Technical Manual V-Belts

Standard Range optibelt SK Wedge Belts to USA Standard RMA/MPTA

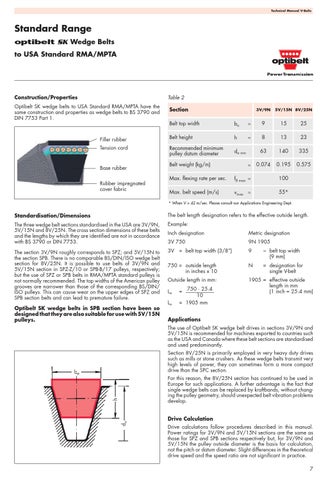

Construction/Properties

Table 2

Optibelt SK wedge belts to USA Standard RMA/MPTA have the same construction and properties as wedge belts to BS 3790 and DIN 7753 Part 1.

Section

3V/9N

5V/15N 8V/25N

Belt top width

bo

≈

9

15

25

Filler rubber

Belt height

h

≈

8

13

23

Tension cord

Recommended minimum pulley datum diameter

da min

63

140

335

0.074

0.195

0.575

Base rubber Rubber impregnated cover fabric

Belt weight (kg/m)

≈

Max. flexing rate per sec.

fB max ≈

100

Max. belt speed (m/s)

vmax ≈

55*

* When V > 42 m/sec. Please consult our Applications Engineering Dept.

Standardisation/Dimensions

The belt length designation refers to the effective outside length.

The three wedge belt sections standardised in the USA are 3V/9N, 5V/15N and 8V/25N. The cross section dimensions of these belts and the lengths by which they are identified are not in accordance with BS 3790 or DIN 7753.

Example:

The section 3V/9N roughly corresponds to SPZ; and 5V/15N to the section SPB. There is no comparable BS/DIN/ISO wedge belt section for 8V/25N. It is possible to use belts of 3V/9N and 5V/15N section in SPZ-Z/10 or SPB-B/17 pulleys, respectively; but the use of SPZ or SPB belts in RMA/MPTA standard pulleys is not normally recommended. The top widths of the American pulley grooves are narrower than those of the corresponding BS/DIN/ ISO pulleys. This can cause wear on the upper edges of SPZ and SPB section belts and can lead to premature failure. Optibelt SK wedge belts in SPB section have been so designed that they are also suitable for use with 5V/15N pulleys.

Inch designation

Metric designation

3V 750

9N 1905

3V = belt top width (3/8“)

9

≈ belt top width (9 mm)

750 = outside length in inches x 10

N

= designation for single V-belt

Outside length in mm:

1905 = effective outside length in mm (1 inch = 25.4 mm)

La La

= 750 · 25.4 10 = 1905 mm

Applications The use of Optibelt SK wedge belt drives in sections 3V/9N and 5V/15N is recommended for machines exported to countries such as the USA and Canada where these belt sections are standardised and used predominantly. Section 8V/25N is primarily employed in very heavy duty drives such as mills or stone crushers. As these wedge belts transmit very high levels of power, they can sometimes form a more compact drive than the SPC section.

da

For this reason, the 8V/25N section has continued to be used in Europe for such applications. A further advantage is the fact that single wedge belts can be replaced by kraftbands, without changing the pulley geometry, should unexpected belt vibration problems develop. Drive Calculation Drive calculations follow procedures described in this manual. Power ratings for 3V/9N and 5V/15N sections are the same as those for SPZ and SPB sections respectively but, for 3V/9N and 5V/15N the pulley outside diameter is the basis for calculation, not the pitch or datum diameter. Slight differences in the theoretical drive speed and the speed ratio are not significant in practice. 7