6 Embodied and operating greenhouse gas emissions in buildings 6.1 Overview Buildings cause not only GHG emissions from the energy that they consume during operation, but also embodied3 GHG emissions from the energy that is used to produce, transport and install materials, components and systems when they are built, maintained, renovated and eventually demolished (Cuellear-Franca and Azapagic 2012; Lavagna et al. 2018; Orsini and Marrone 2019). The importance of addressing both embodied and operational GHG emissions from the building sector has been highlighted by many stakeholder groups in recent years, including the World Green Building Council (WGBC 2020). The largest contribution to the embodied emissions of a building is caused by its initial construction, of which the biggest elements are typically the foundations, floor slabs and structural components that contain steel and cement (Box 1) (Cuellear-Franca and Azapagic 2012; Hrabovszky-Horvath and Szalay 2014; Anderson and Moncaster 2020). However, substantial amounts of embodied emissions can also be caused by renovations. 6.2 GHG emissions produced by buildings over the next 10 years and over their lifetimes Life cycle assessment (LCA) is a tool that can be used to illustrate the importance of both embodied and operational GHG emissions, and to highlight the need to take embodied GHG emissions into account when

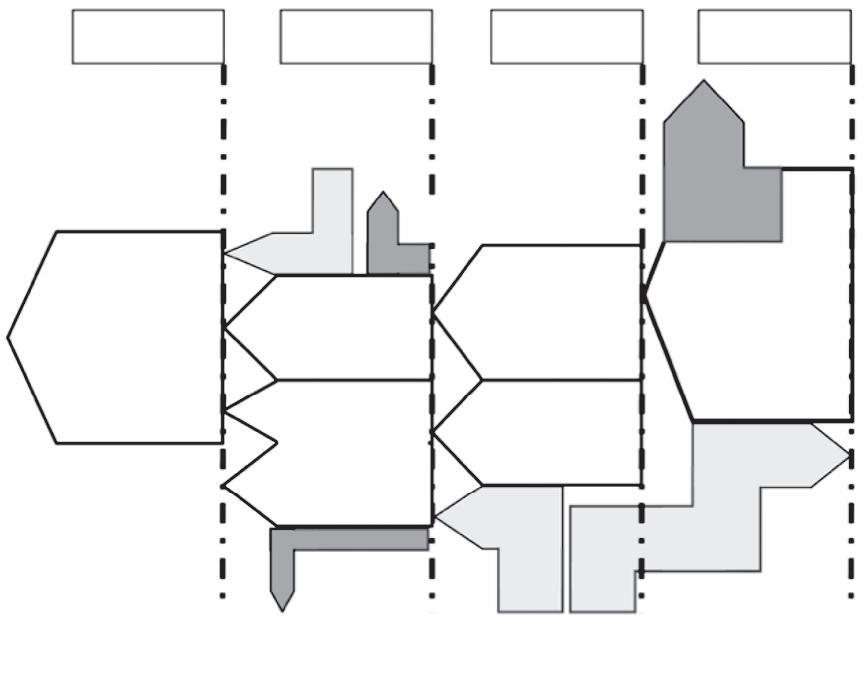

designing new buildings and renovations. It can also be used for drawing up national long-term renovation and building operation strategies. In view of the EU commitment in the Paris Agreement to limit the increase in global average temperature to less than 1.5 °C above pre-industrial levels, it is particularly important to minimise both the operating and the embodied GHG emissions from the construction and renovation of buildings by 2030. This critical period for limiting global warming which, for renovations and new buildings, will include initial and some recurrent embodied GHG emissions (from maintenance and use), is illustrated by the dashed blue line at the bottom of Figure 7 (Röck et al 2020). Embodied GHG emissions in buildings will become an increasingly significant contributor to the total GHG emissions from buildings as the operating emissions are reduced to near zero in the future. The significance of embodied GHG emissions varies with the mix of energy and materials used, and with the design and construction of the buildings or, in the case of renovations, with the depth and measures implemented to reduce both the embodied and operating emissions. 6.3 Embodied emissions created by renovations Figure 8 shows the effects of different levels of renovation on the cumulative emissions from a

Box 1 Embodied GHG emissions in cement and concrete Concrete has lower embodied GHG emissions per kilogram than some other materials (e.g. steel), but the world consumes very high volumes of concrete compared with other materials (Sivakrishna 2020). It is therefore important to note that the criterion for minimising the embodied GHG emissions in a building is not simply the embodied emissions per kilogram or cubic metre of the materials used in its construction, but the total amount used must also be taken into account. Different materials have different strengths (e.g. high-strength concrete), so it may be necessary to use more of one material than another to deliver the required strength in a building structure. It is therefore the total embodied emissions in the whole building structure which must be minimised. A major contributor to global GHG emissions is ordinary Portland cement, which accounts for about 8% of global CO2 emissions (Chatham House 2018). If cement production were a country, it would be the world’s third-largest emitter after China and the USA (Olivier et al. 2016). About half of the embodied GHG emissions in cement come from the chemical reaction (calcination) when making clinker, one of the major components of cement. Embodied emissions from concrete can be reduced by using alternative clinker-free cements or by substituting a proportion of clinker with other materials, such as waste materials or industrial by-products such as fly ash and blast furnace slag (IEA 2018; de Brito and Kurda 2021). Low-clinker cement has an environmental benefit, but the use of alternative constituents can impact the performance of concrete, and their availability depends on the location. Clinker-free cements are a promising alternative but have not yet reached large-scale commercial deployment. Research continues on how to optimise the use of carbon-cured cements that absorb CO2 and could potentially offer significant reductions in the future global warming potential of concrete (Jian Zhan 2016; Huang H. et al. 2019).

3

The use of the terms ‘embodied carbon’ and ‘embodied GHG emissions’ in this EASAC report is broadly consistent with the recommendations of IEA EBC Annex 57 (Mistretta and Guarino 2016).

EASAC

Decarbonisation of buildings | June 2021 | 33