3 minute read

Keeping operations dust free with Wuvio’s technologies

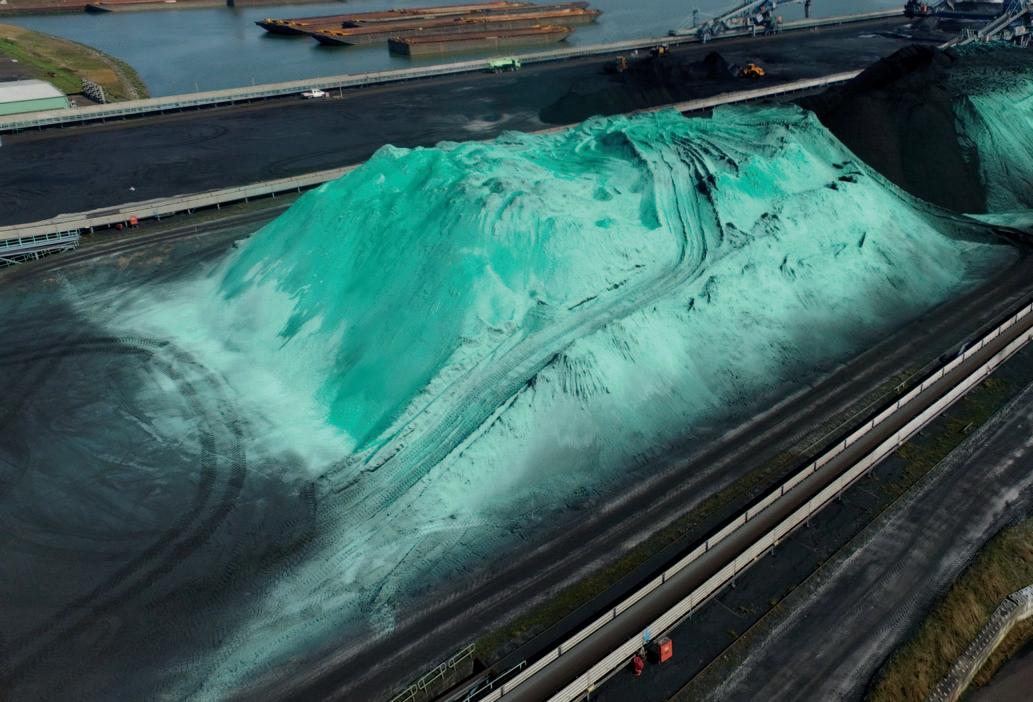

Dust free operations and storage of bulk goods — including coal — can be a challenge. Dust emission is a well-known side effect of the storage of bulk goods in ports, steel mills or other storage areas. The wind is present at these locations; stocks of coal, ores or sand, can blow apart and cause dust emission in the wider area.

A traditional way of capturing dust around large stocks of bulk goods is the use of water. Unfortunately, water has no binding properties and is often a short-lived, ad hoc solution. This solution also requires continuous input of labour and resources.

A CRUST FORMER AGENT IS AN IDEAL SOLUTION TO EFFECTIVELY COMBAT DUST EMISSIONS

EcoCrust S an ideal solution for dust-free coal handing. Wuvio’s crusting agent has binding properties, which means that the use of Wuvio’s crusting agents reduces water consumption by about 80% compared to the traditional method. This solution forms a thin layer that closes off the top layer of the stored bulk goods. After application of the crust, dust formation is reduced by more than 90%.

If desired, the crust can be made in colour. White or green are most used; these colours form a signal effect to the environment. In this way, employees or local residents can recognize that preventative work is being done to reduce dust formation by using crust formers.

READY TO USE CRUST FORMING AGENTS

Dry bulk storage and handling companies want an effective solution that saves time and money, will be easy and quick to prepare and apply. The ideal solution is the use of EcoCrust S technology, this crust forming product will be prepared in dedicated mixing installation locally or will be supplied ready to use. The mixture is sprayed as a thin layer over the bulk goods, so that a nice, thin and welladhesive crust forms when it dries. The application is done by water cannon on a mobile spraying trolley.

The transparent alternative to EcoCrust S is Freko-Crust. This crust former contains no fibres, but has the same binding & protective properties. The crust is colourless (transparent) and can simply be applied with a (mobile) spray gun.

The life of the crust depends on the requirement and site conditions. If desired, the crust can be prepared to protect the dry bulk storage up to six months; application ratios can be adapted to match site throughput and turn around times. Crust is unaffected by harsh weather conditions such as strong winds, heavy rain, hail or snow.

Wuvio’s crust formers are 100% biodegradable and harmless to the aquatic environment.

Advantages of Wuvio’s crust forming agents include: the crust will last up to six months; v more than 90% dust reduction; v save more than 80% on water; v easy to prepare and apply; v loss of product during storage or v transport reduced by 90%; 100% biodegradable; and v 100% safe for people and the v environment.

About Wuvio

Wuvio is a Netherlands-based high tech company established in 2007 with a single mission: ‘a clean and healthy environment for all’. Dealing with dust issues at industrial sites should be easy, non-evasive, cost effective and should be done with a minimal ecological footprint.

Wuvio’s approach: every dust problem is unique. The company’s team of experts is keen to help. Working together with its clients, Wuvio analyses dust problems onsite and works towards an optimized and sustainable solution. It does so both from an economical as well as from an operational perspective.

The in-house developed bio-degradable products and solutions focus on superior crusts, (dry) foams for normal and high temperatures, road dust solutions, binders, and humidifiers. Clients choose Wuvio to access a highly economical solution for their situation, which goes hand-in-hand with having a minimum impact on cargo qualities.

Major clients are top dry bulk transshipment and handling terminals, recyclers, mining minerals and metals companies, infrastructure/civil works contractors, logistics firms, energy producers, and biomass handlers.

EMO celebrates turning 50 with new one-of-a-kind Nemag grab

To celebrate the 50th anniversary of one of its oldest customers, Nemag BV, in collaboration with Raakvlak | ontwerp en communicatie, created a special version of Nemag’s 54m3 scissors grab for EMO BV.

The new KSG20 grab was delivered to EMO’s terminals in the second week of February 2023 and will be used to handle coal.