12 minute read

PRINOTH T6, T8, T12 Crawler Carriers

After selling several hundred vehicles throughout the world in the last years, Prinoth listened to its customers and learned from their usage of the units — the legacy fleet has now been improved to boost the productivity levels, the manufacturer said. Specifically on the bare chassis version, the payload has been increased by about 2,000 lb. per model and now allows for even more implements and tools to be installed, which will provide even more versatility to an already very agile fleet.

Prinoth continues to unveil its next generation of Panther crawler carriers — the Panther T6, T8 and T12.

Sturdier, Even Quicker

Following the improvements on the rotating dumper models, the Panther T14R and T7R, Prinoth is happy to report efficient changes into the T6, T8 and T12 vehicles’ design to improve their operation levels and maximize capacities. By boosting the speed on most of the units, especially the Panther T12 which now presents with a 35 percent speed increment, Prinoth strives to help its customers do more with less like moving less dead weight, fitting bigger implement on smaller machines and continually increasing their profitability on the jobs that they land.

“Our company purpose statement is ‘Your success is our passion’.

“We’ve made tremendous productivity improvements on the Panther T12. These changes will bring the T12 neck to neck with its rotary sister model, the Panther T14R renowned for being best-in-class for ground speed levels.

“Current business conditions dictate that ‘the doing more with less’ approach is the name of the game. That is why the Prinoth corporate culture calls for us to listen closely and communicate constantly with our customers, while using an agile approach to provide long lasting solutions to the specialized off-road construction market,” said Prinoth CEO Alessandro Ferrari.

For the first time, the Panther T12 dumper model will be available with the unique spacious wide cab giving much more room for operators whilst keeping the steering wheel and foot throttle pedal driving system.

“Our vehicles drive just like any truck and this system is part of providing comfort to the operator which we feel is as important to the operator as it is to the contractor who employs them. We’re constantly pushing the envelope and aiming to have the best operator comfort as it clearly boosts productivity,” said Product Manager Patrick Hébert. simply provide customers with the best uptime with these vehicles. Panther crawler carriers continually provide unparalleled uptime and performance by virtue of the vehicles’ high-quality components and built and by working into unit designs less hassle for scheduled or preventive maintenance involving key components that could put the machine down for hours, the manufacturer said.

“Prinoth vehicles are built on an assembly line with strong processes and rigorous quality checks because the company targets nothing but the best quality standards. What’s more, Prinoth has dedicated field testing engineers who put the units through extreme duty cycles in different tough conditions to ensure customers get working vehicles every time.”

Built-in Versatility

The Panther T8 has often been referred to as the most versatile tracked vehicle on the market because of its size and capacities, but also because of the amazing possibilities this vehicle offers for both equipment and materials transportation to hard-to-access areas, the manufacturer said.

As part of its services to customers, Prinoth offers a factory installation guide and has a dedicated factory application team who supports special requests from the field. Customers share their challenges, and the factory application team develops solutions together with them, listening and collaborating intensively throughout the project to ensure the best solutions are found for those specific needs.

Considering that Panther crawler carriers are all built on a 34-in. standard truck style chassis with available power pad and built-in hydraulic connections, equipping off-road vehicles with implements other than dump bodies is simple and safe with Prinoth’s units, the manufacturer said.

Technology Upgrades

This new generation of Panther vehicles are now powered by CAT double-label engine models EPA Tier IV Final/EUROMOT Stage V, making Panther the first complete crawler carrier line-up using the new most demanding emission regulation engine technology. The engine upgrade also is supporting Prinoth’s clean motion philosophy for sustainability; the company’s forward-thinking corporate philosophy synonymous not only with low energy consumption but also with environmental protection in ecologically sensitive areas.

For more information, visit www.prinoth.com.

The Easy Way To Advertise Your Equipment Run In Two Consecutive Issues Black & White $135 • Color $195

Reynolds 17CS Scraper, All new hydraulic hoses, all rebuilt hydraulic cylinders, two-part epoxy paint, new tires 13.00x24 12 ply. Hitch & dump pins and bushings are all like new in excellent condition and very tight, new cutting bit.....Asking $29,500 OBO

Contact Mike via text or phone anytime

at (319) 470-8388. 1-2 AP

1999 Ingersoll Rand DD90HF, 6352 Hrs, Double Drum Roller, High Frequency, 66” Drum Width........ .....................................................................$14,500 Call Steve @ 630-878-8765 1 JM 60 Ton Heavy Haul Lowboy with Jeep, Well above average quad axle trailer with tandem axle jeep has been completely reconditioned, it has a RGN (Removable Goose Neck), self-contained motor and pump, new air hoses, fresh paint, 102” wide, new oak decking will be installed prior to sale.....................................................$42,000 OBO

