Sustainable Practices

01 | MASS TIMBER

2024 SPG MATERIALS

March

Contents

Product Types

Sustainability

Design Considerations

Building Code

Fire Protection

References

Dattner Architects’ Sustainable Practice Group’s Materials

sub-committee has spent a few years researching Mass Timber, delving into critical aspects such as harvesting, processing, manufacturing, and life cycle analysis.

Our research seeks to both grasp what makes Mass Timber sustainable, from extraction to end-of-life, and challenge assumptions about “green” materials. This report encapsulates our commitment to critically examining what material sustainability means for our work and understanding the complexities of incorporating Mass Timber into our projects. The research includes data and feedback from peers, consultants, and clients to broaden our understanding of both the material and its implementation.

Mass Timber is a sustainable alternative to traditional concrete and steel construction. It has the ability to replace some of our most environmentally harmful structural elements with a material that has the capacity to be regenerated within our lifetimes. Wood was once the most commonly used structural material—it can become commonplace once again, with both reflections of the missteps of the past and revisiting of our business-asusual design and construction models in New York City. As architects, we can advocate for large scale change in the way we design and build projects while keeping in mind that sustainability provides social, environmental and financial benefits for all those involved. The future holds promise and our collective efforts can pave the way for sustainable and regenerative practices to be the norm—this report seeks to start that conversation.

Overview

Mass Timber, short for Massive Timber, refers to a category of engineered wood products designed to attain high strength ratings comparable to steel and concrete. To achieve sufficient structural load-bearing properties, Mass Timber products are fabricated with layers of wood, producing large structural panels and beams. Common wood species used in Mass Timber products include pine, spruce, fir, birch, ash, and beech.

Mass Timber minimizes defects and variation by combining and optimizing smaller pieces from larger commercial logs and are the building blocks that make taller wood construction possible. Mass Timber is often conflated with Heavy Timber, but Heavy Timber refers to traditional solid sawn lumber. Sawn lumber is readily available in 2x sizes and is used for rafters, joists, studs, built-up beams, and columns in typical wood frame construction.

Product Types

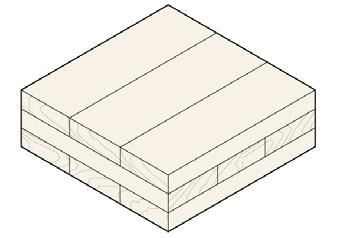

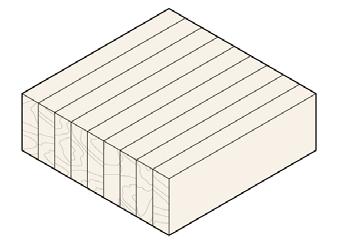

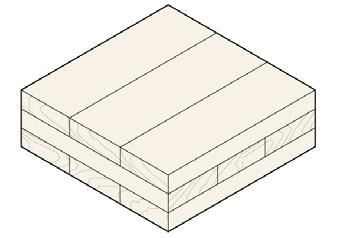

Cross-Laminated Timber (CLT)

Created with layers of dimension lumber oriented at right angles to one another and then glued to form structural panels. The panel delivers excellent structural rigidity in both directions, due to the alternate orientation of the dimensional pieces.

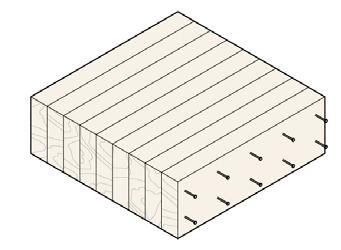

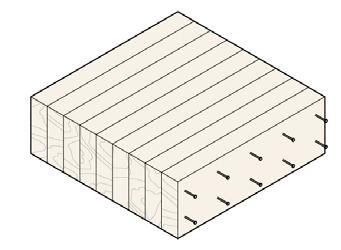

Nail-Laminated Timber (NLT)

Created with dimension lumber stacked together on its edge and fastened together with nails or screws to form a solid structural element, mostly used for floor and roof assemblies. For wall application, wood structural panel sheathing is added to the face of NLT to provide in-place capacity for shear walls and diaphragms.

