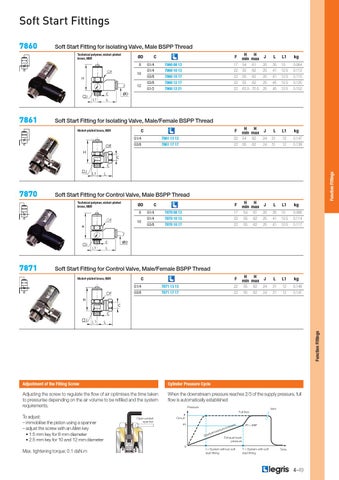

Soft Start Fittings Soft Start Fitting for Isolating Valve, Male BSPP Thread Technical polymer, nickel-plated brass, NBR

ØD 8 10 12

7861

C G1/4 G1/4 G3/8 G3/8 G1/2

C 7861 13 13 7861 17 17

G1/4 G3/8

L

L1

kg

17 22 22 22 22

54 55 55 55 63.5

35 41 41 45 45

10 12.5 12.5 12.5 12.5

0.064 0.112 0.115 0.125 0.152

F

H H min max J

L

L1

kg

22 22

54 55

31 31

12 12

0.147 0.139

F

H H min max J

61 62 62 62 70.5

20 25 25 25 25

62 62

24 24

Soft Start Fitting for Control Valve, Male BSPP Thread Technical polymer, nickel-plated brass, NBR

ØD 8 10

7871

H H min max J

Soft Start Fitting for Isolating Valve, Male/Female BSPP Thread Nickel-plated brass, NBR

7870

7860 08 13 7860 10 13 7860 10 17 7860 12 17 7860 12 21

F

Raccords Functionà Fittings fonctions

7860

C G1/4 G1/4 G3/8

7870 08 13 7870 10 13 7870 10 17

17 22 22

54 55 55

61 62 62

20 25 25

L

L1

kg

35 41 41

10 12.5 12.5

0.066 0.114 0.117

L

L1

kg

31 31

12 12

0.148 0.141

Soft Start Fitting for Control Valve, Male/Female BSPP Thread Nickel-plated brass, NBR

C 7871 13 13 7871 17 17

H H min max J

22 22

55 55

62 62

24 24

Raccords Functionà Fittings fonctions

G1/4 G3/8

F

Adjustment of the Filling Screw

Cylinder Pressure Cycle

Adjusting the screw to regulate the flow of air optimises the time taken to pressurise depending on the air volume to be refilled and the system requirements.

When the downstream pressure reaches 2/3 of the supply pressure, full flow is automatically established

To adjust: – immobilise the piston using a spanner – adjust the screw with an Allen key • 1.5 mm key for 8 mm diameter • 2.5 mm key for 10 and 12 mm diameter

Pressure

Open-ended spanner

Vent

Circuit

P1

0

Max. tightening torque: 0.1 daN.m

Full flow

P

e eas incr sure s e r lp dua Gra Exhaust back pressure

t = System without soft start fitting

P1 = 2/3P

T = System with soft start fitting

Time

4-49