Vigan Engineering 16 Rue de l’Industrie B-1400 Nivelles Belgium

T: +32 67 89 50 41 E: info@vigan.com

PUBLISHERS

Jason Chinnock jason@dc-int.com

Andrew Hucker-Brown andrew@dc-int.com

EDITORIAL

Louise Dodds-Ely Editor louise@dc-int.com

Jay Venter Deputy Editor editorial@dc-int.com

Samantha Smith Directories directories@dc-int.com

Bernice van Wyk Office Manager accounts@dc-int.com

SALES

Matthew Currin Senior Sales sales2@dc-int.com Executive

Zack Venter Advertisement Sales sales@dc-int.com Executive

CORRESPONDENTS

Brazil Patrick Knight India Kunal Bose

Europe Barry Cross UK Maria Cappuccio

UK Michael King UK Richard Scott

ADMINISTRATIVE OFFICE

Business Publishing International Corporate Park, 11 Sinembe Crescent La Lucia Ridge, South Africa, 4051

Tel: +27 31 583 4360

Fax: +27 31 566 4502

Email: info@dc-int.com

Twitter: twitter.com/drycargomag

HEAD OFFICE

Trade Publishing International Limited

Clover House, 24 Drury Road, Colchester, Essex CO2 7UX, UK

Tel: +44 (0)1206 562552

Email: info@dc-int.com

Website: www.drycargomag.com

Twitter: twitter.com/drycargomag ISSN 1466-3643

Insta: www.instagram.com/drycargointernational

Trade

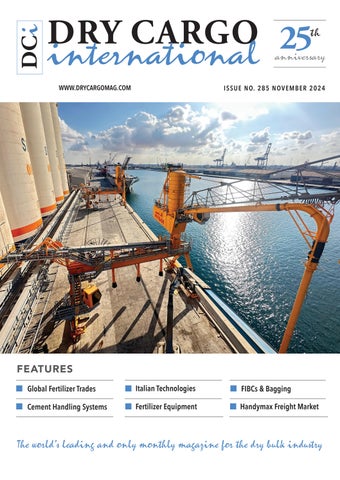

In recent weeks it has become clearer that commodity import demand around the world is well supported. Consequently solid world seaborne trade growth during 2024 as a whole seems to be evolving, and some positive signs for next year are evident.

A modestly firm underpinning of global economic activity is envisaged in the latest (mid-October) assessment of prospects by the International Monetary Fund. World growth of gross domestic product is expected to remain “stable yet underwhelming” through 2025 at 3.2% annually (after 3.3% in 2023). The task of bringing inflation under control “has largely been won”. This background will assist dry bulk trade over the year or more ahead.

Earlier this year it appeared that world seaborne coal trade could see a weaker trend unfold during 2024 following last year’s brisk expansion. A downturn seemed especially likely if China’s 2023 imports surge was reversed. As there has been no sign yet of that decline occurring, and weakness elsewhere among importers has proved limited, the current year’s trade volume may be stable or higher.

But the outlook for coal trade next year and later is still negative. Amid the energy transition towards renewable and other cleaner energy sources, fossil fuels will be affected by downwards pressures. A new report by the International Energy Agency published

last month emphasized that “coal demand is projected to fall in the years ahead”, although the precise timing and pace of decline are uncertain. The pattern of import requirements probably will be similar.

Forecasts for global imports of iron ore suggest that an unchanged or higher volume in 2024 is likely, followed possibly by this trend extending into 2025. A recent report by Australian Government analysts estimated an unchanged 1,619mt (million tonnes) total this year (including land movements but mostly seaborne), and a 31mt or 2% increase to 1,650mt next year.

Some additional support in 2025 may be derived from strengthening demand for steel in a number of countries, implying benefits for production and raw materials usage. The World Steel Association’s mid-October update estimated world steel demand rising by 1% next year after declining by 1% in the current year. While China’s steel demand may remain on a decreasing trend, the European Union and Japan may see turnarounds from reduction to revival.

Prospects for global grain and soya trade can be expected to change frequently and sometimes quite abruptly. Unpredicted weather conditions affecting harvests in both importing and exporting countries, and the impact on

import demand and supplies, is often influential in modifying predictions.

Currently negative signs are prominent. According to the latest US Department of Agriculture monthly estimates and BSA calculations, world trade in wheat, corn and other coarse grains plus soyabeans and meal may be 18mt or 2% lower in the 2024/25 marketing year now starting. The volume (including land movements but mainly seaborne) could fall from 713mt in 2023/24, to 695mt. A large proportion of the reduction may reflect lower soyabeans, wheat, corn and barley imports into China.

Within the agricultural bulk commodities sub-category of the minor bulks segment modest growth appears to be unfolding. This group includes various oilseeds and meals, rice, and sugar totalling over 190mt last year. Extra volumes in all these commodities could be seen in 2024 as a whole, resulting in a continued gradual upwards trend.

Two-fifths of the entire world bulk carrier fleet consists of Capesize bulk carriers, defined as vessels of 100,000 deadweight tonnes and over, including Newcastlemax as well as large ore carrier sizes. As shown in table 2, fleet growth has been around 2% annually in the past two years and may be unchanged in 2024 before possibly slackening in 2025.

Clarksons (historical

by Richard Scott,

& BSA

The International Monetary Fund, (IMF) forecast global growth to remain stable at 3.2% in 2024 and 2025, virtually unchanged from previous forecasts earlier this year. Revisions have taken place, with upgrades

to the forecast for the US offsetting downgrades to those for other advanced economies especially the largest EU countries. For emerging market and developing economies, disruptions to

production and shipping of commodities, like oil, conflicts, civil unrest and extreme weather events have led to downward revisions to the outlook for the Middle East, Central Asia, sub-Saharan Africa and

contrasts with upgrades to the forecast for emerging Asia, where surging demand for semiconductors and electronics, driven by significant investments in artificial intelligence, bolstered growth a trend supported by substantial public investment in China and India.

Global grains and oilseed markets look to be supplied with large quantities of cereals, coarse grains and oilseed crops provisionally forecast at 3.5bn/t in 2024/25. Projections of strong global crop yields continue to put pressure on commodity markets, leading to lower prices. As a result, farmers worldwide are experiencing decreased operating margins after a very positive cycle between 2020 and 2023.

The UN’s Food and Agricultural Organization’s (FAO) theme, for this year’s World Food Day ‘Right to Food for a better life and a Better Future’ was chosen because it emphasizes, the fundamental human right to accessible, nutritious, affordable and sustainable food to ensure everyone's well-being and dignity. And it includes how to access food in different ways while being able to have a nutritional and balanced diet, to nourish the body. The FAO confirmed that over 2.8bn people can't afford a healthy diet so they hope to increase peoples’ knowledge about nutritious food, while helping poorer people to get access to healthy food sources.

Source: FAO, IFA

Fertilizer affordability improved in the first half of this year, compared to the previous 18 months and is expected to support a recovery in nitrogen, phosphate and especially potash consumption. Earlier in the year, the International Fertilizer Association (IFA) forecast global fertilizer use to rise to 203.7mt (million tonnes) Nutrients in 2024/25 and to 217.9Mt Nutrients by 2028/29.

Thereafter, fertilizer use to expand in the medium-term, but at a lower rate of 2.2% in 2025 and 1.5% in 2028 — due to nutrient use efficiency, slower growth in food production reflected in slowing population growth.

While the global outlook indicates improved fertilizer affordability, international prices do not always reflect prices paid by farmers due to exchange rate fluctuations, transport

and

The Argentinian Port of Bahía Blanca has reserved for six months an area of land — previously allocated for the construction of a proposed LNG terminal — to Pampa Energía, which aims to build a large fertilizer plant there. This will ultimately produce urea for export. In total, $1 billion is expected to be invested in the project. Nevertheless, Pampa Energía anticipates that the eventual investment could be within the $1.5 billion to $2 billion band. The exact level will depend on the plant’s maximum capacity, which could be anything between 1.5mt (million tonnes) and 2mt of fertilizer annually. Originally, YPF’s proposed LNG plant,

domestic regulations. Also, interest rates remain high in many countries, affecting farmers’ financial health and their ability to procure inputs.

Nitrogen — urea prices rose by nearly 9% in the third quarter reflecting China’s decision to suspend urea export inspections expected to be in place to the end of the year. Russia extended export quotas for nitrogen and compound fertilizers 11.2mt and 8mt respectively from Dec 1–May 31 ’25.

Concerns remain about capacity expansion projects in the Middle East and whether they will go ahead before further trade restrictions are introduced by China, including spikes in natural gas prices occurring for nitrate production in Europewhere, partly due to weather delays, demand has been slow to buy urea and nitrates for 2024/25. By contrast India snapped up 60,000/t of granular urea for c.$340/t, however, these costs have yet to be accepted by European buyers. But, the rapid advance in regional gas costs has once again brought European nitrogen production costs into focus. To date the lack of farmer engagement, Forex movements and logistics have kept many European distributors, importers on the sidelines. While the slow pace of activity in Brazil, and sluggish demand elsewhere in Latin America, where urea offers were c.$350pt CFT, encouraged the business with netbacks from India around $330/t FOB. India is expected to tender every six

which will now be built in Punta Colorada, Rio Negro, would have covered a total area of 1,200 hectares Interestingly, there was a an even earlier terminated project, which was put forward by Vale. This Brazilian company wanted to extract potassium chloride in the south of Mendoza and export it through the port of Bahia Blanca from a site now taken by Pampa Energía.

Bahía Blanca already has an established fertilizer plant of the same type proposed by Pampa Energía. This has been operated by Profertil in the port’s industrial area since 2000. Profertil is also planning to build a

to eight weeks through to the end of rabi season in April. Upside price pressure anticipated if demand peaks in Europe and India and coincides with purchasing in North and Latin America.

DAP (diammonium phosphate) prices increased by more than 8% y/y, partly due to export restrictions on China’s phosphate aimed at keeping domestic prices low and ensuring greater availability of phosphates for lithium iron phosphate (LFP) batteries used in electric vehicles and ammonia from Russia, which disrupt trade with the impact particularly noticeable in Europe — with phosphates replaced by higher-cost supplies from exporters such as Egypt, Morocco, Saudi Arabia and the US. Phosphate supply remains strained-plant maintenance in Saudi Arabia and the Russian Federation has been prolonged. In the last six weeks, India secured an additional 600,000/t of DAP and announced a generous retail price subsidy scheme for phosphates for the rabi season and will continue to import heavily. Exports from China likely to be modest and become tighter in the fourth quarter as China prioritizes domestic access, further straining global supply. Morocco continues to reshape its production capabilities, prioritizing triple superphosphate (TSP) production, which does not require ammonia feedstock; as a result, prices for DAP and MAP have increased as major markets, like Brazil and the US, prefer DAP and MAP. Affordability concerns, in Brazil

granulated urea plant adjacent to its existing facility, which would export urea mainly to Brazil.

However, the new plant is not yet a done deal, since a second site is also under consideration by the developer in the province of Santa Fe, with studies being undertaken that are expected to be completed within 12 months.

Of note is that, at the end of 2023, the Chinese firm Potassium Chemical Group announced construction of a urea plant and another NPK fertilizer plant in the port area of Bahía Blanca. This consisted of $1.25 billion in investment, and could produce annual exports worth $450 million. Barry Cross

and sub-Saharan Africa, are likely to curb consumption.

MOP (muriate of potash), prices fell by more than 4% in the third quarter, due to seasonally weak demand and robust exports. Exports from Belarus have remained solid despite sanctions. Russia’s potash exports (not subject to sanctions), were up 70% in the first half of 2024. At the same time, Canadian exports have shifted towards Europe. Potassium supply is ample, with trade in 2024 slated to surpass 2023 levels. New capacity additions in Lao People’s Democratic Republic, and higher production and exports in Canada will continue to improve availability and affordability of potash. Pricing is likely to remain stable, though some pockets of upcoming seasonal demand from palm oil plantations in Southeast Asia might cause temporary regional spikes.

USDA’S baseline assessment for the US crop acreage in 2025, pegs wheat at 46m/acres, corn increased to 92m/acres, small increase for sorghum to 6.5m/acres, with a cut in soybean acreage to 85m/acres. While production costs are likely to be similar to those of 2024, some input costs are lower, while fertilizer is relatively expensive.

In the US winter wheat sowing is progressing at an average pace, though

drought conditions are affecting a larger wheat area than in the previous year. Continued widespread rain provided moisture to the Southern Plains and improved drought conditions. As of 12 November, 12–43% of winter wheat is in an area affected by drought, similar to last year’s level. Heavy rains in the EU’s central and western areas impeded sowings for a second consecutive year, while in Romania and Bulgaria, rains have improved depleted soil moisture levels. Russia’s low rainfall and above-average temperatures in the southern and central regions have delayed sowings with similar challenges experienced in parts of Ukraine, where the war continues to undermine agricultural

production. In Far East Asia, attractive prices, government support and generally favourable weather conditions are boosting wheat area prospects in the leading producers, China and India.

According to Rusagrotrans, Russian wheat plantings are lower y/y at 15.4m/acres. SovEcon’s provisional estimate for Russia’s wheat production pegged at 81.6mt. Russian officials confirmed the 2024 grain harvest estimates and the winter grain seeded area data, includes Ukrainian territories currently under Russian control.