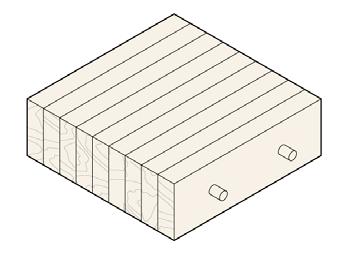

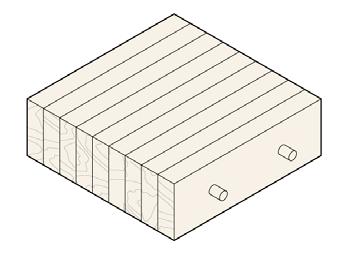

Dowel-Laminated Timber (DLT)

Created with dimensional lumber stacked together on its edge or cross laminated, friction-fit together with hardwood dowels. The friction-fit is achieved by the differing moisture content of the wood panels and the dowels. Typical structural properties are similar to NLT.

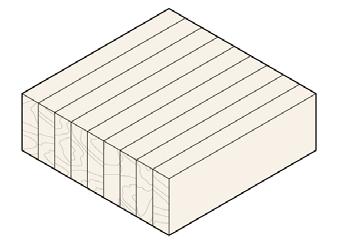

Glue-Laminated Timber (GLT)

Composed of wood laminations (or “lams”) bonded together with durable, moisture-resistant adhesives. The laminations are jointed end to end, allowing for long spans. The grains of all laminations run parallel with the length of the wood member to improve its strength.

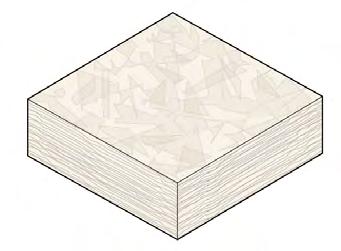

Structural Composite Lumber (SCL)

Created by layering dried and graded wood veneers, strands, or flakes with moisture-resistant adhesive into blocks of material known as billets, which are subsequently resawn into specified sizes. SCL includes laminated veneer lumber (LVL), parallel strand lumber (PSL), laminated strand lumber (LSL) and oriented strand lumber (OSL).

Timber-Concrete Composites (TCC)

Composed of a thicker layer of concrete on the top side and a Mass Timber panel on the bottom side. The concrete acts as a compression element while the timber acts as the tension element, giving flexural stiffness. TCC floor systems are very efficient and can achieve high span-to-depth ratios.

Sustainability

The increasing demand to reduce greenhouse gas (GHG) emission related to the fabrication of the materials used in the construction of buildings is pushing our industry to incorporate low-embodied carbon products. Mass Timber’s low embodied carbon and ability to sequester carbon makes it a part of a climate change solution. Continued research will determine the true extent of its sustainable impact. Some points of consideration:

Speed of Construction

When all disciplines are coordinated prior to construction, Mass Timber is faster to assemble, requires smaller construction screens, and has potential for less materials wasted as well as a quieter construction site.

Biophilic Properties

Mass Timber has the unique ability to be both structure and finish material. It can be used to support the implementation of biophilic design principles, boosting well-being and providing connections to nature, along with daylighting, plants, and ample fresh air. The warmth and natural look of exposed wood can have a positive effect on mood and cognitive performance.

Natural Fire Resistance

Unlike conventional wood framing products, Mass Timber does not easily burn down. In the event of a fire, exposed Mass Timber chars on the outside; the charring insulates and protects the wood from being structurally unsound for a period of time, potentially allowing for evacuation before structural failure. More information is provided under the building code and fire protection section.

