25 minute read

Paving Section

S E C T I O NPaving Pages 23-37

For more information on paving, compaction and milling equipment, as well as comparison charts, visit CEG's Web site at www.constructionequipmentguide.com. Hamm: Offering Sustainable Solutions at Every Level

A year after receiving environmental certification according to ISO 14001, it is clear that Hamm AG, based in Tirschenreuth, Germany, is in a good position in terms of environmental protection.

For many years now, the company has handled finite resources responsibly due to modern production processes and sustainable solutions in the areas of service and spare part supply. This philosophy also is reflected in the current product range.

Highest Environmental Standards

For many years, compaction specialist Hamm has been actively promoting environmental protection through sustainable solutions, and is continuously reducing its carbon footprint. Achieving the ISO 14001 environmental certification at the end of 2020 marked a milestone.

Stefan Klumpp, member of the executive board of HAMM AG, describes the company’s motivation: “Protecting the environment is vital for us. This applies not only to our operations as a manufacturing company, but also to our products. It goes without saying that we therefore comply with the statutory regulations.

“Through our environmental management system, we have also identified further potential for improvement that will enable us to reduce our consumption of resources and energy.”

One of the flagship projects to date is the construction of a geothermal system. It has been heating and cooling the administration building since 2013, yielding savings of around 86 t of CO2 per year.

At the plant in Tirschenreuth, the energy demand for lighting was almost halved in 2019 by switching to LED lights. This also saves over 80 t of carbon dioxide every year. Optimizations in the compressed air cycle also reduce the electricity/energy demand by 50,000 kWh. That corresponds to close to 5 t of CO2.

All Divisions Under Magnifying Glass

Since 2018, an environmental protection manager has been advancing the further minimization of raw material and energy consumption, waste, packaging and emissions of solvents (VOCs) and placing all divisions under the magnifying glass. In this way, Hamm is improving its ecological footprint through large-scale measures as well as numerous finely detailed projects.

At the moment, the energy demand for heating also is being drastically reduced, as well as the consumption of fresh water in production. There also are very high standards regarding waste water and low noise emissions from the plant. Alongside this, paperless production is to be introduced in the near future. Recycling, Recuperation

Waste is also a key focus.

“By implementing numerous individual measures, by 2023 we will have reduced the waste per produced machine by approximately 20 percent compared with 2019,” said Plant Manager Dirk Pressgott.

In production, an innovative painting process reduces the amount of paints and solvents used while offering the same paint quality. Hamm also recycles the solvents used for cleaning the painting systems.

Internal logistics also saves energy by optimizing routes and also uses quiet electric forklift trucks. Shortly before the rollers leave the plant, the brake energy is recovered via recuperation at the test bench, which all machines pass.

Intelligent Solutions Instead of Materials

In general, “intelligent solutions instead of materials” applies in purchasing and logistics at Hamm. Special transport racks therefore render much of the packaging superfluous. And, due to a 4PL strategy, there are virtually no empty runs when supplying purchased parts and semi-finished products. In addition to these measures, suppliers are selected based on their environmental certification and training of employees with a view to environmental protection.

Through dialog with the design and production departments, Hamm also has been continuously reducing excess packaging and optimizing transport capacity for many years.

For many years, Hamm has handled finite resources responsibly across all areas of the company.

Dynapac’s newest range of highway class pavers and screeds built specifically for the North American Market includes four models of tractors, D30T – 10 ft. track; D30W – 10 ft. wheel; D25T – 8 ft. track; D25W – 8 ft. wheel; and two models of screeds Mat Master 16R (8 to 16 ft. screed); and Mat Master 20R (10 to 20 ft.).

Your Success Our Key Focus

Dynapac caters to its customers success across all continents with specific product and application solutions focused on their needs, according to the manufacturer. The North American pavers are designed with six core common principles to bring success in every aspect. • Job Site Confidence • Low cost of ownership • High Quality Results • Maximum Uptime • High Productivity • Environment/Sustainability Simply Smart Paving

From interstate highways, county roads to large commercial job sites, Dynapac’s latest generation of highway class pavers offer optimal solutions to high quality paving. High performance tractor design with focus on simplified smart paving technique, maximum uptime combined with award winning Mat Master Screeds offer high paving quality results.