South American weather continues to

improve with Brazil’s soybean planting moving at a rapid pace. Early indications point to a contraction in corn plantings in Argentina due to moisture deficits. In Brazil, the major safrinha corn crop is due to be planted next year.

South Africa’s near-record corn prices and favourable weather following drought conditions, support an uptick in 2025 corn plantings. The likely return to wetter weather conditions in Southern African countries underpins better prospects for next year’s corn crop.

While the US soybean harvest concludes with yields revised to c.51.7bu/acre, South American farmers are advancing the 2024/25 planting season.

Argentina may see its largest soybean acreage expansion in over a decade. Brazil’s plantings are also expected to grow — the surge in supply, driven by potential record output in both countries, could further pressure international soybean prices in the coming months.

The global wheat harvest is forecast at 795mt. Higher than expected wheat yields boosted an exceptional Australian crop c.32mt (Ikon Commodities forecast 34.5mt). Elsewhere, better crops in Kazakhstan, US, China, India and Pakistan have lifted output.

After reaching a record last year, global coarse grain production is forecast slightly lower at 1.5bn/t in 2024, with larger outturns in Brazil, South Africa, China and the US, expected to outweigh the fall in output in Russia and Ukraine due to adverse weather conditions. Meanwhile, a significant increase in global oilseeds

Source: IFA-Data K20 basis * effective capacity derived [a] capability

10mt to 214mt, with stocks revised lower at 258mt (world 124mt, China 134mt). In November ’24, FOB prices for soft wheat fell below $250/t. CBOT Futures December Contract for Wheat closed down $5.71/bu (08 Nov ’24). Spot prices of Argentine Grade 2 wheat (Up River) $230/t, EU France Grade1 (Rouen) $239, US HRW (Gulf) $261/t and US SRW (Gulf) $258/t (7 Nov ’24).

BUMPER COARSE GRAIN CROPS

ANTICIPATED IN 2024/25

Near record coarse grain output is provisionally forecast at 1.5bn/t, due to an exceptional US corn crop c.385mt. Argentina’s corn crop c. 51mt with corn output in Brazil c.127mt in 2024/25. For other feed grains, global sorghum output is expected to rise to 62mt underpinned by strong sorghum shipments to China, with barley output slightly lower at 142mt.

GLOBAL TRADE , CORN PRICES LOWER IN 2024/25

Coarse grains food/feed and industry use to rise to 1.51bn/t and includes a 10.4mt increase for feed 935.5mt and 7.5mt increase for food 571.2mt in 2024/25. Global coarse grain trade is forecast lower at 229mt, with stocks lower at 330mt (World 123mt, China 207mt). In November ’24, FOB prices for corn fell below $250/t. CBOT Futures December Contract for corn closed $4.271/bu (08 Nov ’24). Spot prices of Argentine Corn (Up River) $213/t, Brazil (Paranagua) $223/t, US Corn (Gulf) $213/t (8 Nov ’24).

OILSEED CROP ANTICIPATED IN 2024/25

Driven by potentially large soybean crops forecast at 425mt. With the US soybean harvest almost completed, the focus shifts to the large growing soybean crops in South America (Brazil 169mt, Argentina 51mt and Paraguay 11mt) yet to be harvested, where weather is improving and soybean planting is moving at a rapid pace, the exception being Rio Grande do Sol-a key producing state, where soil conditions

have led to delays in plantings. For other oilseeds, increased output is anticipated for palm kernel, cottonseed and groundnuts, with smaller crops for copra, rapeseed and sunflower seed.

Strong soybean crush in the US and Argentina and the delayed implementation of the EU’s Deforestation Regulation (EUDR) are contributing to falling prices for soybean meal. Tight supplies of palm oil and new government policies in Indonesia are contributing to higher palm prices. In October, the government announced plans to increase the current biodiesel mandate, while imposing a new tax on palm oil exports.

Global oilseed trade is forecast up to 207mt, crush 557mt with global stocks rising to 148mt. The projected US seasonaverage farm price for soybeans is unchanged at $10.80/bu.

Fertilizer affordability improved in the first half of this year, compared to the previous eighteen months, is expected to support a recovery in nitrogen, phosphate and potash consumption, forecast by the IFA to rise from 203.7mt N in 2024/25 to 217.9mt N in 2028/29.

Nitrogen (urea) capacity in Nigeria was expanded to over 1mt, and in the US Gulf ammonia capacity was increased to 1.15mt. The Russian Federation’s new ammonia export terminal in Taman will soon be in commission and will add to existing supply. Investment in nitrogen capacity in the next five years is expected to be driven by access to feedstocks, located in low-cost regions with abundant natural gas resources like Russia, and in countries with strong support for decarbonization activities, such as the US where the Inflation Reduction Act (IRA) has spurred a

Source: FAO/IFA-Data P205 tonnes basis * effective capacity derived [a] capability

wave of investments in ammonia capacity with carbon capture, utilization and storage (CCUS). China continues to operate a major portion of its nitrogen industry using coal as feedstock rather than using to natural gas or renewables.

Ammonia capacity is forecast to grow by 8% from 192mt N in 2023/4 to 207mt N in 2028/29. Central Europe aside, capacity additions are expected in all regions, China (+4%), India (+4%) West Asia (+14%), Africa (+11%) and EECA (+11%). The US is expected to significantly grow its ammonia capacity on the back of tax credits introduced as part of the Inflation Reduction Act in 2022.

Ammonia capability is forecast to increase from 162.7mt N in 2023 to 177.8mt N in 2028 (+9% over the period), averaging 1.5% growth per year. driven by new capacity additions in EECA (Russia and Uzbekistan), the US, Africa (Egypt and Nigeria), West Asia (Iran, Qatar, Saudi Arabia), India, China and Australia. With total ammonia capability forecast to grow at a slightly faster pace than demand over the next five years, the nitrogen balance is expected to loosen from a theoretically available surplus of 3.6mt N in 2024 to 5.9mt N in 2027, before receding slightly in 2028 to 5.1mt N. IFA’s nitrogen demand

forecasts include conventional industrial nitrogen uses but do not yet include new low-carbon ammonia demand likely to emerge from uses, including power generation, hydrogen carriers and maritime fuels.

IFA forecasts 2.8mt N of green ammonia capacity to be commissioned by 2028, and confirms longer term projects involving larger volumes of green ammonia 120mt N are being tracked by IFA as under consideration/working towards final investment decisions

The IFA expect Latin America and South Asia to be the main engines of global growth in the medium term, adding between 3mt and 4mt N each between 2024-2028. East Asia is expected to expand by 2% and implies an additional 1.5mt N nutrients due to its large market size. Production is expected to grow in the forecast period, with much of the new capacity expected in East Asia and the Middle East. A recovery in urea output is also expected in Europe, where production has been hampered by the surge in natural gas prices.

Potash capability is forecast to increase from 52.1mt K2O in 2023, to 58.9mt K2O in 2028, a 13% growth rate, mostly due to capacity expansions by existing producers in Laos, Russia and new sizeable projects expected in Canada and Russia.

Higher output is forecast in Belarus, in line with recovered export capability. Supply to outpace demand with the potash balance to show a surplus of 9.1mt K2O, in 2028/29.

Phosphoric acid capacity is forecast to increase by 10% between 2023 and 2028, reaching 70.6mt P2O5 by 2028/29. Significant capacity growth is projected in 2026 and 2027, resulting from sizeable investments already under way. Capacity additions are mainly expected to come from existing producers in Morocco, Saudi Arabia; smaller additional capacities are also expected in India, Brazil and Egypt.

Phosphoric acid capability is forecast to increase from 54.3 to 60.3mt P2O5 in 2028, an 11% growth rate. Both Africa and West Asia remain the main drivers of this growth. The phosphate balance has loosened since then and is forecast to be better balanced in the next five years. The theoretically available phosphate surplus is projected at 14% of capability in 2028. Slowing phosphate demand growth and a lack of any sizeable projects outside of existing suppliers drives a stable phosphate balance in the coming years. IFA’s demand forecast does not include widespread roll out of phosphate use in lithium iron phosphate (LFP) batteries in the next five years outside of China.

Canada is the world’s largest supplier of potash and key producer of sulphur, and the Port of Vancouver on its west coast plays a critical role moving Canadian fertilizer to

markets across the world.

Fertilizer exports at the port move through three major bulk terminals — which have handled as much as 10mt

(million metric tonnes) of potash and 3mt of sulphur annually within the past four years. Potash and sulphur exports are mainly destined for the Indo-Pacific and

Americas regions, with most potash going to four key markets (Brazil, China, Indonesia and India), while the top destinations for sulphur are China and Australia.

“Canada has some of the largest reserves of potash in the world, with a mature mining sector that continues to see investment and growth,” said Doug Mills, the Vancouver Fraser Port Authority’s Bulk Sector Account Representative.

“The Port of Vancouver has successfully supported potash and sulphur exports for decades, and we are seeing ongoing investment in the port and its terminals to support future needs. This includes a major upgrade of the Westshore terminal to handle potash from 2026 onwards in support of BHP’s new Jensen mine in Saskatchewan. By the end of the decade, we expect this upgrade alone to add millions of tonnes a year to the port’s annual potash exports.”

Over the past ten years annual potash exports moving through the Port of Vancouver have been around 7–10mt — with China and Brazil each getting about 1–3mt. The port has handled around 2–3mt of sulphur exports a year over the past decade — with production tied to refining and upgrading in Alberta’s oil and gas sector, with volumes escalating in 2022,

2023 and YTD 2024.

“With its distinctive yellow colour and ability to be stored in the open, sulphur has long been associated with the Port of Vancouver — any ships entering the busy Burrard Inlet trade corridor pass by Vancouver Wharves’ stockpile of sulphur near Lions Gate Bridge,” says Mills. “Sulphur is more than just a distinguishing local landmark — it’s a vital commodity used worldwide for fertilizer, and producing sulphuric acid, pharmaceuticals, tyres and more.

“The Vancouver Fraser Port Authority is a federal agency with the job of enabling Canada’s trade through the Port of Vancouver while protecting the environment, including by managing marine traffic and leasing federal land to independent operators who manage terminals.

With ship traffic and cargo volumes growing, the port authority is collaborating with industry and government to enhance efficiency, innovation and safety at the port. This includes optimizing the maritime supply chain through the Active Vessel Traffic Management Program and Canada’s first centralized scheduling system — a transformative tool that allows the port authority to take an active role in managing ship traffic in and out of the busy harbour.

“Active vessel traffic management enhances visibility and fluidity of marine movements in Burrard Inlet — enabling better coordination among port users and allowing ship, terminal and rail operators to foresee demand and optimize operations,” says Mills. “We are using this new digital tool to drive collaboration and inform decision making at the port — helping unlock latent capacity for terminals to support Canada’s growing trade needs.”

Neptune Bulk Terminals: one of v North America’s largest multi-product bulk terminals, it handles exports of potash and Canadian metallurgical coal. Operated by Neptune Bulk Terminals (Canada) Ltd.

Pacific Coast Terminals (PCT): one of v the world’s largest automated export sulphur, potash and bulk liquids marine terminals. Operated by Pacific Coast Terminals Co. Ltd.

Vancouver Wharves: offers services v for bulk shippers moving products to and from regions of Western Canada, and handles sulphur, as well as bulk mineral concentrates, agri-products and bulk liquid. Operated by PKM Canada Marine Terminal LP.

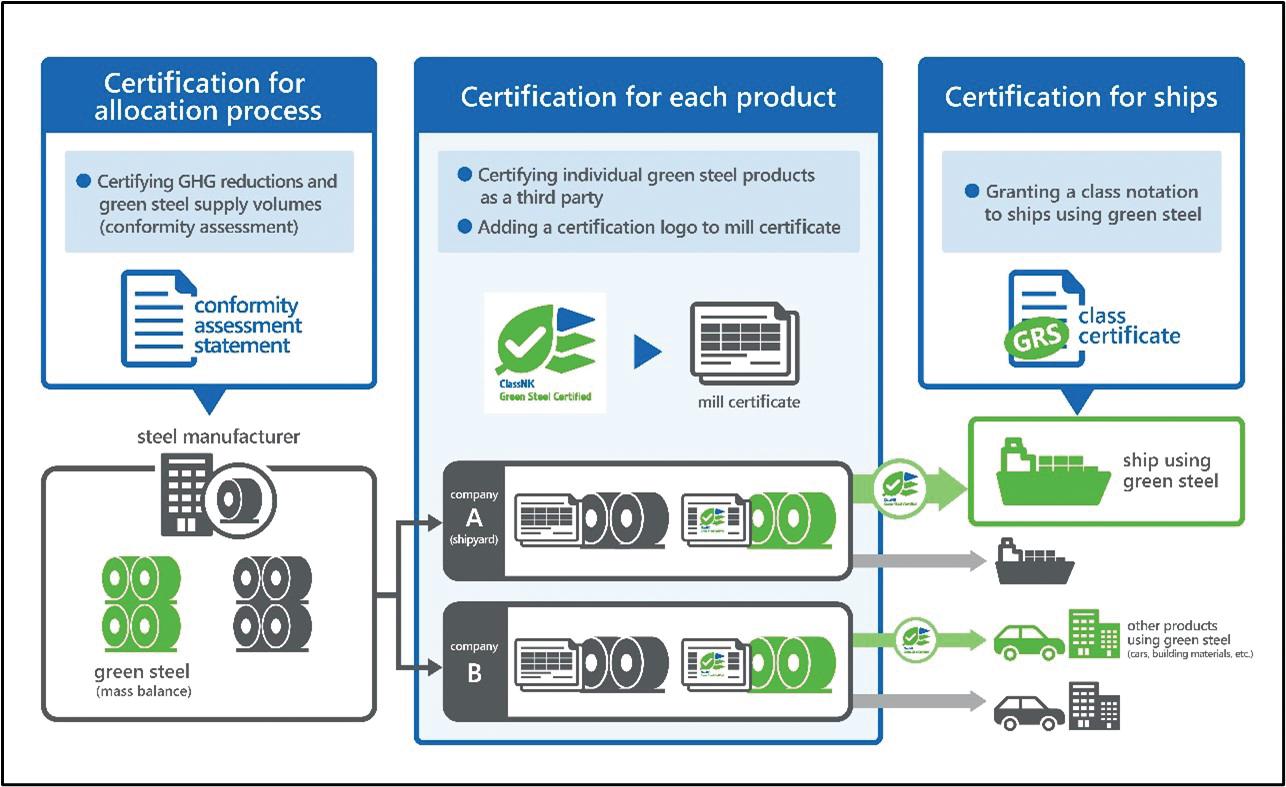

NK CONTRIBUTES TO THE EXPANSION OF PRODUCT USE THROUGH ENHANCED RELIABILITY AND EASE OF IDENTIFICATION

ClassNK has launched a third-party product certification service for individual green steel products. Under the service, ClassNK certifies each green steel product supplied by steel manufacturers using the mass balance approach*1, and affixes a certification logo*2 to its mill certificate. By improving reliability and making identification easier, the service ensures that users feel more secure when ordering and using green steel.

