7 minute read

JONAS ANNOUNCES PROCORE TECHNOLOGIES PARTNERSHIP

Larger control valve and electronic controls deliver smooth, precise performance and up to 12% faster cycle times

Shift-long comfort from a spacious cab, automotive-grade seat and ergonomically-designed, fullyadjustable arm rests

Award-winning Wide Angle Visual Enhancement System (WAVES) provides seamless 270° panoramic view

Ground-level access to routine service points cuts daily maintenance down to just minutes

Tier 4 Final engines deliver up to 12% improved fuel economy…and no DPF to maintain

Robust undercarriage with innovative side-frame design is easier to clean

Contractors Sales Company

www.contractorssales.com 121 Karner Road Albany, NY 12212 518-456-1445 • 888-468-5479 1283 Dolsontown Road Middletown, NY 10940 845-956-0222

Chappell Tractor

www.chappelltractor.com 454 Route 13 South Milford, NH 03055 603-673-2640 251 Route 125 Brentwood, NH 03833 800-616-5666 391 Loudon Road Concord, NH 03301 800-358-6007

Wood’s CRW Corp.

www.woodscrw.com 7096 Carlisle Pike Carlisle, PA 17015 717-795-0700

Heavy Machines, Inc.

www.heavymachinesinc.com 159 North Avenue Skowhegan, ME 04976 888-875-3954 2401 Broadway, Building #3 South Portland, ME 04106 877-202-1275

George & Swede Sales & Service Inc.

www.georgeandswede.com 7155 Big Tree Road Pavilion, NY 14525 585-584-3425 • 800-724-8722

Link-Belt Mid-Atlantic Construction Equipment

www.Link-BeltMidAtlantic.com Ashland, VA 866-955-6071 Chesapeake, VA 800-342-3248 Frederick, MD 833-546-5235

ESSCO Truck & Equipment

info@ESSCOequipment.com 20 Kinsey Place Staten Island, NY 10303 844-44-ESSCO 1300 New Jersey 33 Farmingdale, NJ 07727

Marshall Machinery, Inc.

www.marshall-machinery.com 348 Bethel School Road Honesdale, PA 18431 570-729-7117

Pittsburg Agh, P Lancaste Aer, P Hubbard d, OH Cincinna ati, OH (412) 747-7777 7 (717) 569-4531 1 (330) 534-0082 2 (513) 874-4880 0

