70 minute read

Beth Bartow’s Lifelong Career Spans Decades, Two Continents

By Patricia O’Brien

CEG CORRESPONDENT

Beth Bartow grew up in the heavy equipment industry, while the industry grew and changed around her. Currently the Case business manager southeast of Case Construction, Bartow’s first job in high school, unbeknownst to her, would be the start of a lifelong career that would span decades and several countries around the globe.

“I started working for Hoffman Equipment, in Piscataway, N.J., when I was in high school. It’s a familyowned business. I started filling in during school vacations. They asked if I wanted to come on board and work in sales. The people were super, and it was an interesting business. My education really started there,” said Bartow, whose first role in inside sales gave her the opportunity to learn the whole business, including accounting, parts and service.

Bartow stayed with the Hoffman family for several years. But just like living at home, there comes a time when you need to leave the nest. She was offered a position with Daewoo Equipment as an inside sales manager and accepted this new challenge.

A woman in the role of territory sales manager was unusual in the mid 1980s, particularly in the New York City metropolitan area.

Over the next several years, Bartow held a variety of field sales roles for some heavy hitters in the industry, including H.O. Penn in Connecticut and ALLU Manufacturing in New Jersey. Her big break came when a headhunter working on behalf of Caterpillar Redistribution Services contacted her to discuss filling the role of senior sales regional manager, working out of Florida. She accepted the job and headed south, successfully growing Caterpillar’s used equipment and rental business.

Three years later, Bartow answered a call from Cat’s European group to replicate that success in Europe.

Her work meant traveling throughout England, the Netherlands, Sweden, Denmark, Finland, Latvia and Ireland.

“What was interesting was here I was this ‘pushy American woman’ coming in and telling these men how to run their used equipment business,” she recalled. “To this day, I’m thankful to Cat for that experience. It helped me grow as a person and as a businesswoman. It was an experience that you don’t get every day.”

After two years in this role, Bartow returned to the United States. She held senior sales manager roles with Cat’s used equipment division, Terex and Volvo. She then took her vast experience in the construction equipment industry to software manufacturer Decisiv Inc. as director of business development. She was there for five years before an opportunity opened with Case as dealer development manager.

“I started with Case in September 2021. They had a reorganization with the purpose of becoming more customerfacing. In March of this year, I was asked to take over the role as the Case business manager, southeast,” said Bartow, the only female field regional business manager in the company. As business manager, she covers the Case dealers from Florida to North Carolina.

Bartow’s success has not come easy and certainly not without its challenges, but she’s happy with the path she chose.

“I wouldn’t change it for anything. I never thought I would get into construction. I thought I was going into retail and fashion. Construction was easy; it was like being home. It felt comfortable. This is what I know. Each move I made was a platform to the next.

“Everywhere I go, I have to prove myself to somebody,” she added. “I don’t see men having to prove themselves when they come into the field. One of the best pieces of advice I got early in the industry is to just be a sponge and soak up everything, so that’s what I did. The thing I’ve found in my travels is that there are people who will help you along the path and I’ve been very fortunate to have some very good managers to help me.”

Bartow will gladly offer advice to women looking to break into the construction industry, but her most important piece of advice comes before a decision is made.

“Interview, interview, interview. Make sure you’re going to be the right fit for that location. They will dazzle you with an offer, but see where the opportunities are for growth. You’re not going to want to stay in that position for the rest of your life. Are they providing the tools to help you grow? Then that’s the place you want to be.” CEG

Photo courtesy of Beth Bartow Beth Bartow is the Case Construction southeast business manager.

HCEA Adds Holland Equipment Services to Dealer Network

Hyundai Construction Equipment Americas announced July 28 a dealership agreement with HES — Holland Equipment Services, Holland, Mich., under which HES will sell and service Hyundai wheel loaders and excavators in western Michigan.

Aric Geurink, president of HES, said the agreement with Hyundai represents a major growth opportunity for the dealership, which has built a large presence in southwest Michigan as a supplier of used equipment, attachments, parts, service and rentals.

“Selling, servicing and renting new Hyundai equipment adds important value to the HES brand and gives us a competitive edge,” said Geurink, whose late father, Robert, established the familyowned dealership in 1988 as HES/A&B Farms. “It’s a win for both our dealership and our customers. We’re getting great training and support from Hyundai, and our customers have an expanded variety of Hyundai equipment and financing solutions to meet their needs.”

Geurink said HES looks forward to adding Hyundai’s newly announced articulated dump truck models to its rental fleet.

“We have customers who will find the new Hyundai ADT trucks a great match for their applications,” he said.

“Hyundai welcomes HES to our expanding network of North American dealerships,” said Ed Harseim, Midwest sales manager, Hyundai Construction Equipment Americas. “Having built a successful business on the sales and rentals of used equipment, HES now provides its customers a variety of new equipment solutions from Hyundai.”

For more information, visit hceamericas.com.

Page 40 • August 6, 2022 • www.constructionequipmentguide.com • Paving Section • Construction Equipment Guide New NAPA Report Unveils Emissions Inventory for Asphalt Mix Production

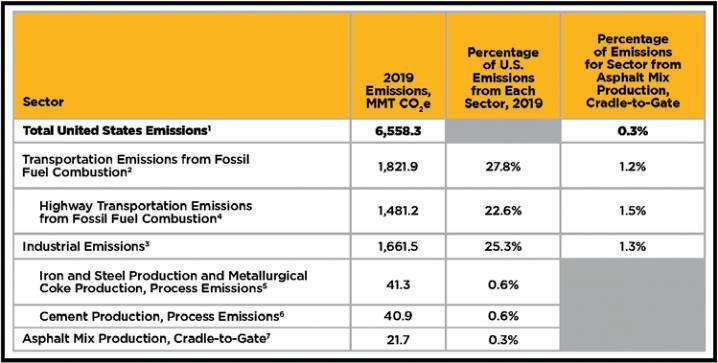

Cradle-to-gate emissions associated with asphalt mix production in the United States represented approximately 0.3 percent of total U.S. greenhouse gas (GHG) emissions in 2019. By comparison, U.S. Environmental Protection Agency data indicate that transportation emissions from fossil fuel combustion represented 27.8 percent of total emissions in 2019, while industrial emissions represented 25.3 percent.

That’s according to a new report from the National Asphalt Pavement Association (NAPA), authored by its director of Sustainable Pavements, Joseph Shacat; vice president of Engineering, Research, & Technology, J. Richard Willis; and TriSight LLC partner Ben Ciavola.

The report, GHG Emissions Inventory for Asphalt Mix Production in the United States (SIP 106), is the first national cradle-to-gate assessment of GHG emissions associated with the production of asphalt pavement mixtures that uses a life cycle assessment-based methodology.

The emissions inventory includes upstream raw materials inputs, transportation of those materials to the production site, and plant emissions (including upstream energy processes) for the years 2009 to 2019.

“Publishing this report puts NAPA and the asphalt pavement industry at the forefront of transparency among carbon emitters,” said NAPA President and CEO Audrey Copeland. “We’re demonstrating our commitment to doing better — as prescribed in The Road Forward initiative we announced in January — by taking stock of where we are and identifying proven as well as innovative strategies to reduce carbon emissions.”

“To our knowledge, this is one of the first cradle-to-gate GHG emissions inventories for any major U.S. industry,” added Shacat. “While there are several studies that show cradle-to-gate emissions intensities for various industries, we’re not aware of any publicly available reports that add up all of the emissions for a given industry nationwide.”

Jim Mertes, director of Environmental Affairs at Construction Resources Management Inc., A Walbec Group Company, and chair of NAPA’s Sustainability Committee, described the report as “a comprehensive industry benchmark, which can be used to measure future industry improvements in carbon reduction.”

What’s more, said Mertes, “It identifies what we can achieve using existing strategies and technologies and demonstrates the unprecedented technological challenge ahead to get to net zero.”

