8 minute read

Optical fibers

by Grupo Asís

transmission system. These systems must meet three basic needs: Ä preserve, at the point of application, a radiant power as close as possible to that of the emission source; Ä be manageable; Ä be replaceable and interchangeable. In odontostomatology the handling and practicality of the means of conduction of the laser beam are fundamental.4 The different branches of the dental discipline require different and customized instruments; it is therefore essential for the clinician to have access to specific inserts, handpieces and tips. The operator must, therefore, be able to change the means of conduction in relation to specific clinical needs.

The ideal and most widespread instrument for laser transmission is, to date, the optical fiber. The optical fibers are of different types and shapes, responding to specific characteristics and requirements. Not all wavelengths cover this medium in an optimal manner.5 There are different construction materials, among which the most suitable for carrying the wavelengths of the diode are silica fibers.6 Then there are fluoride fibers, which are well suited to conveying the wavelengths typical of the erbium laser. The polycrystalline fibers are used to carry high frequency electromagnetic waves such as those of the CO2 laser.

Advertisement

The diameter of the fibers is of particular importance: decreasing the diameter, there is an increase in the intensity of energy due to the greater concentration of the beam, a useful feature for surgery.5,7 For whitening or biostimulation, for example, larger diameters and, generally unfocused are preferred.

There are also transmission tools currently in use (for CO2 erbium lasers), such as articulated arms equipped with mirrors and joints, which allow the various components to rotate so that the handpiece can be handled as freely as possible.

Finally, there are the most modern systems for transporting radiant energy consisting of hollow fibers (alternatives to optical fiber, but with the disadvantage of having higher production costs and being more perishable). Photons bounce off the hollow mirrored surface of the fibers.5

Optical fibers can be reduced to simple tips, similar in size to ultrasonic inserts. The use of disposable tips and interchangeable inserts offers undoubted advantages in terms of ease of use and safety for the patient. The adoption of specific handpieces, capable of hosting precision inserts of crystalline sapphire has recently been proposed. In these newly introduced instruments, the distal end is connected to the main system by optical fibers. The use of sapphire tips would entail significant ergonomic and clinical advantages both for the clinician and the patient.

In medical procedures, laser energy is transmitted through a group of optical fibers.

The use of optical fibers represents an advantage both for patients and clinicians: the fiber, being thin and flexible, can be suitably bent and adapted; the insertion of a fiber inside the tissues therefore requires only a small incision and the energy can be concentrated on the target without damaging the surrounding tissue. Therefore, medical procedures that use optical fibers are minimally invasive and, consequently, result in less traumatic experiences for patients.

The optical fibers consist of a silicate core covered with a protective sheath with a low reflectance index. Light travels inside the core and can travel long distances.

There are single-mode and multi-mode optical fibers. The former are widely used in the telecommunications world, generally for long-distance data transport; the latter, used for short-distance data transport, are frequently used in the medical field.3 Single-mode fibers generally have a diameter of less than 20 µm. Multimode fibers instead exceed 50 µm.

While both the type of laser source and the conditions of activation of the optical fibers affect the laser power performance, other critical aspects are: proper fiber design, fiber termination, and end surface preparation. Typical lasers used in these medical procedures are Nd:YAG lasers (1064 nm), dual frequency Nd:YAG lasers (532 nm), diode lasers (800 nm ~850 nm ~980 nm) and Ho:YAG lasers (2.1 μm). For these common lasers, index hopping multimode optical fibers with pure silicon core can be a good solution for laser energy transmission, as they transmit light well in the visible range and at IR lengths of up to 2.1 μm.

The CO2 laser (10.6 μm) and Er:YAG (2.9 μm) are establishing themselves in the medical field, but traditional optical fibers with silicon core do not work very well due to the high attenuation. As a replacement, it is possible to use hollow silica-based waveguides (silicon dioxide) optimized for these wavelengths.

For the different types of lasers and specific applications it is therefore important to choose the right fiber.

CHARACTERISTICS OF MEDICAL OPTICAL FIBERS

The multimode optical fibers with pure silicon core have several advantages over simple telecommunication fibers (! 2.18).

First, the fiber is capable of handling high powers. The large diameter of the core, often >0.1 mm, allows the fiber to transmit a greater amount of light. The high numerical aperture (NA) gives the fiber a wider angle of light acquisition, thus allowing a greater amount of light to be conveyed into the fiber. The high core/coating ratio allows the fiber to transmit maximum light power with the same core diameter, while maintaining the same flexibility. In addition, the fiber is capable of transmitting greater laser power, this happens because pure silicon-based material has a higher melting temperature and damage threshold than doped silicon. A second advantage is represented by the cost, thanks to the minimal amount of doping materials used in a fiber with a pure silicon core.