ClassNK has supported decarbonization efforts related to green steel through its certification services. Notable examples are conformity assessments for GHG emissions reductions during the manufacturing process and supply volumes of green steel allocated by the mass balance approach, as well as granting notations*3 that indicate the use of green steel in ships.

With the newly launched certification service, every green steel product supplied by steel manufacturers that have received ClassNK’s conformity assessments can now be certified as green steel. As these

products undergo third-party certification, purchasers can order and use them with more confidence.

Once the product has been certified, a logo will be added to its mill certificate. As a result, the certificate is all that buyers need to confirm that the product is green steel.

This service applies not only to green steel products used in ships, but also to products used in various industries, such as automotive and construction.

In addition to this new service, ClassNK will continue to enhance its related certification services, thereby further contributing to decarbonization initiatives.

*1. The mass balance approach aggregates the environmental value of CO2 reductions from the entire manufacturing process and allocates it to specific steel products, which are then considered to have a lower CO2 emissions intensity.

*2. Certification logo

*3. Ships that meet specific requirements will be given the corresponding class notation.

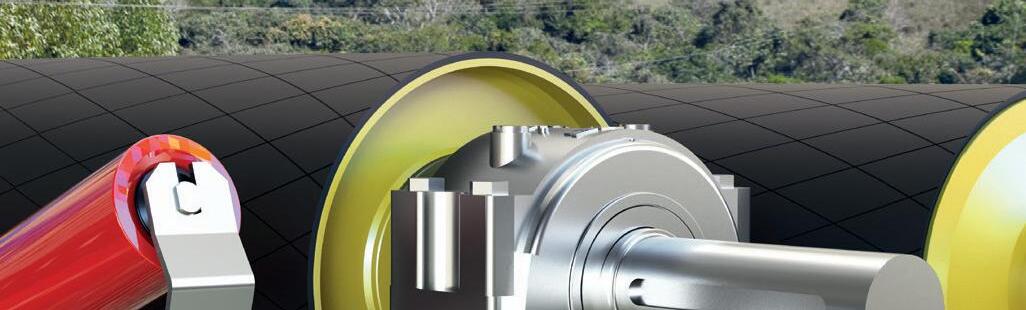

Thordon Bearings has delivered its COMPAC waterlubricated propeller shaft bearing solution to the final vessels in a series of three new bulk carrier newbuilds scheduled to join a fleet of Canadian lakers.

The 35,000dwt boom forward, self-discharging bulkers are the most recent Canadian-owned vessels to be ‘Thordonized’ with a complete COMPAC system. The package includes elastomeric polymer water-lubricated bearings, ThorShield propeller shaft corrosion protection, Thordon Water Quality Package, and the Thordon Bearing Condition Monitoring system.

The 225-metre-long (738ft) Seawaymax vessel was named at the 3 Maj Shipyard in Croatia in May 2024, and is expected to begin operations later this year or in early 2025. It is the shipowner’s 17th vessel to employ a COMPAC water-lubricated bearing system.

The newbuilds, part of the shipowner’s fleet renewal programme, are designed to achieve a 40% improvement in carbon intensity, on average, compared to the ships they have replaced. Thordon Bearings’ water-lubricated propeller shaft bearings add to their clean credentials by ensuring there is no risk of oil leakage from the stern tube, as the propeller shaft is lubricated with water, not oil.

“These vessels operate in the fresh waters of the Great Lakes, so oil leakage is absolutely not tolerated by the authorities,” said José Duarte, Marine Business Development Manager – North America at Thordon Bearings.

“Thordon has been actively supporting Great Lakes shipowners such as American Steamship, Canada Steamship, Algoma, Interlake Steamship, and McKeil Marine for over three decades. To date more than 120 vessels sailing the Great Lakes operate Thordon’s water-lubricated bearing systems as a way of maintaining pristine waters.”

Craig Carter,VP Business Development, Thordon Bearings said: “Awareness of the benefits of water-lubricated propeller shaft bearing technology is increasing among the shipping industry in general. We are pleased that Canadian shipowners have continued to install what is undoubtedly the best option for mitigating the risk of operational oil pollution from the shaft. Based on the operational experience of the vessels currently running COMPAC we expect our relationship with our Great Lakes’ customers to continue for many years ahead.”

In China, where many of Canada’s large tonnage is built, Thordon’s local distributor CY Engineering is key to providing the shipowner with the technical and practical support it needs throughout a newbuilding project. One of the key elements for a successful installation is not only Thordon's technologies, but also our global support network.”

The COMPAC bearing is constructed from a cross-linked polymer alloy that offers a low breakaway friction resulting in quiet and smooth operation. The material’s abrasive resistance is much greater than traditional laminated materials. The visco-elastic nature of the material improves the hydrodynamic performance of the bearing, leading to longer wear life, and as the material is homogenous, it provides consistent wear and friction properties.

Thordon’s shaft coating was specifically developed to complement the COMPAC shaft bearing system by providing corrosion protection to metal components, allowing extended shaft withdrawal. It has been formulated for optimal adhesion, impact resistance, abrasion resistance and tolerance for bending and torsional stresses.

Thordon’s advanced bearing condition monitoring system (BCMv2), meanwhile, delivers real-time information to provide vessel engineering teams with a one-touch remote indication of bearing clearances. BCMv2 reduces the need for sending divers to take poker gauge readings, as it meets all class society requirements for wear monitoring.

Events in the Handymax bulk carrier market have resulted in a fairly smooth trend of freight rates during most of this year, varying only within a relatively narrow range. In the previous year there was a much greater dispersion, with periods of much lower rates than seen in 2024 (up to

early November). Consequently in this year’s first ten months the average freight market level has been substantially higher than seen in the preceding period. Amid larger expected fleet growth in 2025, further gains in market strength may prove hard to achieve.

Handymax bulk carriers, medium-size dry cargo vessels with a carrying capacity of between 40,000 deadweight tonnes and 70,000dwt participate in many dry bulk commodity trades. Notable sub-categories within the size group are the Supramax and Ultramax vessels, which successively gained

most attention from shipowners and charterers.

Investment in Handymax bulk carrier newbuildings — concentrated within the Ultramax group of larger vessels in the past few years — has reflected shipowners’ optimism about longer term future growth in relevant global trades. Confidence in ongoing employment prospects has also been augmented by potential for fleet renewal. Opportunities for replacing existing ships with tonnage of greater efficiency and lower emissions enhanced the popularity. These adaptable vessels are ensured extensive as well as varied employment on numerous routes. Steady world fleet growth of 3–4% annually in recent years reflected the attraction.

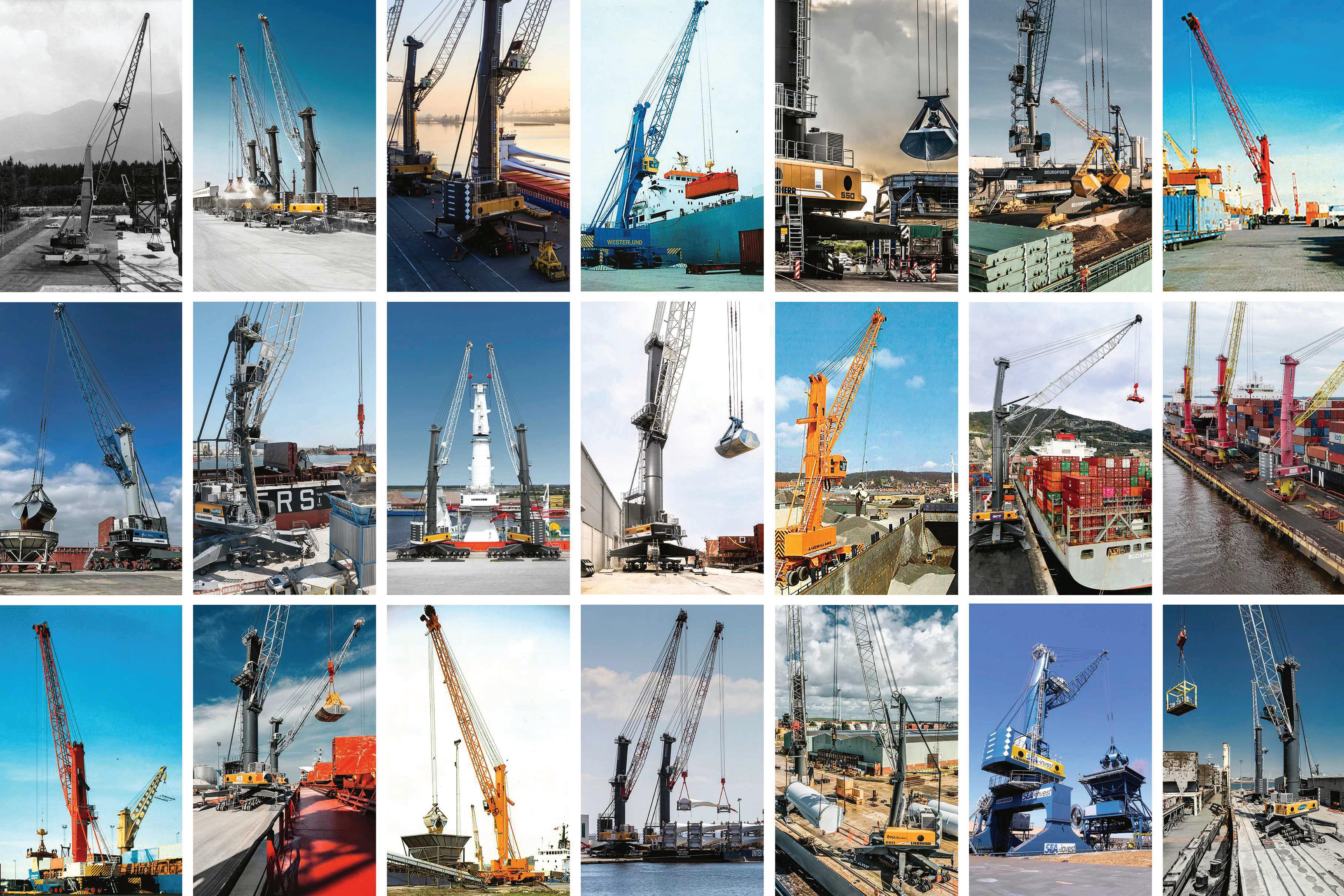

The inherent advantages of Handymax bulk carriers are an outcome of their design features. A typical ship of this type is described as a ‘geared’ vessel (cargohandling gear installed on board), equipped with cranes and grabs for loading and discharging cargo. This characteristic is included in the distinctive sub-categories of larger size ships within the broad Handymax size group, known as Supramax and Ultramax vessels.

Bigger capacity units within the bulk carrier fleet as a whole — Panamax, Kamsarmax, Capesize and Newcastlemax bulk carriers — usually are ‘gearless’ (no installed cargo-handling equipment on board). Such vessels are totally dependent

on loading and discharging equipment at ports.

An obvious advantage offered by a geared vessel is that its equipment allows efficient operation in trades where shorebased facilities at ports are either unavailable, or inadequate. Handymax gear also often assists handling cargo from or into barges moored alongside, at an offshore anchorage or mid-river berth.

Another distinct advantage provided by Handymax ships is that dimensions — length, beam and draught — are suitable for a wide range of ports around the world, on most trade routes. Many of these ports are

inaccessible for bigger ships. Moreover Handymax carrying capacity offers some economies of scale. Varied employment patterns occur as a result. Frequently there is involvement in the coal as well as grain and soya trades. Numerous cargoes in the minor bulk commodity trades are prominent. Steel products, ores and minerals such as nickel ore, other industrial commodity cargoes, fertilizers and various agricultural commodities including oilseeds and meals are regularly carried.

