Paradigm Services shares DIY ingenuity and R&D to help fellow contractors move toward liquids

SPECIAL FOCUS ON ICE MANAGEMENT

Paradigm Services shares DIY ingenuity and R&D to help fellow contractors move toward liquids

By

improving how we govern, strengthening what we offer, and deepening how we listen, we can continue to build an association that serves today’s needs while preparing for tomorrow’s challenges.

As I step into the role of chair of the Board of Directors for the Snow and Ice Management Association, I am both honored by the trust placed in me and energized by the opportunities ahead. SIMA has long been a steady and respected voice for our industry, and my focus this year is to ensure that our governance, our offerings, and our engagement with members and suppliers continue to evolve in meaningful and practical ways.

A key priority for my term is further streamlining the internal processes undertaken by the Board of Directors. Like many volunteer-led organizations, our board members generously give their time while balancing demanding professional responsibilities. It is our responsibility to ensure that board service is efficient, wellorganized, and focused on outcomes that move SIMA and our industry forward.

Continued enhancement of SIMA’s offerings to our membership remains central to our work.

Our members rely on SIMA for education, standards, certification, advocacy, and community. As the industry continues to change, we must continually assess whether our programs and resources are meeting realworld needs. That means listening carefully, evaluating outcomes, and being willing to adapt. Our goal is not change for its own sake, but progress that delivers clear value

Board Chair

Jeff Heller, CSP, Innovative Maintenance Solutions

Immediate Past Chair

Chris Hinton, CSP, GRM Inc.

Vice Chair

Chris Thacker, CSP, Mr. Mow It All

Secretary / Treasurer

Tom Fitzgerald, CSP, Donovan Property Service

to contractors, managers, and professionals across the snow and ice industry.

Equally important is strengthening engagement with our supplier members. SIMA benefits greatly from the expertise, innovation, and perspective that suppliers bring to our association. This year, we will place a stronger emphasis on ensuring supplier voices are heard, respected, and meaningfully considered.

Engagement must go beyond sponsorships and exhibit halls; it should include thoughtful dialogue, opportunities for input, and transparency around how feedback is used to inform decisions. When suppliers know their opinions matter and are taken seriously, SIMA becomes stronger and more relevant for the entire industry.

Underlying all of these efforts is a commitment to collaboration, respect, and shared purpose. SIMA is at its best when board members, staff, contractors, and suppliers work together toward common goals. By improving how we govern, strengthening what we offer, and deepening how we listen, we can continue to build an association that serves today’s needs while preparing for tomorrow’s challenges.

I am grateful to serve alongside a dedicated board and staff team, and I look forward to the progress we will make together in the year ahead.

Directors

Matt Crinklaw, Greenius by Granum

Connie Gaul, ASM, SNOWGO National Services

Andy McArdle, CSP, ASM, Douglas Dynamics

Robert Miller Jr., CSP, ASM, RPM Landscape Contractor

Dean Outhouse, CSP, ASM, North Point Outdoors

Robert Young, CSP, K.E.Y. Property Services

Don’t bluff your way through the season. Draw the winning knowledge you need from our expert-led education sessions, workshops and moderated discussions. Details are still being finalized. Visit show.sima.org for updated topics, schedules and speakers!

June 24, 2026

In an era of unprecedented challenges, the path to your organization’s greatest success lies in finding solutions together. Jeremy Poincenot shows how prioritizing interdependence drives powerful results individually, as a team and as an organization.

June 26, 2026

Winning in business is no longer about low prices and big marketing spends. Nearly every company now sells a commodity. The true differentiator your competitors can’t copy is how you make people feel—because customers talk about experiences, not transactions.

Get in position for a great week by attending one of this year’s preconference workshops:

Sales and Business Development Workshop

This workshop moves past the “math” of bidding and dives into the psychology of the sale. We are shifting the focus from what you charge to how you position your value, gain access to elusive decision-makers, build a book of business through relentless relationship management and more.

Liquids Workshop

Explore the business and operational benefits that can be gained by adding liquids into your operations. Blending classroom instruction with outdoor stations, you’ll gain the knowhow to successfully make and apply liquids, make decisions on when to use them (or not) and how to sell the benefits to your clients.

Build a winning hand when you make powerful industry connections at the week’s special networking events:

Tuesday

SIMA After Hours

Wednesday Snack & Chat Lunch

Welcome Reception

Special Interest Meetups:

Canadian, Women in Snow, Residential

SIMA After Hours

Thursday

Connections Breakfast

Industry Awards Lunch

Thursday Night Party

Learn more about these events and see our full schedule at show.sima.org/schedule.

enhance your experience with the SIMA+ Pass

The SIMA+ pass is a Full Show Pass (access to education, networking receptions and the trade show), plus exclusive extras throughout the week.

Tuesday, June 23

Choice of liquids or business development workshop

Wednesday, June 24

Early access to Trade Show After Dark

Thursday, June 25

Private reception

All Week

Exclusive access to the private SIMA+ Pass

and info hotline

We’re not bluffing—the Best Show in Snow is the biggest trade show dedicated to residential and commercial snow and ice management pros. In addition to 100+ exhibitors, don’t miss these trade show highlights:

Wednesday Trade Show After Dark

Thursday

Product Showcase Studio Presentations

“How do I?” …. Sessions

Ale Trail

Friday

Stop and Shop Breakfast Stations

Product Showcase Studio Presentations

Life, Leadership and Lessons (L3) Sessions

Trade Show Hours

WEDNESDAY, JUNE 24 6:30–8:00 p.m.

THURSDAY, JUNE 25 Noon–5:30 p.m.

FRIDAY, JUNE 26 9 a.m.–Noon

Exhibit booths and sponsorships for the show are available at a variety of price points. Snow pros: Have a favorite vendor?

Let them know Cincinnati, OH is the place to be in June ’26!

Power, productivity, and performance is the promise that WESTERN® has built its reputation upon for the last 75 years. Providing snow & ice contractors with the equipment they can count on to battle winter’s worst while everyone else hunkers down.

The SIMA Leadership Forum is the premier event for snow and ice management professionals to connect, grow, and lead your business forward.

Mark your calendars for August 1618, 2026, as we gather at the historic DeSoto Hotel in Savannah, GA.

Why you need to be there

The Leadership Forum provides a dedicated space to step out of the day-to-day grind and refocus on vision, strategy, and personal and professional growth: Build and strengthen leadership skills: Learn directly from industry experts, business strategists, and leadership coaches. Gain practical tools to enhance decision-making, team-building, and strategic planning.

Network with high-level industry peers: Surround yourself with forwardthinking business owners and executives. Share best practices and real-world

solutions with peers who understand the unique challenges of our industry.

Strategic insight for the future: Explore emerging trends to stay ahead of industry shifts.

True leadership is an ongoing journey of refinement. Whether you are an owner seeking to scale your

impact or a manager evolving into a strategic visionary, the Leadership Forum provides the high-level environment to sharpen your influence and master the complexities of leading others.

Visit sima.org/leadership to view the full schedule, speaker lineup and to register.

Paradigm Services shares DIY ingenuity and R&D to help fellow contractors move toward liquids

BY PATRICK WHITE // PHOTOS BY LONEMAN PHOTOGRAPHY

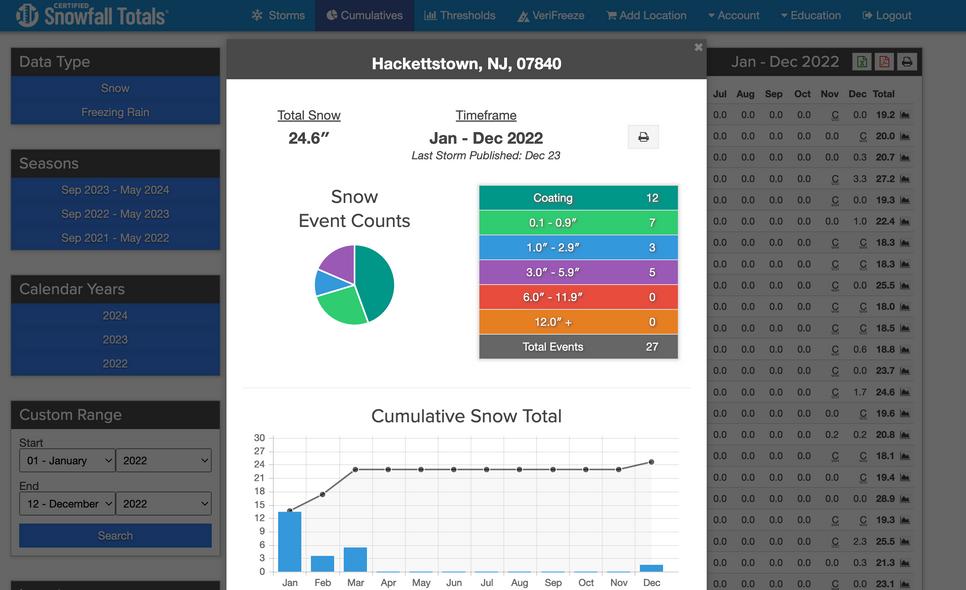

Maintenance owner Ryan Van Dyke looked at the local Montana market, he saw a frustrating gap. His company relied on granular salt and sand for ice management, but he knew liquids offered a cleaner, more efficient path forward. The problem? The liquids they wanted were either unavailable locally or required expensive shipping.