By identifying “avoided emissions,” the report demonstrates how existing environmentally preferable technologies like reclaimed asphalt pavements (RAP), reduced-temperature asphalt mix production (called warm-mix asphalt, or WMA), and switching to alternative fuels for plant operations have already had an industry-wide impact on limiting

see NAPA page 48 BRANDEIS MACHINERY & SUPPLY COMPANY

www.brandeismachinery.com 17000 Highway 41 N Evansville, IN 47725 812/425-4491 7310 Venture Lane Ft. Wayne, IN 46818 260/489-4551 8410 Zionsville Road Indianapolis, IN 46268 317/872-8410 1801 Watterson Trail Louisville, KY 40299 502/491-4000 1484 American Greeting Card Road Corbin, KY 40701 606/528-3700 1389 Cahill Drive Lexington, KY 40504 859/259-3456 160 County Park Road Paducah, KY 42001 270/444-8390 130 Mare Creek road Stanville, KY 41659 606/478-9201

ROLAND MACHINERY

www.rolandmachinery.com Springfield, IL 217/789-7711 Carterville, IL 618/985-3399 East Peoria, IL 309/694-3764 Portage, IN 219/764-8080 Bridgeton, MO 314/291-1330 Cape Girardeau, MO 573/334-5252 Columbia, MO 573/814-0083 Palmyra, MO 573/769-2056 Eau Claire, WI 715/874-5400 DePere, WI 920/532-0165 Deforest, WI 608/842-4151 Franksville, WI 262/835-2710 Schofield, WI 715/355-9898 Slinger, WI 262/644-7500 2600 S. Lincoln Rd. Escanaba, MI 906/786-6920

Page 42 • August 6, 2022 • www.constructionequipmentguide.com • Paving Section • Construction Equipment Guide Hamm’s Environmentally-Friendly Solutions Can Increase Machine Life

HAMM from page 35 comply with the statutory regulations.

One of the flagship projects to date is the construction of a geothermal system. It has been heating and cooling the administration building since 2013, yielding savings of around 86 t of CO2 per year.

At the plant in Tirschenreuth, the energy demand for lighting was almost halved in 2019 by switching to LED lights. This also saves over 80 t of carbon dioxide every year. Optimizations in the compressed air cycle also reduce the electricity/energy demand by 50,000 kWh. That corresponds to close to 5 t of CO2.

All Divisions Under

Magnifying Glass

Since 2018, an environmental protection manager has been advancing the further minimization of raw material and energy consumption, waste, packaging and emissions of solvents (VOCs) and placing all divisions under the magnifying glass. In this way, Hamm is improving its ecological footprint through large-scale measures as well as numerous finely detailed projects.

At the moment, the energy demand for heating also is being drastically reduced, as well as the consumption of fresh water in production. There also are very high standards regarding waste water and low noise emissions from the plant. Alongside this, paperless production is to be introduced in the near future.

Recycling, Recuperation

Waste is also a key focus.

“By implementing numerous individual measures, by 2023 we will have reduced the waste per produced machine by approximately 20 percent compared with 2019,” said Plant Manager Dirk Pressgott.

In production, an innovative painting process reduces the amount of paints and solvents used while offering the same paint quality. Hamm also recycles the solvents used for cleaning the painting systems.

Internal logistics also saves energy by optimizing routes and also uses quiet electric forklift trucks. Shortly before the rollers leave the plant, the brake energy is recovered via recuperation at the test bench, which all machines pass. Intelligent Solutions Instead of Materials

In general, “intelligent solutions instead of materials” applies in purchasing and logistics at Hamm. Special transport racks therefore render much of the packaging superfluous. And, due to a 4PL strategy, there are virtually no empty runs when supplying purchased parts and semi-finished products. In addition to these measures, suppliers are selected based on their environmental certification and training of employees with a view to environmental protection.

Through dialog with the design and production departments, Hamm also has been continuously reducing excess packaging and optimizing transport capacity for many years. Recycled plastics also are used wherever possible for constructing rollers.

Environmentally-Friendly

Products, Compaction Solutions

With regard to products, Hamm follows the objective of “developing lowconsumption machinery and machine control systems that ensure an efficient and, therefore, resource-friendly work process on the construction site,” said Axel Römer, head of research and development.

Specific examples of this are compaction with oscillation, which emits little noise and conserves resources; process optimization through digital tools and networking; and consumption-reducing technologies in the area of the power train.

Hamm rollers also can be operated with non-fossil fuels such as biodiesel or hydrotreated vegetable oil (HVO). Today, many machines can already work with these types of fuels, and applications are being expanded. Biodegradable hydraulic oils also are part of the standard supply range.

Environmentally-Friendly

Operation, Service for

Long Machine Life

Durable products are especially sustainable. This is where Hamm’s telematics system comes in to play, as the service life of the rollers is extended through regular maintenance — and with optimal availability. The long service life of Hamm rollers also is reflected in the spare part philosophy. Hamm still supplies customers with spare parts for all models ever built. Moreover, most spare parts can be ordered separately — not just in assemblies.

Sustainable Shipping

Hamm relies on sustainable materials when shipping spare parts. Films and plastic are avoided as far as possible, and polystyrene packing peanuts are taboo. Instead, Hamm packages spare parts in cardboard; packing paper acts as a fill material and padding. Moreover, Hamm receives a large portion of spare parts and wear parts already ready to ship with the corresponding packaging. Materialintensive repackaging — quite common in the sector — is therefore not required.

Wave Goodbye to

Paper Consumption

A shift also can be seen in machine documentation — it has been completely moved to data carriers. In its inhouse documentation center, Hamm prints documents only upon request based on the “print on demand” principle. It has therefore been possible to reduce the need for paper by more than 70 percent.

AIS CONSTRUCTION EQUIPMENT

www.aisequip.com Grand Rapids, MI 616-538-2400 Lenox, MI 586-727-7502 Williamsburg, MI 231-267-5060 Lansing, MI 517-321-8000 Bridgeport, MI 989-777-0090 New Hudson, MI 248-437-8121

MURPHY TRACTOR & EQUIPMENT CO., INC.

www.murphytractor.com Park City, KS 316-942-1457 Great Bend, KS 620-792-2748 Topeka, KS 785-233-0556 Ulysses, KS 620-356-1071 Dodge City, KS 620-227-3139 Gering, NE 308-436-2177 Omaha, NE 402-894-1899 Lincoln, NE 402-467-1300 Grand Island, NE 308-381-0741 North Platte, NE 308-534-7020 Kansas City, MO 816-483-5000 Springfield, MO 417-863-1000 Des Moines, IA 515-263-0055 Fort Dodge, IA 515-576-3184 Sioux City, IA 712-252-2753 Waterloo, IA 319-235-7085

Page 44 • August 6, 2022 • www.constructionequipmentguide.com • Paving Section • Construction Equipment Guide Trimble’s NextGen 3D Paving Control Improves Productivity, Rideability

Trimble introduced in 2021 the Roadworks 3D paving control platform for asphalt pavers, the next-generation platform for 3D asphalt paving control systems.

Trimble Roadworks is a highly accurate, automatic 3D screed control system that can significantly improve paving productivity and rideability by directly referencing the design rather than a surface or stringline to minimize asphalt usage, reduce waste and overruns and finish projects on time and under budget, according to the manufacturer.

Intuitive Software,

Flexible Hardware

The Android-based application runs on the 10-in. touch-screen Trimble TD520 display. Trimble Roadworks software has a familiar interface for Trimble users, designed for operator efficiency. Colorful graphics, natural interactions and gestures, and self-discovery features make the software intuitive and easy to learn.

Operator scan personalize the interface to match their workflow; configurable views make it easier to see the right perspective for maximum productivity. Modern software and hardware give operators of all skill levels the ability to work faster and more productively than ever before.

Trimble Roadworks leverages Trimble’s proven system hardware, rugged and durable for tough paving conditions. By design, utilizing components from Trimble Earthworks increases the portability of the hardware and increases return on investment, according to the manufacturer.

Using the Android operating system, users also can download other third-party applications that provide the operator with additional useful tools inside the cab.

“Trimble Roadworks is easy to learn and more accessible for many different types of contractors because it leverages the intuitive Trimble machine control interface and applies it to asphalt pavers,” said Kevin Garcia, general manager of Trimble Civil Construction Specialty Solutions.

“This platform also makes it possible to include Trimble’s industry-leading paving technology as part of a connected site ecosystem of solutions, which is valuable for complex infrastructure projects.” Connectivity

Office-to-field connectivity reduces waste and overruns with efficient communication and data transferring across the project. Using a Trimble SNM941 Connected Site Gateway, Trimble Roadworks allows the transfer of 3D designs from the office to the machine via the cloud so that the operator is always using the latest design. In addition, productivity data collected from the machine is automatically synced back to the office. Availability

Trimble Roadworks 3D paving control platform for asphalt pavers is now available globally through the worldwide SITECH distribution channel.