Shipowners’ preferences for new vessels, to be employed within these trades, firmly shifted in recent years towards

The Post-Panamax geared vessel Anna is fitted with grabs from Nemag.

essionProf b b b ompanies in more than nal c hhhihli ff

V

orldwide w ountries w 110 c d bili ork with becauseourgrabso erstegengrabs e Ve gen grabs, cause our grabs o best productivity. Combining our ext the feedback from our loyal custome materials and unloading situations. W

ooking f L foorincreasedreliability and an extended lifespan? Let us know, b

offerthemthehighestrelia er them the highest relia tensive knowledge and exp ers results in optimized gra We call this ‘Grab Intelligen productivity, lower mainte because together we can m

bilityand y and perience with bs f foorallbulk nce’.

enance costs and ove mountains.

source: Clarksons (historical data) & BSA 2024 forecasts *forecast

higher capacity Ultramax 60–69,000dwt bulk carrier designs at the top end of the Handymax size range. Previously the Supramax, typically 52–57,000dwt, was the preferred unit, taking over from smaller Handymaxes below 50,000dwt in an earlier era.

A moderate growth pace unfolded in the world fleet of Handymax bulk carriers over the past few years. In the 40–69,999dwt Handymax size group deadweight capacity increased by an average 3.3% annually in the five years from 2019 to 2023, including 3.4% in the most recent 2023 year as shown in table 1 above. In the current year, 2024, an accelerated pace is foreseen, followed by similar growth next year as well based on partly speculative assumptions.

At the end of 2023 Handymax fleet capacity reached 235.4 million deadweight tonnes according to Clarksons Research data. Vessels in this size group numbered 4,154. The total comprised almost onequarter of the entire 1,004m dwt world bulk carrier fleet of all vessel sizes. Within the Handymax deadweight total, Supramaxes comprised half of the capacity at 51%, while Ultramaxes comprised 37%.

During the first nine months of 2024, the Handymax fleet has been augmented by about 8m dwt or more than 3%, boosting the total to 4,276 ships amounting to 243.3m dwt at end-September. Newbuilding deliveries rose while scrapping decreased from already low levels.

Handymax newbuilding deliveries to

owners, by shipbuilding yards around the world, have revived after falling in 2018 to the lowest volume seen since 2007, averaging almost 8.2m dwt annually in the past five years including 9.4m dwt in 2023. The total over five years was 41.1m dwt. Scrapping of mainly older vessels offset a small part of this volumes. Demolition sales totalled 5.2m dwt in the past five years, including minimal volumes of under 1m dwt in each of three years in the period.

A notable trend within the Handymax segment is the changing fleet composition. Large differences between the size of newbuildings delivered into the fleet, and the size of old ships sold for demolition is a feature. In 2023 newbuildings averaged 61,800 dwt, confirming the popularity of Ultramaxes towards the top end of the Handymax size range. By contrast, ships sold for scrapping averaged 45,700 dwt, with an average 29 years age, representing an earlier era when the original Handymax bulk carrier of 40–50,000dwt size was most popular.

Newbuilding Handymax deliveries during 2024 as a whole are set to exceed last year’s deadweight volume based on tentative calculations. This estimate is based upon the pace so far, coupled with expectations for the remaining weeks. The scrapping volume has fallen, reflecting freight market performance, sentiment and second-hand prices and the annual total could be 1m dwt or below. Although the end of this year is approaching, it is still difficult to estimate these elements precisely because there is potential for unforeseen changes.

Prospects for fleet growth in 2025 suggest that the pace could be similar to the stronger pace emerging this year, based on tentative indications. Newbuilding deliveries, mainly reflecting shipyard orderbook schedules for ships already ordered some time ago, could increase. Also, scrapping may be somewhat higher while remaining low.

Uncertainty surrounds both future inflows and outflows of tonnage, and consequently fleet evolution is hard to predict accurately. Evolving freight market patterns, secondhand prices, and changing market sentiment and expectations will have an impact so perceptions may change.

In table 2 below, current global orders for new Handymax bulk carriers are set out, showing the schedule for newbuilding deliveries over the next twelve months and further ahead, as compiled by Clarksons Research. But these orderbooks at shipyards, as reported, provide only a rough guide to the amount of future fleet capacity likely to be added within any given period. Orderbook slippage and postponements, usually difficult to predict, occur while more orders could be added.

The entire current Handymax orderbook for all future delivery years now totals about 28m dwt, equivalent to 12% of the existing world fleet in this size group. Most of the deadweight capacity on order (96% of the total) consists of Ultramax vessels, emphasizing how these ships have become the dominant investment focus for owners.

Decisions to invest in new ships, in the bulk carrier sector as a whole and for

source: Clarksons Research *fourth quarter of year

Handymaxes in particular, are affected by ideas about the outlook for the freight market and profitability. Orders for Handymaxes rose strongly in the past few years, but the pace has slackened during 2024, apparently reflecting market rate trends and renewed caution about how the future may evolve.

Amid greater uncertainty about longer term freight market prospects, shipowners’ views evidently have become more cautious, causing hesitation in ordering new ships. The effects of tightening regulation of shipowning operations and, especially, surrounding the intensified focus on cutting ships’ greenhouse gas emissions, are still unclear. The technology needed for alternative fuels facilitating decarbonization, suitable for the entire lifetime of a typical new ship, is still work in progress. Until more clarification is available, fleet growth may remain restrained.

Variations in the pace of scrapping (recycling) are another imponderable for fleet growth forecasts. This influence is always hard to predict, both in the immediate future and further ahead. The likely impact of changes in secondhand vessel prices and scrap prices is usually unclear. Owners’ views of current and expected freight market trends are among unpredictable influences, while regulatory aspects have become a more prominent aspect.

Nevertheless clear potential is apparent for scrapping older Handymax tonnage. Currently 11% of the world fleet (about 27m dwt) is 20 or more years old, an age group where recycling is more likely. The

40–49,000dwt and 50–59,999dwt size subgroups each comprise half of the 20+ years old total.

Tightening regulations and compliance costs could encourage extra sales to demolition yards. Higher scrapping is therefore predictable after recent minimal volumes, acting as a restraint on the deadweight capacity addition to the fleet in 2025 and beyond.

A high proportion of dry bulk commodity movements accessible to Handymax bulk carriers, with relatively few limitations, is confirmed by analysis of trading patterns performed. The dimensions and cargohandling capability of typical ships facilitates their employment, carrying numerous commodities in most geographical areas.

However, in practice, large parts of global long-haul iron ore and coal movements do not normally employ Handymaxes. On many of these routes bigger Panamax, Kamsarmax, Capesize, Newcastlemax and even larger bulk carriers can be accommodated. These higher-capacity vessels enable greater economies of scale to be derived, providing cheaper transport.

As a rough guide to the significance of various trades for Handymax 40–70,000dwt size bulker employment, available calculations suggest that over half of the total trade volume carried is in the extensive and diverse minor bulk commodities segment. The iron ore and coal trades each contribute up to one-

tenth of total employment. Grain and soya trade contributes about one-fifth.

Among the numerous commodities carried by Handymax bulk carriers one of the most prominent, providing many cargoes, is grain and soya trade. This trade category experiences a continuously changing pattern of routes and quantities, and is highly variable in both the short and longer term. It also tends to be largely unpredictable. World trade in wheat and coarse grains, together with soyabeans and meal, recently saw strong overall expansion but in the current period a reduction is tentatively predicted.

Based on Bulk Shipping Analysis calculations derived from US Department of Agriculture data global trade in grain and soya during the 2023/24 trade year ending third quarter 2024 was 42.5mt (million tonnes) or 6% higher, at 712.6mt. The total includes land movements but is mostly seaborne. Over half of the annual increase consisted of additional imports into the largest individual importing country, China, where a rise of 22.4mt (15%) to 172.8mt was seen.

Large rises or falls from year to year, in volumes of grain or soya available in exporting countries, and quantities required in importing countries, often reflect harvest output fluctuations. These production changes are frequently caused by unpredictable weather variations. This characteristic requires flexible shipping capacity. Employment opportunities for Handymax bulk carriers are also enhanced Capesizes

by port and storage limitations in many countries, restricting the cargo size that can be accommodated.

Recent estimates of grain and soya trade in the 2024/25 year now beginning point to a downturn of about 18mt (3%) to 695mt, based on calculations using USDA data. As seen in the previous trade year, a large part of the annual variation is expected to be caused by a change in China’s imports. These are forecast to fall by 14mt (8%) to 158.7mt, reflecting lower volumes of wheat, corn, barley and soyabeans purchases by Chinese importers. Volumes received by some other Asian buyers also may be lower.

Carrying cargoes within the ‘minor dry bulk trade’ category forms a large part of Handymax bulk carrier employment. Some individual elements of this group are not actually ‘minor’ but amount to massive annual volumes. The commodity range is broad and in the past few years the overall total has been estimated at well over 2000mt annually. Last year there was resumed growth when positive influences were seen.

The two biggest trade components among minor bulk commodities are steel products (coil, sheet, plate and other items), and forest products, although not all quantities are carried by bulk carriers. Large volumes are contributed by bauxite/alumina (aluminium raw materials), fertilizer raw materials and semi-finished fertilizers, agricultural commodities, and cement trades. These are accompanied by big quantities of ores such as nickel and manganese, and steel scrap.

Minor bulk commodities are related to manufacturing and construction, together with those connected with agricultural activity. Estimates suggest that in 2023 there was an overall increase of 1%, to

2175mt according to Clarksons Research calculations, following the previous year’s decline. Changes in individual commodities varied last year, although many saw increases amid some positive influences in both the industrial and agricultural bulks categories Indications suggest a stronger overall advance could be seen in 2024 as a whole.

Within the coal segment numerous routes chiefly employ Panamax and Capesize ships but Handymax cargoes amount to big volumes, especially on specific trade routes. Global seaborne coal trade is the second largest commodity trade employing bulk carriers (after iron ore), and amounted to 1,316mt in 2023, based on Clarksons Research data. Coal still comprises almost one quarter of all global dry bulk cargo movements, despite environmental restraints affecting consumption in many regions.

Coal trade expanded strongly last year after remaining flat in the preceding twelve months. Seaborne movements comprise steam coal (used chiefly in power stations, also in other industries), and coking coal (used in the steel industry). Steam coal is the dominant component, four-fifths of the total. During 2023 the main positive global coal trade import elements were China and India, partly offset by reduced European volumes.

During 2024 seaborne coal trade is again benefiting especially from additional imports into China. Mainly because of this boost forecasts indicate that world coal trade may be marginally higher than seen last year. In the longer term, however, the global shift towards cleaner energy sources is exerting downwards pressure on fossil fuels including coal consumption and is likely to be a restraining influence on coal import demand in many countries.

Charter earnings obtained by Handymax bulk carriers in the global freight market have been quite stable during the first ten months of 2024, fluctuating within a relatively narrow band. Using the Baltic Supramax Index calculated by the Baltic Exchange as a guide to the pattern unfolding, the market varied mainly in a range of 1,100 to 1,500 index points, although it started the year at around 1,000 points. Higher charter earnings resulted in a peak of just under 1,500 before mid-year, followed by a decreasing trend since then, down to below 1,200 in early November.

This pattern of earnings in 2024 has reflected numerous influences, the underlying trends evolving coupled with short-term temporary changes. One underlying trend has been the growing global cargo volumes in many commodity trades providing Handymax employment, exerting a positive influence on the market. That contribution has been accompanied by an expanding Handymax (including Supramax and Ultramax) bulk carrier world fleet, with a tendency to accelerate moderately as a consequence of higher newbuilding deliveries, acting as a restraint on the market demand/supply balance.

Prospects for Handymax freight rates in the period of twelve months or so ahead are as usual surrounded by uncertainties. In particular it is difficult to foresee how much further growth in relevant dry bulk commodity trades and vessel employment may be seen, and there are some doubts about several aspects. Import demand from China (almost four fifths of global dry bulk commodity trade) may cease growing or diminish, while imports into the remainder of the world are not yet showing signs of substantial enlargement.

Vessel demand has been strengthened this year by longer voyage distances amid disrupted trading patterns. Assuming a more normal pattern returns during the course of the next twelve months, a negative impact on the freight market could be seen.

The outlook for the supply side of the Handymax freight market next year currently suggests continued fairly brisk growth of fleet capacity. Elevated newbuilding deliveries may be partly offset by additional scrapping reflecting the ageing fleet and reinforced by tightening regulations designed to cut ships’ carbon emissions. But the likely extent of this factor is unclear and estimates are to some extent speculative. Fleet growth could be enough to restrain any tendency for freight rates to evolve an improving trend.