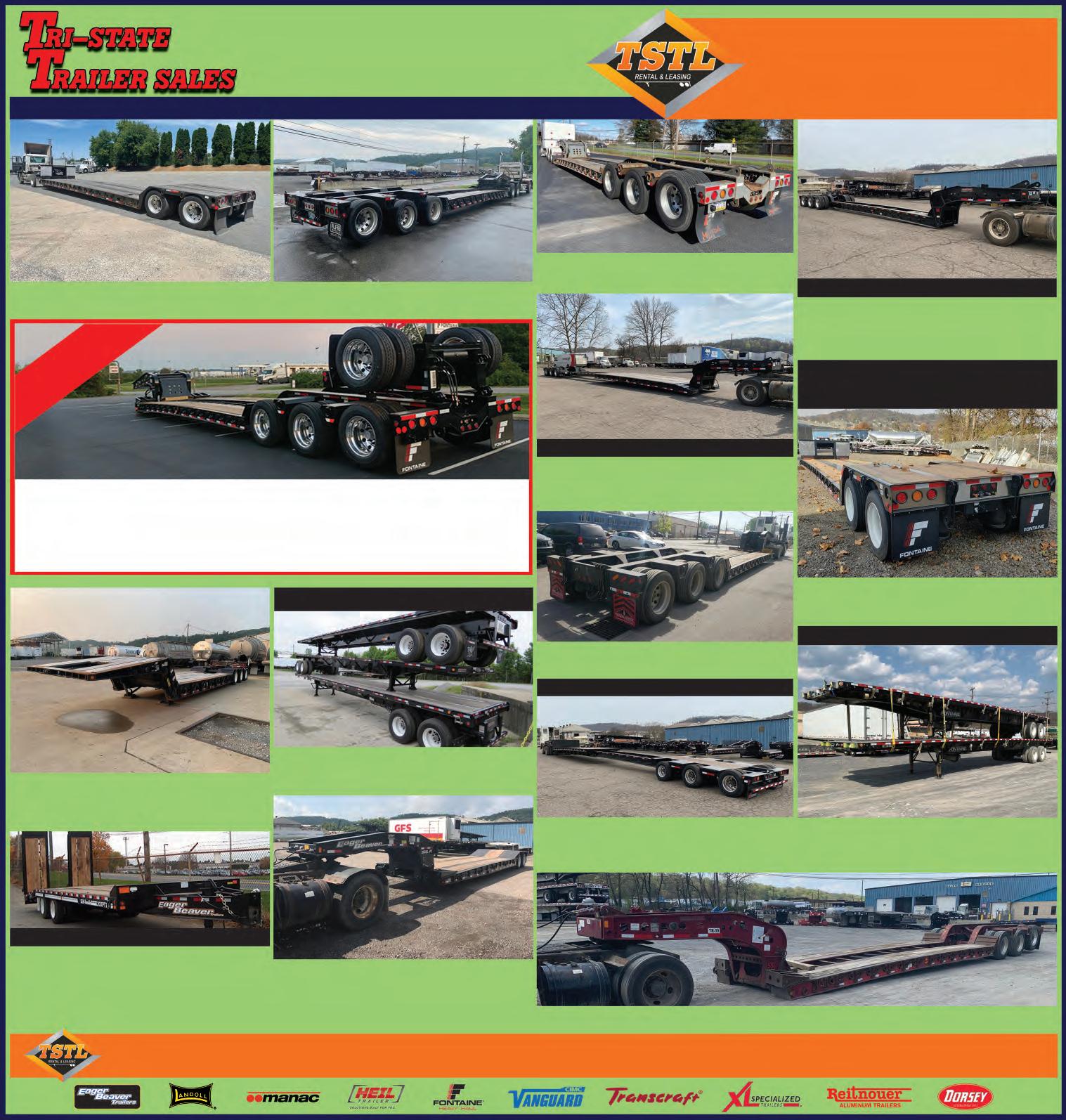

railer Sales • Rental / Leasin New & Used T ng • Financing • Service • Parts ce • Parts

Long-Term m LEASING!

(412) 747-7777 47-7777

2014 Fontaine LXT40, 34'-60'.

ese F e Boxlip l e ve Ha l We & F

Unit # 4770 2018 XL XLSpecialized on o-T5510 HDGS, 1

ell. , 26' in W Unit # 4894 ell. e 2018 Fontaine 55H, 26' in W

Unit # 4432

60 on Beam-T

Qty 1

- Fontaine Magnitude 60 MBMD, 28' Beam, gnitude 60 MBMD, 28' Beam, Modular Connection at Rear, Painted Red. at Rear COMING IN DECEMBER NG IN DECEMBER

FONTAIINE DOUBLE

DROP EX XTENDABLES

orkhorse o – New Fontaine WQty 6 e 55LCC, 18” Deck Alum Wheels ell, o/s e Height, 26’ W Axle, s, Rear Lift Some w/ Wheel Covers, Both Red d and Black. Qty 2 Qy – New Fontaine Magnitud de 60LCC, g , Alu ell, o/s e 18” Deck Height, 26’ W um Wheels, Axle, BlacFront Ramps, Rear Lift ck. Qty 1

– New on Drop o Fontaine Magnitude 55-T Side Rail, Rea Alum Wheels.Axle, o/s ar Lift

Qty 1 – New . Fontaine EQI Hydraulic Spreader

Qty 3

– New ell, e , 24’on Paver o Fontaine 55-T W Both Red and Black.

