the L6 band, which is used not only for navigation services but also for correction services that help improve positioning accuracy.

The new u-blox X20 platform provides maximum flexibility, with built-in support for all types of correction services. It supports local base stations and correction

Barracuda threat analysts have discovered novel evasive techniques that cybercriminals are using to avoid detection by security tools.

One such technique involves a QR code that, instead of being a static image, is constructed using combinations of ASCII/Unicode ‘block ( █ )’ characters. This tactic is designed to prevent security software from extracting the malicious URL embedded within the QR code.

Around a year ago, the volume of QR code-based phishing attacks suddenly surged. Barracuda data shows that approximately 1 in 20 mailboxes were targeted with QR code attacks in the last quarter of 2023.

These attacks typically involved static, image-based QR codes. Attackers would embed malicious links in the QR code and encourage users to scan it, leading them to a fake page that appeared to be a trusted service or application.

Security measures quickly adapted, and tools such as optical character recognition (OCR) scanning were developed to extract,

The X20 platform support all GNSS bands L1, L2, and L5. It also adds support for the new L6/E6 band.

types such as RTK (real-time kinematic), Network RTK, and PPP-RTK, while also introducing the option to utilize PPP (precise point positioning) corrections. The platform’s versatility and scalability allow users to choose the optimal solution for their specific application, balancing cost and precision. Potential applications are numerous, from port logistics and machine control in construction to emerging industrial applications such as UAVs and ground robotics, including lawnmowers.

check, and block malicious URLs within QR codes.

However, Barracuda threat analysts have now identified a new generation of QR code phishing designed specifically to evade OCR-based defenses. In these attacks, the QR code "image" is formed using ASCII/Unicode characters rather than a traditional static image.

In the case discovered by Barracuda, the attacker attempted to impersonate the courier company DHL, asking the recipient to fill out a form by scanning the QR code. Once scanned, the QR code redirected the victim to a phishing site.

In Finland the electronics sector had a turnover of 21 Billion EUR in 2023 and it employs 43 100 people. Computer and IT industry had a turnover of 20 Billion EUR and it employs 85 200 people.

In total these high tech industries cover for more than 50 per cent of Finnish exports. The technology sector does more than 65 per cent of all r&d investments in Finland.

ETN is a Finnish technology media for everyone working, studying or just interested in technology. Through website with daily news and technical articles, daily newsletters and columns ETN covers every aspect of high technology. Join us in 2025. See the media kit here.

face recognition is the first visible benefit of the EU's Artificial Intelligence Act. The goal is to provide support for SMEs to accelerate innovation.

ETN

Artificial intelligence legislation aims to ensure that AI systems and common European data spaces are not only safe, transparent, and traceable but also functional in terms of usability.

The AI regulation now presents a unique opportunity to boost the effectiveness of real-time security monitoring, particularly as social problems escalate in welfare states. Suitable pilot sites for intelligent camera surveillance include Kaisaniemi Park and the main train station in Helsinki. However, technical readiness still depends on receiving permission to use bio-identifiers from the police register.

New Zealand, which has been a peer to Finland in research environments, has greatly benefited from the digital twin (DT) concept. The GenAI4EU initiative of the AI innovation package aims to achieve similar effectiveness.

The next generation of technical surveillance environments, featuring realtime problem detection from a remote control room, can provide rapid emergency response for security gaps, says Thomas Thoden, Technology Director of Hedengren Security, a company that has been developing surveillance technology for 25 years.

In Finland, there is a lack of safety measures in public buildings, business centers, and transportation systems. Predicting problems in the control system is based on learning intelligence, which sifts through large amounts of data, Thoden says. Some of these problems and potential solutions are universal to the Nordic region, such as restraining

orders that prohibit individuals from approaching shops and educational institutions.

The EU's General Data Protection Regulation (GDPR) and its ten data protection rules have prevented the use of real-time biometric registers in security technology. Restraining orders issued by the court regarding schools and shops will not be effective without bioidentification based on police registers. While the digital twin can stop an intruder's progress within a building by locking doors and turning off lights, official assistance would already be on the way.

- The new solutions will improve business and workplace safety, says Miia Ljungqvist, Head of Unit at the Ministry of Justice.

In addition to the EU regulation, real-time facial recognition also requires supplementary national legislation. Beyond facial recognition, intelligent recognition can also include gait and voice recognition, as well as several other biometric systems. Intelligent control systems continuously work to reduce the number of incorrect approvals.

In Finland, there are three separate legislative preparations currently underway in the Ministries of the Interior and Justice. According to Suvi Pato-Oja, a special expert at the Ministry of the Interior, the police are already able to perform biometric facial recognition, but real-time identification at specific

locations is not yet available.

- Currently, the police in Finland use a facial recognition system that can, in some cases, search for a suspect using a single image from police registers to identify them, Pato-Oja explains.