Fast, Efficient Paving for Thick or Thin Layers

The new generation of highway class pavers are optimal to provide high paving speeds for thin or thick layers. The track and wheel pavers are designed with maximum productivity and uptime for the customers.

High transportation speeds, up to 10 mph, allows fast repositioning of the machine at the start or end of the day. iTrack ultra duty rubber track design offers reliable performance with enhanced wear life offering low maintenance costs.

Innovative Dynamic suspension control (DSC) on the wheel pavers offer enhanced tractive effort and highquality results needed for highway paving with lower investment and maintenance costs, according to the manufacturer.

For thin overlays on highways, the Mat Master screeds are equipped with DiveStop and Active Screed Assist technique delivering high paving quality results regardless of material types. A double width (10 to 20 ft. or 8 to 16 ft.) heavy duty screed design is highly suitable for paving highway, new construction or large commercial job sites with less number of passes. Keep Things Simple, Smart

The new pavers are built with dual independent tractor consoles for flexible working positions for the operator.

The Dynapac smart dashboard and HMI design on the tractor and screed allows the operator to be focused on the paving job during long paving hours, improving efficiency and productivity. The Dynapac PaveManager makes the paving process itself simpler and smarter.

There are several operators assist functions such as FeedAssist, CleanAssist, ImpactAssist, DiveStop, LightAssist built-in so that the paving crew can maximize the paving time and focus on the job at hand. Pave With Confidence

The user-friendly swing out dashboards are equipped with toggle and rocker switches within easy reach, making for an ergonomic and relaxed working day. The smart arrangement of switches combined with easy feel reduces the time to learn significantly. The learning time needed on Dynapac pavers is further reduced by making it a simplified operating concept.

Multiple choice of feed systems are customizable to the operator’s preference. With new Dynapac highway paver range, operators can choose to pave the way they always paved without adding a learning curve. The feed system is designed to provide multiple options depending on the crew’s preference and paving scenarios. • Proportional Dual Sensor Mode — auger speed is controlled by ultrasonic sensors and conveyor follows the auger speed • Proportional Quad Sensor Mode — auger and conveyor work independently with their own sensors • Flow Gate — optional flow gate for controlling the head of material

Maximize Paving Time,

Reduced Set Up/Cleaning Time • Set the paver quick to pave. Dynapac Clean assist and Fill Assist system helps to get started early and start paving. With smart options like Hydraulic Tunnel extensions, the auto lube system reduces daily maintenance time and allows for more productive paving time. • Fast Machine Clean up time. Easy cleaning with the integrated emulsion spray equipment with tank and hose reel and a dedicated cleaning assist mode for conveyor, auger and screed. With the smallest front conveyor cover (<10 in.) in the market the cleaning of hopper has never been this easy. • Heat up the screed fast and efficient. Get ready to pave with shorter heating-up times. Dynapac heat control box is a multi-zone heat control with fail-safe heating design. This keeps the screed heated at the right time at the right temperature. When working with different materials operators always have the choice of selecting the right temperature needed for job. The heat control system is designed to provide nonstop fail-safe heating to screed. With two heating modes — Heat Boost and Eco Mode’ — the preferred heating method is always at your fingertip. The Heat Boost mode heats the screed fast to get you going during the cold mornings. The ECO mode keeps the heat uniform across the screed saving fuel. Proven Reliability

The key components of this machine have been proven in the field for many decades. The powertrain, strong steel structures combined with ultra-heavy-duty ground engaging and wear parts design makes the paver highly reliable, according to the manufacturer.

The Dynapac Mat Master screed with stable design never lets you down in achieving your productivity and quality. iTrack — The strong Dynapac iTrack system offers longer track life combined with smart detract system ensures continuous and trouble-free operation. Unique Track system design with box frame design reduces the cost of upkeep and maintenance significantly. Perfect Mat Quality — Pave Relaxed