Rather than settling for a subpar solution, Van Dyke and Operations Manager Kellan Stevenson, ASM—two “ranch kids” with a knack for tinkering—decided to stop buying and start building.

“We went to some seminars, took some classes, took a trip down to Salt Lake City and talked to a bunch of different brine companies there to kind of learn where they were sourcing their raw products and the different methods they were using, and just kind of started,” Van Dyke says.

The pivot from frustrated consumer to DIY innovator didn’t just solve North Grounds’ supply chain woes; it sparked the creation of Paradigm Services, a venture coowned by Van Dyke and Stevenson that has grown into Montana’s largest salt distribution business.

Van Dyke says the fact they are snow management contractors that use brine on a regular basis has helped them both from a product development standpoint as

well as in being able to knowledgeably talk with customers and get them started with liquids.

“When we were starting our liquids program at North Grounds, 1,500 gallons would last a long time, because we were putting down a very minimal amount,” he says. “Customers would say something like, ‘Can you use it just in front of our store?’ And then, when they saw the results, they’d say, ‘Why don’t we do a few of the other drive lanes?’ And then it turns into, ‘Well, hey, just do our whole parking lot, because we like the way it works.’”

While it’s easy to see granular salt when it’s spread on a parking lot, applying liquids take more of an education, Van Dyke says: “We’ve had people chase our spray trucks down asking why we’re spraying water on the ground.”

As contractors they also keep a close eye on the performance of the brine they make. “We’re using our own products, so if we have any issues, I’m going to be the first one to know what that issue is,” notes Stevenson. “Being contractors also facilitates a lot of R&D. For example, I can do some really cool things as far as experimenting with melting temperatures and monitoring how long it takes the products to work.”

They also build their own spray trucks, which gives Stevenson the opportunity to experiment with how they’re putting down the liquid, testing out which patterns work best, and using geofencing to see exactly how much liquid is getting applied where.

MAKING IT WORK IN MONTANA:

Water restrictions and product availability force Paradigm Services to think outside the box.

Page 14

SERVICING AIRPORTS IS A DIFFERENT BEAST

Bozeman International Airport requires a military-like approach to service.

Page 17

Stevenson says there is still some hesitancy about liquids among contractors in the state, which is why he and Van Dyke are so open about sharing their experiences in the market.

“A lot of guys will say, ‘Well, I’ve used sand for the last 40 years, and it works just fine for me. So why would I switch?’ And they see these liquid sprayer setups that cost $20,000 or $30,000 and they’re very hesitant to spend that much money,” he says.

“It helps being able to show them how much they’re going to save on salt by switching to a liquid. And that you don’t need to go out and buy a $30,000 setup to get into liquids. You can build a very rudimentary spray setup for a fraction of the cost,” Stevenson says.

Working together

Van Dyke and Stevenson have been deliberate about growing Paradigm in a way that works in conjunction with their responsibilities at North Grounds, which is one of the larger snow contractors in the area, with roughly 50 employees.

“We’re very fortunate at Paradigm; with essentially three people (they employ one full-time delivery driver), we can keep things moving pretty smooth,” says Van Dyke, who makes the majority of the brine, while dealing with material suppliers. Stevenson handles delivery

Continued on page 15

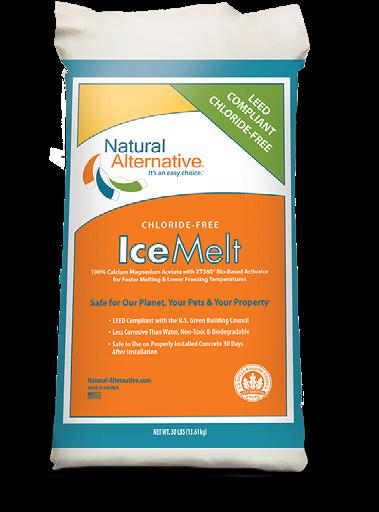

• Works to -16o F & Melts Ice Fast

• Non-Toxic & Biodegradable (Safer for Fish & Pets)

• Use 3X Less Product than Rock Salt

• Does Not Harm Lawns, Vegetation, Hardscapes, or One Year Old, Properly Cured Concrete*

& Ice for Easier Removal

• Includes an Activator to Initiate the Deicing Process

• LEED Compliant with the U.S. Green Building Council

• Less Corrosive than Tap Water, Non-Toxic & Biodegradable

• Safe on Properly Sealed and Installed Concrete 30 Days after Installation

Not surprisingly in a state renowned for its natural beauty, the environment is a major factor in snow and ice operations in Montana. “It’s important to us that we take care of the resources we have here – in part that means paying attention to how much salt we’re using,” says North Grounds Property Maintenance Operations Manager Kellan Stevenson.

“What started as a personal mission has grown us to being able to help other snow contractors give their accounts, their properties, the results that they deserve, while also being able to be conscientious about salt usage.”

That has required a lot of experimentation with brine additives, because their customers’ needs can vary dramatically depending on their location.

“We get some pretty insane weather here. For example, in Chester, which is in very north Montana near the Canadian border, it might be -5 degrees with snow. But here in Bozeman, on the same day, it can be

45 without a lick of snow on the ground,” says Stevenson.

They make a “base mix” brine with a few performance additives that can then be tailor-blended for specific scenarios. “You know, like when it’s -40 degrees here, which is a very real thing come January and February,” jokes Stevenson.

They also custom-designed their brine maker to operate under a unique constraint in Montana: limited water availability. Municipal water is prohibitively expensive, so they use a well for their brine operation; but the state limits well output to 35 gallons

a minute. Most large-scale brine equipment is designed for constant production of, say, 85 gallons a minute. Instead, they designed their equipment to work in batches, while waiting for their water capacity to come back up.

Van Dyke says the state’s isolation is another factor that poses logistical challenges, especially when it comes to getting parts or materials: “Many of the different brine additives come from the East Coast, where they might cost $500 per tote. Well, to get it to Montana is an extra $1,000 in shipping. It’s a challenge to figure out the best materials to use without making things cost prohibitive.”

Even getting salt can be more difficult, adds Stevenson. “If you’re in the Midwest, or you’re on the East Coast, your salt can be brought in 20,000 tons at a time on a barge. But there’s not as many freight options for us here. That’s a challenge with anything we buy at Paradigm or North Grounds,” he explains.

Continued from page 13

logistics, dispatching, and equipment maintenance. Paradigm is located at the North Grounds facility, so they can quickly shift back and forth between duties as needed. “And we’ve got really good managers at North Grounds, both in the field and in the office — they make it possible,” Van Dyke emphasizes.

When Van Dyke and Stevenson started experimenting with making brine, they began with a simple 250-gallon tote. Paradigm now produces over 400,000 gallons a year, but the DIY ethos has remained. “A few years ago, we purchased a big fancy commercial brine maker, but we didn’t get the results we wanted, so Kellan and I spent the last year developing our own brine maker, with help from some good friends who are engineers. It has custom tanks, a custom pump

system, digital screens, and is mostly automated,” says Van Dyke.

Stevenson and Van Dyke both say they “geek out” when it comes to all things snow and ice — especially when the topic is brine. Stevenson says that’s why he enjoys the opportunity to talk with other contractors from all parts of the country at SIMA events to learn about how they’re innovating their

operations — which is often quite different than how things are done in Montana.

“Being able to engage with them, that’s a huge advantage. Because at the end of the day, we’re in the same

Continued on page 16

Continued from page 15

that I do that they’ve never thought about trying,” he says.