The transition to real-time bioidentification is also being governed by a draft law related to background checks. "The Ministry of the Interior's police department is also preparing another law that aims to explore the broader use of biometric data from passport and identity card registers to prevent, detect, and investigate crimes," adds Pato-Oja.

There will be a centralized identification register for individuals banned from entering specific companies by coercive measures.

The Ministry of the Interior’s law preparation focuses specifically on the modification of passport and identity card registers, as well as information on foreign nationals. According to Pato-Oja, the aim is to determine how biometric data from passport and identity card registers, as well as biometric data of foreign nationals in police registers, can be utilized in technical crime prevention.

According to the current plan, the government's proposal will be presented to parliament after a round of consultations and further preparation by the end of the spring session in 2025. Meanwhile, the EU’s regulation on realtime facial recognition by police will be ratified separately into national law.

64-bitmicroprocessors withNeuralProcessingUnit builtforspeed,securityandreliability

STM32MP2serieselevatesindustrialcapabilities withaperformancesurgeandrobustresilience, engineeredforcritical,time-sensitivetasks, AI-drivenprocesses,andsecurecommunications, ensuringadecadeofreliable,uninterruptedservice.

When will the downturn end? When will the market pick up? ETNdigi spoke with Graham Maggs, VP of Marketing EMEA at Mouser Electronics, to learn from his insights and experience.

Mouser previously stated that the turn to growth would occur in Q3 or early next year. Now, everyone is talking about a prolonged downturn. What has happened?

Predicting today’s markets remains challenging. In 2024, we have seen a global economy marked by interesting highs and lows. The projected growth of 3.2% in 2024 may not meet expectations, but the International Monetary Fund (IMF) anticipates slightly higher growth of 3.3% in 2025. Those who showcase resilience, invest strategically, and remain open to new opportunities are seeing positive results.

Germany seems to be struggling significantly. Is this related to specific sectors (automotive, industrial perhaps?), or is it more general?

The impact of the automotive and industrial sectors on Germany is a complex interplay. When these sectors thrive, Germany's economy prospers as well, as they are key drivers of its gross domestic product (GDP). For instance, the automotive industry makes up almost 5% of Germany's GDP, compared to about 2% of the UK's GDP. In recent years, however, these industries have faced numerous challenges.

The global semiconductor shortage and the complex shift towards electric vehicles (EVs) have presented many challenges for the automotive sector, often requiring heavy investments to address. Moreover, the added pressure from emerging manufacturers in China has further increased the difficulties for German brands. For example, Chinese OEMs are diminishing Volkswagen Group’s market share in China—a region that has historically been crucial for the company. Additionally, car production in Europe has decreased by 2.5 million vehicles over the past five years, which significantly affects Germany as the largest car manufacturer in Europe.

Component shortages have also impacted the industrial sector. However, arguably, the biggest challenge has been the surge in energy prices. Between 2021 and 2023, energy prices in Germany rose by over 40% due to geopolitical tensions. This increase has made energy-intensive industrial operations more costly, reducing their profitability and competitiveness.

What about the rest of 2024? Can you forecast the entire distribution market? How will Mouser perform?

The distribution market continues to evolve, driven by rapid technological advancements across sectors such as industrial, telecommunications, and consumer electronics. Innovations in Artificial Intelligence (AI), machine learning (ML), power electronics, and communication technologies are creating new opportunities and shortening development cycles, particularly in smart home and industrial solutions.

For Mouser, this translates to increased demand for low-power microprocessors (MPUs), communication modules, hardware security solutions, and development kits supporting AI and ML integration. IoT and renewable energy sectors are also showing strong growth, driven by these advancing technologies.

Nevertheless, significant market challenges remain, which may hinder growth for many companies. However, investments and diversification of product lines should help manufacturers and distributors find new opportunities in 2025.

Mouser's business is closely linked to design and development activities, where engineers need small to medium quantities of components to be delivered quickly. Therefore, it is essential for us to closely support sectors such as IoT and renewables, as well as specific

technologies like AI and ML, where development activities and market competition are high. This can be achieved by maintaining stock levels and expanding our product range, with a significant focus on new product introductions (NPIs).

Many say that Europe is not capable of benefiting from the AI hype. Is there a reason for this?

While Europe’s stricter regulatory environment and greater aversion to risk compared to the US and China have slowed the development of certain types of AI, particularly generative models, there are still areas where European companies excel. For example, in the healthcare sector, AI companies are successfully developing applications for medical diagnostics and personalized medicine. There are also numerous success stories across the automotive, industrial automation, agricultural, environmental, and energy sectors. So, while Europe may not be at the forefront of the AI 'hype', it is certainly contributing to and benefiting from its success.