Mat Master screeds avoid bending or torsion with unique double extension system, which will have a direct quality output of the paved mat. High pre-compaction is achieved with the heavy weight screed design. • Dynapac fail-safe multizone heat control system ensures perfect quality mat with consistent heat distribution throughout the complete working width for screed plates and end-gates. • Precise Screed adjustment with Anti Drift Technology: Screed functions are activated by positive lock thread mechanism avoiding the need of constant screed adjustment while paving. • Avoid Bump/Marks in the Mat with Smart Solutions: Avoid bumps and marks in the paved mat with the hydraulic Safe Impact System and the Dynapac DiveStop technology. • Even and Smooth Mat: Dynapac DiveStop combined with Active Screed Assist technology easily handles tricky mixes and thin layer paving. • The Dynamic Suspension Control (DSC) is next level technology in providing traction to wheel pavers. When the wheels are working on soft and/or uneven surfaces there is always ground contact for drive wheels with no spinning. This maximizes the traction and avoids uneven screed movement while running over objects creating perfect mat quality. • Anti Segregation Auger system offers is the largest diameter (17-in.) and slimmest drive chain box providing homogeneous mix

Reduce Total Cost of Operation, Maximize Uptime

One of the key drivers with new highway class paver design is to reduce customers total cost of operation. The main wear parts on the new range of pavers such as push rollers, conveyor and auger wear parts designed to extend the wear part life. Unique U-shape screed plate designed for longer usable life.

Enhanced ground engaging parts life is achieved by the super duty design of tracks and wheels system offering long intervals between rebuild, saving time and money. The iTRack track tensioning system keeps optimal track tension in forward and reverse. Losing track tension is near impossible with our intelligent track tension sensing system, while working on gravels and soft materials, the intelligent track tension sensing system alerts and stops the paver if inadequate tension to the tracks.

Night paving is made easy with a Flicker-free Generator system design that allows to directly connect the night-lights to the paver quick and easy. The need of renting external generators and plugs are removed.

Environment, Sustainability Care

Dynapac highway class pavers are equipped with ECO-Mode engine technology for lower fuel consumption and smart design allows to operate the paver at lowest possible engine RPM. Screed heating also is possible with either ECO Zonal heating consuming less power and fuel saving money for customers. Mat Master screeds are designed to handle variety of mixes like polymer modified, rubberized asphalt, WMA and SMA etc.

For more information, visit www.dynapac.us.

Page 30 • July 31, 2022 • www.constructionequipmentguide.com • Paving Section • Construction Equipment Guide LeeBoy Announces Its 2021 Dealer Award Winners for Top Overall Sales, More

LeeBoy recently announced the winners of its 2021 Dealer Awards. Top overall sales dollars for all products • Ambrose • Stephenson Equipment • Ascendum • Nixon-Egli • Reynolds-Warren Top product support (based on top dollars in parts sales) — Ascendum Top marketing dealer — Dobbs Top paver dealer —Ambrose Top tack tank dealer — Nixon-Egli Top grader dealer — Ascendum Top broom dealer — Reynolds-Warren Top max dealer — Richmond Top patcher dealer (new) — Mid-South Top RW dealer (new) — Richmond Top FFL dealer (new) — Stephenson Equipment

Nixon-Egli

Stephenson Equipment

Ascendum Ambrose Equipment

Hamm’s Newest Solutions Lead to Longer Life for Its Machines

HAMM from page 23 Recycled plastics also are used wherever possible for constructing rollers.

Environmentally-Friendly Products, Compaction Solutions

With regard to products, Hamm follows the objective of “developing low-consumption machinery and machine control systems that ensure an efficient and, therefore, resourcefriendly work process on the construction site,” said Axel Römer, head of research and development.

Specific examples of this are compaction with oscillation, which emits little noise and conserves resources; process optimization through digital tools and networking; and consumption-reducing technologies in the area of the power train.

Hamm rollers also can be operated with non-fossil fuels such as biodiesel or hydrotreated vegetable oil (HVO). Today, many machines can already work with these types of fuels, and applications are being expanded. Biodegradable hydraulic oils also are part of the standard supply range.

Environmentally-Friendly Operation, Service for Long Machine Life

Durable products are especially sustainable. This is where Hamm’s telematics system comes in to play, as the service life of the rollers is extended through regular maintenance — and with optimal availability. The long service life of Hamm rollers also is reflected in the spare part philosophy. Hamm still supplies customers with spare parts for all models ever built. Moreover, most spare parts can be ordered separately — not just in assemblies.