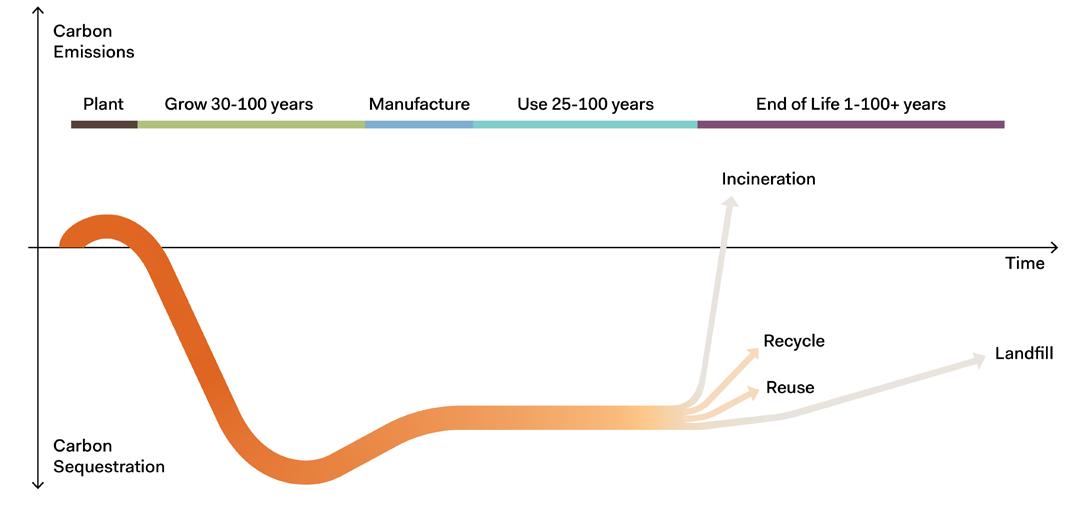

Life Cycle Analysis (LCA)

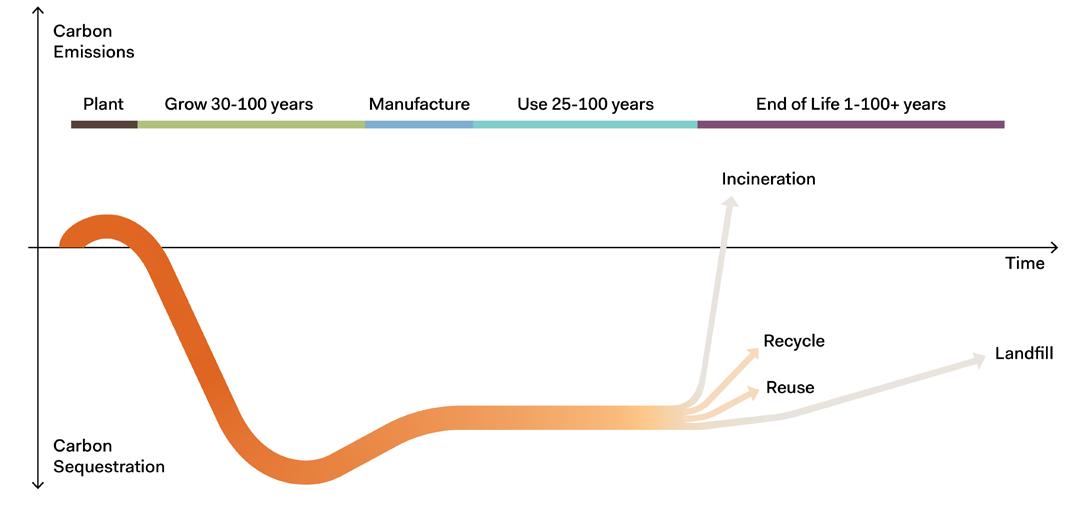

Both the low-embodied carbon and carbon sequestration potential are significant drivers behind the growing interest in Mass Timber. To understand the true impact of its use, a comprehensive Whole Building LCA is essential. Encompassing all stages of life, along with pertinent material information such as a material passport, an LCA describes defined characteristics of material and provides value for recovery and reuse. Prolonging material lifespans plays a pivotal role in advancing our transition from a linear to a circular economy.