Sumeet Kulharni

SiTime

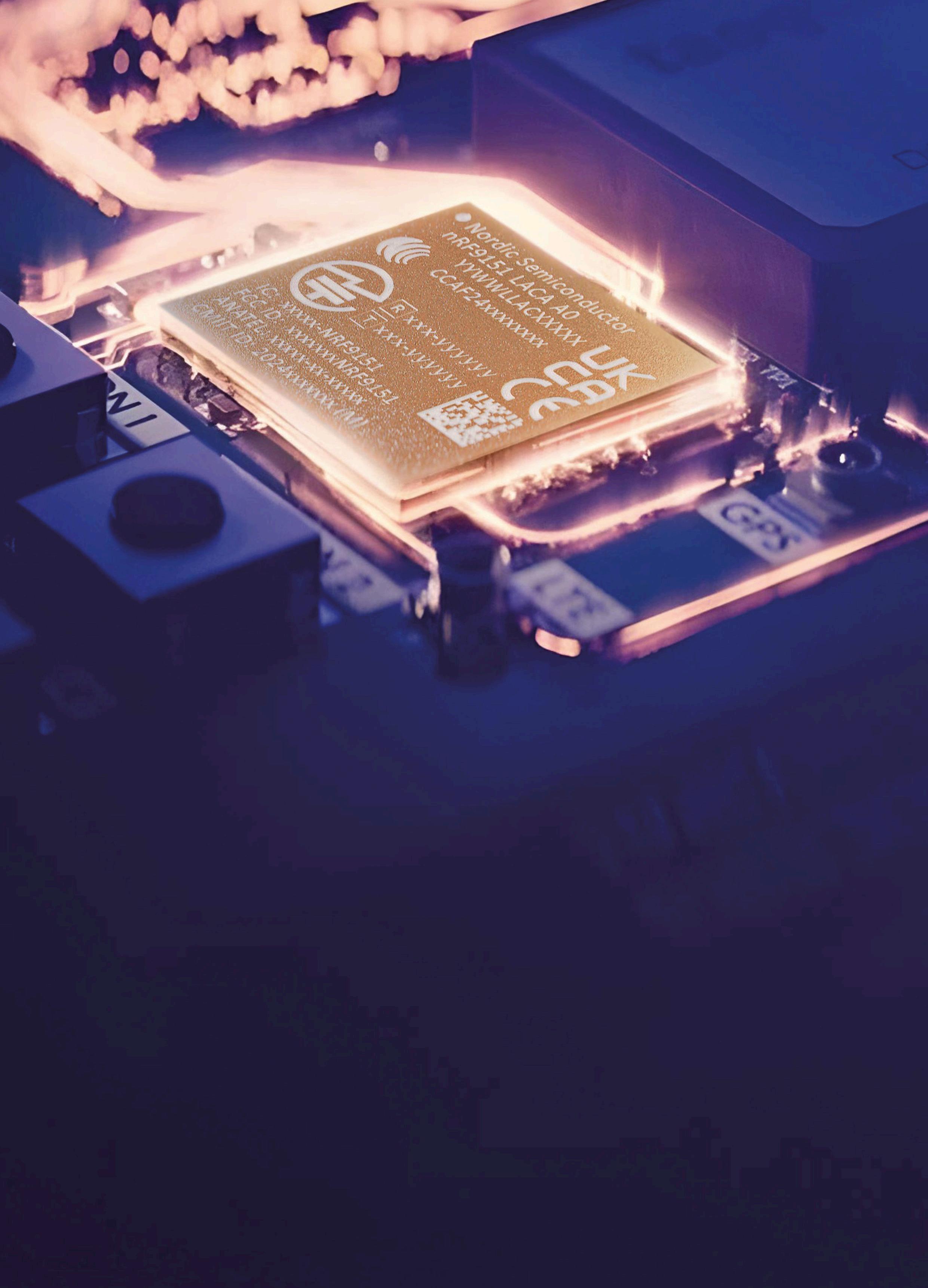

SiTime has introduced Chorus Automotive Clock Generators—the industry’s first fully integrated clock system-on-a-chip (ClkSoC) with built-in fault monitoring mechanisms for the entire clock generation signal path. The FailSafe technology in Chorus automotive delivers a new approach to the industry, integrating a MEMS resonator, oscillator and advanced safety mechanisms into a single package.

This integration simplifies system timing architecture and accelerates functional safety development time by up to six weeks. Hardware designers get the combined benefits of up to 10X higher performance in half the size compared to standalone oscillators and critical diagnostic coverage to achieve functional safety metrics more easily.

Autonomous and semi-autonomous driving are becoming reality, and the automotive industry is fast converging on the ultimate goal of software-defined vehicles (SDVs). Whether implementing autonomous driving (AD) or advanced driver assistance system (ADAS), Chorus with FailSafe technology fulfills the timing needs of safety-critical systems.

Automotive engineers face unique challenges in implementing SDVs. Car buyers expect a user-

experience as seamless as smartphones but without compromising safety. As vehicles become more autonomous, hardware malfunctions are not merely annoying, they also can have serious consequences for life and property.