“Whether it’s Paradigm or North Grounds, we want to always be thinking innovation,” Van Dyke emphasizes. “Kellan and I are both very passionate about this industry. We want to help other people be able to provide great service; have cleaner, safer lots; and be more efficient, so they can save their customers money. That’s the way the whole snow industry grows.”

FULL-TIME DELIVERY: Joel Sanders crosses Montana delivering liquids to Paradigm Services’ customers. He’s the only other employee besides the company’s co-owners.

I want to know 100% of the time that the customer will get serviced on time, that they’re taken care of.”

—KELLAN STEVENSON

Growing both businesses organically through innovation rather than over-aggressively trying to grow North Grounds or Paradigm for growth’s sake is key: “As soon as quality starts to slip, meaning customers are complaining we’re not getting things done, that’s a really good sign to me that we may be a little bit too big for our britches,” says Stevenson. “When we plow or when we sell a product, I want to know 100% of the time that service

or product is going to work. I want to know 100% of the time that the customer will get serviced on time, that they’re taken care of.”

Patrick White has covered the landscape and snow and ice management industries for a variety of magazines for over 25 years. He is based in Vermont. Contact him at pwhite@meadowridgemedia.com.

Kellan Stevenson began as a mechanic at North Grounds Property Maintenance and now is one of the company’s operations managers. One of the major accounts he oversees is the Bozeman Yellowstone International Airport—a challenging, highly technical, 24/7/365 operation.

One of the biggest hurdles, he notes, is dealing with “insane amounts of foot traffic.” With no covered parking, snow and ice must be managed around cars that might be parked for weeks at a time and people walking through the lots constantly.

“You have to have your head on a swivel at all times – you have to be 100% locked in and focused at all times, which I think leads to a little bit more exhaustion for our crew,” Stevenson says. “I can’t tell you how many times I’ve been plowing at the airport and somebody just walked out in front of me with their family of four. When you’re in a 35,000-pound machine, there’s no stopping quickly.”

Then there are the ultra-high expectations. “Everything has to be so precise – every single time. There’s no room for misses, because if you do miss, you hear about it. And the expectation is just that much higher, not only from the airport as a customer, but also just from the public,” says Stevenson.

To cope, he falls back on his past experience in the Marines, when he would train his soldiers on the importance of setting and then holding expectations: “The standard for airports is zero tolerance, 24/7. I actually call it a negative tolerance account, because the

TECHNICAL CHALLENGE:

Kellan Stevenson uses his mechanical and military expertise to drive airport operations.

expectation is that we create a slip/trip-free environment, and that’s how it’s to be kept at all times. And our crew of 15 to 17 guys working there knows that is the standard for them.”

“Kellan keeps that property running like a well-oiled machine,” praises North Grounds owner Ryan Van Dyke. But Stevenson says the credit really goes to the crew. “The guys do the majority of the work; I’m often just the one driving around with a plow making sure everything is done.”

By KEN BOEGEMAN, JR., CSP, ASM

By February, most snow and ice operations are deep into the season. Crews are tired, storms are stacking up, and conditions are changing by the hour. This is also the point in the season when risk is at its highest— not because contractors stop caring, but because volume, fatigue, and urgency collide.

Slip and fall claims, property damage, and emergency service requests tend to spike during this stretch of the season. When these issues arise, naturally your first priority is to remedy the situation immediately. After the situation is addressed, what you do in the following 24 hours can determine whether an issue becomes a minor operational headache or a major legal and insurance problem.

Managing risk in real time is not about reacting emotionally or scrambling to explain what

EDITOR’S NOTE:

This is the third article in a series addressing practical risk strategies across the snow season. Additional topics (visit resources.sima.org for past articles):

9/25: Become a snow company that carriers want to insure

10/25: Use documentation to build your legal defense

12/25: In-season documentation that defends

6/26: What to keep and how to store it

6/26: Contracts that Protect, Not Expose

Dispatchers are often the first point of contact when something goes wrong. How emergency requests are logged sets the foundation for everything that follows.

Every emergency request should include:

• Date and time of the call

• Who made the request

• Exact concern reported

• How the request was handled

If the service falls outside the original contract, that should be noted clearly. Emergency requests should also be tied to weather conditions at the time of the call. Was there active precipitation, a refreeze, or rapidly changing temperatures? These details provide important context later.

happened later. It is about having a clear, repeatable process that starts the moment an incident is reported.

The moment an incident is reported — whether it is a slip and fall, a damaged curb, or an emergency service request — the clock starts ticking. Conditions change quickly, and details are easy to lose if they are not captured right away.

Your goal in the first 24 hours is not to assign blame or defend your company. The goal is to preserve facts. That means documenting what you knew, what actions were taken, and what conditions existed at that moment in time.

EDITOR’S NOTE: Post-Incident Playbook Checklist on pages 20-21

Not every incident becomes a lawsuit, but every incident should be handled with the same level of discipline. The same process should apply

whether someone slips on a sidewalk, a plow damages a curb, or a client calls requesting emergency service outside the normal scope of work. Inconsistent responses from one site to another or one storm to the next create gaps that attorneys and insurance carriers notice later.

Emergency requests deserve special attention, not because they are the only situations that matter, but because they are where even strong systems are most likely to break down. Emergency requests refer to unplanned, reactive callouts that fall outside normal contract triggers or scheduled service — not routine snow removal performed as part of regular operations.

Emergency services should never be documented the same way as routine service. They require their own logs, time stamps, and notes explaining why the service was needed and who authorized it. Clear separation between routine and emergency work helps explain real-

supervisors onsite steps after a reported incident

Supervisors play a critical role once an incident is reported. If you are dispatched to a site, your responsibility is to observe and document, not to speculate.

Document surface conditions, lighting, signage, and weather upon arrival. Record what mitigation steps were taken and when. If additional services were performed, log them as a separate occurrence.

Do not attempt to alter, filter, or “clean up” the facts. If a mistake was made, or if something feels uncomfortable to document, it is still important to record it accurately. Always assume there is existing documentation, including photos or video, that reflects the actual site conditions at the time of the incident.

If your report is later shown to be incomplete or misleading, it can seriously damage your defense. If the situation progresses to litigation, your attorney will be far better positioned with a complete and honest account of what occurred.

Not every incident requires executive involvement, but some should never stay at the field level. Clear escalation triggers protect both your company and your team.

Consider automatic escalation when an incident involves medical treatment, emergency responders, significant property damage, or allegations of negligence. Incidents outside the normal contract scope should also be reviewed promptly.

executives when to involve your carrier or legal team

Early notification allows your insurance carrier or legal counsel to guide next steps and help preserve coverage under your policy. Delays in reporting can create unnecessary exposure.

Most insurance policies also require incidents to be reported promptly. If you are unsure whether an incident needs to be reported, contact your insurance carrier right away and discuss the situation with them. It is far better to ask early than to find out later that a reporting requirement was missed.

time decisions if questions arise months or years later.

The worst time to decide how to handle an incident is in the middle of one. A post-incident playbook gives your team clarity under pressure. The first 24 hours checklist focuses on capturing facts immediately, while the post-incident playbook ensures the incident is managed consistently from start to finish.

Your playbook should outline who documents what, where records are stored, when leadership is notified, and how follow up communication is handled. It should be simple, repeatable, and used every time.

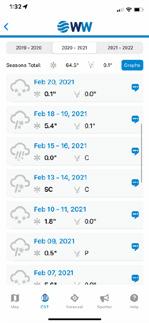

Forecasts and post-event summaries matter

Archived forecasts and post-event summaries provide critical context. They show what was known when real-time decisions were made, not what became obvious later. Pairing service logs with forecast data helps demonstrate that actions taken during a storm were reasonable based on actual or forecast conditions.

Risk doesn’t wait

February storms test even the best operations. The companies that come out strongest are not the ones that avoid incidents altogether. They are the ones that manage them well in real time. Risk does not wait until the season is over. How you respond during the storm often matters more than what you say months later.

Ken Boegeman is a snow & ice industry consultant and President of SG Advantage and Swinter Group. He has over 13 years of experience as a snow and ice slip-and-fall expert and more than 30 years in the snow industry. Contact him at kenb@swintergroup.com.

Use this checklist anytime there is a reported incident, complaint, or emergency request.