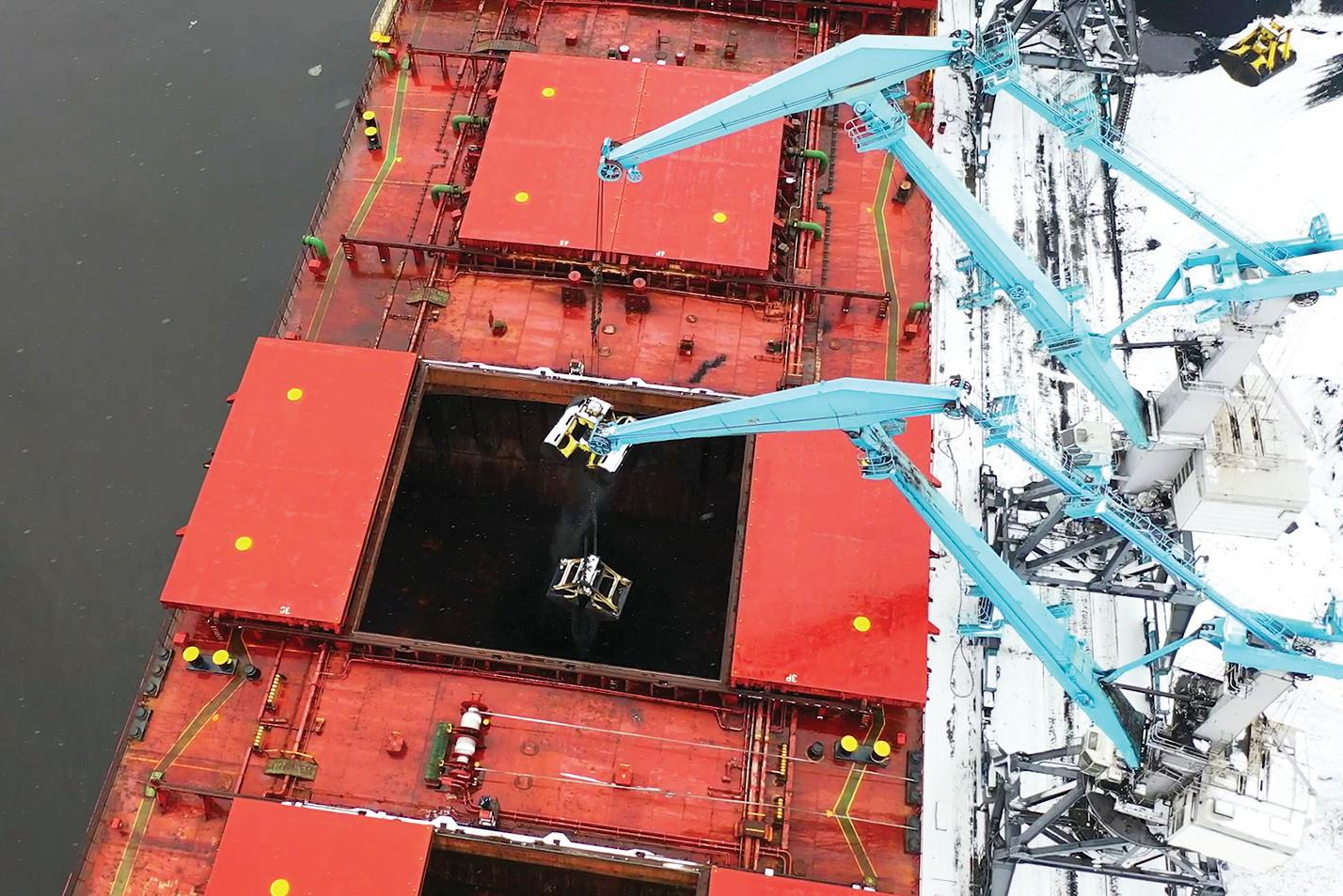

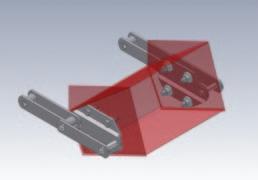

Bateman’s ship’s gear hydraulic grapples

In the world of maritime logistics, efficiency in cargo handling can make or break a vessel’s operational success. Bateman Manufacturing, a leader in specialized material handling equipment, has increasingly positioned itself at the forefront of supplying high-performance equipment tailored for geared bulk vessels. These bulkers, equipped with onboard cranes and handling systems, offer unparalleled flexibility in ports worldwide, especially where shore-based loading and unloading infrastructure may be limited or absent.

Bateman has developed robust, highcapacity attachments that are integral to these self-sufficient vessels. Imagine a skip pan that not only meets but exceeds your expectations in every aspect of performance. Bateman’s skip pan boasts a host of cutting-edge features designed to streamline operations, enhance productivity, and elevate safety standards.

Versatility is at the core of Bateman’s skip pan design. With a 360° continuous rotation capability, its skip pan empowers operators with unprecedented manoeuvrability. Gone are the days of restricted movement and cumbersome handling. Whether it’s navigating tight spaces or accessing hard-to-reach areas, the skip pan offers supreme flexibility, ensuring optimal efficiency in every operation.

But versatility alone is not enough without reliability. That’s why Bateman has equipped its skip pan with a dual motor rotator, ensuring smooth and seamless rotation under any conditions. This robust design not only enhances durability but also minimizes downtime, keeping operations running smoothly and efficiently.

Furthermore, safety is a top priority in every aspect of the skip pan’s design. With a 45° dumping angle, operators can unload materials with utmost precision and control, minimizing the risk of accidents or spillage. Additionally, the skip pan is equipped with a 4½” cylinder, providing the

necessary power and stability to handle heavy loads with ease.

Durability is another key consideration, particularly in demanding environments. Bateman’s skip pan is constructed from abrasive-resistant material, ensuring longlasting performance even in the harshest conditions. From abrasive materials to extreme temperatures, the skip pan is built to withstand whatever challenges come its way, ensuring years of reliable service.

Two other key products in Bateman’s line-up for these vessels are the ship’s gear hydraulic grapples and clamshell buckets, each designed to maximize operational efficiency and minimize downtime.

The Bateman Ship’s Gear Hydraulic Grapple is a versatile, powerful attachment that operates with remarkable precision, allowing operators to handle a variety of materials from coal to aggregates. Built with

durable steel and powered by a reliable hydraulic system, the grapple can deliver impressive handling rates and adaptability across diverse cargo types, ensuring quick and effective port operations.

Meanwhile, the Bateman Clamshell Bucket is engineered for high-capacity loading and unloading. Its design focuses on minimal spillage and smooth operation, even under challenging conditions, making it ideal for handling bulk materials. The

clamshell bucket’s rugged construction and replaceable wear parts provide a long service life, which translates to reduced maintenance and greater operational uptime for vessels equipped with Bateman’s solutions.

As the global demand for flexible, selfsufficient cargo vessels continues to rise, Bateman Manufacturing’s commitment to

engineering excellence remains strong. The company’s ability to adapt to changing industry needs through high-performance, durable equipment ensures that geared bulk vessels — and their operators — can maintain efficient and competitive operations. Through innovation and strategic partnerships, Bateman Manufacturing is not just a supplier of equipment but a driver of operational success for the geared bulker sector.

Copenhagen-headquartered NORDEN has once again added to its projects and parcelling activities, acquiring Norwegian dry bulk operator Norlat Shipping, which specializes in the shipment of forest products and other bulk commodities, with main trading routes from Northern Europe to North Africa and North America.

The acquisition is NORDEN’s second, following the mid-2023 acquisition of the

activities of Thorco Projects, which is today fully integrated into NORDEN’s Freight Services & Trading business unit, operating as ‘Projects & Parcelling’. Norlat Shipping will become part of the Projects & Parcelling team in NORDEN.

“With a customer-centric business and trading routes complementary to NORDEN’s, Norlat is a great fit with NORDEN,” says NORDEN CEO Jan

Rindbo. “Norlat allows NORDEN to further cement our growing position within projects and parcelling, enabling us to offer our customers fully flexible solutions, as a global provider of oceanbased freight services for bulk and project cargo of all sizes.”

A GROWING GLOBAL OFFICE NETWORK

Norlat was founded in 1986 and has since

developed a core business focusing on the shipment of sawn timber from Baltic and Continental ports to North Africa and North America. The company’s offices in Sarpsborg and Bergen in Norway and in the Swedish capital of Stockholm, are now added to NORDEN’s global office network.

“Norlat is an extremely skilled parcelling business, increasing NORDEN’s access to the Northern European forestry trade, new customers and cargo. Matched with NORDEN’s size and access, there are significant opportunities for further growth and commercial synergies,” adds Jan Rindbo.

The Norlat activities are merged with the already growing projects and parcelling team in NORDEN, which focuses on the general cargo segment including breakbulk, steels and wind energy, all of which complement NORDEN’s asset-light business model.

Besides the expansion of it’s projects and parcelling activities, NORDEN also continues to grow it’s Capesize focus, to meet strong demands from customers looking to unlock economies of scale by sizing up to improve efficiencies while

lowering emissions.

Besides giving customers the opportunity to upsize to improve supplychain efficiencies, Capesizes also enable NORDEN to enhance the scope of current and future logistics projects, all while strengthening the ambitions to decarbonize its customers’ supply chains.

With these latest investments in not only Capesizes, but also in Projects & Parcelling and logistics, NORDEN now provides customers with a truly unique fullservice approach across all dry cargo segments, with a strong focus on decarbonization. DCi

Jay Venter

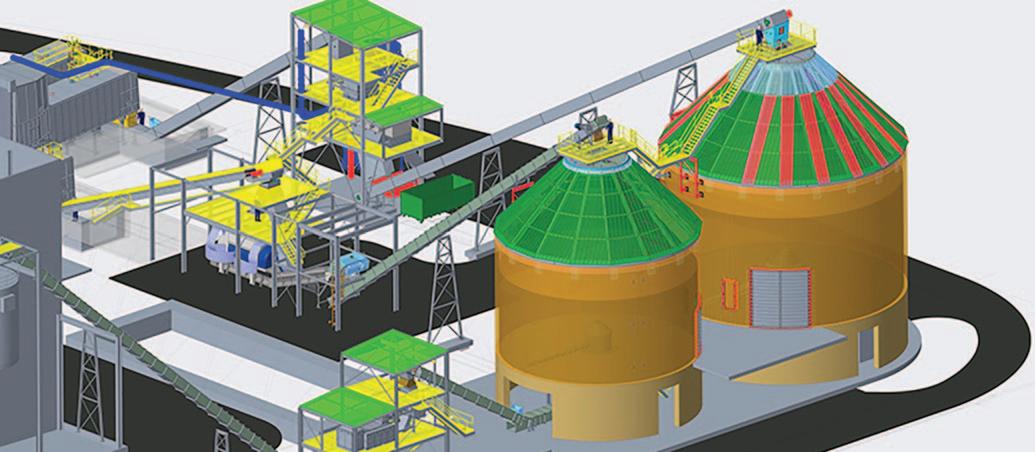

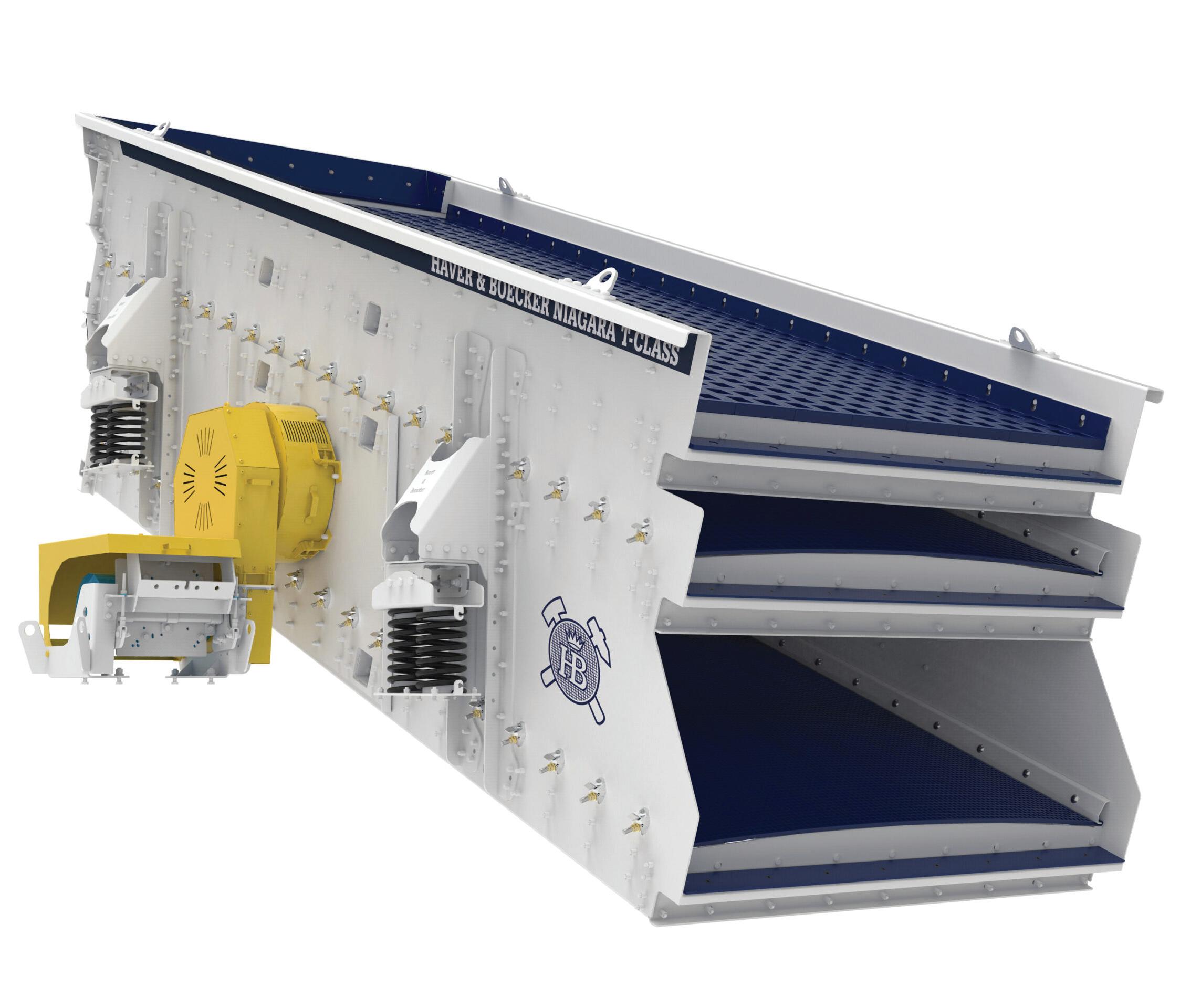

TMGA automates its agrifood terminal in A Coruña, consolidating its strong position in the northwest of the Iberian Peninsula

The modernization of TMGA’s Punta v Langosteira terminal reinforces the Port of A Coruña’s strong position in agrifood traffic in the northwest of the peninsula.