The Android-based application runs on the 10-in. touch-screen Trimble TD520 display. Trimble Roadworks software has a familiar interface for Trimble users, designed for operator efficiency. Operators can personalize the interface to match their workflow; configurable views make it easier to see the right perspective for maximum productivity.

Rudd Equipment Company

www.ruddequipment.com 4344 Poplar Level Road Louisville, KY 40213 502-456-4050

Corbin, KY 606-528-9440 Prestonsburg, KY 606-874-2104 Evansville, IN 812-867-6661 Fort Wayne, IN 260-482-3681

Indianapolis, IN 317-247-9125 Cincinnati, OH 513-321-7833 Cleveland, OH 216-393-7833 Columbus, OH 614-636-4050

Miller-Bradford & Risberg, Inc.

www.miller-bradford.com

W250 N. Hwy 164

Eau Claire, WI 800-585-7232 De Pere, WI 800-638-7448 Marathon, WI 888-886-4410 Negaunee Township, MI 800-562-9770 Rockford, IL 800-585-7231

McCann Industries

www.mccannonline.com 543 S. Rohlwing Rd

Addison, IL 60101 630-627-0000

Crestwood, IL 708-597-3110 McHenry, IL 815-385-0420 Wauconda, IL 847-526-9444 Merrillville, IN 219-576-7800 Schereville, IN 219-865-6545

Page 46 • August 6, 2022 • www.constructionequipmentguide.com • Paving Section • Construction Equipment Guide Bomag’s BM 2200/65 Sets Standard for Performance

With its lighter, more compact and highly maneuverable design, the new Bomag BM 2200/65 large planer raises the bar for performance and operating ease and comfort for mills in its class.

A modest, 58-in. milling radius — up to 14 percent smaller than other models — improves machine productivity in the field, increasing efficiency in tight-radius applications like small roundabouts and cul-de-sacs, according to the manufacturer.

Its conveyor offers a 16-ft. discharge height plus larger, 130-degree conveyor slewing angle — 65 degrees to the left/right of center — allowing material to be efficiently discharged into trucks on both sides of the mill. To facilitate transport, the conveyor retracts to a length 23.6 in. shorter than previous designs.

Meeting Tier IV Final/Stage V emissions standards, the mill’s powerful 630 hp (470 kW) engine effectively matches power with milling speed for greater operating efficiency. The slim profile of the advanced Bomag BMS15L quick-change cutting tooth holder system reduces resistance and delivers up to 20 percent fuel savings.

System design extends holder service life to lower costs. Offering a range of milling drum designs and the choice of three different rotor speeds to tailor rotor speed to the job, the BM 2200/65 planer can be used on a wide range of asphalt and concrete milling applications.

Intuitive operation is the hallmark of the new 60,296-lb. BM 2200/65 half-lane mill. To simplify milling control, Bomag Easy Cut technology automatically regulates the height of the rear drive, so the rear of the machine follows the front to its set depth, making the operator’s work simpler. Bomag Easy Level clearly displays grade and slope settings on the large 7-in. display, and settings are quickly changed with minimal screen navigation. Comfort, Visibility, Efficiency

Designed for comfort and efficiency, the BM 2200/65’s vibration-isolated operator’s station delivers comfortable operation from either a seated or standing position. Additional cushioning at the platform’s standing areas help to ensure fatigue-free operation. Stepless platform side-shift up to 7.8 in. provides added visibility to the right cutting edge and side plate, allowing the operator to hold the milling line. Minimal navigation with limited submenus to get to machine parameters delivers intuitive, efficient operation, according to the manufacturer.

The mill’s slim contoured design gives the operator all-round visibility to the machine. Enhanced forward visibility offers operators an unprecedented view of the cutting edge, milling track and the front danger zone around the conveyor for exceptional milling precision. A flat rear design offers an improved view of the area behind the mill for increased operating safety.

The standard water spray and dust extraction systems, complete with conveyor shrouding, efficiently removes fine particulate matter from the machine. Removing up to 80 percent more fine dust particles smaller than 10 microns in size, the optional Bomag ion dust shield meets the most stringent fine dust regulations.

With all key machine service points easily accessible, routine maintenance is completed quickly and efficiently. All filters can be conveniently reached from the operator’s platform through the wide-opening engine hood, as are the fill ports for fuel and AdBlue.

Large left- and right-hand service panels provide simple accessibility to the machine’s auxiliary drive and milling gear, while engine service points are easily accessed from both above and below.

For more information, visit www.bomag.com.

Bemidji, MN 218-751-1033 Brainerd, MN 218-829-9800 Buhl, MN 218-258-3232 Columbus, MN 651-982-5600 Crookston, MN 218-281-4245 Duluth, MN 218-722-6628

ZieglerCAT.com Fergus Falls, MN 218-736-2680

Jackson, MN 507-847-7600

Madison, MN 320-598-3150

Mankato, MN 507-388-1444

Marshall, MN 507-532-4403 Minneapolis, MN 952-888-4121 Rochester, MN 507-285-1775 Shakopee, MN 952-887-4570 St. Cloud, MN 320-253-2234 Wilmar, MN 320-235-8123 Altoona, IA 515-957-3828 Atlantic, IA 712-243-1039

Wichita, KS 316-943-4211 Chanute, KS 620-431-3600 Colby, KS 785-462-3913 Concordia, KS 785-243-1960

foleyeq.com Dodge City, KS 620-225-4121 Great Bend, KS 620-792-5246 Kansas City, MO 816-753-5300

Liberal, KS 620-626-6555 Manhattan, KS 785-537-2101 Olathe, KS 913-393-0303 Park City, KS 316-943-4211 Salina, KS 785-825-4661

Grand Rapids, MI 616-827-8000 Kalkaska, MI 231-258-8265 Macomb, MI 586-997-5300

michigancat.com Novi, MI 248-349-4800 Kalamazoo, MI 269-383-7880 Lansing, MI 517-699-4800

Fenton, MO 636-343-5900 Cape Girardeau, MO 573-332-1122 Columbia, MO 573-442-6880 Foristell, MO 636-673-2530 Joplin, MO 417-624-3010

fabickcat.com

Springfield, MO 417-866-6651 Willow Springs, MO 636-680-1359

Salem, IL 618-548-1400

Mt. Carmel, IL 636-680-1514 Troy, IL 636-660-0029 Milwaukee, WI 414-461-9100 Eau Claire, WI 715-874-5100 Green Bay, WI 920-498-8000 La Crosse, WI 608-783-4891 Madison, WI 608-271-6200

Fort Dodge, IA 515-576-3161 Mason City, IA 641-423-7240 New Hampton, IA 641-394-4226 Postville, IA 563-864-7461 Sheldon, IA 712-324-5604 Sioux City, IA 712-252-4401

Sedalia, MO 660-829-7400 St. Joseph, MO 816-233-2516 Topkea, Ks 785-266-5770

Metro South, MI 734-479-5800 Saginaw, MI 989-752-7300

Superior, WI 715-398-9696 Wausau, WI 715-359-6220 Marquette, MI 906-475-4191

866-430-7539

www.jfwequipment.com sales@jfwequipment.com S e r v i n g t h e A s p h a l t I n d u s t r y f o r 3 0 Y e a r s

New Marathon TPS500PT tack distributor, Honda gas eng, 18GPM pump, 500 gal, 5 ft spray wand w/50 ft hose, hose reel, 6 ft spray bar, operator’s platform, propane burners, flushing system, electric brakes - $26,650

2015 Hamm HD12VV double drum 47” vibratory roller, water system, Kubota diesel engine, 3 ton roller - $31,000 2006 Cat AS2301 electric screed, 10-18 ½ ft, power crown, slope & height - $4,500

2015 Laymor Sweepmaster SM400 broom, Kubota diesel engine, water system, 8 ft broom, cab w/heat & a/c, all new tires - $36,000

New Warren aggregate tailgate spreaders, GS84 & GS87, 8 ft wide maximum spreading w/1 ft gates, gravity flow - $5,900 - $6,300 New ones also available 2015 Superior DT80-K broom, Kubota diesel eng, 8 ft broom, heat & a/c, water system - $36,000

New Marathon TPS250T tack distributor, Honda gas eng, 18GPM pump, 250 gal, 5 ft spray wand w/50 ft hose, 6 ft spray bar, operator’s platform, propane burners, flushing system, electric brakes - $17,950

NAPA: New Technology Must Be Developed to Reduce Emissions

NAPA from page 40

emissions.