Sustainable Shipping

Hamm relies on sustainable materials when shipping spare parts. Films and plastic are avoided as far as possible, and polystyrene packing peanuts are taboo. Instead, Hamm packages spare parts in cardboard; packing paper acts as a fill material and padding. Moreover, Hamm receives a large portion of spare parts and wear parts already ready to ship with the corresponding packaging. Material-intensive repackaging — quite common in the sector — is therefore not required.

Wave Goodbye to Paper Consumption

A shift also can be seen in machine documentation — it has been completely moved to data carriers. In its in-house documentation center, Hamm prints documents only upon request based on the “print on demand” principle. It has therefore been possible to reduce the need for paper by more than 70 percent.

For more information, visit wirtgen-group.com/en.

866-430-7539

www.jfwequipment.com sales@jfwequipment.com S e r v i n g t h e A s p h a l t I n d u s t r y f o r 3 0 Y e a r s

2010 Rosco Max II distributor, 1900 gallons, EZ-2S computer w/1 ft cut-offs, diesel burners, 12 ft spray bar, 2010 Freightliner M2 w/Mercedes diesel eng, manual trans - $98,000

New Marathon TPS500PT tack distributor, Honda gas eng, 18GPM pump, 500 gal, 5’ spray wand w/50’ hose, hose reel, 6’ spray bar, operator’s platform, propane burners, flushing system, electric brakes - $26,650

New Marathon TPS250T tack distributor, Honda gas eng, 18GPM pump, 250 gal, 5 ft spray wand w/50 ft hose, 6 ft spray bar, operator’s platform, propane burners, flushing system, electric brakes - $17,950

New Warren aggregate tailgate spreaders, GS84 & GS87, 8 ft wide maximum spreading w/1 ft gates, gravity flow - $5,900 - $6,300 New Marathon TPS115S tack distributor, Honda gas eng, 10GPM pump, 115 gallons, 5 ft spray wand w/50ft hose, hose reel, 80,000 BTU propane burner, flushing system - $10,300

2015 Hamm HD12VV double drum 47” vibratory roller, water system, Kubota diesel engine, 3 ton roller - $31,000

2015 Laymor Sweepmaster SM400 broom, Kubota diesel engine, water system, 8 ft broom, cab w/heat & a/c, all new tires - $36,000

Bomag’s BM 2200/65 Sets Standard for Performance

With its lighter, more compact and highly maneuverable design, the new Bomag BM 2200/65 large planer raises the bar for performance and operating ease and comfort for mills in its class.

A modest, 58-in. milling radius — up to 14 percent smaller than other models — improves machine productivity in the field, increasing efficiency in tight-radius applications like small roundabouts and cul-de-sacs, according to the manufacturer.

Its conveyor offers a 16-ft. discharge height plus larger, 130-degree conveyor slewing angle — 65 degrees to the left/right of center — allowing material to be efficiently discharged into trucks on both sides of the mill. To facilitate transport, the conveyor retracts to a length 23.6 in. shorter than previous designs.

Meeting Tier IV Final/Stage V emissions standards, the mill’s powerful 630 hp (470 kW) engine effectively matches power with milling speed for greater operating efficiency. The slim profile of the advanced Bomag BMS15L quick-change cutting tooth holder system reduces resistance and delivers up to 20 percent fuel savings.

System design extends holder service life to lower costs. Offering a range of milling drum designs and the choice of three different rotor speeds to tailor rotor speed to the job, the BM 2200/65 planer can be used on a wide range of asphalt and concrete milling applications.

Intuitive operation is the hallmark of the new 60,296-lb. BM 2200/65 half-lane mill. To simplify milling control, Bomag Easy Cut technology automatically regulates the height of the rear drive, so the rear of the machine follows the front to its set depth, making the operator’s work simpler. Bomag Easy Level clearly displays grade and slope settings on the large 7-in. display, and settings are quickly changed with minimal screen navigation. Comfort, Visibility, Efficiency

Designed for comfort and efficiency, the BM 2200/65’s vibration-isolated operator’s station delivers comfortable operation from either a seated or standing position. Additional cushioning at the platform’s standing areas help to ensure fatigue-free operation. Stepless platform side-shift up to 7.8 in. provides added visibility to the right cutting edge and side plate, allowing the operator to hold the milling line. Minimal navigation with limited submenus to get to machine parameters delivers intuitive, efficient operation, according to the manufacturer.