The ultimate SDV is a ruggedized datacenter-onwheels. SDVs pipe in real-time information from sensors – cameras, Lidar, radar and more. The car is expected to process the data and make decisions instantaneously, prioritizing safety for the people in the car and on the road. This high-performance computing (HPC) infrastructure supports 1000s of tera operations per second (TOPS). It requires a synchronous precision timing network with guaranteed reliable performance under shock, vibration, and extreme weather, with lifetimes spanning decades.

SiTime brings its pioneering leadership in ruggedized MEMS timing technology and

synchronized high precision timing networks for datacenters to the automotive space. Chorus automotive with an industryfirst wide operating temperature range from -40°C to 125°C is uniquely positioned to remove any thermal bottlenecks in the design of safety critical modules.

Conventionally, if the clock for a critical component fails, catastrophic failures can occur – a processing unit may stop operating, or a high-speed link may drop packets. A safety microcontroller in the system monitors such large-scale failures and disables the failing function to reach a safe state. For instance, when a car alerts you that lane assist is no longer available, it is ensuring a safe state where you do not rely on the malfunctioning feature. Time is of the essence in these life-saving functions. Engineers aim to reduce this fault-tolerant

time interval (FTTI, or the time between a fault occurring and the system notification). Chorus automotive can shave off critical milliseconds by reporting clock failures far earlier.

FTTI requirements are common for Automotive Safety Integrity Level (ASIL), part of the ISO 26262 standard, the framework for classifying hazards caused by malfunctioning automotive systems. ADAS sensors and central compute ECUs are expected to meet the requirements of high ASIL ratings to be certified for managing the most critical hazards despite malfunctions. Each module requires a detailed analysis of failure scenarios, assigning failure probabilities and diagnostic coverage metrics to every component part.

To ease the certification journey, engineers must start from the right building blocks— components that are less likely to fail and

This example shows how Chorus automotive with FailSafe technology simplifies the ADAS ECU clock tree. A single Chorus handles the precision timing for ADAS compute SOCs and multiple highspeed interfaces.

have effective diagnostics for early fault detection. Chorus automotive, with its FailSafe technology, addresses the limitations of legacy quartz-based clock generators in meeting these challenges, with up to 10X lower failure rates and advanced diagnostics.

In the past, the timing network consisted of standalone oscillators. These oscillators could not be synchronized, nor did they have diagnostic features. Sometimes multi-output clock generators were used, commonly paired with an external quartz resonator, which suffers from impedance matching and noise issues. Chorus automotive replaces up to four differential or eight single-ended standalone oscillators, shrinking the timing footprint on circuit boards by up to 50% and eliminating any noise or impedance mismatch issues.

Moreover, each Chorus clock output is individually programmable and controllable. Its behavior can be tuned for specific system needs, controlling electromagnetic interference (EMI) or adjusting phase shifts and delays to manage long circuit board traces.

Now, multiple clocks can be easily integrated into a single compact device, for example, to consolidate a complex clock tree of an ADAS ECU or zonal gateway (see picture on the adjacent p. 24).

This example shows how Chorus automotive with FailSafe technology simplifies the ADAS ECU clock tree. A single Chorus handles the precision timing for ADAS compute SOCs and multiple high-speed interfaces. It is the only precision timing device with end-to-end signal monitoring and alerting, enabling greater safety while reducing power, total cost of ownership and board space.

1000X FASTER

Competing clock generators, if they have any monitoring features, focus mainly on detecting external quartz resonator failures, which are notoriously common. This leaves a dangerous blind spot in fault coverage with no visibility into the rest of the clock signal chain (oscillator, phase-locked loop, output drivers, etc.).

Having solved the quartz failure problem, Chorus automotive provides end-to-end, continuous, real-time fault monitoring from the MEMS resonator to output pin, as well as the power rails, internal memory, and chip temperature. Safety visibility for each clock output can be individually tailored, depending on the system’s functional safety goals.

With the capability to alert a safety microcontroller of a clock-related fault within microseconds instead of milliseconds, far before any downstream failures can occur, automobiles can return to a safe state up to 1000x faster than before. This combination of dramatically lower failure rates, expanded diagnostics, and faster reporting allows engineers more room in their overall “safety budget.” It can save weeks of engineering work and lower solution costs spent on external monitoring mechanisms.

Notably, the safety microcontroller itself should be clocked by a separate oscillator to avoid any potential dependent failures. SiTime has the required expertise to advise on intelligent partitioning of the clock tree to achieve the twin goals of integration and safety.

Chorus automotive orchestrates complex timing for automotive compute and sensor

systems by providing up to four configurable differential or up to eight single-ended low skew outputs. Its FailSafe technology enables ease of functional safety design by providing programmable end-to-end safety monitors. It is PCI Express (PCIe) Generations 1 - 6 compliant, with spread-spectrum options, onchip regulators for extremely good power supply noise rejection, and phaseconfigurable and programmable skew outputs.