In addition, the fiber has greater mechanical strength and flexibility (normally the fibers are tested in line up to 150 kpsi and have a small bending radius).

Other benefits include ease of termination and the ability to sterilize fibers using standard methods including medical grade autoclave.

La fibra di silicio con guaina in poliimmide (PI) indurito e rivestimento o buffer in silicone è comune nelle applicazioni medicali.8

PIs are polymers (consisting of imide monomers) with very high performance, suitable for extremely critical situations, which combine heat resistance, self-lubricating properties, dimensional stability and chemical resistance. Their mechanical, chemical and heat resistance is so high that these materials often replace glass and metals such as steel in many industrial applications.9,10

Polyimide works at temperatures up to 400° C. Since this coating is tough and thin, the polyimide-coated fiber is an excellent choice and sometimes does not require, in practice, additional buffers or sheaths.3

As material for the sheath, it is possible to use an optical polymer with a refractive index lower than that of silicon, this increases the mechanical strength of the fiber, as well as facilitating rapid sectioning and easy termination on site.8,11

Silicone has a high nominal temperature of up to 200° C. A rubber-based material, silicone is an excellent solution for applications requiring minimal losses in micro-creases. Secondary coatings are normally extruded onto the fiber to increase the mechanical protection. Commonly used materials are Tefzel, Nylon and Teflon. As fluoropolymers, Tefzel and Teflon are chemically inert, while Nylon is often used in cases where the sheath must be glued to the connector.

Hard polymer clad fibers (HPCF) are widely used in medical applications8,11 (! 2.19 and 2.20). From the point of view of the fiber configuration, there are single sheath HPCF and double sheath HPCF.

Optical fibers transmit laser light. They consist of two specially prepared ends: the proximal and the distal termination (! 2.21-2.23).

The manufacturer usually interfaces the optical fiber with the medical laser by applying a special connector on the proximal side of the fiber itself. The SMA 905 type is the most frequently used solution in medical systems.

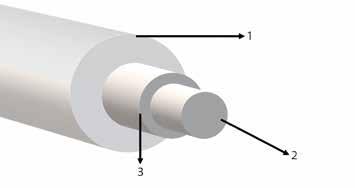

! 2.18 Standard optical fibers. (1) External silicone coating; (2) core of the optical fiber. ! 2.19 HPCF optical fibers. (1) External silicone coating; (2) core of the optical fiber; (3) cladding-coating, closely bonded to the fiber.

Both ends (proximal and distal) have peculiar characteristics.

In order to generate an emitting light beam suitable for specific applications, the distal portion of the fiber must be adequately “prepared”: sectioned, sculpted or polished.

The sectioning of the fiber, which is the subject of a specific discussion, is often performed by the operator and is one of the most important preliminary stages in the preparation of the laser before use. The correct execution of the cutting of the fiber is able to guarantee effectiveness in clinical performance, vice versa it can make the instrument inadequate. When done correctly, sectioning can provide a mirrored distal surface with minimal marginal alteration.3,12

The sculpting of the fiber, instead, is obtained during the production process to generate an emitting light beam (usually in an angled or lateral position) suitable for specific applications. Today there are sculpted ends with a lateral beam and, also, with a spherical shape capable of emitting the beam at about 360°. A lateral beam end emits light at an angle close to 90° from the end of the fiber and finds application, for example, in prostate surgery, where laser energy is directed on the pro static tissue which is generally located lateral to the fiber. Fibers with a spherical terminal morphology are able to emit the 360° beam and are frequently used in intravenous therapy for the treatment of varicose veins of the lower limbs, for laser-assisted angioplasty and, again, for endodontic and periodontal applications.3,8,13,14 Mechanical polishing using specific microabrasive pastes is a typical process that produces a flat, possibly angled surface. The polishing process can be industrially automated by the manufacturer and, consequently, lead to a reduction in costs in the case of large productions.

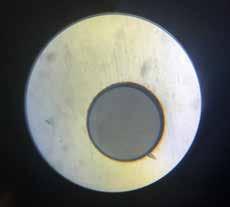

! 2.20 Detail under the 20× optical microscope. (1) JACKET (external silicone coating); (2) fiber core; (3) cladding/interior lining.

! 2.22 Magnified view of the connection area, obtained from a microscope for optical fibers (200×). It is possible to appreciate the presence of structural alterations and impurities at the interface of the optical fiber. In such conditions the quality of the transmission is compromised. ! 2.21 SMA 905 connection. The male pole is protected with an airtight silicone seal after use.

! 2.23 Magnified view of the connection obtained from a microscope for optical fibers (200×). We can appreciate the absence of structural alterations and impurities at the interface of the optical fiber. In such conditions the quality of the transmission is guaranteed.