In 2019 alone, the industry avoided 2.9 million metric tons (MMT) CO2e emissions — equivalent to the annual emissions from approximately 630,000 passenger vehicles.

The authors note that increased implementation of such measures could further reduce emissions by up to 24 percent relative to 2019. In fact, each ton of RAP used in new asphalt mixtures reduced 2019 GHG emissions by approximately 27 kg CO2e.

However, they caution, “Although the report provides an estimate for the national average GHG emissions associated with asphalt mix production, it is not an industry average Environmental Product Declaration (EPD) and should not be used as a benchmark for project-level decision making during procurement or project delivery.”

Nonetheless, the report “will be a valuable tool as discussions with government, agencies, and owners accelerate in the coming years,” said Ron Sines, vice president, Performance — Asphalt, CRH Americas Materials Inc.

“Additionally, it provides clear direction on what the industry should be doing today, as well as what the industry could do in the future, if the identified obstacles can be overcome,” added Sines, who chaired NAPA’s Climate Stewardship Task Force, which created The Road Forward, the industry’s goal to reach net zero carbon emissions by 2050.

To advance that goal, the report states, “New technologies and additional innovative practices will need to be developed and implemented to achieve more significant GHG emission reductions.”

The industry, along with its suppliers, partners and customers, must invest in emission reduction strategies related to materials, transportation, and mix production. Examples include carbon capture, utilization and storage (CCUS); use of carbon sequestering bio-based materials; use of local recycled materials and alternative fuels for trucking; and technologies that reduce burner fuel consumption.

Raven Adams, vice chair of NAPA’s Sustainability Committee and Granite Construction’s sustainability manager, remarked, “NAPA’s publication of this document will empower our industry to advocate for the funding, research, and support needed to allow us to respond to climate change.”

RAIL from page 1 to operate more trains during rush hour and reduce travel time between Michigan City and Chicago. In addition to increased economic benefits, the project will provide more competitive travel options.

Plans call for a new station and two new high-level six-car platforms at Gary/Miller Station, along with one eight-car storage track and one four-car storage track for additional rush hour trains and an additional 519 parking spaces. At Portage/Ogden Dunes Station there will be one new high-level sixcar platform on the south side of the tracks and an additional 327 parking spaces. Other major upgrades will take place at Dune Park Station, Beverly Shores Station and 11th Street (Michigan City) Station.

The latter includes removal of embedded street-running track along 10th and 11th Streets; two new tracks south of the 10th Street ROW from Sheridan Avenue to the Amtrak crossing near Chicago Street; two new tracks along 11th Street; one high-level four-car platform; one high-level eight-car platform; a new station house with a parking structure with 437 additional spaces; and a new surface parking lot with 108 additional spaces and conversion of 11th Street to oneway automobile traffic.

“In the opening year, service is planned to operate every 16 minutes during weekday peak periods and approximately every 75 minutes during weekday off-peak periods and evenings,” said Barker. “In the horizon year, service is planned to operate every 14 minutes during weekday peak periods and approximately every 70 minutes during weekday off-peak periods and evenings. In both the opening and horizon years, service is planned to operate every 135 minutes on weekends.”

The expected ridership, using current year inputs of population and employment, is 6,000 daily linked trips. This number is expected to grow to 9,700 daily linked trips by horizon year 2040.

“This is a good time to perform the work, in that temporary reductions in ridership due to COVID allowed construction contractors to have maximum access to the rail corridor for construction purposes,” said Barker.

Construction began in early 2022 and will end in mid-2024. WSP USA Inc. is the construction manager of the project, with Walsh/Herzog Joint Venture serving as the primary contractor. Six smaller contractors, including Grimmer Construction, are handling select portions of the work.

“It’s incredibly exciting to be in the actual construction phase,” said Barker. “I’ve been working for the past seven years to get to this point. The entire team has worked so hard to get here, including our project partners at the Federal Transit Administration, Regional Development Authority, Indiana Finance Authority, the state of Indiana and other regional/local partners. It truly took a strong federal, state, regional and local collaborative effort to make this happen. Now, everyone is laser focused to bring the project in on time and within budget.

“The project will provide major improvements to travel time, which is already driving development and drawing people to the area. In essence, most commuters to downtown Chicago travel around one hour, and this project will place a large portion of our system within that hour. Given our wonderful quality of life, adjacency to natural beautiful nationally recognized landscapes like the dunes and vibrant communities, more people will be calling northwest Indiana home as a result.”

Barker noted that monitoring material availability has been critical, as the pandemic affected global supply chains and product availability.

“NICTD procured various items ahead of time to minimize risk, which was a great decision. There are various natural resource restrictions that don’t allow certain activities within certain windows to protect species of concern, such as the Indiana bat. The construction teams must carefully sequence work to ensure all work remains within those windows. The seasonality of work, when overlaid on those restrictions, requires careful attention to small schedule shifts to ensure everything is in alignment.

“We are busing most of our riders during the two-year construction period, which is a challenge for NICTD and our passengers. There also are four bridges that will be constructed. Lastly, having multiple cutovers as we return segments of track into service, along with requisite commissioning and testing and ensuring operability of our Positive Train Control system, are integral to the success of the project.”

Barker explained that moving the streetrunning tracks along 10th and 11th Streets in Michigan City is among the necessary tasks for crews.

“On 11th Street, space is very limited. As a result, we are converting the roadway from a two-way to a one-way single lane street on a permanent basis. The track will be fully separated from the roadway. On 10th Street, we acquired all the houses south of the tracks so we could shift our tracks out of the road and be fully separated from the roadway in the permanent condition.”

Currently, substantial work is taking place in Michigan City, with construction expected to end in the area in November. Crews also are installing culverts throughout the project, and major sewer work is under way in Gary. Teams are preparing to begin con-

NICTD/South Shore Line photo Crews are installing culverts throughout the project and major sewer work is under way in Gary.

Y EXCLUSIVEINDUSTR TIC TAUTOMA TRACK TENSIONING SYSTEM

Star Equipment, Ltd.

starequip.com

1401 2nd Avenue Des Moines, IA 50314 515-283-2215

2950 6th Street SW Cedar Rapids, IA 52404 319-365-5139 2625 W Airline Hwy. Waterloo, IA 50703 319-236-6830 2100 E Lincoln Way Ames, IA 50010 515-233-9500

Looking for a simple way to improve your grading performance? Now, with Komatsu’s easy and affordable Smart Construction Retrofit Kits, conventional Komatsu excavators can be equipped with 3D guidance and payload monitoring, giving operators and managers alike more ways to help work efficiently and accurately, according to the manufacturer.

Designed to improve grading performance and provide more time- and cost-management tools, Smart Construction Retrofit can bring 3D to most Komatsu excavators in your fleet. Easily installed by a local Komatsu distributor, Smart Construction Retrofit is a low-cost guidance kit that gives operators in the field and managers in the office access to 3D design and payload data to help drive accuracy, control load volumes and improve operations.

“No matter where you are in your Smart Construction journey, we have the expertise to help you integrate and optimize your fleet, based on your specific needs,” said Komatsu’s Ron Schwieters, senior product manager, customer solutions.

Benefits of Smart Construction Retrofit • Gives operators the latest design data • Measures payload volume and load counts • Lets you monitor production from the office

Once a conventional excavator is fitted with Smart Construction Retrofit, operators no longer have to set up a laser or bench every time the machine moves. The global navigation satellite system (GNSS) can determine where a machine is on the job site and what the target grade is. The need for additional labor is reduced because the technology collects and delivers information directly to the operator, so fewer people have to be working on the ground, or in an open trench. Increase Productivity

Machine production can be monitored from the office by integrating Smart Construction applications, and as-built and payload data can be collected for progress tracking. With Smart Construction Retrofit you can reduce handling and reworking material which helps drive both productivity and profitability. The payload meter helps prevent overloaded trucks by promoting proper loading weights for on- and off-road vehicles, to reduce the potential for equipment damage and other risks.

For more information, visit www.komatsu.com.

Organizations offering CDL training must be listed on the FMCSA’s Training Provider Registry.

RULE from page 1

Kevin Ridens, director of product support of Ditch Witch Midwest, sees the new rule as a huge burden on employers who are not dedicated motor carriers, but use Class A vehicles to do business every day.

What Passed in the Past

Before the rule went into effect in February, the CDL licensing process was no different than getting a driver’s license.

Candidates studied an instruction book, got their permit and hit the road. They had to pass an inspection and prove they could understand technical terms related to operating a Class A vehicle.