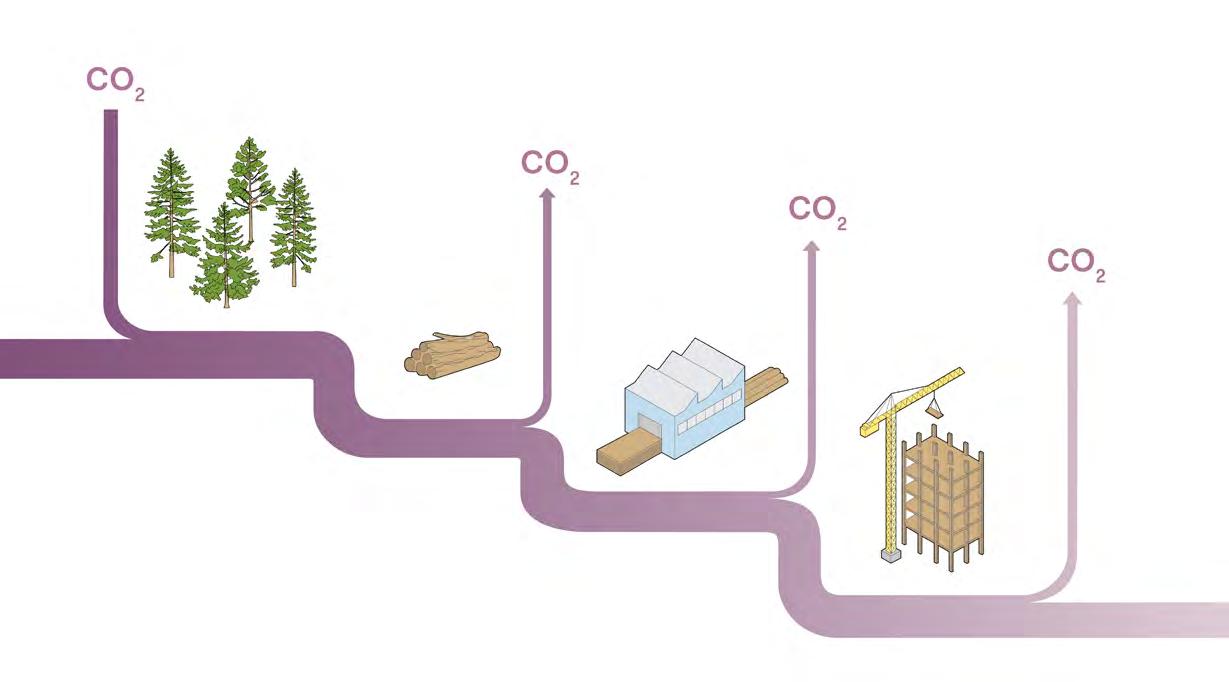

· Product Stage includes raw material supply, transportation, and manufacturing phases.

- Material Origin: Certified forestry plays a large role in carbon sequestration. Harvesting large number of trees can potentially reduce forest biomass stocks if not managed properly. We should be mindful that the potential increase in demand for timber as building materials can intensify deforestation and illegal logging, and only specify Mass Timber products that come from sustainably managed forestry.