1

CAPTURE THE REPORT

• Date and time the incident or request was reported

• Who reported it and how it was reported

• Exact concern as stated, not assumptions or interpretations

3

LOG SERVICES PERFORMED

• Services completed before the incident

• Services completed after the incident

• Time services were performed

• Who performed the work

2

DOCUMENT CONDITIONS

• Weather conditions at the time of the report

• Observed or reported surface conditions

• Lighting, signage, and access conditions

• Any active precipitation or refreeze conditions

4

PRESERVE COMMUNICATIONS

• Save call logs, emails, and texts related to the incident

• Keep internal notes separate from client communications

• Do not edit or overwrite original records

Arctic's unique galvanizing process ensures your plow outlasts harsh winters. So get plowing, put it away wet, and say goodbye to corrosion.

Arctic's unique galvanizing process ensures your plow outlasts harsh winters. So get plowing, put it away wet, and say goodbye to corrosion.

If yes to any of the previous, notify management.

DETERMINE ESCALATION

• Does the incident involve an injury?

• Were emergency responders involved?

• Is there significant property damage?

• Was the request outside contract scope?

5 6 7 8

ARCHIVE SUPPORTING RECORDS

• Service logs tied to the incident

• Emergency request documentation, if applicable

• Forecasts and post-event summaries

• Incident reports and follow-up notes

NOTIFY WHEN REQUIRED

• Management or ownership

• Insurance carrier or broker, if thresholds are met

• Legal counsel, if advised

• Assign responsibility for client communication

• Track any additional services or mitigation steps

• Close the incident internally only after documentation is complete

Vulcan® Edges Last 3X Longer—So You Can Plow Profitably on Every 2-3" Snow Event

Most contractors skip plowing light snowfalls (2-3") because factory edges wear out too fast. Instead, they dump expensive salt. That changes with Vulcan®

Our boron steel cutting edges with cast steel PlowGuards filled with Americanmade Winter Carbide™ last 3x longer than factory edges. Install once in fall, then plow confidently all season—even those light dustings that used to cost you in chemical treatments.

Stop leaving money on the table. Scrape the light snow. Save on salt. Make more profit per storm.

Fits BOSS, Western, Fisher, and SnowEx V-plows. American-made. 5-star rated by contractors. $1,285-$1,565 depending on plow size.

By ERIK DYBA, CSP, ASM

Snow and ice management does not stop once a storm ends. Crews are already planning for the next event, addressing repair needs, and maintaining equipment. Clients expect sites to be ready for whatever comes next. Without deliberate review, familiar issues recur, including missed areas, late starts, uneven material use, and recurring equipment problems. Not because teams do not care, but because lessons were not documented when they mattered.

After-action reviews address this

Meaningful reviews require accurate information, and service tickets provide that foundation. Service tickets document the work performed, site observations, and any additional scope requested. They also capture when areas are missed or require additional service. They define when the work occurred and the conditions under which it was performed. When completed consistently, they create a dependable record of operational performance.

Reviewing tickets collectively reveals patterns that individual tickets do not. These patterns shift the discussion from isolated outcomes to system-level issues. The focus moves to understanding why issues recur and what needs to change to prevent them.

gap. When done well, after-action reviews give teams a structured way to learn from each event. Built on a straightforward process and reliable data, they support steady improvement over time. Consistent, incremental improvements can change the trajectory of an entire season.

Start with the good stuff

Effective after-action reviews begin by recognizing what went right and who made it happen. Strong decisions in the field, clear communication, and progress from previous events should be acknowledged first. Equally important is recognizing team members who go above and beyond,

whether by staying late to complete a route, stepping in to support another crew, proactively addressing a site issue, or making sound judgment calls under challenging conditions.

Celebrating these wins reinforces the behaviors leaders want to see repeated and sends a clear message about expectations. When team members feel valued and see their contributions acknowledged, engagement increases and turnover pressure decreases. Starting reviews this way sets the tone for productive discussion and encourages honest participation.

Effective after-action reviews do not stop at surface-level observations. A

Material use is one of the most critical and most mismanaged aspects of snow operations. After-action reviews should

evaluate performance, not volume alone. Rather than only asking how much material was applied, effective reviews ask whether the material performed as intended. That requires looking at application timing alongside air temperature, pavement temperature, humidity, and event progression. A callback may result from rapidly changing conditions, residual moisture, or pavement temperatures dropping faster than anticipated, not from a lack of material. Higher application rates do not guarantee better outcomes when timing and conditions are misaligned.

When teams review service tickets, GPS data, and weather information together, they gain a clearer picture of what happened in the field. This reduces assumptions and improves judgment during marginal events, where timing matters more than volume alone. Making material performance a standard part of after-action reviews strengthens consistency, improves defensibility, and supports responsible material use without compromising service expectations.

Attendance also affects execution.

Late call-offs, fatigue during extended events, and reliance on a small group of individuals can impact response times.

Routes that consistently run behind schedule are not always poorly planned. In many cases, staffing depth is the limiting factor. Including attendance trends in after-action reviews helps leaders identify where schedules, availability expectations, or staffing models need adjusted.

Equipment performance and routing decisions directly affect service quality and cost. GPS data adds clarity by showing where equipment operated, how long it ran, idle time, and whether routes matched the plan. When reviewed alongside service tickets, GPS data confirms what occurred in the field and reduces reliance on assumptions. Layering this information with repair history often highlights training needs or maintenance gaps.

missed area may result from a gap in the site plan, limited visibility, or unclear expectations. A delay may be tied to dispatch timing, routing, equipment availability, or fatigue. Without identifying the root cause, corrective actions tend to be temporary. This process begins with an objective view of the current state. What happened? Under what conditions? What decisions were made at the time? Service tickets, weather data, attendance records, GPS information, equipment data, and incident reports

keep the discussion grounded in facts. Equally important is defining the desired state. Faster response. Fewer callbacks. Clearer communication. More consistent material performance. Without clear expectations, improvement efforts lose focus.

After-action reviews are effective because they are repeatable. Not every issue requires a major change. Refining dispatch timing. Updating a site map. Adjusting application timing. Coaching one operator. Improving documentation for a single ticket.

Incident reports and safety assessments are another critical component of effective after-action reviews. Near misses, slips and falls, property damage, and equipment incidents often reveal risk factors. Reviewing these incidents helps teams understand how conditions, timing, site layout, or communication increased exposure.

Safety assessments add value by identifying site-specific hazards, including drainage issues, lighting gaps, pedestrian routing conflicts, pile placement concerns, and traffic flow challenges. Addressing these risks through planning and site adjustments helps prevent repeat incidents and reinforces a proactive safety culture.

These incremental improvements compound over time. When applied consistently, after action-reviews become more than an operational task. They become a leadership practice that strengthens communication, reinforces professionalism, improves safety, supports retention, and builds stronger teams. In an industry defined by changing conditions, organizations that learn deliberately and consistently are better positioned to perform at a high level throughout the season.

Erik Dyba, CSP, ASM is the Specialty Services Operations Manager at the Bruce Company of Wisconsin, a SIMA Foundation board member, and a Wisconsin Salt Wise subject matter expert. Contact him at EDyba@brucecompany.com.

IBy JP SANIESKI, CSP, ASM

n this industry, we spend months preparing for winter and countless hours and days reacting to storms. But after decades in snow and ice management, I’ve learned that the most telling work often happens after the final push—when the snow is gone and the excuses are, too.

Post-winter cleanup is where professional snow contractors distinguish themselves. It’s not glamorous, it doesn’t always generate immediate revenue, and it rarely gets discussed. Yet it is one of the most critical phases of a successful snow operation.

For both established contractors and companies new to the business, spring cleanup and operational reset should be treated as a formal, repeatable process—not an afterthought.

Continued on page 26

Set yourself up for success with post-winter cleanup and operational review

Snow operations leave behind residue abrasives, salt buildup, plow scarring, and debris that becomes visible once the snowpack disappears. Without a formal cleanup process, these conditions quickly turn into trip hazards, drainage problems, and client dissatisfaction.

Contractors should have a built-in schedule for postseason site walkthroughs that include sweeping paved areas, clearing catch basins, inspecting curbing and walkways, and documenting site conditions. This work reinforces to customers that your service is part of overall site care and not a standalone task isolated to winter events. At this time, you should be comparing your preseason inspections to the current conditions, and taking responsibility to fix anything that is not in the same condition.

If you want to assess the maturity of a snow operation, look at their salt storage.