The mill’s slim contoured design gives the operator all-round visibility to the machine. Enhanced forward visibility offers operators an unprecedented view of the cutting edge, milling track and the front danger zone around the conveyor for exceptional milling precision. A flat rear design offers an improved view of the area behind the mill for increased operating safety.

The standard water spray and dust extraction systems, complete with conveyor shrouding, efficiently removes fine particulate matter from the machine. Removing up to 80 percent more fine dust particles smaller than 10 microns in size, the optional Bomag ion dust shield meets the most stringent fine dust regulations.

With all key machine service points easily accessible, routine maintenance is completed quickly and efficiently. All filters can be conveniently reached from the operator’s platform through the wide-opening engine hood, as are the fill ports for fuel and AdBlue.

Large left- and right-hand service panels provide simple accessibility to the machine’s auxiliary drive and milling gear, while engine service points are easily accessed from both above and below.

For more information, visit www.bomag.com.

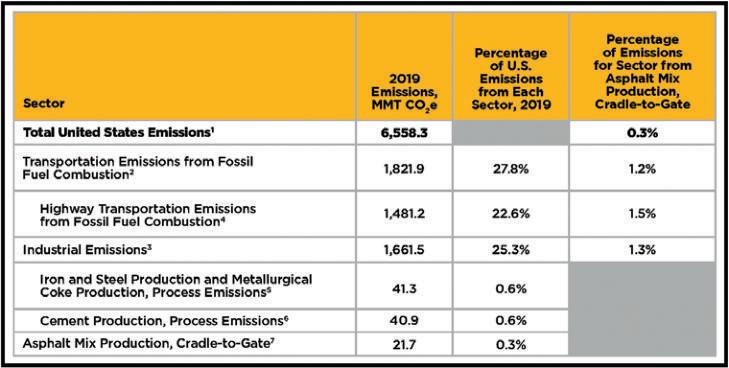

Cradle-to-gate emissions associated with asphalt mix production in the United States represented approximately 0.3 percent of total U.S. greenhouse gas (GHG) emissions in 2019. By comparison, U.S. Environmental Protection Agency data indicate that transportation emissions from fossil fuel combustion represented 27.8 percent of total emissions in 2019, while industrial emissions represented 25.3 percent.

That’s according to a new report from the National Asphalt Pavement Association (NAPA), authored by its director of Sustainable Pavements, Joseph Shacat; vice president of Engineering, Research, & Technology, J. Richard Willis; and TriSight LLC partner Ben Ciavola.

The report, GHG Emissions Inventory for Asphalt Mix Production in the United States (SIP 106), is the first national cradle-to-gate assessment of GHG emissions associated with the production of asphalt pavement mixtures that uses a life cycle assessmentbased methodology.

The emissions inventory includes upstream raw materials inputs, transportation of those materials to the production site, and plant emissions (including upstream energy processes) for the years 2009 to 2019.

“Publishing this report puts NAPA and the asphalt pavement industry at the forefront of transparency among carbon emitters,” said NAPA President and CEO Audrey Copeland. “We’re demonstrating our commitment to doing better — as prescribed in The Road Forward initiative we announced in January — by taking stock of where we are and identifying proven as well as innovative strategies to reduce carbon emissions.”

“To our knowledge, this is one of the first cradle-to-gate GHG emissions inventories for any major U.S. industry,” added Shacat. “While there are several studies that show cradle-to-gate emissions intensities for various industries, we’re not aware of any publicly available reports that add up all of the emissions for a given industry nationwide.”

Jim Mertes, director of Environmental Affairs at Construction Resources Management Inc., A Walbec Group Company, and chair of NAPA’s Sustainability Committee, described the report as “a comprehensive industry benchmark, which can be used to measure future industry improvements in carbon reduction.”

What’s more, said Mertes, “It identifies what we can achieve using existing strategies and technologies and demonstrates the unprecedented technological challenge ahead to get to net zero.”