Chorus can alert an external safety manager MCU to any clock faults via configurable general-purpose I/O (GPIO) pins. The serial interface (I2C or SPI) can be used to read

internal registers, including the status of the internal monitoring functions. These devices additionally enable high levels of flexibility using the in-system configuration (ISC) mode to modify the device configuration and each output behavior via the serial interface.

• Chorus Automotive

• Related content:

The future of E/E architecture and its impact on clocks

• Higher performance: Up to 10X better resilience with integrated MEMS resonator.

• Features to enable functional safety: Built-in programmable fault monitors.

• Design simplicity: Integrated MEMS technology speeds the design process and eliminates common issues such as noise and impedance matching.

• Smaller footprint: up to half the size in a 4 mm x 4 mm QFN.

• Flexible frequency: Programmable frequency from 1 MHz to 700 MHz.

• Low RMS phase jitter: 70 fs typical (12 kHz to 20 MHz).

• Excellent frequency stability: ±20 ppm (-40°C to 105°C) or ±50 ppm (-40°C to 125°C).

• Flexible output types: Up to four differential (LVPECL, FlexSwing, LVDS, HCSL, LPHCSL) or eight LVCMOS outputs.

• Reduced power and simplified circuitry: FlexSwing output reduces power consumption and eliminates termination resistors.

• Flexible supply voltage: Programmable, 1.8V, 2.5V, or 3.3V.

• EMI reduction: Configurable spread-spectrum, programmable rise/fall times.

• Compliant with the latest PCIe standard: Generation 1 to 6.

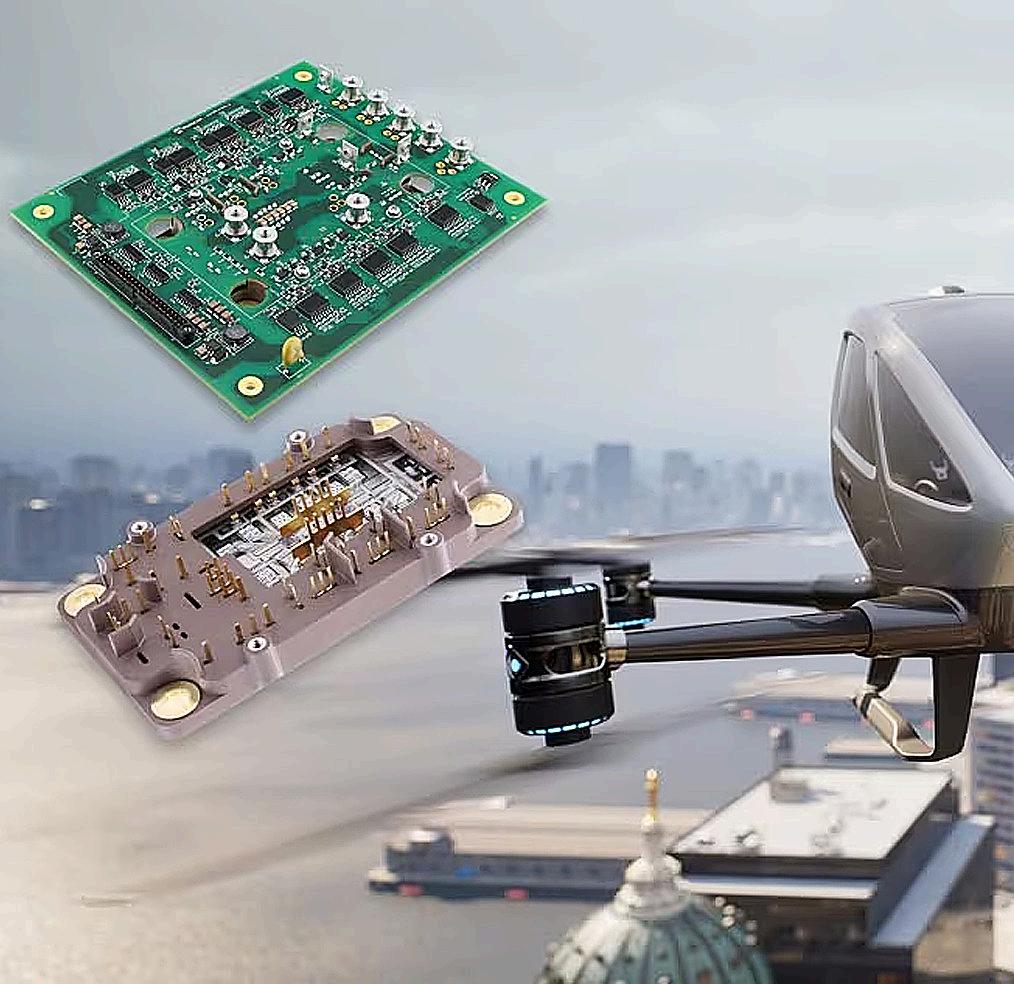

Traditionally, aircraft have used hydraulic actuators to maneuver primary and secondary flight controls, landing gear, braking systems, and deicing systems. The electrification of the aerospace sector is driving a transition from hydraulic actuators to power electronics drives to reduce weight, complexity, and maintenance requirements while improving reliability.

