THE STACK

Case Study: Tony Dowd

Case Study: Kuru Crushing

Case Study: Tony Dowd

Case Study: Kuru Crushing

There’s something undeniably nostalgic about the smell of diesel in the morning, the low rumble of engines from a bygone era, and the proud glint in the eyes of the older generation as they bring vintage machinery to life. The Wheels at Wānaka event is more than just a celebration of mechanical history—it’s a reminder of where we’ve come from and what grit, ingenuity, and perseverance look like in motion.

Watching the plant operators of yesteryear handle their machines with practiced ease is a masterclass in resilience. They built our industry from the ground up—sometimes quite literally—and that spirit is something we can all draw strength from as we face into a still-slow, yet steadily shifting, landscape.

Yes, it’s been a tough stretch. Workloads have thinned, quoting cycles have dragged, and the usual momentum has been harder to find. But green shoots are starting to appear. We’re seeing signs of life in quoting activity and jobs starting to line up again. The tide is turning—and the question is, are we ready?

Now is the time to tune up—not just our machines, but our systems, our thinking, and our approach. Efficiency isn’t just about getting more out of what we have, but finding value where we might not have looked before.

Take by-products, for example. There’s growing opportunity in exploring how we manage and repurpose what used to be dismissed as waste. One promising area gaining traction is soil washing—transforming what some might call “junk” into usable, even valuable, material. These aren’t just green initiatives; they’re smart business. It’s about innovation meeting necessity, and turning cost centres into revenue streams.

It’s easy to become reactive when things are slow. But the companies that come out stronger are those who continue to think long-term, finding ways to sharpen their operations and invest in smarter practices. Now is the time to build leaner processes, explore circular approaches, and ensure we’re not leaving value on the table—or in the ground.

The energy at Wheels at Wānaka reminds us that while the machinery may age, the industry doesn’t have to. There’s optimism in the air—and not just from the exhaust. It’s in the opportunities we’re beginning to see, the innovations being explored, and the quiet confidence that with persistence, the good times will roll again.

Let’s keep looking forward, not just with hope, but with action. The road ahead might be dusty, but it’s wide open.

Bert Hart General Manager

Tag us on Facebook, Instagram or Linkedin if you are working on a project and using Equip2 equipment.

@equip2solutions

#equip2

In quarrying, as in life, success isn’t about making the most noise—it’s about making the most impact.

That’s the quiet truth behind Tony Dowd’s story. For over three decades, he’s been shaping New Zealand’s quarry landscape— not from the boardroom, but from the front lines. He’s stood in the dust, adjusted the jaws, handled the setbacks, and learned how to turn big rocks into small profits… and small rocks into more profitable ones.

Now, as Operations Manager at South Taranaki Quarries, Tony leads three active sites - Whenuku Road, Waiteika Road and Nukumaru. But what sets him apart isn’t just his experience. It’s how he’s applied a lifetime of lessons from the corporate world to build a leaner, safer, and more profitable private operation—one that runs with precision, purpose, and gear that doesn’t miss a beat.

This is the story of how Tony, backed by the right people with the right machine, is rewriting what it means to run a profitable quarry in today’s fast-moving industry.

Tony’s journey started in 1987—not behind a desk, but on the tools. “I left school in ’87 to be a tyre fitter at Beaurepaires,” he says. “I used to fit tyres on dumpers and loaders at Winstone Aggregates in Otaki.”

From there, he worked his way up the chain—dumper operator, shot firer, assistant manager, and eventually quarry manager at some of the country’s most active sites. “By the time I was 21, I was assistant quarry manager at Otaki,” he recalls. He later managed quarries at Belmont, Petone, Dry Creek, and held regional roles across the lower North Island.

It was during his time at Winstone Aggregates that Tony developed his strategic mindset. “I learned a lot of my background for quarrying and business case scenarios in the roles I had,” he says. From managing resources and people to planning capital investment, he was immersed in the complexity of running operations at scale.

But when corporate cuts came during the recession, he returned to site-level management—first at Wiremu Road, and eventually, through a well-timed Trade Me job posting, to South Taranaki Quarries.

For Tony, it was a fresh challenge - and a chance to apply his full toolkit in a more agile, independent setting.

“The key drivers were the pre-screen for making the fines out the side, and then the throughput and the technology within the machine - for ease of clearing the crusher when it’s blocked.”