Spring is the time to remove caked material, clean and wash sheds, repair containment systems, and reconcile material inventories. Damaged tarps, compromised pads, or drainage issues should be addressed immediately.

With increasing scrutiny around chloride usage and environmental impact, clean and compliant salt storage is no longer optional. It protects the environment, preserves material quality, and demonstrates operational discipline.

Snow stacking areas often become dumping grounds for debris over the course of a winter. Broken asphalt, damaged signage, trash, and ice chunks can remain hidden until equipment or people encounter them later.

Spring cleanup includes full debris removal, restoration of sightlines at entrances and intersections, and regrading areas impacted by snow piles. Addressing these areas in spring prevents avoidable damage to mowing equipment and eliminates safety concerns before the busy summer maintenance season begins.

Salt exposure does not stop when the snow melts. Corrosion continues to attack brake lines, frames, wiring, and suspension components long after winter ends.

A postseason fleet recovery program includes thorough undercarriage washing, corrosion neutralization, mechanical inspections, and early rust mitigation. These steps extend vehicle life and prevent safety issues that often surface months later.

Clean trucks are not only about appearance—they are about longevity and reliability.

The most cost-effective time to service snow equipment is when it’s not needed.

Plows, wings, and spreaders should be removed, cleaned, and thoroughly inspected. Hydraulic systems, wiring, cutting edges, mounting points, and welds all require attention. Scheduling repairs during the offseason reduces downtime, lowers costs, and improves reliability when the next winter arrives.

Too many failures blamed on “bad luck” are really the result of skipped spring maintenance.

Winter produces a significant amount of operational data. The companies that grow are the ones that review that data.

Postseason back-office work should include reconciling invoices, labor hours, and material usage; reviewing storm documentation; and closing out claims while records are still current. It is also the ideal time to evaluate contract language and identify scope gaps before renewal season. Operational discipline in the office is just as important as performance in the field.

Continued from page 24

Professional snow contractors don’t disappear when winter ends.

Postseason summaries, site condition reports, and repair recommendations reinforce value and build trust. These conversations also position contractors for renewals and allow for proactive planning ahead of next winter. In many cases, retention is secured in the spring—not the fall.

Field crews know what worked and what didn’t.

Capturing that knowledge is essential.

Postseason debriefs should focus on route efficiency, equipment performance, staffing challenges, and communication gaps. Standard operating procedures should be updated based on real-world experience, and training plans established before the next winter begins.

Experience builds knowledge; reflection builds excellence.

The professional standard

• Skid Steers

• Wheel Loaders

• Snow Pushers

Snow and ice management is not defined solely by how quickly we respond to storms. It is defined by how responsibly we manage the aftermath.

Contractors who commit to post-winter cleanup, documentation, and operational reset are not just preparing for the next season—they are raising the standard of the industry.

The end of winter is not the end of the job—it is the final measure of it.

Postseason cleanup and operational reset are not optional tasks reserved for slow weeks or excess capacity. They are deliberate acts of professionalism that protect clients, preserve assets, strengthen teams, and set the foundation for the next winter’s success. Contractors who skip this phase may survive another season, but they do so at the expense of credibility, efficiency, and long-term profitability.

Spring is when accountability becomes visible. Sites reveal how they were managed. Equipment shows how it was maintained. Records expose whether operations were controlled or chaotic. Clients remember whether communication continued or abruptly stopped when the snow did.

The contractors who lead this industry understand that winter service does not conclude with the last storm event. It concludes when sites are restored, equipment is reset, data is reviewed, and lessons are documented. That discipline is what allows organizations to grow, scale, and endure.

The storms may end in March. Professional responsibility does not. Think snow, when no snow.

JP Sanieski, CSP, ASM, is director of commercial accounts for Perrone Landscaping. Email him at jp@perronelandscaping.com.

ABy AVI S. OLITZKY

t 2:30 a.m., with a winter storm intensifying faster than forecasted, the phone rings. Equipment is already rolling, crews are stretched thin, and clients are anxious. This is the moment snow and ice professionals train for… and the moment when leadership matters most.

High performance under pressure does not happen by accident. It is not the result of heroics, adrenaline, or sheer grit. It is built long before the storm hits, reinforced during the event, and reflected on afterward. The best operators understand a simple truth: pressure does not create problems, it reveals them. And it reveals leadership habits, good and bad, at full volume.

In snow and ice management, pressure is not episodic. It is structural. Weather volatility, labor

How leaders keep people, performance, and trust intact when everything is on the line

shortages, tight margins, equipment risk, client expectations, and safety concerns converge in real time. The organizations that thrive are not the ones that eliminate pressure, because that is impossible, but the ones that learn how to lead through it with clarity, consistency, and care.

Under pressure, even strong crews behave differently. Communication shortens. Assumptions increase. Patience erodes. Small frustrations become outsized conflicts. Leaders who misread these shifts often attribute problems to attitude or effort, when the real issue is stress overload.

Pressure also amplifies differences in experience. Operators who feel confident in their assignments tend to respond with focus and urgency, while newer or less certain team members may withdraw, freeze or overcorrect.

Misalignment in experience levels becomes more noticeable, not because skill changes, but because the margin for error shrinks. In these moments, a leader’s ability to level-set expectations and pair the right people matter far more than raw capability.

Fatigue adds another layer. Long hours, cold conditions, and the physical strain of operating equipment make it harder for crews to regulate emotion and concentration. Someone who is normally easygoing might snap. A usually meticulous operator may miss a detail. These changes are not signs of weakness; they are predictable human responses to cumulative stress.

High-performing crews do not need less accountability during highpressure events. They need clearer accountability. They do not need leaders who bark louder; they need leaders who anchor the system. The most effective supervisors slow the pace of communication while keeping the pace of work moving. They

translate urgency into direction rather than volume.

This starts with understanding that pressure narrows focus. When people are overwhelmed, they default to habits—good or bad. That means leadership behaviors must be practiced before the storm, not invented during it. Crews that have rehearsed routes, decision points, and handoffs in advance can operate on muscle memory when conditions deteriorate. Crews without that preparation tend to improvise, and improvisation is rarely scalable under pressure.

Most importantly, pressure exposes whether a crew feels psychologically safe. When team members believe they can ask questions, admit concerns, or flag issues without immediate judgment, they communicate earlier and more clearly. When they do not, they keep quiet until the situation forces their hand. Silence under pressure is often a symptom of fear, not defiance.

Leaders who recognize these dynamics respond with clarity and composure. They normalize stress reactions instead of shaming them. They interpret conflict as information rather than insubordination. By treating pressure as a shared challenge rather than a personal failing, they create an environment where crews can perform at a high level even when the stakes are high.

One of the most persistent myths in operational leadership is that great leaders must be constantly available, constantly decisive, and constantly in

• Define decision rights clearly. Who decides what, and when?

• Standardize escalation triggers so issues surface early.

• Train leaders to communicate priorities, not just tasks.

• Reduce noise. Fewer messages, clearer direction.

• Stay visible without micromanaging.

• Reinforce safety standards, even when timelines slip.

• Hold structured after-action reviews focused on learning.

• Separate people from process.

• Close the loop by communicating what will change.

• Calm tone under stress

• Consistent expectations

• Visible trust in supervisors

• Willingness to hear uncomfortable truths

control. In reality, this approach often backfires. Leaders who attempt to monitor every decision and personally resolve every issue believe they are demonstrating commitment, but what they frequently create is dependency. Teams learn to wait rather than act, and initiative erodes.

When leaders try to be everywhere at once, they become bottlenecks.

Decisions slow down. Crews hesitate. Confusion spreads. Worse, leaders unintentionally signal that they do not trust their supervisors or operators to execute. The message is subtle but unmistakable: “You cannot handle this without me.” Over time, this undermines confidence and reduces resilience, particularly during long-

Continued on page 30

Continued from page 29

duration events when endurance matters as much as speed.

High-performing leaders under pressure do something counterintuitive: they constrain themselves. They do not insert themselves into every communication channel or every tactical decision. Instead, they establish structure. They define who escalates what and when. They reinforce standard operating procedures so supervisors know how to proceed without pausing for permission. They empower people to make decisions at the lowest appropriate level, which keeps the operation agile.

Effective presence is not measured by how many problems a leader solves personally, but by how many problems are solved without them. This involves resisting the instinct to react instantly to every call or update. It means taking the time to think strategically rather than being consumed by tactical noise.