Amit Gole Microchip Technology

Airplanes have several flight controls that help it to maneuver on land and in the air. An airplane rotates in bank, pitch, and yaw while also moving horizontally, vertically and laterally. The four fundamentals (straightand-level flight, turns, climbs and descents) are the principal maneuvers that control the airplane through the six motions of flight. On land, the rudder is used to taxi the airplane left, right or straight. In the air, both primary flight controls and secondary flight controls are used. Primary flight controls consist of rudder to control the yaw, along the vertical axis, elevator to control the pitch up and down along the lateral axis, and aileron to control the bank or to turn the airplane along the longitudinal axis, which coordinate rudder and elevator as necessary.

Secondary slight controls consist of trim, flaps and spoiler. Trim control surfaces are required to offset any constant flight control pressure inputs provided by the pilot. Pitching moments may also be generated by

extension and retraction of flaps, landing gear and other drag producing devices, such as spoilers.

Primary flight controls are a must and hence the name while secondary flight controls help to enhance the motion of the airplane in the air with finer control.

In addition, there are many other tasks that are performed by the actuator namely deicing, landing gear operation, power door opening and deicing.

The flight controls get active as the plane gains speed in the air and encounters a large amount of force. To move these surfaces, pneumatic actuators were used in the early 20th century. Around the 1930s, aircraft started using hydraulic actuators. These hydraulic actuators consist of centralized hydraulic reservoir, filters, pumps and incompressible liquid to move the actuators with aircraft engine directly driving the

hydraulic pumps. These actuators eventually moved to electro-hydraulic actuators that maintained the centralized hydraulic fluid reservoir, while electric motor being used to drive the centralized hydraulic pumps. Most of the old generation aircraft in service use this technology. The key issue with this central hydraulic system is maintenance, plumbing, frequence changes in filters, higher weight, bulkier systems and higher energy consumption.

With the invention of actuation technology there is a transition from traditional hydraulic systems (EH) to Electrohydraostatic actuators (EHA), Electrical back up hydraulic actuators (EBHA) and Electromechanical Actuators (EMA) with the end goal to replace the central hydraulic system with Fly by Wire (FBW) to reduce system weight, power consumption, complexity and maintenance all while improving reliability.

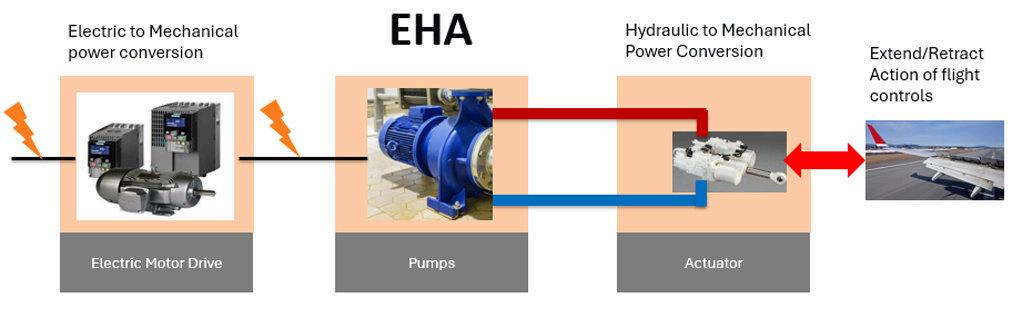

Electro hydrostatic actuation (EHA): Electro hydrostatic actuation (EHA) system eliminates the need for central hydraulic systems These systems use electric power for aircraft flight control-surface actuation that results in reduced aircraft weight, efficient power consumption, and improved maintainability.

EHA systems are power-by-wire actuation systems that utilize aircraft electric power for flight control surface actuation. These systems are highly energy efficient and provide an overall weight benefit to the aircraft. EHA technology is power-ondemand actuation that results in reduced overall aircraft power consumption. EHAs

result in improved maintainability since there are no hydraulic connections between actuation equipment and the vehicle system. EHAs consist of a fixed displacement, high speed, reversible pump driven by a brushless DC electric motor. Actuator position is controlled by the pump rotation direction and actuator piston velocity is controlled by pump rotational speed. The actuator output force is a function of the electric motor output torque.

Electrical backup hydraulic actuation (EBHAs): EBHA system is like that of EHA Systems. However, it is generally used to provide back up for the central hydraulic systems and has similar advantages as those of EHA.

