1 minute read

COMPUTATIONDESIGN FORFABRICATION

from Selected Work - 2023

by Deval Ambavi

MSc. CMA - SEM II|DESIGN FABRICATION

Advertisement

├ ProjectBrief

The aim of this module is to introduce you to computational design and optimisation techniques that facilitate the fabrication of digital 3D shapes. We were introduced to advanced digital fabrication techniques including 3D printing, laser cutting, CNC routing, and gain hands-on experience in using these tools to realise geometric models. In addition, we learned how to create and optimise 3D designs according to the fabrication tools and materials.

Introduction-

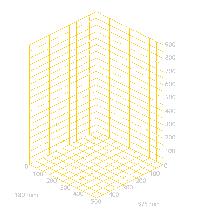

Designing a form and infill pattern aiming to print a cob wall. The wall should consist of several blocks, each block maximum of 10000 cm3 and a minimum of 45000 cm3 in volume.

Takingthefollowingfactorsintoaccount:

- The smaller the block, the more blocks we will be able to print.

- Considering the block interlocking strategy.

- Developing a Grasshopper parametric design system for the block with relevant parameters.

- Developing a printing path for Kuka PRC to fabricate the model.

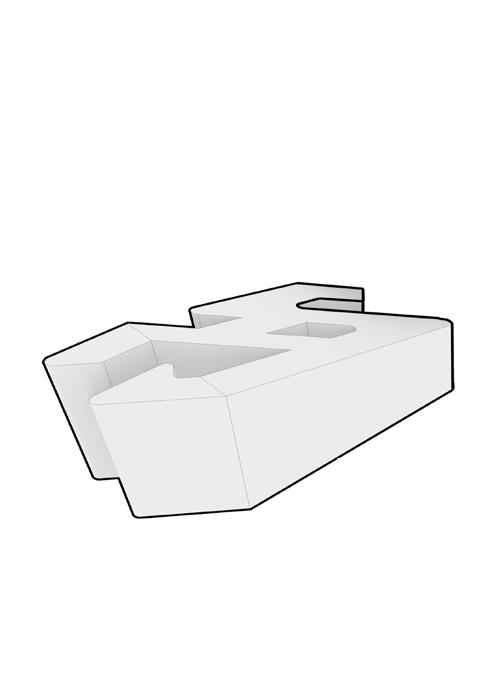

These are the stages of design exploration that were observed to achieve the opitmal structure that could be printed with the hand made mixture.

These were three variations of the final iteration that were observed to create a stable wall which could be printed to stand firmly.

This iteration was the achieved on the final segment of the design options observed before. The process code and printing path are mentioned for further observations and optimisation which can lead to designing complex geometries applicable to various fields.