The company would set a timeline and set a licensing window for the employee. The company would say, “You have four months to go get your CDL.”

The employee would study the CDL information in an instruction book, take a test and get the permit.

“The rest of that time he was driving with someone who already had a CDL as his partner,” said Ridens.

Beyond the CDL, still today if the employee is set to be an airbrake driver when he comes in, an automatic is all he’ll be endorsed for.

If he’s going to drive a stick, he’s regulated for everything, explained Ridens.

“But it was all in the hands of that employee to go get everything he needed in the way of licensing and endorsements,” said Ridens.

With the new rule, any driver who doesn’t currently have a commercial Class A license is affected.

In Ridens’ office at Ditch Witch, that’s currently seven people, but it will challenge new hires who don’t come on board with a CDL in hand.

And, if a carrier provides training to employees seeking a CDL, the carrier now has to register as a TPR-approved training provider.

However, the carrier as employer can customize the program to include in-house rigspecific instruction as well as company policy and procedure.

The rule applies to not only over-the-road truck drivers, but anyone applying for a Class A commercial license.

Model Loader Loader Loader Backhoe Max Travel Speed Operating SAE Lift Capacity Breakout Force Loading Height Digging Depth 4th Gear Fwd Weight HP (kW) lbs. (kg) lbs. (kg) ft. (m) ft. (m) MPH (kmh) lbs. (kg)

CASE

580N 90 (67) 6,803 (3,086) 10,622 (4,818) 11.9 (3.6) 14.9 (4.5) 24.6 (40) 16,589 (7,525) 580 Super N 97 (72) 7,044 (3,195) 10,947 (4,965) 12.1 (3.7) 14.6 (4.4) 24 (38.8) 17,269 (7,833) 580 Super N WT 110 (82) 8,425 (3,821) 10,873 (4,932) 12.0 (3.7) 14.6 (4.4) 24.1 (38.8) 20,077 (9,107) 590 Super N 110 (82) 8,202 (3,720) 12,776 (5,795) 13.1 (4) 15.6 (4.8) 25.2 (40.6) 20,532 (9,313) 580N EP 74 (55) 6,503 (2,950) 9,607 (4,358) 11.7 (3.6) 15 (4.6) 21.3 (34) 15,810 (7,171)

CATERPILLAR

415 70 (52) 6,730 (3,053) 12207 (5,537) 12 (3.7) - 13.9 (4.2) 14.2 (4.3) 23 (37) 15,426 (6,997) - 24,251 (11,000) 415 IL 69 (51) 5,862 (2,659) 10,898 (4,943) N/A N/A 22 (36) 17637 (8,000) 416 86 (64) 6,730 (3,053) 12207 (5,537) 12 (3.7) - 13.9 (4.2) 14.2 (4.3) 25 (40) 15,591 (7072) - 24,251 (11,000) 420 92 (68) 7,230 (3,280) 12,643 (5734) 12 (3.7) - 13.9 (4.2) 14.2 (4.3) 25 (40) 16,279 (7384) - 24,251 (11,000) 420 XE 92 (68) 7,230 (3,280) 12,643 (5734) 12 (3.7) - 13.9 (4.2) 14.2 (4.3) 25 (40) 16,279 (7384) - 24,251 (11,000) 430 107 (80) 7,230 (3,280) 12,643 (5734) 13 (3.9) - 15.1 (4.6) 15.5 (4.7) 26 (41) 16,590 (7625) - 24,251 (11,000) 440 104 (76) 8,782 (3,983) 13,560 (6,151) 13.5 (4.1) - 15.4 (4.7) 15.5 (4.7) 24 (39) 21,544 (9,772) - 29,321 (13,300) 450 131 (98) 8,886 (4,031) 13,560 (6,151) 14.9 (4.5) - 17.3 (5.3) 17.0 (5.2) 25 (40) 24,039 (10,904) - 29,321 (13,300)

JCB

1CXT 49 (36.3) 1,466 (665) 5,180 (2,350) 8-9 (2.67) 10-1 (3.08) 4.6 (7.5) 9,572 (4,342) 3CX Compact 74 (55) 3,364 (1,526) 8,285 (3,758) 12-3 (3.72) 14-2 (4.33) 24.9 (40.1) 13,514 (6,130) 3CX 74 (55) 7,705 (3,495) 13,603 (6,170) 15-6 (4.72) 18-6 (5.63) 22.8 (36.7) 17,196 (7,800) 3CX-14 74 (55) 7,670 (3,479) 13,603 (6,170) 14-0 (4.27) 18-6 (5.63) 22.8 (36.7) 17,704 (8,030) 3CX-14 Super 91 (68) or 109 (81) 9,233 (4,188) 13,603 (6,170) 14-0 (4.27) 18-6 (5.63) 26 (41.8) 18,614 (8,443) 3CX-15 Super 109 (81) 10,225 (4,638) 13,603 (6,170) 15-3 (4.65) 20-1 (6.12) 26 (41.8) 19,090 (8,659) 4CX-14 Super 109 (81) 10,225 (4,638) 13,728 (6,227) 14-0 (4.27) 18-6 (5.63) 26 (41.8) 19,172 (8,696) 4CX-15 Super 109 (81) 10,225 (4,638) 13,728 (6,227) 15-3 (4.65) 20-1 (6.12) 26 (41.8) 19,648 (8,912)

JOHN DEERE

310L EP 69 (52) 6,610 (2,998) 9,564 (4,338) 11.5 (3.48) 13.8 (4.16) 23.6 (38.0) 13,822 (6,270) 310L 100 (75) 6,602 (2,995) 9,512 (4,314) 11.1 (3.38) 14.1 (4.30) 22.8 (36.7) 14,669 (6,654) 310SL 103 (77) 7,698 (3,492) 11,052 (5,013) 11.3 (3.42) 14.3 (4.35) 23.1 (37.1) 15,872 (7,199) 310SL HL 113 (84) 7,552 (3,425) 11,116 (5,042) 11.11 (3.63) 15.1 (4.59) 23.9 (38.4) 16,571 (7,516) 315SL 103 (77) 7,225 (3,277) 10,608 (4,812) 12.0 (3.65) 13.5 (4.08) 24.7 (39.7) 17,554 (7,962) 410L 116 (87) 6,967 (3,160) 10,361 (4,701) 13.0 (3.97) 15.11 (4.85) 23.9 (38.4) 17,786 (8,068) 710L 148 (110) 9,866 (4,475) 16,539 (7,505) 14.7 (4.45) 17.3 (5.26) 22.9 (36.9) 25,588 (11,607)

KUBOTA

B26TLB 24.3 (18.1) 1,301 (590) 2,343 (1,062) 6.4 (1.9) 8.3 (2.5) 11.1 (17.8) 4,001 (1,815) L47TLB 47.1 (35.1) 2,848 (1292) 4531 (2,055) 7.7 (2.4) 10 (3) 14 (22.5) 7,205 (3,268) M62TLB 63 (47) 3,960 (1796) 5,992 (2,717) 10.9 (3.3) 14.2 (4.3) 15.5 (24.9) 8,925 (4,048)

MECALAC

TLB840R 74 (55) 8,287 (3,759) 10,341 (4,691) 13.8 (4.2) 17.10 (5.4) 24 (38) 16,138 (7,320)

NEW HOLLAND

ILLINOIS

ALTA 479Bloomington • 855-5 4-0 75

Orand Park • 877-823-4965

Ottawa • 815-324-3697

South Elgin • 877-823-4965

Spring Grove • 815-581-1530

Wauconda • 877-823-4965 DIAMOND EQUIPMENT, INC.

Mt. Vernon • 618-242-2273 O’LEAR RY YS

Chicago • 773-252-6600 SUNBEL LT EARTH MOVING SOLUTIONS 5-Morris • 81 941-1900 REXCO

Quad Cities • 563-381-1200

INDIANA

ALTA 40-09Gary • (219) 2 946 B & W EQUIPMENT CO., INC.

Fort Wayne • 260-422-0945 CONSTRUCTION MACHINER RY Y CO RPM MACHINER te • 7

CONSTRUCTION MACHINER CO.

Jeffersonville • 812-850-6160 DIAMOND EQUIPMENT, INC.

Evansville • 812-425-4428 99-47Terre Haute • 812-2 74 47 YR , , LLC

Fort Wayne • 260-888-3735

Lafayet 6 65-300-4572 IOWA

JW BELL

Cedar Rapids • 319-362-1152 MIDWEST UNDERGROUND SUPPL LY

Bondurant • 515-967-5656 REXCO EQUIPMENT T INCREXCO EQUIPMENT, , INC.