- Tony Dowd

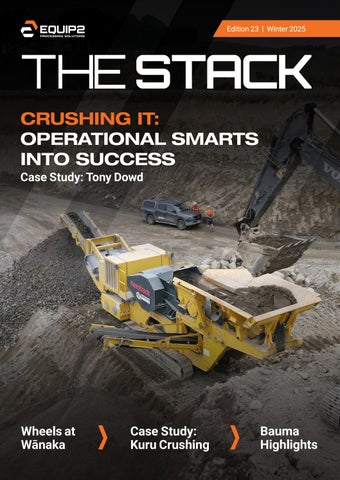

Within six months of joining South Taranaki Quarries, Tony sat down with The General Manager to workshop concepts in how they could operate smarter and safer. They saw an opportunity to better optimize their business through a larger jaw crusher that offered mobility across multiple sites while simplifying production and reducing cost per tonne, without compromising product quality.

“We went through the process of pricing that off with most suppliers out there - and settled on the Keestrack as the best option for our situation.” Tony explains.

Why the Keestrack B4?

“The key drivers were the pre-screen for making the fines out the side, and then the throughput and the technology within the machine - for ease of clearing the crusher when it’s blocked and adjusting the crusher from the seat of the digger.” Tony Dowd says.

This wasn’t just about increasing tonnes per hour. It was about creating control.

With the new jaw crusher now running at 300 tonnes per hour, the operation can produce stock faster, with fewer breakdowns, less pressure on staff, and more time to make better decisions.

“One of the big opportunities it creates, I believe, is the ability to make more sound decisions around safety - because you’re not rushing to get product out the gate,” Tony says. “When you’re making decisions around safety, you’re not taking shortcuts for production issues.” Tony went onto explain in the video.

300 tph output = Reduced production days and lower running hours

Safety-first: slower, smarter decisions under less production pressure

Adaptable output settings to hit varying product specs

Real-time adjustments from digger seat to increase responsiveness

Minimized downtime = Maximized profit per hour

At the heart of the setup is adaptability. With three sites, varying resource profiles, and multiple products to supply, South Taranaki Quarries needed more than just a high-output machine—they needed a smart one.

Tony’s team are using the B4 to produce everything from AP120 for Forestry, AP65 for infrastructure projects, to requiring a specific material feed used in their production of TNZ M4 AP40 basecourse, each requiring different specs and fines content. The jaw crusher delivers that flexibility with ease.

“If I’m talking about the production run we’re doing here at the moment - the fines out the side of the belt and the jaw crusher set at 125 ” Tony explains. “One of the main reasons for that is because the amount of fines coming out the side and the resource type that we have. You’ve got to slow the machine down slightly so that it will deal with the fines and not put too much fines in the second part of it.”

Feeding into their impactor, the crusher delivers a consistent product that’s ideal for downstream shaping. “It increases the production on a GAP 65 to our machine to around about 200 ton per hour, which is working quite well.”

When switching to M4 base, the team slows the jaw down and pulls back fines to ensure the crushed output delivers the right compaction properties.

Tony’s team recently supplied 20,000 tonnes of M4 base course to a local infrastructure project—and thanks to their setup, the material was delivered consistently, on spec, and without production bottlenecks.

The result? Products that hit spec every time.

“We are now making a very consistent M4 base course and we’ve been supplying a project this year on that of around about 20,000 ton… and to date that’s gone very, very well.” - Tony Dowd

This kind of reliable performance has positioned South Taranaki Quarries as a go-to supplier, even as demand shifts. The team can ramp up, slow down, or pivot products with minimal disruption—and with the B4’s mobility, they’re able to deploy production where it’s needed most.

“We can move to the other sites and do the same there and have a completely mobile unit that goes around our sites.”

Tony didn’t just invest in machinery—he invested in a partnership. And that’s made all the difference.

“Dealing with Equip2, I’d seen them at Quarry Conference a few times,” he says. “I spent a bit of time with them and done dealings with them over the years. I am quite impressed with Equip2.”

From factory tours in Masterton to hands-on site set up for success and support, the experience has been positive from the outset.

“They put the deals on the table, showed us the plant and we had a good crawl around it. They were very knowledgeable about the plant and helpful for us and what we needed to know.”

And when it came time to Quarry install?

“They were very helpful, sending Robin over as a trainee guy to teach us all about the machine and try and soak into us quarry men the way to operate something. Not only just taught us that; he has been a person to get a hold of after the fact and easy to explain things, of how to do things.”

“You don’t learn everything on the first visit,” Tony adds. “Backup support is brilliant.”