The company, a pioneer in Punta v Langosteira, has undergone significant expansion in recent years.

In 2024, TMGA implemented a new closed transportation circuit for solid food bulk, with an investment exceeding €8 million. This development is part of a comprehensive project valued at over €45 million, including the construction of new agrifood warehouses of more than 6,000m², currently under construction, which will expand the total area to 42,000m², with a storage capacity of over 250,000 metric tonnes of agrifood products.

This new equipment optimizes the efficiency of unloading and horizontal

transport operations through a closedcircuit system of conveyors, covered storage, and the reception and re-shipment of solid bulk. The terminal incorporates advanced technology that automates processes, prioritizing environmental sustainability. Green hoppers and transport systems have been integrated to reduce CO2 emissions.

In February 2015, TMGA unloaded its first grain ship, with a capacity of 20,000 tonnes, at the first private warehouse in Punta Langosteira, measuring 5,000m². Nine years later, the company has consolidated its expansion with a highly skilled professional team and the necessary resources to manage both solid bulk and general cargo.

With these modern facilities, the Port of A Coruña enhances its competitiveness, improving operational times and increasing its capacity for bulk handling, strengthening its leadership in agrifood traffic in the

northwest of the Iberian Peninsula. This advancement will significantly benefit the agrifood industry in Galicia and the northwest of the Peninsula.

The new facilities are key to managing the supply chain in the northwest peninsula’s hinterland, providing clients with greater flexibility in the marketing and distribution of their products. TMGA, integrated into a robust logistics ecosystem, offers end-toend solutions, including chartering, customs management, unloading, securing, storage, and direct delivery to the final customer.

The new terminal incorporates innovative, eco-friendly technology, contributing to reducing CO2 emissions in the port. It is estimated that the new facilities will eliminate around 20,000 truck trips

annually, significantly reducing emissions. The green hoppers, designed to minimize airborne dust during ship unloading, reinforce this environmental commitment.

Equipped with Liebherr LHM 550 cranes, dual hoppers, infrared thermography systems, and temperature monitoring, the facilities comply with strict safety standards like ATEX D and feature a fixed fire protection system. The warehouses use self-supporting prefabricated walls to properly segregate bulk cargo lots.

TMGA’s terminal in Punta Langosteira offers key competitive advantages, making it the best access point to the markets of

northwest Spain and Portugal.

Privileged geostrategic location in the v northwest peninsula, along major international maritime routes.

Modern facilities for handling, storing, v and processing goods such as agrifood, agricultural products, bulk cargo, wind energy, project cargo, and steel.

Functions as a hub terminal for the v storage and distribution of large volumes of goods.

Draughts of up to 22 metres allow the v docking of large bulk carriers.

Recently, TMGA has incorporated new traffic, such as stone for concrete production and offshore maritime construction. Other bulk traffics include:

fertilizers; coal; calcined coke, and urea for the wood panel manufacturing industry.

Traffic volume projections for 2024 point to sustained growth, with forecasts exceeding levels reached in 2023. This increase reflects not only the consolidation of the momentum gained in recent years but also a positive trend of expansion projected through 2025. This upward trajectory is driven by the diversification of trade flows, the incorporation of new strategic clients, and the optimization of logistics operations at the Punta Langosteira terminal. Factors such as process automation, expanded storage capacity, and infrastructure improvements will enable the terminal to efficiently handle larger traffic volumes, anticipating steady growth in the coming years.

TMGA stands out for its commitment to safety, quality, and sustainability, backed by certifications such as OHSAS 18001:2007, ISO 9001:2015, ISO 14001:2015, the GMP European Code of Good Hygiene Practices, EMAS (Environmental Management and Audit System), the CRAEGA seal

of guarantee, which certifies that food was produced in an environmentally friendly manner without the use of chemicals, and the Authorized Economic Operator (AEO) status.

TMGA has operated as a terminal and stevedoring company in the Port of

A Coruña since 1995. In 2013, it became the first company to establish itself in the outer port of Punta Langosteira, without abandoning its facilities in the inner port. The company has been one of the most active in attracting new traffic, both in bulk and general cargo, as well as special projects, consolidating its presence in the ports of A Coruña, Ferrol, and other regional ports in Galicia.