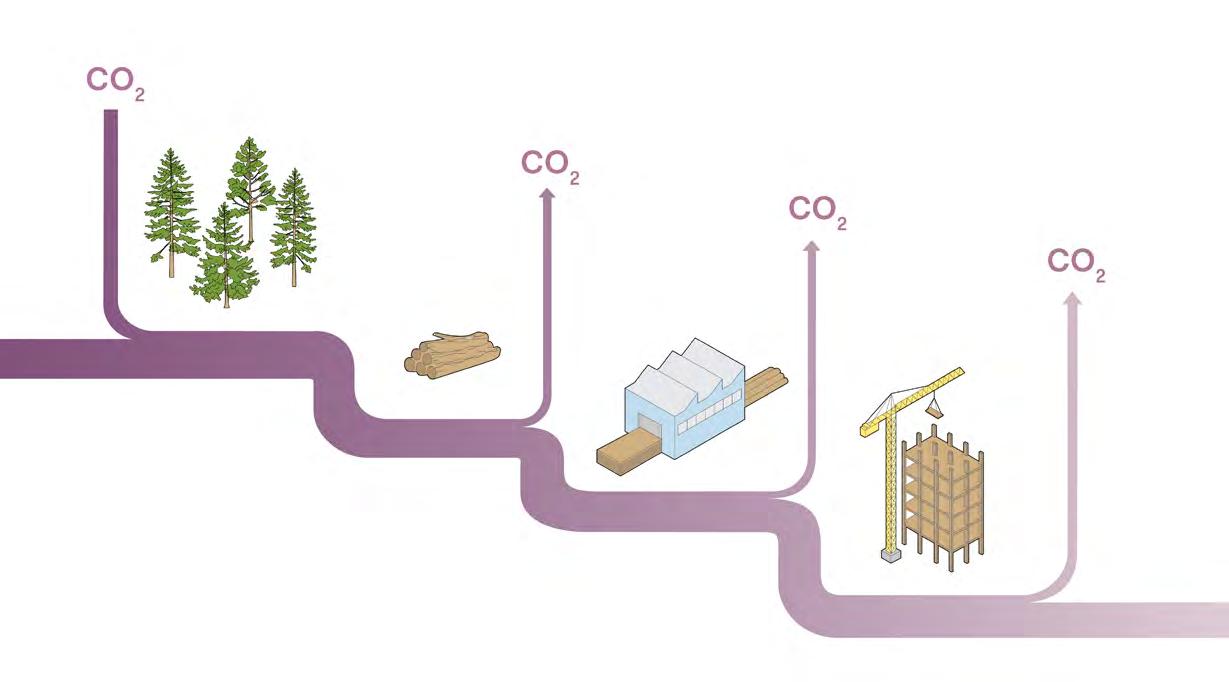

- Carbon Storage and Time: Trees capture CO2 from the atmosphere through photosynthesis during their growth period, a process commonly referred to as sequestration. However, an oftenunspoken point about sequestration is the impact of the timing of the carbon emission. Studies have demonstrated that timber products have a longer rotation period due to slow forest growth periods, so they cannot be simply stated as carbon negative or carbon neutral without understanding the timeframe. Conversely, fast-growing bio-based materials, such as straw and hemp, have a short rotation period and can provide an effective mitigation effect on GHG emissions by rapidly removing carbon from the atmosphere.

· Construction Phase includes analysis for the construction phase in a LCA includes impacts related to transportation to site and installation. A unique consideration for Mass Timber is the need for temporary moisture control. Typically, temporary protection is provided to prevent wood from molding when exposed to moisture for an extended period of time, and to prevent steel from rusting on wood in hybrid steel and mass timber structures.

· End-of-Life Stage analyses includes deconstruction, transportation, waste processing and disposal, with specific attention paid to processing deconstructed Mass Timber components to extract usable materials. Extended Life analyses includes recovery, reuse, and recycling beyond end-of-life—breaking down components into raw materials which can be used for manufacturing new products, such as recycled timber for engineered wood products or furniture.

Mass Timber Carbon Sequestration Potential

Mass Timber Carbon Sequestration Potential

Design Considerations

The most effective Mass Timber design maximizes its strength and minimizes waste and by-products. Timber is a beautiful, universally loved product—and the architectural benefits can only be realized while keeping structural, MEP and acoustic points in mind.

Structural Considerations

Mass Timber feasibility is best explored during early phases of a project. It is more efficient in square grids or rectangular grids, as indicated in the diagrams to the right. Grid spacing is often dictated by vibration and deflection considerations, rather than bending or shear capacity. Mass timber systems have different structural considerations from traditional structures, and changing systems after Schematic Design can be cost prohibitive.

MEP Considerations

Accommodating mechanical, electrical, plumbing and fire protection services is a critical design consideration, especially when the intent is to expose the wood surfaces of the Mass Timber elements at ceilings, columns, and walls. Careful consideration of the integration of these systems with structural elements is required as is the coordination between trades to determine sequencing of install and what can be exposed.