New Manac tbedsla-C-H F - - c S-T-R-E-T

on Extenda55-T ble

Qty 1

, 29' W – Fontaine Magnitude 55MXT ell Closed e 29' W - 50' Open, Modular Connection at Rear. ar COMING IN DECEMBE ER

ell. e o o 2017 Towmaster 55-Ton, 25'7" in W

Unit # 4691

k Height*30" Dec t*

Qty 3

ell e - ne LXT-40, 53'-74'x102", 34' W – New Fontaine LXT Mechanical Detach. on, o Open, 40-T O ell - e 60' Closed, - W

MATCHED GROUP OUP GRCHED CTMA

Axle Folding Neck, 21'4" on Quad o 2008 Load King 40-T ell. e in W

Unit # 4807 Qty 3

48’-80’x10 - .Air Slider & Spring Slider02”, inch i All with W inches. ir h Track and Galvanized W

on XL90SDE Single Drop Extendable, 53'-76'4", o 45-T ble, 53'-76'4", op Deck, Reinforced for Flip Neck o 1' 102" Wide, 1 T r Flip Neck and

Flip Axle. Qty 18

- 2018 & 2019 Fontaine 48'x102" Steel Flats, 9 Fontaine 48'x102" Steel Flats, T, Winch Spring Slider rack.

s 5033-5050Unit #’

EAGER VER V BEA A T GS

Qty 18

on, 21' o – New 20XPT, 20-T Air Flat Deck, Brakes with Spring Ramps ( – Qty 6 – with Hydraulic Ramps) Both Red and Black. Qty 6 on ( o – New 25XPL, 25-T Qty 2 – with Hydraulic 2

Ramps) Both Red and Black. Qty 4

- New Eage er Beaver Pavers, 35 GSL-PT Hydraulic Detacha on, 24' Deck, o able Lowboys, 35-T Air Ride.

- New 35 GS Qty 1 ail. aon, 24' Deck, Beaver o SL-BR, 35-T T 2016 Fontaine 55 on o-T ell e, 26' in W . Unit# 4663

Trailers play a key role in the construction industry — whether they’re moving equipment or materials, no work gets accomplished on the job site until trailers are called into service.

As with all construction equipment, a trailer must properly perform to help keep work on schedule … and maintenance is the key to accomplish this.

However, there are two factors that can contribute to trailer maintenance being overlooked or neglected. First, compared with other types of construction equipment, trailers are relatively simple in design and as such, can often be an afterthought when keeping up with inspections. And second, machine operators in the cab of equipment, such as a dozer or excavator, receive constant feedback on the condition of the equipment. Instrument panel alerts or an odd noise coming from the engine will be noticed immediately and acted upon. In the case of trailers, however, the truck driver is isolated from the trailers, so issues such as a bad bearing can go unnoticed.

According to Tri-State Trailer Sales Director of Service Greg Brown, prevention is the solution to keeping trailers operating safely and profitably.

It sounds pretty obvious, but the key to maintenance is proper inspections,” he said.

Brown urged that inspections should be a regular part of the routine every time prior to a trailer leaving the equipment yard.

A complete inspection form is available from the U.S. Department of Transportation; however, the primary areas of concern for daily inspections include a look at every functional point of the trailer. A review should be done to ensure there are no issues with the running gears and tires should be checked for wear. Hub oil levels, lights and brakes also should be checked. A walkaround of the trailer to look for signs of structural damage also is important. Brown also recommends that spot checks by qualified service personnel be conducted regularly to confirm that the driver is performing thorough inspections.

Brown advises that maintaining a regular, professionally conducted preventive maintenance schedule at three-month intervals or a

set number of miles based on usage should also be implemented.

“Staying on top of maintenance and keeping the trailer in good condition is much less expensive than paying for safety violations or having an accident,” Brown said.

These inspections can save a lot of money on repair service, as well, Brown added. “Catching the fact that a hub is low on oil allows the owner to address the issue before it leads to bigger problems.”

The preventive maintenance schedule should review the following primary components of a trailer that may not be immediately apparent during daily inspections: • braking system, including the anti-lock braking system; • bearings; • suspension (axle, shocks, airbags); • main frame, including cross members; • electrical system; and • tires

An annual Federal Highway Administration (FHWA) inspection, conducted by a qualified inspector is required for all commercial vehicle fleets. Brown cautioned that it is crucial to use a reputable technician for these inspections.

“Unfortunately, we see a lot of FHWA stickers on trailers that should not have passed inspection,” he said. “At Tri-State Trailers Sales, we approach every inspection and service we perform as though that trailer will be traveling on the road next to our family car.” CEG

Shown here are a new air bag, new brake chamber and a new brake drum.