CYLINDER HEAD AND VALVE MECHANISM • Strike the valve several times against the valve seat while rotating the valve a little at a time. • Wash away the compound with diesel fuel. • Apply engine oil to the valve contact surface of the valve seat and rub in the valve and seat well. • Inspect the contact pattern of the valve and valve seat again. • If the contact pattern is still defective, replace the valve seat.

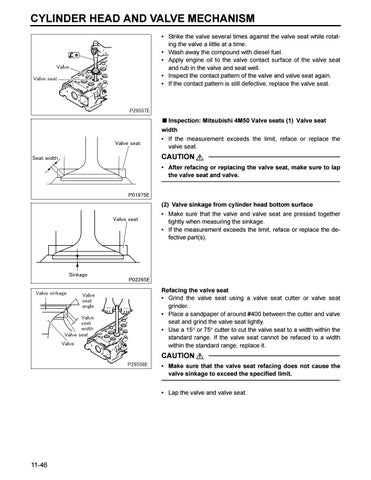

Inspection: Mitsubishi 4M50 Valve seats (1) Valve seat width • If the measurement exceeds the limit, reface or replace the valve seat.

CAUTION • After refacing or replacing the valve seat, make sure to lap the valve seat and valve.

(2) Valve sinkage from cylinder head bottom surface • Make sure that the valve and valve seat are pressed together tightly when measuring the sinkage. • If the measurement exceeds the limit, reface or replace the defective part(s).

Refacing the valve seat • Grind the valve seat using a valve seat cutter or valve seat grinder. • Place a sandpaper of around #400 between the cutter and valve seat and grind the valve seat lightly. • Use a 15° or 75° cutter to cut the valve seat to a width within the standard range. If the valve seat cannot be refaced to a width within the standard range, replace it.

CAUTION • Make sure that the valve seat refacing does not cause the valve sinkage to exceed the specified limit. • Lap the valve and valve seat.

11-46