Cedar Rapids • 319-393-2820

Davenport • 563-381-1200

Des Moines • 515-287-4910 ANTIT MACHINER RY 9-Sioux City • 712-23 49 941 WISE EQUIPMENT

Council Bluffs/Omaha • 402-597-0860 KANSAS

G. .W. ANVA KEPPEL COMP PA ANY

Garden City • 620-272-0535

Kansas City • 913-281-4800

Topeka • 785-357-2652

Wichita • 316-945-6556 KENTUCKY

CONSTRUCTION MACHINER RY Y CO.

Carrollton • 502-732-4661

Louisville • 866-901-2262

Owensboro • 877-683-2262 DIAMOND EQUIPMENT, INC.

Bowling Green • 270-781-1061 MCKEEL EQUIPMENT CO., INC.

Paducah • 270-444-0110 RUDD EQUIPMENT

Louisville • 502-456-4050 MICHIGAN

TMICHIGAN CA - CORPORA 9-7

0-Burton • 81 74 44-4840 8-Bryon Center • 616-87 74 450 New Hudson • 248-356-5200 Sterling Heights • 586-977-6000 Wixom • 248-449-6700 A AT TE Brownstown Twp. • 734-479-5800 Grand Rapids • 616-827-8000 Kalkaska • 231-258-8265 Mason • 517-699-4800 Novi • 248-349-4800 Portage • 269-383-7880 Saginaw • 98 52-7300 Shelby Twp. • 586-997-5300 RPM MACHINERY, , LCC Dorr • 616-371-7250 MINNESOTA

HA AY YDEN-MURPHY EQUIP PMENT CO.

Minneapolis • 952-884-2301 MCCOY CONSTRUCTION && FORESTR RY 22Duluth • 218-7 -74 456

Grand Rapids • 218-326 6-94 4276 9Grand Rapids 218 32 NUSS TRUCK EQUIPMENT 9Burnsville • 952-8 4 4-9595 53-Sauk Rapids • 320-2 69 941 TRENCHERS PLUS

Burnsville • 952-890-6000 MISSOURI

CROWN POWER & EQUIPMENT CO.

Columbia • 573-443-4541

Eldon • 573-392-0230

La Monte • 660-347-5855

Jefferson City • 573-636-5281 .G.W ANVA KEPPEL COMP PA ANY

Springfield • 417-865-3550

St. Louis • 314-872-8440 Omaha • 402-597-0860

WHEN N YEVER STRIK

E COUNTS, COUNT ON RAMMMER

x e Rammer ExhT aulic hadrycellence line h smmer and Ho- ac coP e astrik fter stri

.cammerVisit r

NEBRASKA

MIDWEST UNDERGR

Omaha • 402-861 ANTIT MACHINER RY

Lincoln • 402-464-

North Platte • 308

Omaha • 402-733 WISE EQUIPMENT OUND SUPPL LY -6500 3711 -532-6571 7-3 0 00

NORTH DAKOTA

ASCENDUM MACHINER RY

Bismark • 701-250-4882

Fargo • 701-271-2360

Williston • 701-577-1249 FARGO TRACTOR

Fargo • 701-282-5290 AN MACHINERTIT RY

Bismarck • 701-250-7925

Dickinson • 701-227-5309

Fargo • 701-237-3333 1-Grand Forks • 70 77 75-8108

Minot • 701-852-3188

Williston • 701-577-0024 Monroe • 513-539-5255 Richfield • 330-659-0800 7Toledo • 419-8 4 4-6001

S oduee Rammer Pr cts

OHIO

HIGHWAW Y Y EQUIP PMENT CO. OF OHIO

Canton • 330-915-8391 LESLIE EQUIPMENT COMPANY

Marietta • 74 40 0-373-5255 RECO EQUIPMENT, INC.

Belmont • 7 74 40 0-782-1314

Columbus • 61 74-2 6-0001

SOUTH DAKOTA

MIDWEST UNDERGROUND SUPPL LY Y

Harrisburg • 605-368-9880 ANTIT MACHINER RY

Aberdeen • 605-225-0505

Rapid City • 605-388-0266

Sioux Falls • 605-336-3434 TRANSOURCE TRUCK & EQUIPMENT 69Rapid City • 605-342-5 94

Sioux Falls • 605-336-2000 , Waukesha • 800-242-9559

WISCON NSIN

BROOKS TR RACTOR, INC.

De Pere • 920-336-5711

Milwaukee e • 414-462-9790

Plover • 7 715-254-2777

Sun Prairie e • 608-837-5141

West Salem • 608-786-2644 L.F. GEORG GE, INC. MCCOY CONSTRUCTION & FORESTR RY

Ashland • 715-682-5522

Chippewa Falls • 715-834-2924

Merrill • 715-536-0633

Loader backhoes have been an efficient tool in every operation bringing maximum force and surgical precision from either end of the machine.

New Holland Construction’s B75D loader backhoe, its economy class solution, is ready to tackle a wide range of projects with 74 gross hp, over 18 ft. of maximum digging depth and standard 4WD.

“Adding the economy level B75D loader backhoe is the new solution for diverse operations,” said Ryan Anderson, construction product marketing manager, New Holland North America.

The B75D offers fuel-efficient power with a simple, costeffective Tier IV Final solution. The 74-hp 3.4-L FPT engine features a diesel oxidation catalyst (DOC) for increased fuel efficiency and faster response times. No fluids to add or diesel particulate filters to replace means simplified maintenance to operator.

Standard 4WD and a power shuttle synchromesh transmission with four forward and four reverse gears puts the operator in complete control in nearly any job or terrain. The operator environment of the B75D keeps safety at the forefront with a ROPS/FOPS certified canopy. Four front and two rear halogen work lights keep the operation running into the night.

For more information, visit www.newholland.com.

The B75D offers fuel-efficient power with a simple, cost-effective Tier IV Final solution. The 74-hp 3.4-L FPT engine features a diesel oxidation catalyst (DOC) for increased fuel efficiency and faster response times.

Deere Improves Performance With Its L-Series Upgrades

John Deere’s L-Series backhoe loaders offer significant machine improvements designed to boost productivity, maximize uptime and reduce operating costs.

Ranging across the L-Series Backhoe lineup includes engine upgrades, pressurecompensated load-sensing (PCLS) hydraulics on the 310SL model and machine control improvements, enhance operation and machine performance.

The 310L, 310SL, 315SL, 310SL HL and 410L models are equipped with a 4.5L John Deere PowerTech EWL engine, increasing power, improving torque and providing greater reliability. This Final Tier IV engine results in a boost in horsepower across the models, while the removal of the exhaust gas recirculation system and components improves reliability, according to the manufacturer.

The L-Series also includes improved filter locations for easier access when changing or servicing fuel and diesel exhaust fluid filters. Additionally, the 310SL is now available with PCLS hydraulics.

Already offered on the 310SL HL, 410L and 710L, the PCLS system results in increased productivity and improved backhoe controllability at any engine speed. In addition, trenching operation can be conducted at lower engine rpm, reducing fuel consumption and lowering job site noise.

“We are committed to continuously improving our equipment to offer our customers more value out of their machines,” said Brian Hennings, product manager, John Deere. “With these upgrades, we are directly addressing our customers’ needs. These features build upon the best features found on the L-Series machines, resulting in a lineup designed to power through the toughest jobs.”

The 310SL is equipped with Lift Mode. When enabled, it automatically sets the engine speed to 1,400 rpm and increases max hydraulic pressure to 4,000 psi, for up to a 10 to 15 percent increase in backhoe lift capacity. Additionally, buttons for the horn, selective flow, auxiliary proportional roller and extendable dipper stick have been integrated into the backhoe pilot controls, improving ease of use.

Available as a base offering on the 310SL, 315SL, 310SL HL, 410L and 710L models, AutoShift technology automatically adjusts the transmission to the most appropriate gear for an enhanced operator experience. Additionally, the five models feature Auto Ride Control as the only ride control option, eliminating the need to manually turn on and off during load and carry applications. Auto Ride Control enhances ease of use, improves ride quality and reduces front bucket material spillage.

Other key features include an LED boom light kit for increased visibility to the bottom of the trench and a redesigned loader lever linkage that reduces resistance and improves its throw and feel.