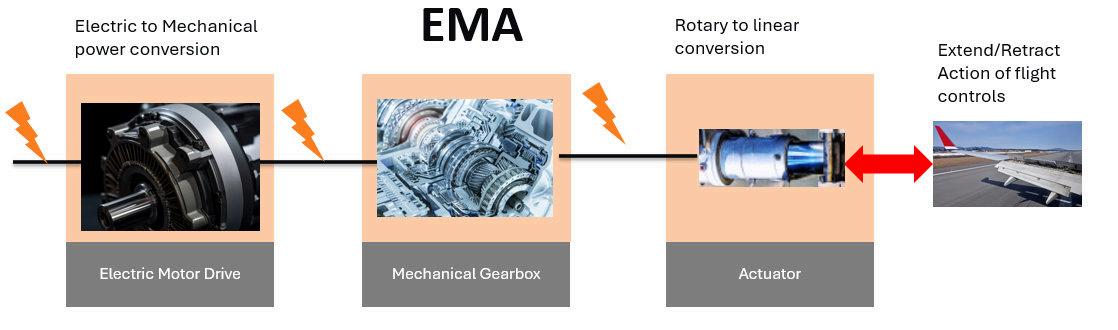

Electromechanical actuation (EMAs): EMA systems are power by wire system that eliminates the need for central hydraulic systems, as well as any sort of hydraulic elements because of its use of mechanical actuators. Electric motor is dedicated and located at each mechanical actuator on the aircraft. These type of actuators remove the use of pumps and instead use mechanical gearbox or similar arrangement powered by an electric motor. This mechanical gearbox drives rotary to liner conversion to move the flight controls.

The key benefit of this transition from centralized hydraulics systems to EHA/EBHA and EMA includes but is not limited to significant weight savings, increased

Primary Flight controls from FAA Airplane Flying Handbook.

performance, enhanced safety due to improved reliability in demanding conditions, reduced maintenance cost and lower operating life cycle costs. All these factors together reduce the carbon footprints of the airplane. The bigger the airplane the more significant the benefits. This transition needs rugged, reliable, cost efficient, compact power electronics drive to run the motors that in turn drive the actuators.

As aircraft evolve to More Electric Aircraft (MEA) and eventually to fully electric aircraft, actuation systems will be one of the first systems that is likely to get electrified. This gives us the opportunity to provide solutions for applications including but not limited to commercial, cargo and smaller training aircraft, in addition to the defense sector, eVTOL, drones and multi-copters.