“We are now making a very consistent M4 base course and we’ve been supplying a project this year on that of around about 20,000 ton…”

In-person demo & site visit prior to purchase

On-site commissioning and operator training

Continued technical support available post-sale

Fast response times = less waiting, more crushing

Tony still gets excited about the daily variety of quarry life.

“You don’t really know from one day to the next what you’re going to be doing… one day you’re in the engineering shop, the next you’re in a loader or operating a crushing plant. It’s all exciting stuff.”

More than anything, he appreciates the sense of community, because its about the people

“We are very passionate people about making big rocks into small rocks… everybody’s very helpful within the industry. It’s just a great industry to be in.”

That camaraderie, combined with the right tools, creates the conditions for long-term success.

Looking back, Tony’s seen it all—from 40-year-old fixed plants that “have been very productive machines in their time,” to today’s modern crushers that offer real-time control, remote adjustment, and safety guarding as standard.

“The technology that’s in the machines nowadays have made it so much easier and better to operate machines,” he says. “You can produce a similar or a little bit bigger jaw crusher

nowadays, but produce at a much greater rate… and it’s just safer. Everything’s covered in. It’s great for the industry.”

It’s that combination—of technical edge, practical control, and people-focused leadership—that’s driving South Taranaki Quarries forward.

Tony Dowd isn’t chasing headlines. He’s simply doing the work— cleverly, consistently, and with calm confidence. With decades of experience, a clear business brain, and machinery that’s built for the long haul, he’s built an operation where downtime is rare, output is reliable, and every shift moves the dial.

His story is proof that you don’t need flash to win—you need focus, great gear, and the right partner in your corner.

Watch the video of Tony Dowd to the right and discover how strategic leadership and the right tools are helping reshape the future of quarries in New Zealand.

“The technology that’s in the machines nowadays have made it so much easier and better to operate machines… safer too.”

Scan here to watch the full interview

Over Easter weekend, Wheels at Wānaka cemented its place as Australasia’s largest all-vehicle and machinery event, drawing a staggering 65,000 attendees across three days, with an incredible 45,000 people on Saturday alone. From heritage tractors to modern earthmovers, the show celebrated the machines that have built our past and are shaping our future.

One standout was Equip2, whose impressive display of Keestrack crushers and screens turned heads and drew crowds.

Live demonstrations gave attendees an up-close look at cuttingedge technology in action—machinery designed not just to work, but to drive real business results through efficiency and performance.

Equip2 doesn’t just showcase impressive machines—they equip New Zealand’s quarries and contractors with the modern processing gear they need to thrive in today’s demanding environment. As the exclusive supplier of Keestrack, Rockster, and MWS Washing Systems, Equip2 helps businesses achieve maximum profitability per tonne in an increasingly commoditised industry.

Before the world ran on steam, oil, electricity or the internet—it ran on infrastructure. Roads, railways, and buildings moved people, enabled economies, and spurred discovery. And while today aggregates are a forgotten commodity, the reality remains: no house, road, or city exists without them.

Equip2’s presence at Wheels at Wānaka was more than a display—it was a statement. A reminder that infrastructure remains the backbone of progress, and that behind every successful quarry and contractor is equipment built for performance, supported by a team committed to long-term success.

Ricky Kuru starts his day at 4 a.m. and often works late into the evening — driven by responsibility to his family, team, and the business they’ve built together. For Ricky, Kuru Crushing isn’t just a job — it’s a generational legacy shaped by mana (respect and strength) and mahi (hard work). From managing quarry crews to keeping projects on track, he ensures everything is running smoothly before the day is done.

Founded in April 1997 by Ricky, his father Jack, his mother, and his wife, Kuru Contracting began with forestry and roading work. Over the years, it evolved into a multifaceted operation, expanding into civil works and quarrying. The company has always followed opportunity. “Sometimes that’s logging, sometimes it’s roading,” Ricky says. “Then we saw crushing — and we haven’t looked back.”

Launched seven years ago, the crushing division — Kuru Crushing — has played a key role in the company’s growth. Today, they manage eight to nine active quarries and continue to expand.

The business hasn’t had an easy road. In the early 2000s, a shift in Gisborne’s forestry industry left many companies struggling.

“We worked for three years practically for free,” Ricky recalls. “We just focused on paying wages and staying alive.”

More recently, Cyclone Gabrielle devastated the East Coast. With roads washed out and access cut off, Kuru Crushing stepped up to rebuild routes around the Hukuwai Bridge and Mangahauini Gorge. “We didn’t have the roading infrastructure, but people needed access — so we built it,” says Ricky. That effort became a catalyst for the growth of their civil division, rooted in service rather than strategy. “It was about showing up for our community,” he adds.