The 310L EP model includes designs to deliver more value at an economical price. The 310L EP includes a simpler front-axle design and a four-speed manual synchromesh transmission. Directional changes remain controlled with a steering column mounted lever for forward, neutral and reverse.

For more information, visit www.deere.com/.

The 310L, 310SL, 315SL, 310SL HL and 410L models are equipped with a 4.5L John Deere PowerTech EWL engine, increasing power, improving torque and providing greater reliability.

Sales • Service • Parts • Rentals

Contact your local authorized Takeuchi dealer:

3

Alta Equipment Company

5105 Loraine Street • Detroit, MI 48208 313-394-1811 56195 Pontiac Trail • New Hudson, MI 48165 248-356-5200 8840 Byron Commerce SW • Byron Center, MI 49315 616-878-7450 3283 S Dort Hwy. • Flint (Burton), MI 48529 810-744-4840 3725 Old 27 S • Gaylord, MI 49735 989-731-9988 7500 E 15 Mile Road • Sterling Heights, MI 48312 586-474-5063 1061 Stepke Court • Traverse City, MI 49685 231-714-6210 613 E Stevenson Road • Ottawa, IL 61350 815-313-2070 www.altaequipment.com

McCann Industries

543 S. Rohlwing Rd • Addison, IL 60101 630-627-0000 250 E. North Frontage Rd. • Bolingbrook, IL 60440 630-739-7770 2350 S. Laflin St. • Chicago, IL 60608 312-942-9200 4701 West 137th Street • Crestwood, IL 60445 708-597-3110 900 Louisiana Street • Merrillville, IN 46410 219-576-7800 1133 Indianapolis Blvd. • Schererville, IN 46375 219-865-6545 1360 N. Rand Rd. • Wauconda, IL 60084 847-526-9444 4102 W. Crystal Lake Rd. • McHenry, IL 60050 815-385-0420 www.McCannOnline.com

Star Equipment Ltd.

1401 2nd Avenue • Des Moines, IA 50314 515-283-2215 • 800-369-2215 2625 W. Airline Hwy. • Waterloo, IA 50703 319-236-6830 • 800-791-9249 2950 6th Street SW • Cedar Rapids, IA 52404 319-365-5139 • 800-728-5139 2100 E. Lincoln Way • Ames, IA 50010 515-233-9500 • 866-856-2312 www.starequip.com Kirby-Smith Machinery, Inc.

8320 Ruby Avenue Kansas City, KS 66111 913-850-6300 877-851-5729 www.kirby-smith.com

Kelbe Brothers Equipment Co.

12770 W. Silver Spring Drive • Butler, WI 53007 262-781-4970 4621 Dutch Mill Rd. • Madison, WI 53716 608-221-8300 3101 French Rd. • De Pere, WI 54115 920-343-6496 www.kelbebros.com

Wilson Equipment Company

2180 Old Frankfort Pike • Lexington, KY 40510 859-254-6443 • 800-432-0913 828 W. Cumberland Gap Pkwy • Corbin, KY 40701 606-528-0700 • 800-274-9457 2124 Watergap Road • Prestonsburg, KY 41653 606-874-8036 • 800-955-9457 www.wilsonequipment.com

Equipmentshare

8376 I-70 Dr SE • Columbia, MO 65201 573-273-4525 www.equipmentshare.com

Diamond Equipment Inc.

1060 Diamond Avenue • Evansville, IN 47711 800-258-4428 • 812-425-4428 120 Flex Park Drive • Bowling Green, KY 42103 800-489-1061 • 270-781-1061 17035 North IL Hwy 37 • Mt. Vernon, IL 62864 800-388-6396 • 618-242-2273 2000 Harlan Drive • Terre Haute, IN 47802 888-343-4747 • 812-299-4747 www.diamondequipment.com Columbus Equipment Company

2329 Performance Way • Columbus, OH 43207 614-443-6541 12500 Williams Rd. • Perrysburg, OH 43551 419-872-7101 712 Shepherd Ave. • Cincinnati, OH 45215 513-771-3922 3942 Brecksville Rd. • Richfield, OH 44286 330-659-6681 290 Old Steubenville Pike • Cadiz, OH 43907 740-942-8871 7570 New Carlisle Pike • Dayton, OH 45424 937-879-3154 2200 Venture Circle SE • Massillon, OH 44646 330-833-2420 818 Lee St. • Zanesville, OH 43701 740-455-4036 864 Richmond Rd. • Painesville, OH 44077 440-352-0452 3668 US Route 23 South • Piketon, OH 45661 740-289-3757 www.columbusequipment.com

Brandeis Machinery & Supply Company

17000 Highway 41 N Evansville, IN 47725 812-425-4491 7310 Venture Lane Fort Wayne, IN 46818 260-489-4551 8410 Zionsville Road Indianapolis, IN 46268-1524 317-872-8410 1801 Watterson Trail Louisville, KY 40299 502-491-4000 www.brandeismachinery.com

FPT Industrial Touts Sustainable Future of Powertrains at Event in Turin, Italy

From July 13 to 17 at the Officine Grandi Riparazioni (OGR) in Turin (Italy), Iveco Group and its brands hosted their many stakeholders for a major, carbon-neutral event called BEYOND — Iveco Group Days.

The aim was to shed light on Iveco Group’s integrated structure and internal business ecosystems, while sharing the company’s purpose, values and future roadmap based on three strategic pillars: technology, sustainability and partnership.

FPT Industrial took center stage on both July 14 and 15 with Sylvain Blaise, president of the Iveco Group Powertrain Business Unit and brand president of FPT Industrial, and two propulsion-themed roundtables.

In his keynote speech “The future of Powertrains”, Blaise stressed the key role that powertrain manufacturers play in developing the powertrain of the future in order to achieve carbon neutrality, and how it is necessary to approach the route to sustainability in a holistic way, with a complete view of the cycle. In addition, he highlighted the importance of low- or zero-carbon energy in terms of sourcing and distribution in achieving the set goals.

It also means ensuring continuity and competitiveness in strategic sectors that use current products and technologies, as well as developing new and greener propulsion solutions designed to be delivered to and adopted by the widest possible customer base in the shortest possible time.

These high-profile themes were discussed in the following roundtables: “Focus on propulsions: technological roadmap”, moderated by Fabrizio Goria, Financial Reporter at La Stampa, and “Propulsion evolution and partnerships ecosystem”, moderated by Alberto Onetti of Mind the Bridge, further evidencing the next steps that FPT Industrial and its partners are taking together.

At the first meeting, participants including Philip Scarth, head of open innovation at FPT Industrial, and Giorgio Ricci, head of manufacturing at FPT Industrial, shared ideas about the future of internal combustion engines as one of the many solutions to reduce emissions and their importance in current agricultural and construction industries, while also discussing the impact of electric evolution on powertrain manufacturing.

During the talk, the speakers indicated the direction that FPT Industrial wants to take, becoming a “game changer” in the electrification era and positioning itself at the center of an ecosystem of skills.

The second roundtable featured, among others, Pierpaolo Biffali, vice president of product engineering at FPT Industrial, who presented the brand’s vision about the decarbonization of industrial On-Highway and Off-Highway sectors. This vision includes a close collaboration with each partner combined with continuous leveraging of both its specific powertrain expertise and partners’ market experience to develop sustainable and successful projects together.

FPT Industrial thanks all its guests and partners who joined the event for their valuable contributions, which further reinforced the open, collaborative, forward-looking spirit that underlies all of FPT Industrial’s partnerships: For the “Focus on propulsions: technological roadmap” roundtable: Daniela Vinci, CEO of Masmec, Sascha Kelterborn, president of Microvast, and Neeta Khare, director of Battery, Fuel Cells & MD at Potenza. For the “Propulsion evolution and partnerships ecosystem” roundtable: Anirudh Bhuwalka, CEO of Blue Energy Motors, Chris Mann CTO of Bennamann, Francesco Farinetti, CEO at Green Pea, board member at Eataly, Partnerships at Fontanafredda, Oscar Baroncelli, head of Tractor Product Management at New Holland Agriculture, and Alessandro Rossi, chief technical officer at Azimut Benetti Group.