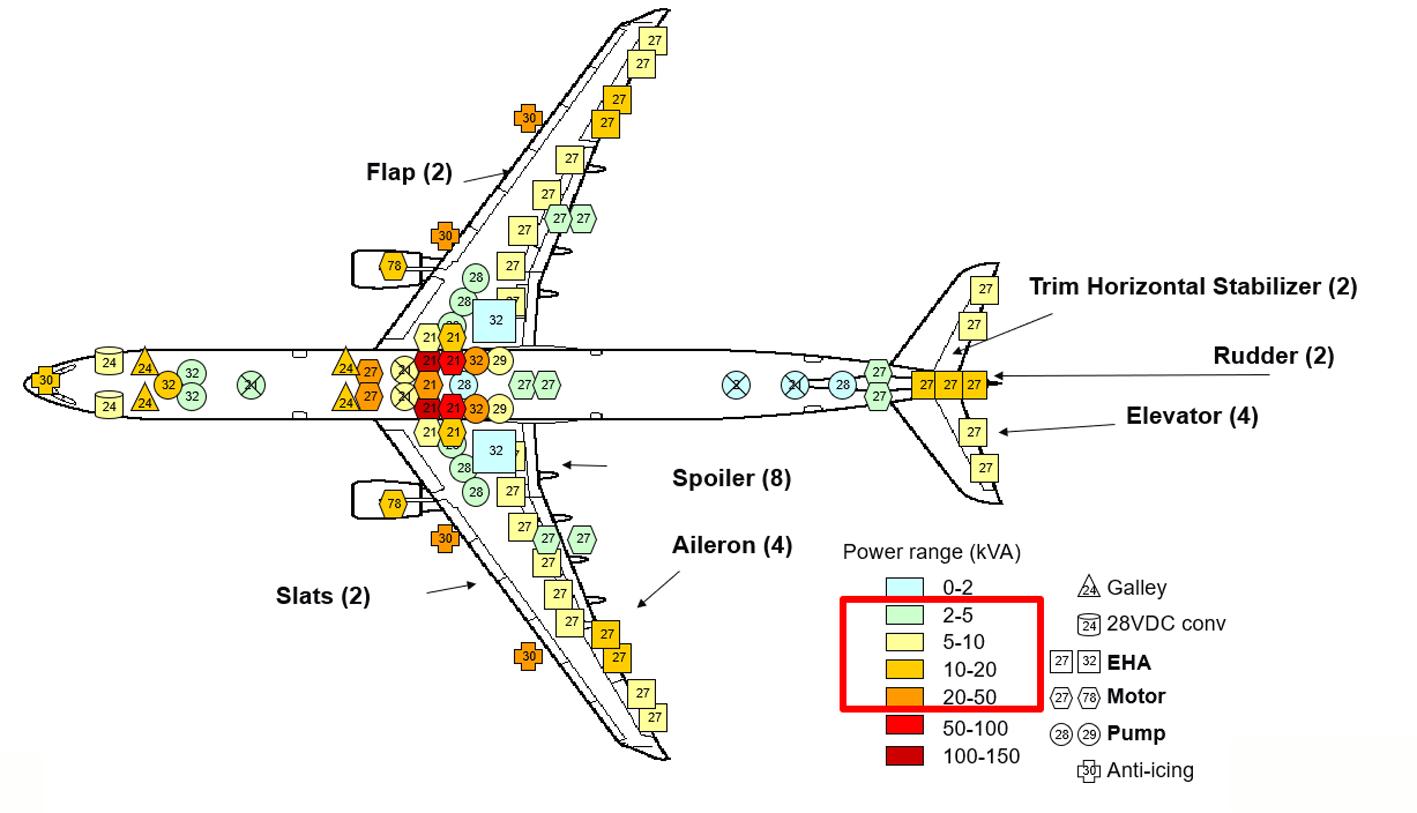

The figure below shows an example of More Electric Aircraft (MEA) that will need power electronics solutions for 24 flight controls, 5 landing gear, 10 fuels pumps and

Types of Actuators, Transition to EHA and EMA is the first step in decarbonization.

8 doors. This demonstrates the need for power solutions that enable the change towards decarbonization.

There are multiple growth drivers that enable the demand for actuation electrification:

• Electrification of commercial and cargo airplanes

• Growth in passenger traffic

• Fleet modernization

Market segments and growth drivers.

• Electrification of military and defense airplanes

• Fully electric/H2/hybrid smaller aircraft

• Electric VTOL (EVTOL) use for public and cargo transfer

• Drones and multi-copter usage for service and agriculture

Some of the key forecasts and analyses from the commercial aviation market reinforce the potential for an expanding electric actuation market.

Fleet modernization: Airlines will require the latest, most efficient and lowest-emission aircraft. As of the year 2022, only 25% of the commercial fleet has been electrified.

Passenger Traffic: Passenger traffic is expected to grow at 3.6% from 2019 to 2041 and will increase the number of aircraft to satisfy this demand.

New generation planes: By 2041, the new generation of airplanes will represent more than 95% of the fleet. Since these planes will use electrical actuation instead of hydraulic, the demand is likely to be higher. When compared to 2021, only 20% of the fleet represented new planes.

In summary, there is a demand of more than 40,000 new airplanes considering both growth ( >23,000) and replacement ( > 17,000) by 2042.

To enable this transition, the capability to integrate different power electronic components for functions like motion of power control but also to provide configurability, standardization, modularity, and reliability to meet the aerospace standards.

The actuator generates a translational motion in the forward and reverse direction, which gets converted into rotational motion for flight controls. To replace the traditional hydraulic system with power electronics, we need to have several capabilities. Depending on the nature of flight control, the configurations could be mandatory or optional.

The power range of the typical actuator ranges up to 25 kW for operating pressure of 5000 Psig with stroke length of 10 inches. These ratings vary depending on the applications but provide a very generic rating that is commonplace in the aviation industry. The DC link voltages are primarily 270V and 540V. The electric motor switching frequency varies between ~2 to 10KHZ. Due to the higher voltage involved it is important to have fully isolated module with enhanced thermal capabilities to provide low power loss and high efficiency to enable smaller weight and footprints. It is essential to have 650V to 700V power modules for 270V DC

link and 1200V for 540V with the ability to provide derivatives up to 1700V, if required.

Both Hybrid SiC (IGBT + SiC D) and SiC are recommended to provide optionality to the customer. For relatively high frequency, full SiC, including SiC MOSFETs and Schottky diodes, helps to reduce switching losses while hybrid SiC balances the benefits versus cost when the Fsw is relatively lower. The low junction to case thermal resistance and Silicon Nitride (Si3N4) substrate improves the thermal performance of the module. Use of Aluminum-Silicon Carbide (AlSiC) baseplate further reduces the weight while extending the reliability of the solution. This results in high-power density, which helps to shrink the size and weight of the solution, thereby allowing greater power density in the given area. This is a critical differentiator in aerospace applications. Lower thermal losses reduce the cooling requirements and improve the overall efficiency of the converter, impacting the power consumption positively.

The Integrated Actuation Power Modules need to have very low package inductance. The rate of change of current (di/dt) could be substantially higher due to high switching frequency (Fsw). This high di/dt with higher stray inductance results in higher overall inductance and higher voltage overshot during the switch turn-off. [V overshoot = V & L di/dt]. Having lower overshoot improves the ruggedness of the power module.

It is also important to have temperature monitoring that can be easily implemented to control temperature conditions and improve protection. Monitoring of DC bus,

Qualification test plan.

Inverter, and solenoid current with feedback to control circuity enhances durability of the power module.