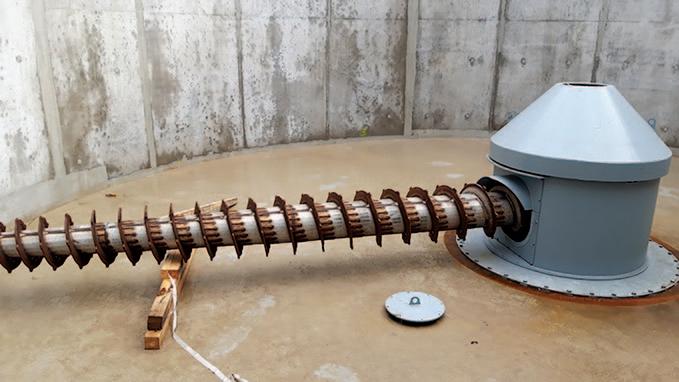

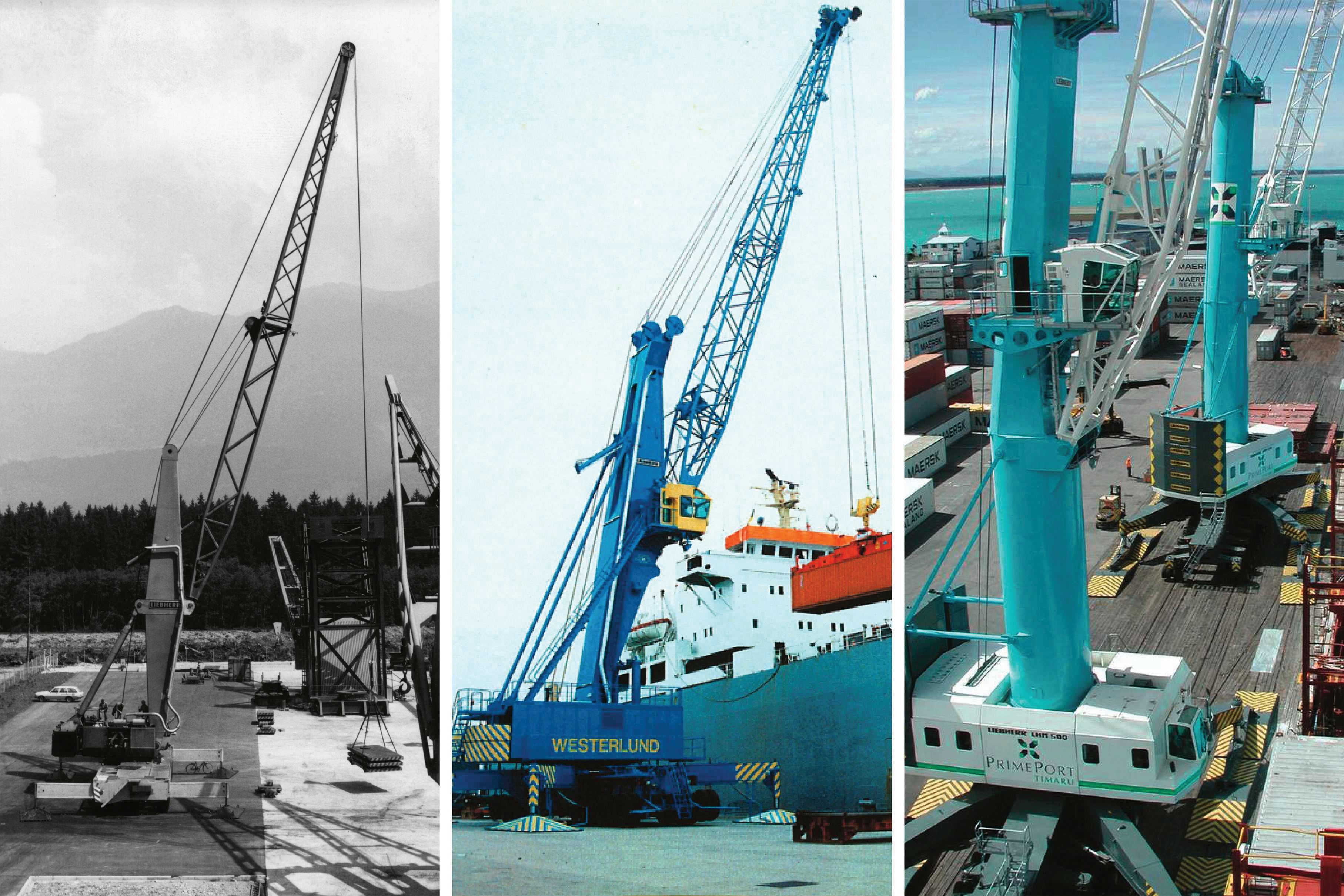

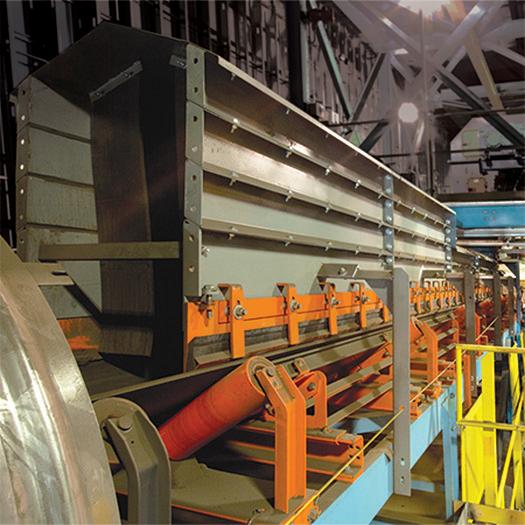

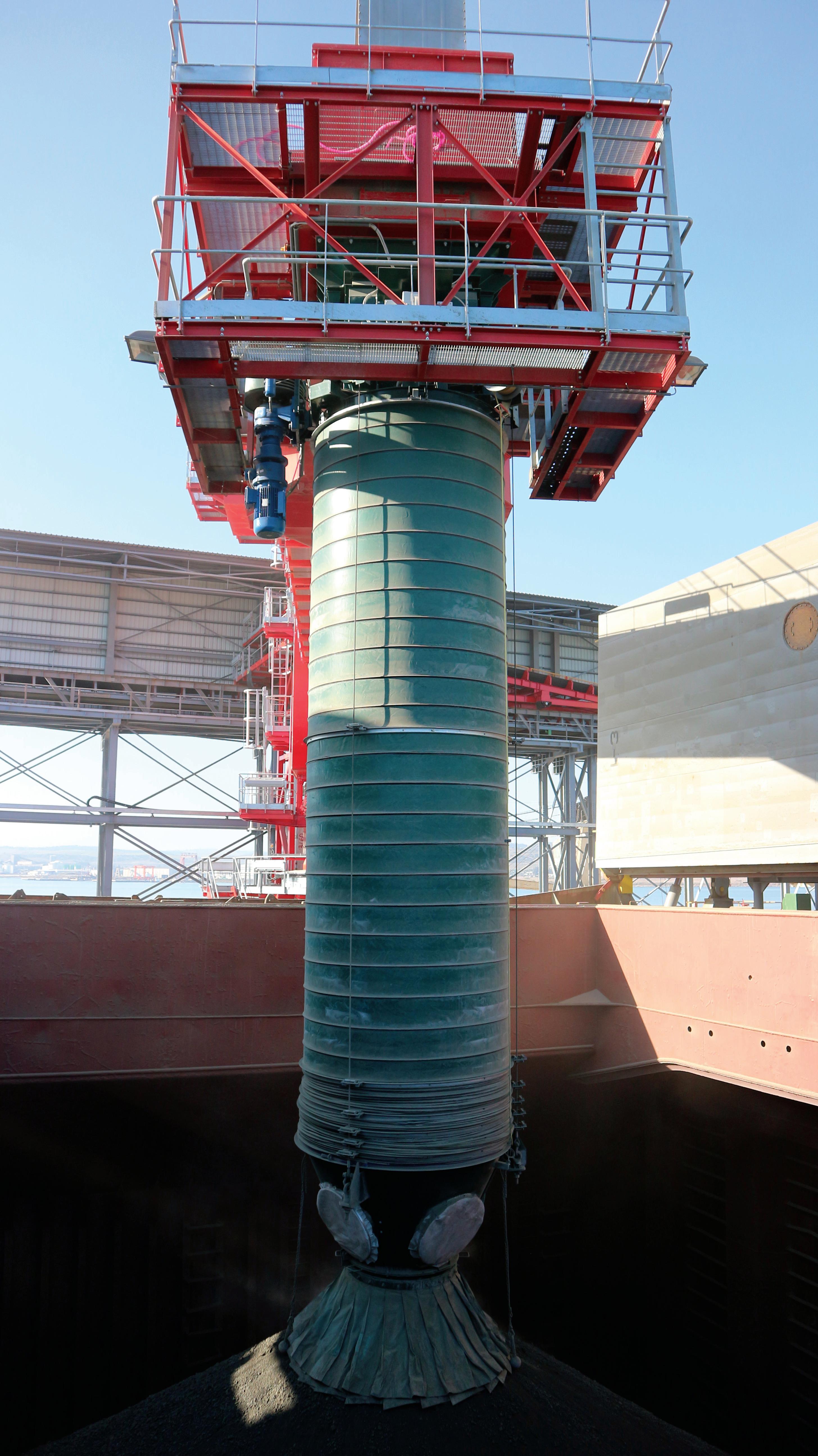

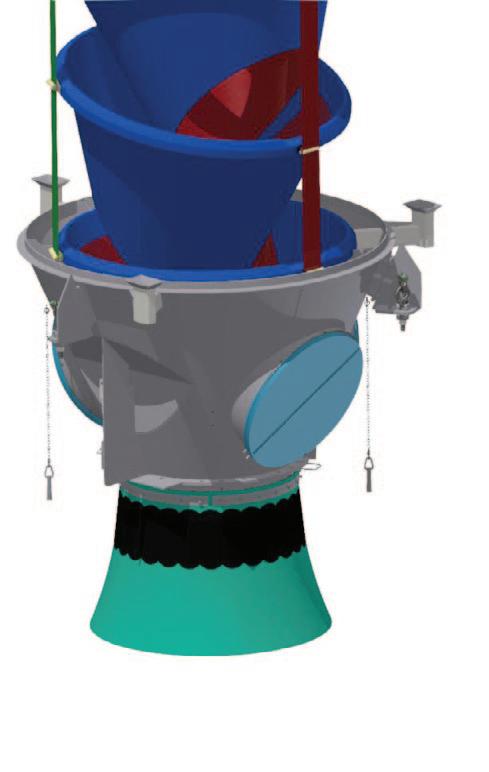

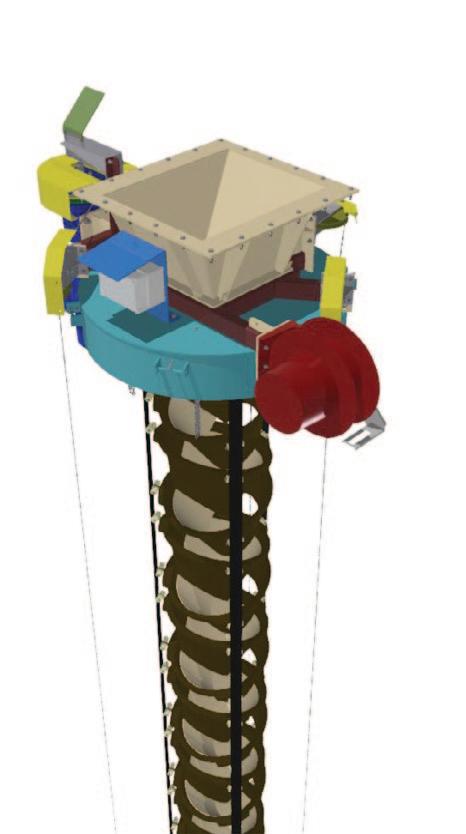

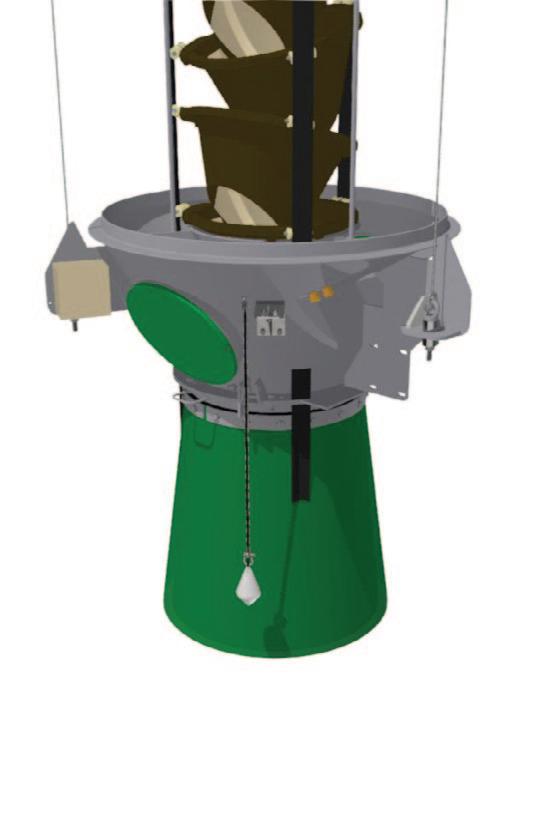

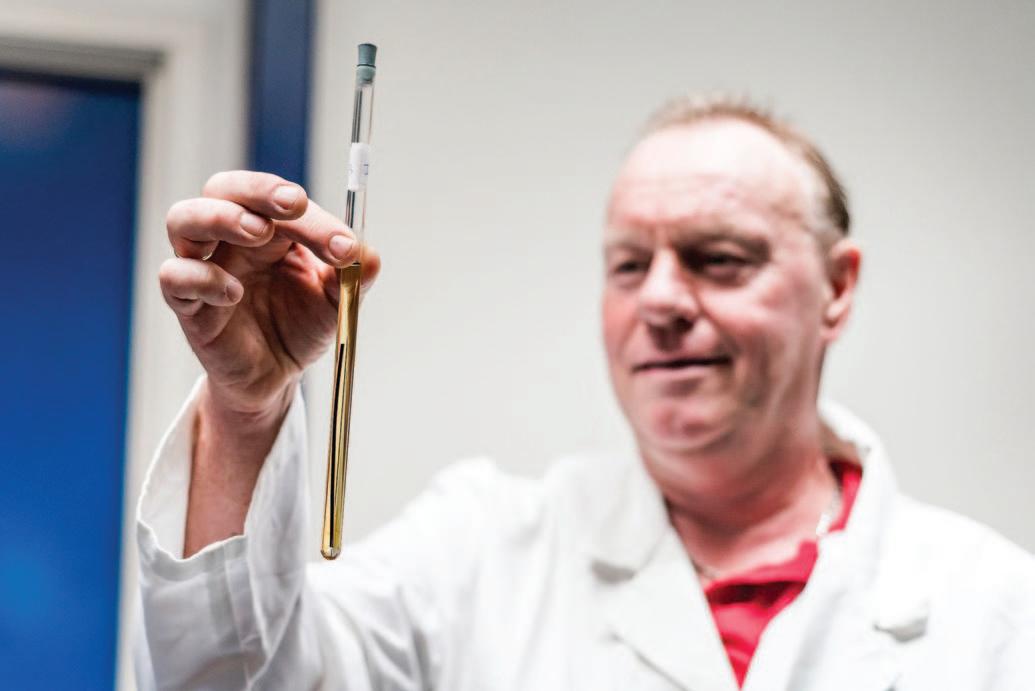

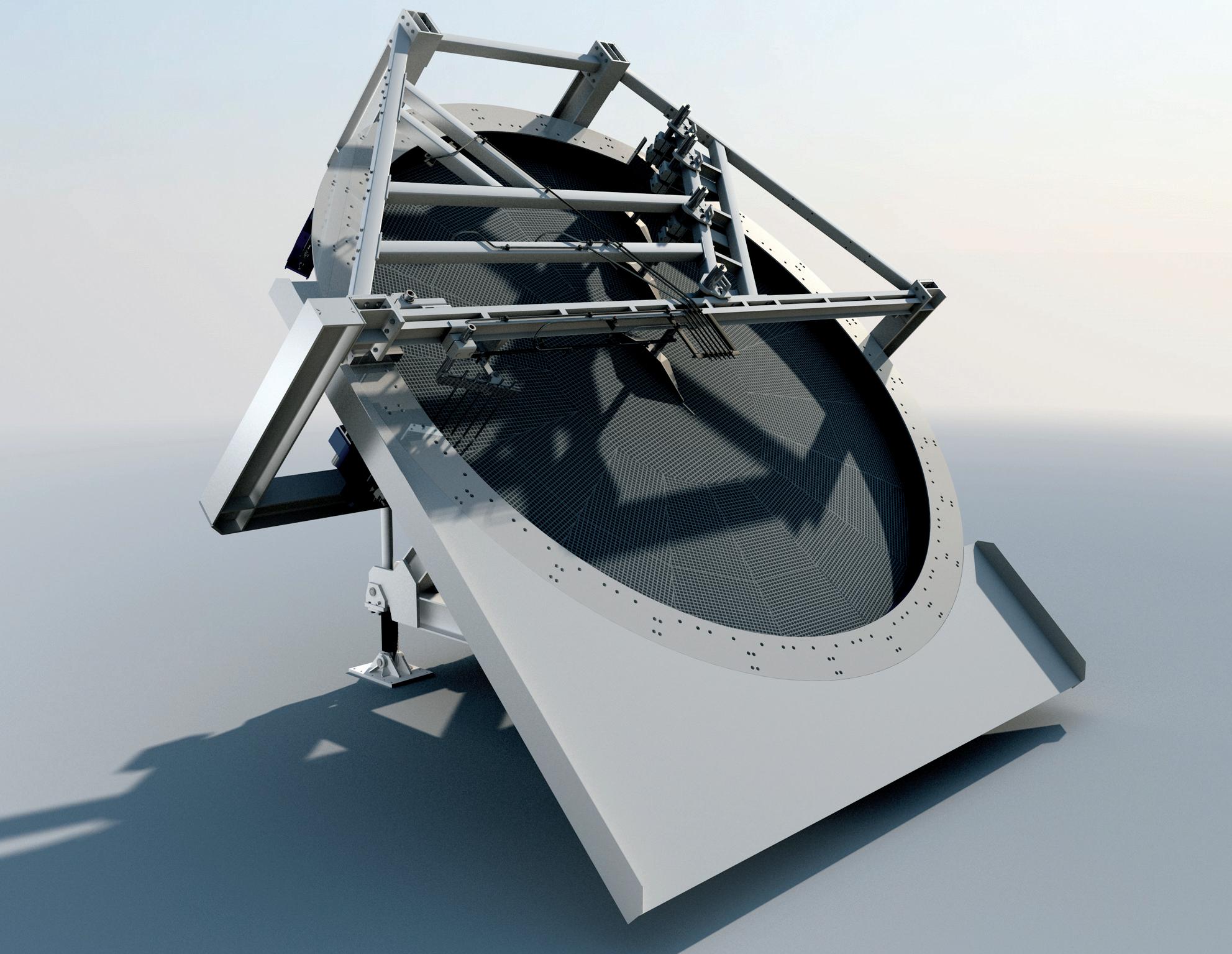

Founded in 1968, VIGAN is a Belgian manufacturer with a global reputation for its advanced pneumatic ship-unloading equipment. Known for the quality and reliability of its products, VIGAN is supported by a team dedicated to precision and innovation.

The company’s headquarters are in Nivelles, Belgium, strategically located just 30km south of Brussels and close to the international port of Antwerp. This central European location facilitates worldwide shipping and enhances VIGAN’s connectivity with top-quality suppliers across the region.

VIGAN initially focused on pioneering pneumatic unloaders based on a unique turbine concept. Over time, it has enhanced its equipment through new materials and advanced steering systems, which boost both capacity and efficiency. VIGAN’s commitment to continuous improvement and customer satisfaction has led it to diversify its offerings, making it a one-stop solution for various port needs: Grain pumps: compact and mobile, v these pumps are designed for rapid deployment, with capacities of up to 250tph (tonnes per hour).

Pneumatic and mechanical ship- v unloaders: available in fixed and mobile versions, these unloaders reach capacities up to 800tph, with mechanical options capable of

handling 1,500tph.

Loaders: adaptable for bulk products v and various vessel sizes, VIGAN’s loaders achieve mechanical loading capacities up to 2,000tph.

Terminals: VIGAN offers turnkey v terminal solutions, including shipunloading/loading, storage, and bagging operations.

All metallic structures are manufactured from alloyed steels provided by a sister company, ensuring that VIGAN’s production remains rooted in Belgium. Local manufacturing guarantees rigorous quality control and enables rapid aftersales support, underscoring the company’s commitment to excellence.

In recent years, VIGAN has doubled its production capacity, enhancing its facility in response to growing demand. This expansion reflects VIGAN’s dedication to long-term customer relationships, with many clients still using machines built 40 years ago. All operations are conducted on VIGAN’s 12,000m2 site, where close collaboration between sales, engineering, manufacturing, and customer service teams ensures efficiency and streamlined communication. Each machine is preassembled in Nivelles, reducing on-site assembly times, precision and ensuring timely delivery.

VIGAN exports 99% of its equipment, with emerging markets primarily in rapidly

growing regions. The company’s expertise in emissions-reducing technology aligns with global environmental priorities, creating new market opportunities.