For more information, visit www.fptindustrial.com. Midland Engine

www.midlandengine.com 622 Jefferson Ave. Midland, MI 48640 989-631-4608

CSTK

www.cstk.com 401 Shawnee Avenue Kansas City, KS 66105 913-371-0868 Reco Equipment, Inc.

www.recoequip.com 4250 Perimeter Dr. Columbus, OH 43228 614-276-0001 Monroe (Dayton Area), OH 513-539-5255 Perrysburg (Toledo Area), OH 419-874-6001 Florence, KY 859-727-7970 Indianapolis, IN 317-781-8100

Hardings Heavy Equipment

www.hardingsinc.com 109 W. Commercial Ave. Lowell, IN 46356 219-696-8911

Yes Equipment & Services

www.yesequipment.com 11715 W. Silver Spring Rd. Milwaukee, WI 53225 414-263-9001 Madison, WI 608-243-9253

Buck & Knobby Equipment Co.

www.buckandknobby.com 6220 Sterns Rd. Ottawa Lake, MI 49267 MI 734-856-2811 OH 419-476-5293 Diamond Equipment

www.diamondequipment.com 17035 N. Illinois Hwy. 37 Mt. Vernon, IL 62864 618-242-2273 • 800-388-6396 Evansville, IN 812-425-4428 Terre Haute, IN 812-299-4747 Bowling Green, KY 270-781-1061

Team Boone

www.teamboone.net 150 Schuler Dr. Bardstown, KY 40004 502-369-2475 136 Ferguson Lane Shepherdsville, KY 40165 502-215-6235

I-69 Highway Project Puts Hoffman Bros. Sizable Technology Investment in Focus

HOFFMAN from page 20 models for our operators and send them off.”

However, when it came to delivering up-to-date models to the machines in a timely manner, connectivity became a problem.

The company reached out to Trimble distribution partner SITECH Michigan for advice and were intrigued to learn about Trimble’s Internet Base Station Services (IBSS), a solution that broadcasts Real-Time Kinematic (RTK) corrections from the base station over the Internet, delivers highly accurate GNSS for site positioning and machine control at a low cost.

“SITECH Michigan Rep, Jason Winger, gave us a demonstration, and we were impressed. We decided to give it a try, and after just a day or two of training, we were up and running on our own,” said Bell. “With IBSS, we can connect to all of our equipment from one single base station, which proved invaluable on the I-69 project. As a design-build project, changes happen regularly to fit the existing conditions or accommodate the schedule, and we need to adapt. The transfer of data to our equipment on the job site has been seamless, particularly to the Trimble Earthworks solution.”

Hoffman Bros. completed the first phase I-69 project earthwork on time and on budget.

Partners in Progress

As the project team prepares for the second phase of the I-69 project this year, they also are continuing to look for ways to advance and improve their workflow.

For instance, Bell is looking forward to testing Trimble WorksOS for as-built validation this year on the I-69 project. He’s also looking to give field crews visualization capabilities similar to what operators have using Trimble SiteVision, an augmented reality solution that enables project teams to see spatial data in a real-world context. With Trimble SiteVision, field crews can use Android phones to conduct inspections, track progress and make quick survey measurements—and particularly important on this design-build project, help communicate design adjustments.

“In today’s highly competitive environment, it’s essential that we provide our people with the best possible tools to deliver jobs,” said Bell.

“We’ve utilized Trimble grade con-

Keaton PR photo The company takes advantage of a full range of machine control configurations, including GNSS, lasers, Trimble SPS930 Universal Total Stations and even sonic tracers for slope control as needed. Keaton PR photo Hoffman is considered a regional leader in the implementation of construction technology. trol solutions for more than 20 years on our projects to increase production, decrease costs and improve worker safety,” said Bill Rizor, Hoffman project manager. “The production gains we have realized through the utilization of grade control technology has helped to shape the ‘Hoffman way’ of performing earthwork and grading operations. In cooperation with SITECH and our engineering partners, we continue to find new ways to improve our project workflows utilizing the latest technological advancements Trimble has to offer.” The I-69 Rebuild project in Eaton and Calhoun counties continues in 2022 with work on phase two, a 12-mi. stretch of the corridor on the northbound side and then the same stretch on the southbound side in 2023. BRANDEIS MACHINERY & SUPPLY COMPANY

www.brandeismachinery.com 1801 Watterson Tr. Louisville, KY 40299 502/491-4000 Evansville, IN 812/425-4491 Corbin, KY 606/528-3700 Lexington, KY 859/259-3456 Stanville, KY 606/478-9201 Paducah, KY 270/444-8390 Indianapolis, IN 317/872-8410 Ft.Wayne, IN 260/489-4551

ROAD BUILDERS MACHINERY & SUPPLY CO., INC.

www.roadbuildersmachinery.com 1001 S. 7th St. Kansas City, KS 66105 913/371-3822 Omaha, NE 402/331-9200 Lincoln, NE 402/325-0447 Grand Island, NE 308/384-2620 Norfolk, NE 402/316-2606

ROAD MACHINERY & SUPPLIES CO.

www.rmsequipment.com 5633 W Hwy 13 Savage MN 55378 952/895-9595 • 800/888-9515 Duluth, MN 218/727-8611 • 800/888-9535 Virginia MN 218/741-9011 • 800/752-4304 Des Moines IA 515/282-0404 • 800/555-1445 Sioux City IA 712/252-0538 • 800/633-9104 Cedar Rapids IA 319/363-9655 • 800/616-6615 East Moline, IL 309-755-7203 • 800-633-9114

MANUFACTURING from page 16 industry do every single day,” said Kip Eideberg, AEM’s vice president of government and industry relations.

“Lawmakers in Washington and in state capitals across the country make decisions that impact our jobs and our communities, and these photos will hopefully help them recognize that their decisions have real-life consequences for hardworking Americans.

To encourage investment, job growth and development and production of more equipment in the United States, AEM advocates on behalf of its more than 1,000 members to urge state and federal lawmakers to champion policies that create a globally competitive business environment, rebuild our nation’s infrastructure, open foreign markets for equipment manufactures in the United States and keep the U.S. agricultural economy strong.

The association’s membership represents companies with more than 200 product lines

Candace Hills installs wheel hubs on the skid steer mainline.

JCB

“JCB North America and our team members were honored to recently host the AEM team and support the important work they are doing with the Through the Lens: Equipment Manufacturers Make America photo series,” said Tonya Poole, vice president of human resources, JCB North America.

“Our team members are the backbone of our success in North America and serve to further demonstrate the impact manufacturing has on the American economy through their work. We are excited this project provided the opportunity to highlight, our hard-working team members that produce the equipment necessary to build, feed and defend America.” in the agriculture, construction, mining, forestry and utility industries.

To continue following the Through the Lens: Equipment Manufacturers Make America photo series, follow I Make America’s Facebook, Instagram and Twitter accounts. (All photos courtesy of Brad Romano/Association of Equipment Manufacturers)

Power Curbers Inc.

“Power Curbers Companies is pleased to participate in AEM’s photo storytelling project,” said Stephen Bullock, CEO of Power Curbers Inc.

“As our equipment is used in road building projects from major U.S. interstates to rural roads in developing countries, we are proud to have a role in connecting people across the globe.

“There’s no better way to show who we are as a manufacturer than through pictures of our hardworking associates at their craft.

Perry Campbell, a Power Curbers plasma table operator, deburs a mold mounting component cut from 1.5-in. steel plate.

Kubota

“The team members representing Kubota equipment manufacturing businesses in North America were so excited to be a part of this project and to help tell the amazing story of how American ingenuity and manufacturing skills are alive and well today,” said Phil Sutton, vice president of Kubota Manufacturing of America Corporation and Kubota Industrial Equipment Corporation.

“The significant contributions of our team and our more than 400 supply base partners represent a huge economic impact all across this nation.

“With North America being Kubota’s most important market, our growth and strength in the manufacturing sector has made our philosophy ‘Local Production for Local Consumption’ into reality. Thank you AEM for featuring our dedicated team as part of the pictorial history of manufacturing in America! On Your Side!”

LeeBoy painters are spraying several racks of miscellaneous weldment parts.

LeeBoy

“LeeBoy is a proud supporter of the Association of Equipment Manufacturers and its grassroots and advocacy efforts,” said Brian Bieller, LeeBoy president and CEO.

“This photo series gave us the opportunity to showcase the men and women responsible for building the world’s most dependable and productive commercial asphalt paving equipment.

Attention Contractors!

Post Your Wanted To Buy Listings FREE!

Here’s How! List Your Wanted Items. If you would like to place your Wanted To Buy listings on our website for inclusion in our newsletters, simply visit: www.ConstructionEquipmentGuide.com/wanted-to-buy and enter your listings. Inappropriate or Sale Ads will be Deleted