An effective leader defines decision rights clearly. They delegate authority explicitly. They stay visible without hovering. Their presence stabilizes rather than agitates. Crews read calm body language and steady tone as confidence, not indifference. In pressured environments, demeanor is as influential as direction.

This does not mean disengagement. It means disciplined engagement, knowing when to step in and when to step back. It means stepping in to remove obstacles, align priorities, or manage client expectations, and stepping back to let capable supervisors lead their teams. Leaders who practice this balance model selfcontrol for their crews, which often prevents panic or reactivity from cascading through the operation.

beats motivation every time

During a storm, motivation is rarely the problem. People know the work matters. What fails is clarity. Who owns which sites? What is the priority if conditions worsen? What happens if equipment goes down? What does “good enough” look like

These questions shift the culture from blame to problem-solving, which is exactly what pressure demands.

• “What are you seeing that I might not be?”

• “What’s the risk we are underestimating?”

• “What do you need right now to keep this moving?”

when perfection is impossible?

The strongest operators answer these questions in advance and repeat them relentlessly. They reduce cognitive load so crews can focus on execution, not interpretation.

When clarity is present, pressure becomes manageable. When it is absent, even small disruptions feel catastrophic.

Trust is operational, not abstract Trust is often discussed as a cultural value, but in high-pressure environments, trust is operational. It shows up in whether people share bad news early, admit mistakes, or ask for help before things spiral.

Crews do not hide problems because they are careless. They hide them because past experiences taught them it was safer to stay silent.

Leaders who want high performance under pressure must actively reward transparency, especially when the news is inconvenient. The fastest way to lose trust is to punish honesty during a crisis.

Clients experience pressure during storms, as well. Their operations, liabilities and reputations are on the line too, and they often communicate that urgency to contractors. When leaders do not proactively manage expectations, client anxiety can quickly translate into crew stress.

The strongest operators set expectations before the first flake falls. They explain service level agreements in practical terms, clarify trigger thresholds, and outline

realistic timelines based on weather and resource availability. During an event, they provide concise updates but not constant play-by-play. Clients do not need every detail. They need to know the plan, the status, and any adjustments being made.

By staying ahead of client communication, leaders protect crews from unnecessary or misdirected pressure. This also reinforces professionalism. When clients see that their contractor remains calm, focused and transparent, they mirror that stability rather than escalating demands.

Managing pressure externally is as important as managing it internally. When client expectations are well aligned, crews can focus on execution instead of interpretation, which strengthens performance and protects morale.

In calm conditions, many leadership styles work. Under pressure, only a few hold up. High-performing leaders are not defined by charisma or intensity. They are defined by predictability. Crews know what to expect from them in difficult moments. That consistency builds confidence.

The question every leader should ask is not, “How did we perform?” but “Who did we become under pressure?” Because crews remember that long after the snow melts.

Avi S. Olitzky is the president and principal consultant of Olitzky Consulting Group, based in Minneapolis, MN. Contact him at avi@olitzkyconsulting.com.

BY EVAN TACHOIR

Amajor part of industry conferences like SIMA’s Snow & Ice Symposium is classroom training. As a training specialist by trade, I have been intrigued by the discussion I’ve heard about the value of classroom training at industry events. Some find value in it. Some say they don’t get much from the sessions. Rather than fueling a debate, I wanted to add some perspective on how to get the most out of classroom training before you head to conferences this year.

Children can take in lots of new information as their brains are forming; however, adults can’t handle an “information dump” the same way. This is why many classroom trainings that share tons of information are ineffective. Adults need to apply what they learn; so, when you attend a session, think about how you can apply the information in your work.

Getting the most out of training starts before you go to the session. Considering the following questions can inform which conference sessions are best for your career and professional development:

• Where do you want to go next in your career?

• What strengths can help you get there?

• What areas of weakness do you need to improve?

• What skills and tasks do you still need to learn?

In addition to considering your goals, review the training schedule with your supervisor and/or company leadership to discuss current company priorities and identify which sessions would be most beneficial for you.

70%

Job-related experiences, which includes on-thejob training and practical application of skills.

20%

Interactions with others, such as mentoring, coaching, and networking.

10%

Formal educational events, including workshops, courses, and seminars.

During the session

Once you select a session, come ready to learn and take notes. Participate in discussions and ask questions—you will retain more by interacting. One of the best ways to get the most out of the session is to ask yourself, “What is one thing you will start, stop, and continue doing based on what you learned?”

Learning is not a one-time event; it’s an ongoing process. When you get back to work, keep the momentum going:

Put lessons into action. Take the one thing you will start, stop, or continue doing based on what you learned and start applying it on the job. For example, if you learned about a sales technique, try it on your next call or meeting. Take note of what worked well and where you need to improve.

Recap with management. Have follow-up discussions with your supervisor and leadership about what you learned and how you will put it

into action. These ongoing discussions and how you track progress on what you’re working on will help you perfect it over time.

Share the knowledge. In addition to discussions with leadership, ask them for time to teach others, even if it’s just a few minutes at the morning huddles. Learning is valuable when it’s done together.

I hope this gives you practical tips on how to get the most out of training. Remember, pro athletes train consistently to win money and a trophy. How much more should we train since we keep essential, lifesaving organizations running during the worst of winter? Never stop growing and you will see success!

Evan Tachoir is the founder of Jack of All People Trades, HR/People Consulting to help snow companies recruit, develop and retain the best employees. He leads the monthly networking/ teaching series NET Gain. Email him at evan@ jackofallpeopletrades.com.

We don’t throw around that title, Superhero, lightly. But snow and ice operators save the day all winter long —so the title fits the job. Now meet your sidekick: The XRS™ Automatic Winged Blade.

Trusted on skid steers for years, the XRS is one of the most adaptable and user-friendly plows in the galaxy—led by automatic wings that anticipate your every move. FISHER® Nation specifically requested this truck-mounted version— so we’re answering with unmatched scrape, six degrees of oscillation, and Trip Edge technology. Let’s just say winter will need all the luck it can get. THE XRS™ AUTOMATIC WINGED BLADE Dig in at FISHERPLOWS.COM

By CHERYL HIGLEY

In the commercial snow industry, the end of winter isn’t a finish line; it is the strategic launchpad for the next sales cycle. But clients often delay signing until the first flake falls; but this “wait-and-see“ approach creates unnecessary risk and degrades operational efficiency. For the contractor, securing “ink on paper“ early is the difference between a controlled season and a high-stakes scramble.

power of the postseason review

For Bob Young, CSP, owner of K.E.Y. Property Services in Palmer, MA, the

renewal process begins immediately after the season ends with a formal review. By asking clients “what went right, what went wrong, and what can we change/do better next season,” he transitions the vendor relationship into a strategic partnership.

“This meeting is the precursor to having the customer sign early. We identify issues, find the solution, monetize a new proposal and get them to sign,” Young says. For a small operation, these early commitments are foundational to logistical planning: “Getting the customer to sign early… allows me to plan potential cash flow and to allocate existing equipment and plan for any additional equipment or resources I may need.” Furthermore, he uses early renewals to hedge against market vola-

The first winter tire for tractors, Nokian Hakkapeliitta TRI , makes sure your winter contracting has all the grip and control you need –with or without studs.

tility, noting that: “With manufactured salt shortages and price gouging, I am able to reasonably guarantee holding my prices for commodities.”

Educating clients on risk, readiness

To move the needle with a client, you must frame early signing as a form of operational insurance. William Moore, ASM, President of Executive Property Maintenance in Plymouth, MI, says early commitments allow him to earmark deicer quantities for a client’s property—a critical advantage during supply chain disruptions.

“Early signers are guaranteed priority access to materials and uninterrupted service during severe weather,” Moore says. He is equally

Continued on page 36

The first winter tire for wheel loaders, Hakkapeliitta Loader, offers you speed, stamina and control. Unmatched grip and durability in the market –both winter and summer.

Continued from page 34

throughout the winter season.” of service our clients expect and we

Built for professionals who demand durability without compromise, our new stainless drop spreader is engineered to stand the test of time. Crafted from corrosion-resistant stainless steel and precision components, it delivers consistent, accurate spreading season after season—no rust, no warping, no shortcuts. It’s not just a new tool—it’s a long-term investment in reliability, efficiency, and confidence on every pass.

Sponsorship available!