Like Belgian beer and chocolate, VIGAN’s equipment is renowned worldwide, serving as a testament to Belgian quality and craftsmanship. The company has fostered strong partnerships with key players in Belgium, including leading partners such as Brabomills, Dossche Mills, Malteries Albert (Heineken Group), and Cargill, which operates facilities in Ghent and Antwerp. A recent installation of a pneumatic unloader at Maselis in Roeselare further solidifies VIGAN’s presence in the domestic market, underscoring its reliability and strong client relationships.

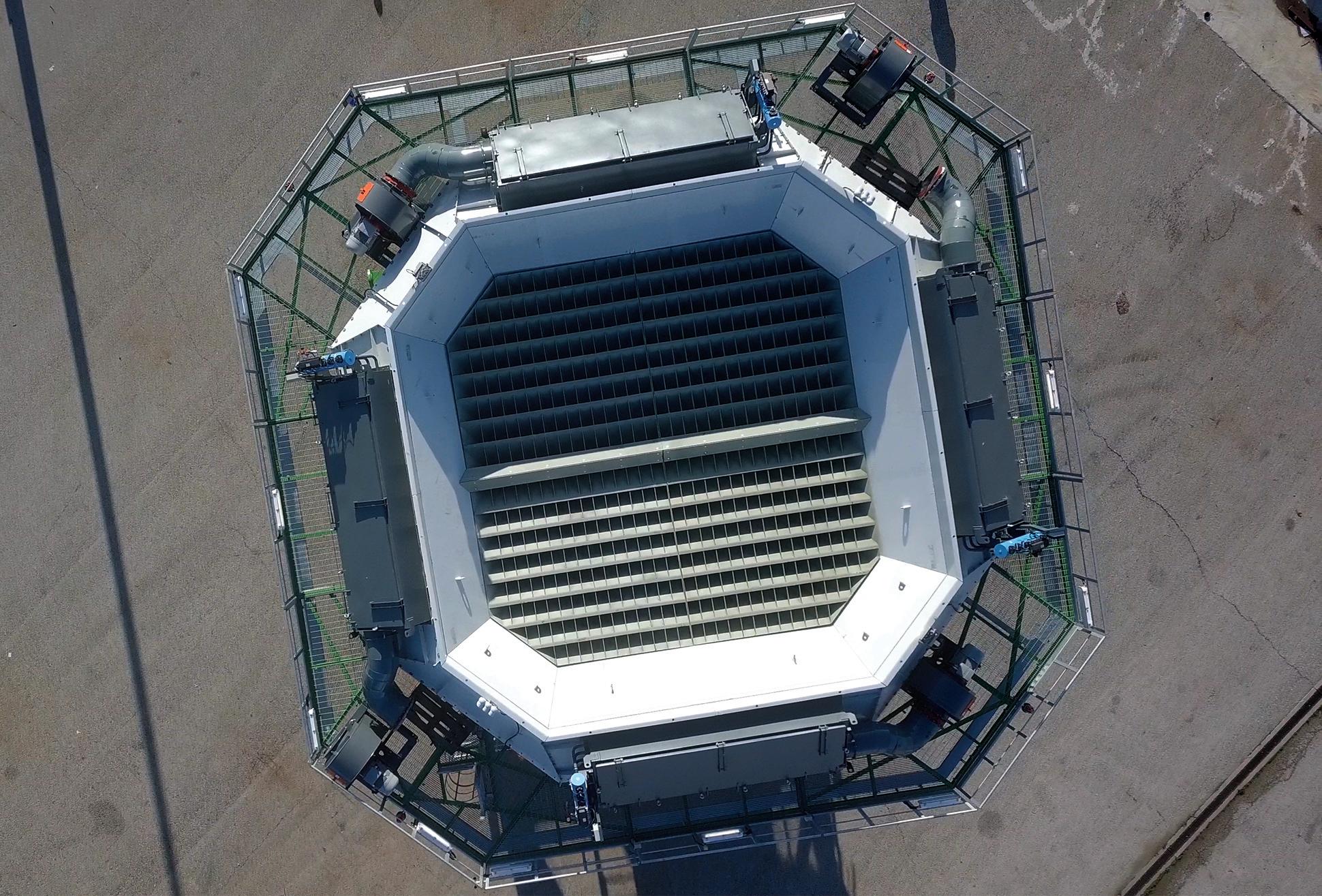

VIGAN is set to install two new continuous pneumatic unloaders NIV800

in Ghent, each with a capacity of 800tph. These machines mark a significant achievement for VIGAN. Several additional units for other clients worldwide are already in production to meet growing demand.

VIGAN’s vertical integration ensures comprehensive control over all stages of production, a distinction from competitors who rely on subcontractors. This approach enables the company to oversee every aspect, ensuring exceptional standards in: design and engineering of machinery; v manufacturing and assembly of mechanical v components; preparation, coating, and protection of v structures; instrumentation and control systems; and v electrical design and enclosure fabrication. v

By pre-assembling and testing each machine in Nivelles, VIGAN ensures optimal reliability and durability, resulting in equipment that often operates continuously for decades in demanding environments. The company’s commitment to operational availability extends to careful vetting of new technologies, which are integrated only after rigorous testing for resilience and ease of use. A dedicated department for electrical and electronic components exemplifies VIGAN’s dedication to technological advancement.

Recently, VIGAN introduced a new generation of high-capacity pneumatic CSUs (800tph). Scaling up machine size involves addressing various factors, including turbine dimensions, piping diameters, and air-lock capacities. VIGAN has adeptly managed these challenges, demonstrating its responsiveness to evolving industry demands.

In summary, VIGAN stands as a beacon of innovation and reliability in the field of pneumatic ship unloading equipment. With a rich history dating back to 1968, the company has consistently demonstrated its commitment to quality, customer satisfaction, and technological advancement. By maintaining a vertically integrated production process and investing in state-of-the-art facilities, VIGAN ensures that every machine meets the highest standards of performance and durability.

As it continues to expand its global footprint, VIGAN remains dedicated to addressing the evolving needs of its clients, offering tailored solutions that enhance operational efficiency in ports worldwide. With a strong emphasis on sustainability and a proactive approach to innovation, VIGAN is well-positioned to lead the industry into the future, solidifying its reputation as a trusted partner for businesses in the maritime sector.

On 11 October Dutch king WillemAlexander and Belgian king Philippe opened the larger New Lock in Terneuzen, North Sea Port. Their presence is indicative of the economic boost the lock has the potential to provide, associated with the arrival of larger seagoing vessels at Terneuzen and Ghent.

The opening of the New Lock in Terneuzen is not an end point but the start of the next stage in the economic development of the cross-border North Sea Port area. The economic importance and future of one of the biggest locks in Europe and the world cannot be underestimated. After all, the New Lock will be extremely significant for maritime and inland navigation, for the growth of existing businesses and the arrival of new investors to the multimodal port — in short, for the economic development of the Netherlands, Belgium, Flanders and the port area.

As Europe’s ninth-biggest port, North Sea Port occupies a prominent position in European and global shipping traffic. The New Lock further enhances that position since it will henceforth form part of two European transport corridors on which North Sea Port is located: the North SeaBaltic corridor and the North Sea-RhineMediterranean corridor.

With the New Lock, North Sea Port not only has a second sea lock but also a larger one, through which larger seagoing vessels can sail from the North Sea towards Terneuzen and Ghent. Ships can be up to 100 metres longer (up to 366 metres) and

a third wider (up to 49 metres). And that is quite an advantage, since those larger ships — the so-called Neo/Post-Panamax vessels — have become increasingly important for international trade and shipping routes over the past twenty years.

This second sea lock, located next to the West Lock for maritime navigation, will also allow North Sea Port to guarantee permanent maritime access to the port area beyond the lock. This means an alternative will be available during maintenance on a sea lock, for example, assuring supplies to businesses at all times.

North Sea Port is a crucial hub for inland navigation in Europe and has direct connections by water in every direction. This is useful for inland barges wishing to sail from Ghent and Terneuzen to the Western Scheldt and beyond to the Netherlands and Germany, or vice versa up to 32 kilometres inland (i.e. as far as Ghent), or to northern France.

The New Lock increases the capacity of the North Sea locks at Terneuzen, which include the West Lock and the East Lock for inland navigation — allowing more barges to pass through the locks at the same time and significantly reducing waiting times. This represents a huge capacity boost for transport via inland waterways. Over 60% of all transport between the port and the hinterland is already provided by inland shipping.

The bigger ships that can pass through the New Lock carry more cargo. That means lower costs for businesses, making expansion of existing businesses and new investments more attractive. And that in

turn offers room for economic growth for both the Netherlands and Flanders, with new employment and development opportunities in the Canal Zone for Terneuzen and Ghent.

FUTURE SEINE–SCHELDT CONNECTION

As a gateway to Terneuzen and Ghent, the North Sea locks, including the New Lock, are a crucial link in the future Seine-Scheldt connection. The development of this European inland navigation link between the Seine and Scheldt basins will allow larger barges to sail even deeper into France from North Sea Port in the future — as far as the Paris conurbation, with a population approaching 10 million.

The New Lock has been described as the crowning glory of the merged port. Since 1 January 2018, the former Dutch Zeeland Seaports (Vlissingen and Terneuzen) and the port of Ghent have been merged as North Sea Port. The 60-kilometre-long cross-border port area, which provides 106,000 jobs, is a recent result of co-operation between the Netherlands and Flanders that goes back centuries.

The port authority, North Sea Port, and the companies that use the New Lock and those bigger seagoing vessels, or will in future, are keen to celebrate that cooperation, and to extend it in the future in order to enable larger ships from the New Lock to reach Terneuzen and Ghent within a few years. The first steps to that end have already been taken.

Trials with ships up to 37 metres wide have been taking place in the weeks before and after the opening of the New Lock. These will enable to partners in the nautical chain, such as traffic controllers, pilots and towing services to ‘get to grips’ with the operation of the New Lock in practice. Subsequently, trials with wider vessels between 38.5 metres and 40 or even 42.5 metres wide are planned for 2025.

North Sea Port makes no secret of the fact that it very much wants to see, in the near future, a deeper canal that can accommodate vessels with a draught of up to 14.5 metres, right up to the bulk cargo port in Terneuzen. That is the first

kilometre beyond the lock, and deepening it is technically feasible in the short term. Oceangoing vessels would then no longer need to offload cargo on the Western Scheldt in order to reduce their draught before passing through the New Lock, but instead could do so more safely and cheaply at the port.

The port authority also looks forward to 43-metre-wide vessels sailing from the New Lock to Kluizendok and Rodenhuizedok in Ghent within about three years. For a ship of this kind carrying dry or liquid bulk, that would mean several hundreds of thousands of euros in cost savings.

Future steps to optimize the accessibility of the canal obviously need to take full account of local residents and the surrounding area.

The end point of seven years of construction, the New Lock, at once marks the beginning of the further economic development of the Dutch-Flemish cross-border port area of North Sea Port.

SEA

TO PROMOTE SUSTAINABLE SHIPPING ON THE RHINE

North Sea Port has co-signed a charter for more sustainable, climate-friendly and efficient water transport throughout the Rhine basin. In doing so, it is also highlighting its own role as a Rhine port.

Anyone who consults a map can see that North Sea Port is a true Rhine port. Barges navigate seamlessly from Vlissingen, Terneuzen and Ghent to the Rhine and back. After all, North Sea Port is located on the European North Sea-RhineMediterranean transport corridor.

60% TO THE HINTERLAND BY

This is a major asset, since the Rhine is by far the most important European artery for water transport. It helps explain why inland navigation is the main inland transport mode at North Sea Port, with over 60% of all goods moving to and from Europe’s hinterland doing so by barge — no fewer than 61 million tonnes last year. To transport that volume by road would require a little under three million trucks.

At the ‘Länderkonferenz Rhein’ (Rhine country conference), which took in Düsseldorf this year, some 90 governments, authorities, ports and economic players from the six Rhine countries — Germany, the Netherlands, Belgium, Luxembourg, France and Switzerland — signed a charter to promote sustainable, climate-neutral and competitive inland navigation. Such broad co-operation is unprecedented.

The cooperation aims to get (even) more cargo onto barges. It is not only companies that benefit, because greener logistics chains help address the challenge of climate change by reducing CO2 emissions from the transport sector. Europe wants to see those emissions reduced by a quarter by 2030.

Ports have a key role to play here, and North Sea Port is keen to make its contribution.

The Port of Cartagena is Spain’s largest industrial port and is at the forefront of bulk cargo traffic in the country. In 2023, it handled a total of 36.5mt (million tonnes), of which 27.8mt were liquid bulk and 8.7mt were solid bulk.

The Port of Cartagena is an important port for solid bulk. In 2023, it handled 8.75mt, reflecting a 20% growth compared to 2022. In 2024, dry bulk traffic continues to rise, with a 9% increase in the first eight

months (January to August) compared to the same period in 2023, already surpassing 6mt.

Follows a detailed breakdown of the solid bulk products handled at the Port of Cartagena:

Agri-food products: a key sector for v the Port of Cartagena, which closed 2023 with 4.7mt. The main products include:

o 3.3mt of cereals.

o 1mt of soybeans.

o 0.3mt of animal feed.

o Minor amounts of fruits and vegetables.