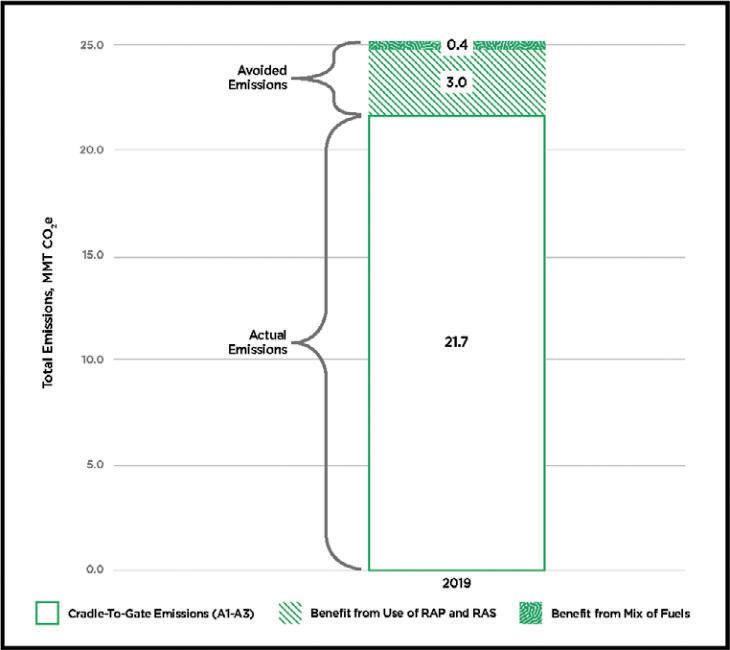

By identifying “avoided emissions,” the report demonstrates how existing environmentally preferable technologies like reclaimed asphalt pavements (RAP), reduced-temperature asphalt mix production (called warm-mix asphalt, or WMA), and switching to alternative fuels for plant operations have already had an industry-wide impact on limiting emissions.

In 2019 alone, the industry avoided 2.9 million metric tons (MMT) CO2e emissions — equivalent to the annual emissions from approximately 630,000 passenger vehicles.

The authors note that increased implementation of such measures could further reduce emissions by up to 24 percent relative to 2019. In fact, each ton of RAP used in new asphalt mixtures reduced 2019 GHG emissions by approximately 27 kg CO2e.

However, they caution, “Although the report provides an estimate for the national average GHG emissions associated with asphalt mix production, it is not an industry average Environmental Product Declaration (EPD) and should not be used as a benchmark for project-level decision making during procurement or project delivery.”

Nonetheless, the report “will be a valuable tool as discussions with government, agencies, and owners accelerate in the coming years,” said Ron Sines, vice president, Performance — Asphalt, CRH Americas Materials Inc.

“Additionally, it provides clear direction on what the industry should be doing today, as well as what the industry could do in the future, if the identified obstacles can be overcome,” added Sines, who chaired NAPA’s Climate Stewardship Task Force, which created The Road Forward, the industry’s goal to reach net zero carbon emissions by 2050.

To advance that goal, the report states, “New technologies and additional innovative practices will need to be developed and implemented to achieve more significant GHG emission reductions.”

The industry, along with its suppliers, partners and customers, must invest in emission reduction strategies related to materials, transportation, and mix production. Examples include carbon capture, utilization and storage (CCUS); use of carbon sequestering bio-based materials; use of local recycled materials and alternative fuels for trucking; and technologies that reduce burner fuel consumption.

Raven Adams, vice chair of NAPA’s Sustainability Committee and Granite Construction’s sustainability manager, remarked, “NAPA’s publication of this document will empower our industry to advocate for the funding, research, and support needed to allow us to respond to climate change.”

For more information, visit www.asphaltpavement.org.