✓ Focused—Short, role-focused lessons

✓ Real—Field-tested

✓ Consistent—A single safety standard

✓ Credible—Designed by SIMA experts

✓ Repeatable—Quick onboarding for new hires

✓ Comprehensive—Training and resources for all levels

By MIKE McCARRON

In the world of snow and ice management, timing is everything. When a winter storm is on the horizon, contractors scramble to pre-treat surfaces, mobilize crews, and deliver on service agreements. Salt brine — an increasingly popular pre-treatment solution — can make or break your operation’s efficiency. But if you’re still relying on external suppliers for salt brine, you may be putting your business at risk during peak demand.

For contractors who’ve scaled beyond a few trucks and lots, investing in an in-house salt brine maker isn’t just a convenience, it’s a strategic upgrade that can transform your workflow, margins and reputation.

Before making the decision to invest in a brine-making operation, make sure to consider the following:

Volume needs

Estimate your average and peak usage. If you’re using more than 25,000 gallons per season, you’re likely ready for in-house production.

Space and setup

You’ll need room for the brine maker, salt storage, water access, and finished brine tanks. Some systems are portable; others are fixed. Choose what fits your operation and space.

Mixing capabilities

Look for systems that support additives and custom blends. Flexibility is key to maximizing performance. Make sure your water flow can supply the machine you are looking to purchase since many locations have poor water flow.

Automation and monitoring

Modern units offer salinity sensors, flow control, and remote access. These features improve consistency and reduce labor. The cost variance is major at this level.

Training and maintenance

Make sure your team is trained to operate and maintain the system. Most manufacturers offer support, but internal know-how is essential.

and water. Applied before a storm, it prevents snow and ice from bonding to pavement, making post-storm cleanup faster and more effective. It’s cost-efficient, more environmentally friendly, and increasingly expected by clients who want proactive service.

But here’s the catch: When everyone needs brine at the same time, suppliers get overwhelmed. That’s where owning your brine maker changes the game.

The contractor’s dilemma: Timing is crucial

Let’s say you have a dozen trucks, a few municipal contracts, and a growing list of commercial clients. You’re ready to pre-treat before a storm, but your brine supplier is backed up. You wait. You call. You

Take the example of a regional contractor servicing commercial lots and municipal roads across three counties. Before investing in a brine maker, they relied on a supplier 40 miles away. During storms, they’d wait hours—or days—for deliveries. After installing a brine maker, everything changed:

• They produced brine ahead of storms, eliminating delays.

• Custom blends improved performance on high traffic lots and locations.

• Annual savings exceeded $25,000

They began selling excess brine to smaller contractors, creating a new revenue stream.

The brine maker didn’t just solve a problem—it became a growth engine.

Scotia company does its homework brine to its ice management toolbox

The brine maker advantage Owning your salt brine maker puts you in control. It’s like flipping a switch from

reliability. It can help you win bids, retain contracts, and stand out in a crowded market.

Brine as a business. Some contractors use their brine maker to supply others. If you have excess capacity, you can sell salt brine to smaller operors who aren’t ready to invest. It’s a win-win: you offset costs, and they get reliable supply.

When’s the right time for your company to jump into brine making?

If you’re consistently using large volumes of brine, facing supplier delays, or looking to improve service quality, the time is now. Owning a brine maker gives you control, flexibility, and resilience—exactly what contractors need to thrive in winter operations. You need to do your homework and decide on the appropriate system size and water flow to make sure you are getting exactly what your location can handle.

It’s not just about mixing salt and water. It’s about mixing strategy with execution. And for contractors ready to level up, brine independence is the next step. For more information and to see machines and speak with vendors, come to the annual SIMA Symposium in Cincinnati OH, June

Mike McCarron is president and founder of Image Works Landscape Management, a commercial landscape maintenance and snow removal firm in the Northern Virginia market. He has 20+ years of industry experience. Email him at mike@ imageworkslandscaping.com.

business grows.

maker signals professionalism and

Ever wonder why that bulk salt pile disappears so quickly? With more reports throughout the US and Canada of bulk rock salt shortages this winter, it has never been more important to know exactly where your salt is being spread and at what rate. This information allows you to ensure you spread only as much salt as you need to deliver the service your customers expect, and get the most coverage from your salt supply.

The all-new Auto Speed Control from Western Products provides more insight into spread rates and reduces wasted material. The control utilizes an interface that legacy WESTERN hopper spreader operators are already familiar with, built off the current control platform. By pairing enhanced operation with a direct tie into the vehicle’s OBD-II port, the operator can set a targeted application rate and track the amount of deicing material that has been spread on the property. By using the OBD-II port the control can instantly react to changes in truck speed, saving you material and money.

The Auto Speed Control provides the following benefits:

Set the desired spread rate and the control takes it from there. It will notify operators with an “S” if they are going to slow and an “F” if they are going too fast to maintain the set rate. The control will also keep a running

The Auto Speed Control kit comes with the following components:

➜ Control

➜ OBD-II Port Y-Harness

➜ Control Harness with OBD-II Plug

➜ Control Mounting Bracket

INSTALLATION IS SIMPLE. If you’re updating a current hopper in your fleet, the Auto Speed Control will work with the current spreader wiring harness. If you are purchasing a new hopper, you or your dealer will receive the wiring harness with the hopper spreader and will install as directed. Once the control is plugged into the spreader wiring harness, attach the OBD-II plug into the in-cab port. If you are already using the port for another device, use the included OBD-II port Y-harness to split the signal. Secure the wiring harness and wire routing as necessary and you’re ready to use the Auto Speed Control.

total of material spread until the counter is reset. Operators can then log the value into an electronic system or notebook for future use in billing or service level allocation.

The control layout is like the adjustable rate control from Western Products. The all-new Auto Speed Control function can be engaged or disengaged by pressing the AUTO button at the top of the control. This aids in faster adoption for your deicing specialists. This allows operators to choose which control mode they prefer to utilize.

Utilizing the OBD-II port in the truck allows the Auto Speed Control to instantly adjust deicing material flow to changes in

vehicle speed. This reduces wasted material and pooling when coming to a stop for moving vehicles, pedestrians, or traffic signals while material is being spread. When the vehicle travels over 45 mph, the deicing material flow is stopped to eliminate accidental spreading while traveling between sites.

The Auto Speed Control is compatible with WESTERN® hoppers equipped with the FLEET FLEX electrical system, first released in 2016. This allows you to upgrade the spreader control in the fleet you already own to unlock monitoring without having to invest in new hopper spreaders.

Based on operator feedback, the Auto Speed Control can save operations up to 6.25 tons of salt per route, per event. Without knowledge of application rates, operations report

Given insight into the application rate, most operations were able to reduce their spread rates to 500 lbs/acre or less with the same level of deicing performance.

using more than 750 lbs/acre on their properties. Given insight into the application rate, most operations were able to reduce their spread rates to 500 lbs/acre or less with the same level of deicing performance. This allows businesses or contractors the opportunity to conserve their available salt supplies without negatively impacting service levels.

The Auto Speed Control is available at WESTERN hopper spreader dealers. Visit westernplows.com/dealers to find your local dealer.

If your bulk salt pile disappears faster than you think it should, the all-new Auto Speed Control from Western Products is the upgrade you need for 2026.

Compatible with WESTERN® hoppers dating back to 2016, this control upgrade allows your operators to set the targeted application rate and track the amount of material spread on each property.

Tying into the truck’s OBD-II port, the Auto Speed Control instantly reacts to changes in vehicle speed, stopping the material flow when the truck stops and alerting the operators if they are traveling too fast or too slow to maintain the set rate.

MORE JOBS. DONE FASTER.

Agri-Fab’s new handheld spreader (model #45-0644-800) is ideal for areas that are difficult to access with larger spreaders. This easyto-operate spreader lets customers simply fill the cup and turn the knob to quickly spread salt, seed, fertilizer, and more. www.agri-fab.com

The Ice Master 5000 has been upgraded to enhance the efficiency of walk-behind salt spreading with a reinforced, more durable gear system. It is specially designed for heavy duty commercial use in the elements to ensure that all of your properties are safely salted. www.discountsnowstakes.com

The SaltDogg PRO-M Series Spreader is built for modern truck cabs, featuring a compact in-cab controller with simple twowire installation. A double-wall poly hopper, direct drive, 3/4-hp motor, and 14” spinner deliver reliable, precise spreading. www.buyersproducts.com

A compact power unit delivering professionalgrade liquid application to your existing tank. Mounts in minutes, runs for years, and is built for snow and ice contractors who want serious performance without the bulk. www.camionsystems.com

Suppliers submit your FREE product spotlight that will be featured in Snow Business magazine at www.sima.org/product-spotlight

Each issue features a different product focus:

JUNE | Software, Tech, Weather, Insurance, Consultants

SEPTEMBER | Heavy & Compact Equipment & Attachments

OCTOBER | Work Trucks, Plows, Pushers, Lighting, Accessories

DECEMBER | Sidewalk Equipment & Attachments, Shovels/Hand Tools, Safety

Bring your experience and gain insight from like-minded snow pros by joining a SIMA interest group!

