3 minute read

David Gardner’s Custom

Couture Creations

Advertisement

more

than I could have ever dreamed of special significance

you to feel a part of the family genuinely want

DG Custom Design Process:

The labor-intensive process that each item goes through is unique and depends on the customer’s desires as well as the nature of David’s design.

1. Pleasure to Meet You

The first step in the DG custom design process involves David getting to know the customer. Many times, David asks them to go through the store and collect items they like and discuss with David what they like about each piece. This process provides David with insight on the customer’s jewelry style.

2. Show & Tell

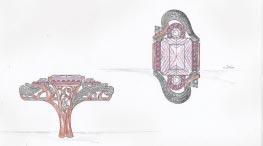

On what is usually a second meeting, David shows sketches that he has drawn that reflect the customer’s preferences and personality. Sometimes he creates several sketches that are variations of one another so the customer has options to see.

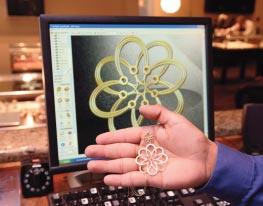

3. Model

Once the design has been finalized, an actual size wax model is made. Depending on the design, either hand carving or a computer controlled mill is used to create the wax and if the dimensions, look and feel of the model pass David’s inspection the piece makes it to the next step in the process.

4. Breaking the Mold

The approved wax model is placed inside a flask, which is then filled with a special plaster called investment. This flask containing the wax surrounded by investment is then placed inside a kiln, which heats to over 1350 degrees in order to melt the wax away and harden the plaster. The end result is a void where the wax once was and a mold for metal to be poured insidehence the name lost wax method.

5. Casting

The metal of choice is brought to its optimal melting point of up to 3300 degrees. Then, the flask containing the mold is placed inside a crucible which uses centrifugal force to draw the liquid metal into the plaster mold.

6. Design Revealed

The flask is then temperature shocked cracking the mold. This allows the jewelers to pull away the plaster exposing the design. A jeweler carefully files away excess metal and polishes the piece to prepare it for stones to be set.

7. Stone Setting

Setting stones requires extensive training and knowledge of the molecular structure that makes up each type of stone. A simple error can crack a valuable stone that can be difficult to replace. Many times a single ring can hold hundreds of pave set diamonds, taking several days to be set.

8. A Thorough Inspection

Once stone setting is complete, each piece goes through a careful inspection by David to ensure the piece meets DG’s highest standards.

9. Anticipation

The most exciting stage in the process for the entire David Gardner’s team: This is the point when the entire store buzzes with excitement as everyone awaits the arrival of the person for whom the DG Custom piece was made. DG Insiders know that there is always an exciting project in

process and know to ask what is going on in the shop.

Designer Designer Spotlight: Spotlight: David Gardner David Gardner

Sources of Inspiration: Museums, Art, European Fashion, Julia, Customers Greatest Compliment: When David Yurman called him “a real jeweler” Greatest Achievement as a Designer: Being commissioned to design a pendant for former first lady, Barbara Bush. Average Number of Sketches per Design: 3 Greatest Challenge: Julia

Greatest Fear: That the customer won’t like what I have designed for them.