MF25 eedF500CS der500CS

ellahC te Sg tnign he Sg t o —s Quuta Mh ItiW wON X tIo s Qu X t to swo s g ixie ma e m

Follow Dyynapac North America

BANE MACHINERRY Y Y,, INC. BEE EQUIPMENT SAALES LTD. 2449 Manana R Rd. (214) 352-2468 82506 Slaton Highway (817) 847-5894 4 (806) 745-151 1 (903) 597-6641 1

C. L. BOYD CO., INC. BEE EQUIPMENT SA ALES LTD. 4220 West Reno A Ave. 2506 Slaton Highway(800) OKC-BOYD ï (405) 942-8000 (806) 745-151 1Ardmore, OK K (866) 720-2693 ï (580) 224-2693 Lawton, OK (800) 633-2693 ï (580) / /355-6667

C. L. BOYD CO., INC. 4220 West Reno AAve. (800) OKC-BOYD ï (405) 942-8000 Ardmore, OK K CLAIREMONT EQUIPPMENT (866) 720-2693 ï (580) 224-2693 Lawton, OK 7651 Ronson Roaad (800) 633-2693 ï (580) / /355-6667San Diego, CA 92111 (858) 278-8351 1330 W Mission Rooad Escondido, CA 92029 (760) 739-9100 440 West Aten Rooad (760) 355-7700 4726 Convoy Streeet San Diego, CA 92111 (858) 278-8338

CLAIREMONT EQUIPPMENT 7651 Ronson Roaad San Diego, CA 92111 (858) 278-8351 1330 W Mission Rooad Escondido, CA 92029 (760) 739-9100 440 West Aten Rooad (760) 355-7700 4726 Convoy Streeet San Diego, CA 92111 (858) 278-8338

6532 East Highway

Rhome, TX 7607 (817) 708-9108 21910 FM 2252

Schertz, TX 7815 (210) 732-2131 13800 FM 973 N

Manor, TX 78653 (512) 272-8200 114 78 54 N 3

Coming Soon

Houston, TX

6532 East Highway Rhome, TX 7607 (817) 708-9108 21910 FM 2252 Schertz, TX 7815 (210) 732-2131 13800 FM 973 N Manor, TX 78653 (512) 272-8200 114 78 COOPER EQUIPMENNT CO. www.cooperequip..com 54 5210 N Loop 16044 E San Antonio, TX 788247 N (210) 657-5151 3 201 Commerce Blvvd. Georgetown, TX 788626 (512) 930-5151

COOPER EQUIPMENNT CO. www.cooperequip..com 5210 N Loop 16044 E San Antonio, TX 788247 (210) 657-5151 201 Commerce Blvvd. Georgetown, TX 788626 (512) 930-5151

DOGGETT HEAAVVY MACHINERRY Y SERVIC www.doggett.com (318) 442-0455

Baton Rouge, LA (225) 291-3750

Broussard, LA (337) 837-9481

Covington, LA (985) 893-3005 Y CES MACHINER m (337) 430-3045 Monroe, LA (318) 343-8787

Shreveport, LA (318) 631-3090 St. Rose, LA (504) 466-5577

Beaumont, TX (409) 842-1754 Bryan, TX (979) 823 1905 (979) 823-1905

Corpus Christi, TX (361) 289-0727 Houston, TX (713) 679-6700 Longview, TX (903) 758-3326 Lufkin, TX (936) 634-8801 San Juan, TX (956) 787-0001 (903) 592-8900 Victoria, TX (361) 570-6666

DOGGETT HEAAVVY RY Y SERVIC www.doggett.com (318) 442-0455 Baton Rouge, LA (225) 291-3750

Broussard, LA (337) 837-9481

Covington, LA (985) 893-3005 Y CES m (337) 430-3045

Monroe, LA (318) 343-8787

Shreveport, LA (318) 631-3090

St. Rose, LA (504) 466-5577

Beaumont, TX (409) 842-1754

Bryan, TX X (979) 823 1905 (979) 823-1905 Corpus Christi, TX (361) 289-0727

Houston, TX (713) 679-6700

Longview, TX (903) 758-3326

Lufkin, TX (936) 634-8801

San Juan, TX (956) 787-0001 X (903) 592-8900

Victoria, TX (361) 570-6666

MODERN MACHINER www.modernmachinery. (409) 842-1754 Boise, Idaho (208) 336-8670 Jerome, Idaho (208) 324-4522 (800) 829-4450 R RY Y com (800) 829-4450 (800) 735-2589 (800) 434-4190 Eugene, Oregon (800) 826-9811 (800) 950-7779 Kent, Washington (800) 669-2425

Rochester, Washington g (800) 304-4421

Spokane, Washington (800) 541-0754

ROAD MACHINERRY Y www.roadmachinery.co 902 S. 7th Street