» Business Development

» Pacific Northwest/ Western Canada

Groups meet via Zoom 4x a year.

» Single-family Residential » Women in Snow To learn more or sign up, visit sima.org/interest-groups.

Arctic Snowplows

Tough, reliable, and easy to handle—the Arctic Walk-Behind Spreader gets the job done on any surface. From sidewalks to driveways, it’s built to keep up with you, season after season. www.arcticsnowplows.com

Upgrade your brine system with U-shaped brine tanks. These tanks are designed for 550 and 3500 smaller municipality trucks, ensuring efficient, even brine distribution with 100% gravity-fed operation. Less tank sloshing means more lane miles can be covered. A low-profile design means better handling. Gravity-fed means no pumps, no hassle!

www.customplasticfabrications.com

The IceStriker 550SS TR stainless steel spreader provides durable, corrosionfree performance for tractors and loaders. Its 0.55-cu.-yd. hopper and 4.5” auger ensure smooth, even spreading of salt, sand, gravel, and mixes. www.hilltipna.com/en

Virnig Manufacturing

Preload, store and apply salt with Virnig’s modular Salt Spreader system, scalable to any size site. Reduce liability with faster application and eliminate the need to use salt trucks in snowstorms. Perfect for snow removal companies and property managers. www.virnigmfg.com

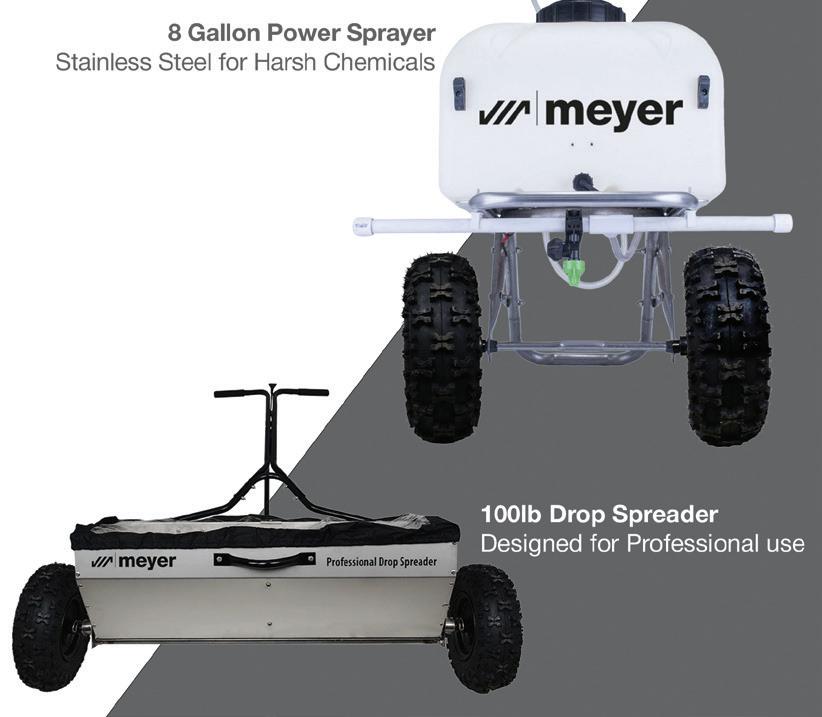

Tackle any season with Meyer’s 8-Gallon Power Sprayer and 100-lb. Drop Spreader. The DeWalt battery-powered sprayer makes applying liquid treatments easy year-round, while the stainless-steel drop spreader delivers precise, even coverage for ice melt or seed—protecting landscapes and ensuring professional, accurate results on every job. www.meyerproducts.com

The 100-lb. Spyker ERGO-PRO walkbehind salt spreader tackles winter jobs, spreading salt and ice melt with ease. A stainless-steel blade cuts dense material, the hopper prevents bridging, and an ergonomic adjustable handle reduces fatigue. www.spyker.com

Boost your ice control and herbicide capabilities year-round by using one versatile sprayer attachment for your skid loader. www.frostserv.com

Natural Alternative 100% CMA Ice Melt is chloride-free, nontoxic, and biodegradable. Less corrosive than tap water, it is safe for concrete, pets, lawns, and waterways; meets LEED standards; and will not burn paws or turf. www.natural-alternative.com

Hot Pink Deicer is a safer, more effective, and less expensive ice melt product made in the U.S. and Canada. Sales support local families affected by breast cancer. Each year, more local contractors and retail stores embrace the idea and become Hot Pink Heroes by choosing Hot Pink Deicer! www.hotpinkdeicer.com

PELADOW Calcium Chloride Pellets work faster so you can use less! Switch to PELADOW instead of magnesium chloride to melt more with less time, cost and waste. A 30-lb. bag will achieve the same or better coverage than a 50-lb. bag of magnesium chloride. www.oxycalciumchloride.com

Our ready to use liquid Calcium Chloride Brine is a natural de-icing product that acts as an anti-icing agent when applied prior to a winter event, and a de-icing agent when applied after. Other organic liquid deicers are available upon request. www.chloridesolutions.com

Legacy Building Solutions

Legacy offers high-quality fabric buildings for salt/sand storage. A durable rigid frame provides several engineering advantages, including customization to exact width, length and height. Straight sidewalls maximize useable square footage. I-beams can be epoxy-coated for maximum corrosion protection. Translucent PVC cladding allows natural daylight. www.legacybuildingsolutions.com

SIMA LEADERSHIP

Chief Executive Officer

Martin Tirado, CAE martin@sima.org

Full SIMA staff contacts are available at sima.org/about-us

CONTENT MANAGEMENT

Education & Content Director

Cheryl Higley cheryl@sima.org

Design & Production

Lisa Lehman

lisa@sima.org

Supplier Services Manager

Aimee Krzywicki aimee@sima.org

SIMA STAFF

K.C. Hallgren Chief Business Officer

Nikki Luedtke

Office Manager / Executive Assistant

Heather Carew

Events Director

Nakishia Randle

Business Process Manager

Ellen Lobello

Education Senior Manager

Gwendolyn Gabree

Brand and Design Manager

Stephanie Orvis

Marketing and Operations

Senior Manager

Andrew LaPorte

Education Sales and Membership

Development Manager

EDITORIAL ADVISORY COMMITTEE

Charmaine Allen

10140 N. Port Washington Road, Mequon, WI 53092 414-375-1940 // info@sima.org // www.sima.org

Allen Builders & Landscape

Nichole Ashton, CSP

North Country Snow and Ice Management

Jim Hornung Jr., CSP Elbers Landscape Service

Rick Kier, CSP Forge Ahead Consulting and Software LLC

William Moore, CSP, ASM

Executive Property Maintenance

Dean Outhouse, CSP, ASM North Point Outdoors

Jason Ostrander, CSP Eastern LLC

Thomas Skuta, CSP USM

Robert Young, CSP

K.E.Y. Property Services

Michael Wagner, CSP, ASM Colorado DesignScapes Co.

SIMA BOARD OF DIRECTORS OFFICERS

Board Chair

Jeff Heller, CSP, Innovative Maintenance Solutions

Immediate Past Chair

Chris Hinton, CSP, GRM Inc.

Vice Chair

Chris Thacker, CSP, Mr. Mow It All

Secretary / Treasurer

Tom Fitzgerald, CSP, Donovan Property Service

Directors

Matt Crinklaw, Greenius by Granum

Connie Gaul, ASM, SNOWGO National Services

Andy McArdle, CSP, ASM

Douglas Dynamics

Robert Miller Jr., CSP, ASM

RPM Landscape Contractor

Dean Outhouse, CSP, ASM North Point OUtdoors

Robert Young, CSP

K.E.Y. Property Services

RENEW AND SUBSCRIBE www.sima.org/subscribe