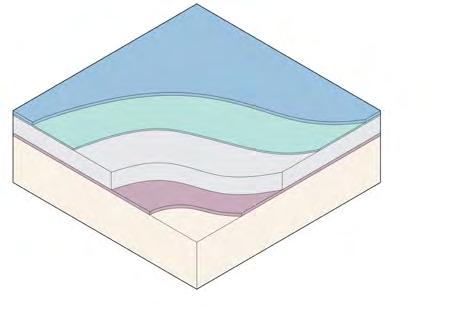

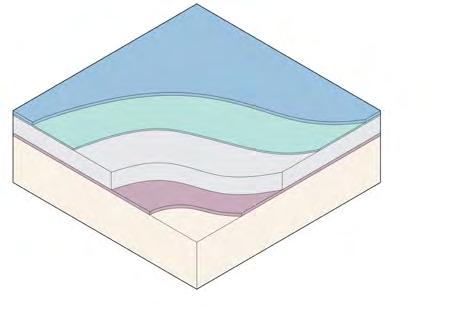

Acoustics

Given Mass Timber’s relative light weight compared to traditional construction materials, acoustics can pose challenges if not specifically addressed. Areas requiring special attention in acoustics design include floor-to-ceiling assemblies and demising walls. To enhance acoustical performance, focus should be on three main methods: increasing material mass, adding noise barriers, and implementing decouplers to isolate noise transfer.

RECTANGULAR

GRID

Rectangular grids typically range from 12x20’ to 20x32’

SQUARE

GRID

Square grids typically range from 20x20’ to 30x30’

Finish floor Underlayment

Concrete

Topping Slab

Acoustic Underlay

Mass Timber Slab

X’ Y’

X’ Y’ X’ X’

Building Code

NYC Building Code

The 2022 NYC Building Code (NYCBC) allows the use of Mass Timber construction with limitations and safeguards based the City’s dense urban environment. The International Building Code (IBC) allows more extensive use of Mass Timber, including greater height allowances. It is possible that future editions of the NYC Building Code will make further allowances for the use of Mass Timber; this report addresses the use of Mass Timber as per 2022 NYCBC.

Building Height

The 2022 NYCBC allows combustible construction (including Type IV construction) for R-2 and B occupancies up to 7 stories or 85 feet above grade, provided the exterior walls are noncombustible and the building is fully sprinklered.

Type IV-A Max Height 270’ Up to 18 Stories Type IV-B Max Height 180’ Up to 12 Stories Type IV-C Max Height 85’ Up to 9 Stories 270’ 180’ 85’ 85’ Type IV for R-2 and B Occupancies Max Height 85’ Up to 7 Stories 2021 IBC 2022 NYCBC

Fire Protection

Fire Protection & Life Safety is of paramount importance. There are provisions in IBC and NFPA 13: Standard for Sprinkler Installation that address life safety in Mass Timber construction. There are no specific provisions in 2022 NYCBC that address concealed spaces in Mass Timber construction. Illustrated below are three options based on what is currently approved by IBC. Until this portion of the NYCBC code is clarified, these will need to be individually approved for each building.