“The strength of our company is in the people we surround ourselves with.”

At the heart of Kuru Crushing is its people. “We’re only as good as our staff,” Ricky says. From quarry workers to traffic crews, the company thrives on strong relationships and shared values. Their annual Jack Kuru Kai-Comp — held in memory of Ricky’s late father — brings all divisions together for a weekend of competition and celebration, from hunting to food prep. “It builds culture. People talk about it all year,” says Ricky. Key leaders like Paul Te Kira (PT) are central to operations. “Without PT and his crew, Kuru Crushing wouldn’t be where it is,” Ricky adds. “He runs a tight ship.”

Alongside people, the right equipment has been vital. Kuru Crushing runs a modern fleet, including Caterpillar machinery and Keestrack crushers like the B4 Jaw Crusher and K4 Screen, sourced from Equip2. “They’ve been more than a supplier,” says Ricky. “They’ve given us advice, support, and have become part of the family.” The partnership has helped the company scale sustainably and stay competitive.

Kuku Quarry stands as a symbol of the company’s grit. Once condemned, the site is now a thriving operation producing ag lime, AP65, AP40, riprap, and boulders — essential materials for forestry and infrastructure. “It took years to get consented,” Ricky says. “Now it’s one of our top producers.” But beyond supply, it’s about impact. “We’re here to feed families,” he says. “That’s what drives us.”

“They’ve been more than a supplier.” says Ricky

Kuru Crushing is a story of long hours, loyal people, and lessons learned through hard times. For Ricky, lasting success isn’t about having the biggest machines — it’s about showing up, leading with values, and doing right by your team.

“If you’re thinking about getting into crushing or working with Equip2, give it a go,” says Ricky. “We did — and it’s worked out.”

Kuru Crushing continues to lead through mana and mahi, proving that strong values and steady leadership build businesses that last — and communities that thrive.

Watch Ricky share insights into what has made them the success they are today

Bauma, the world’s largest construction machinery trade fair, kicked off in April with its trademark grandeur. Held every three years, the sheer scale of this event is mind-blowing — it can take up to 30 - 40 minutes just to walk from one end of the site to the other. With 3,601 exhibitors, 200,000m² of hall space, and 414,000m² of outdoor exhibition area, Bauma is nothing short of a construction industry mega-event.

Keestrack had an impressive stand, drawing strong attention with the launch of two new machines. One of the key highlights for our team with Keestrack was the launch of the new R2 model, a product that generated strong interest and is seen as a great fit for the New Zealand market. This compact yet powerful unit promises to bring added versatility and performance to local operations.

Another key takeaway was the opportunity to meet with key suppliers including McCloskey Washing and Rockster. These catch-ups offered valuable insight into new developments and reaffirmed ongoing collaboration.

The show overall had a great positive atmosphere, with a lot of attendees commenting that business is on the rise — a welcome sentiment for the industry.

Bauma remains a critical event for staying connected and keeping up with the latest in equipment and technology.

Watch some insights into the latest innovation from the show below

R2 Walkthrough

KEESTRACK B3 JAW CRUSHER

Hours: 1600 +/-

Toothed reversible Jaw Plates

10 function radio remote

Central greasing system

139kw John Deere Engine

Asking Price: $495,000 NZD + GST

KEESTRACK H4E CONE CRUSHER

Hours: 3500 +/-

3 Deck Post Screen

Hybrid Electric Drive

Metal Detector EGE 3000

Radio Remote Control 10 Functions

Asking Price:

$790,000 NZD + GST

KEESTRACK K3 SCALPING SCREEN

Hours: 460 +/-

Double Deck scalping screen

2.7m x 1.2m screen box

17 Tonnes

Hydraulic adjustments

Asking Price: $367,000 NZD + GST

BARFORD SM312 SCREENER

Power unit: CAT 2.2 37kw

Screen box on coil springs

Head motor on conveyor 400cc

Foldable Conveyor 27CC Pump

Asking Price: $97,000 NZD + GST

KEESTRACK R5H IMPACTOR

Hours: 6200 +/-

Double deck prescreen

Double deck afterscreen

Tilting Chassis

Asking Price: $615,000 NZD + GST

KEESTRACK R3

Hours: 7370 +/-

Year: 2017

Engine: Volvo

Postscreen

Asking Price: $300,000 NZD + GST

Paul Thompson: 027 404 4430

Bert Hart: 021 244 5797