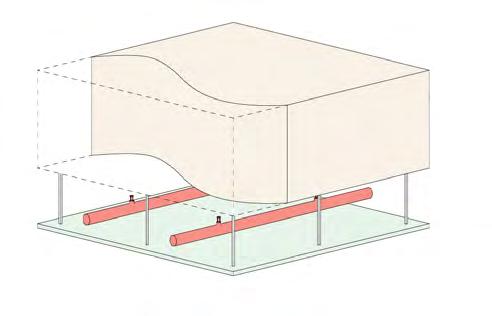

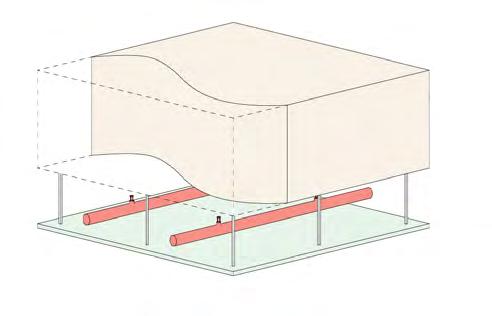

Option 1

Mass Timber floor construction

Sprinklers within concealed space

Nonrated dropped ceiling

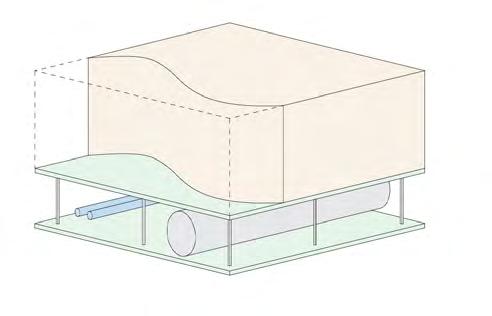

Option 2

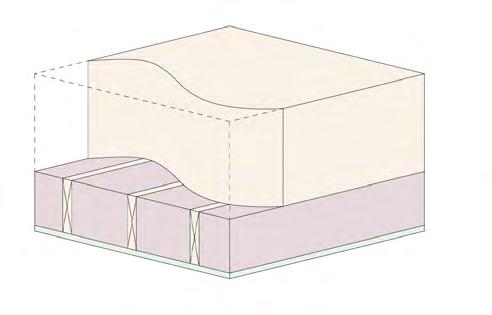

Mass Timber floor construction

Noncombustible insulation

Nonrated dropped ceiling

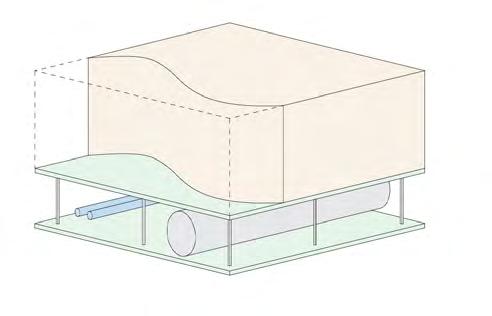

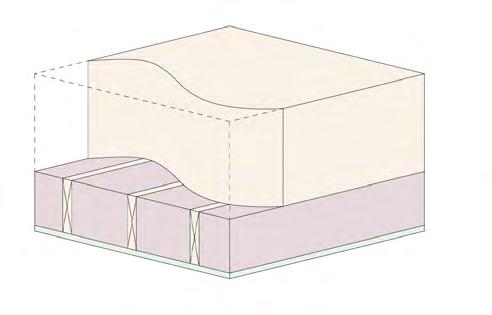

Option 3

Mass Timber floor construction

Type X gypsum board on all Mass Timber surfaces within concealed space

Dropped ceiling

Mass Timber offers a sustainable alternative to conventional construction materials. Local regulatory limitations are expected to change in coming years as more Mass Timber projects come on line. Rigor and transparency is required when calculating and communicating carbon sequestration data, life cycle impact, and construction advantages. As architects advocate for low-carbon design solutions that account for future adaptability, innovative disassembly strategies, and prolonged material life spans, Mass Timber’s merits deserve continued research.

Together we can advance the urgently needed shift from a linear to a circular economy.

References

www.woodworks.com

www.thinkwood.com

Naturallywood.com

Parson’s Healthy Materials Lab

Arup’s presentation on Mass Timber

Forest Stewardship Council (FSC)

Ellen MacArthur Foundation

PLOS ONE

New York Wood Products Development Council

Dattner Architects’ Sustainable Practice Group (SPG) is a volunteer group dedicated to environmental equity. They facilitate the exchange of information to allow each of our projects to maximize its positive environmental impact. Research is focused on critical areas that effect our projects: energy use, renewable energy, indoor environment and human health, sustainable materials, site ecology, and urban infrastructure.

SPG

Mass Timber Carbon Sequestration Potential

Mass Timber Carbon Sequestration Potential