Contact Mike via text or phone anytime

at (319) 470-8388. 1-2 AP

2018 Carlson CP130, s/n 109DB8P, 520 Hours, Contractor deluxe package.......................$179,900 call Steve @ 630-878-8765 1 JM 2017 New Holland C232, 2 Speed, Open ROPS, EH Controls, Block Heater, Turn Signals, 78” Low Profile Bucket with Bolt on Edge kwietbrock@ronsonequipment.com 1 JM

1994 Blaw Knox PF150 8’ Paver with Deutz Diesel

Engine, 8’ screed with hydraulic strike offs, approximately 2,900 hrs use..............................$15,000 as is 800-283-1336 1 JM

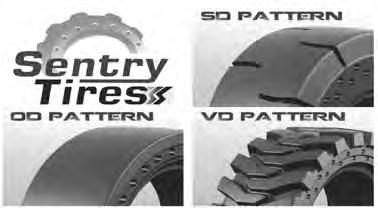

Sentry Tires - Skid Steer and Wheel Loader Tires at Volume Buyers Prices!

Call Company Wrench for Sizes & Pricing

Call 866-294-6103 1-2 EB

2017 DD120C, w/Intelligent Compaction and Pass Counting, #7540.................................................$97,000 800-283-1336 1 JM

2012 Cimline 150 crack sealer, w/ heated hose, diesel burner, 2000 hours. #8557....................$19,750 800-283-1336 1 JM

2014 Manitowoc 8000 80 Ton Crawler, Request Boom Jib Combination Certified, Cleveland, Ohio........ ............................................................................CALL Call Andy Forepaugh 216-316-1511 1-2 EB 2016 Volvo DD120B roller, 78” wide drums, 148HP engine, 1125 hours, #7768..............................$95,000 800-283-1336 1 JM 2007 Hyundai R320LC-7A, 0% for 36 Mos Available, Heat, AC, 13’3” Arm, 36” Grouser Pads, Pattern Changer, Add’l Cntrwht, Cummins QSC Dsl Eng, 54” Digging Bkt, 39’2” Digging Reach, 3615 Hrs....$95,000 Call George 219-696-8911 1 JM 2015 Grove GHC 55 Tele Crawler, 55 Ton, 100’ Main Boom + jib Aux Hoist, Certified 2500 Hrs, original owner, Cleveland, Ohio.......................................CALL Call Andy Forepaugh 216-316-1511 1-2 EB

Here's how the BARGAIN ADS Work:

• Supply us with a photo of a machine (one machine per Bargain Ad) and a maximum 17 word description, plus contact and phone number. • Either email your copy & photo to: production@cegltd.com, or mail to: Construction Equipment Guide, 470 Maryland Drive, Ft Washington, PA 19034. • Cost is $135 per ad, $60 additional for color. • Your ad will run for two consecutive issues in 1 region.

Your Ad Will Be Seen By Over 25,589 Construction Equipment Buyers in the Midwest States. For more information, call Construction Equipment Guide today at 800/523-2200

OSHA from page 8

Ask the Right Questions

When it comes to best practices, it matters not which category of responsibility you fall under on the job site. Regardless of whether you are the general contractor or a subcontractor, there are steps you can take to improve your safety program.

As Braun sees it, managing contractors is “exponentially more straightforward” if you hire contractors with a solid track record for safety. That starts at the prequalification stage.

Requiring a contractor’s health and safety plan, OSHA logs and experience modification rate is a good approach to the prequalification process, said Braun.

Make sure this information is reviewed by someone who knows what to look for, he said, adding “not all incidents and citations are created equally.” The reviewer should know the difference between a de minimus and a serious violation, should check the frequency and severity of a company’s incident record in relation to its safety performance, for instance.

“In addition, if you know other companies who have used these contractors in the past, ask about them,” said Braun.

Did they perform safely? How was management support for the safety program? Did the company seem to have a safety culture? Did they use well-kept equipment or old, beat-up stuff?

Next, make sure the contractors and subs you work with know what you expect from them. Even before work commences there are opportunities to spell it out, said Braun. Bid documents should make clear what you want how they expect to meet safety responsibilities.

This will give the subcontractor ample time to price necessary equipment and staff to perform work properly on your job, he added.

“Once you’ve decided to award the bid to a company, the contract should also include what you expect their safety responsibilities to be. This goes beyond just saying that they must meet OSHA requirements,” said Braun.

Are there areas in the job site where going above and beyond OSHA will be necessary? Are there disciplinary policies that they need to know? What are the drug and alcohol screening requirements for the job?

Finally, you should explicitly require all certification and training documentation relevant to the project. For instance, will they be operating aerial lifts? Get training records. Forklifts? Get their licenses. Working on excavation sites? Do they have excavation training?

“Also, have your contractor name — in writing — who their competent person will be and justify that designation by submitting that person’s background to you,” he said.

According to Braun, that orientation should include safety requirements, disciplinary policies, drug and alcohol policies and everything else you addressed at the contract level relevant to the workforce.

Managing contractors is much easier if you hire contractors with a solid track record for safety. Requiring a contractor’s health and safety plan, OSHA logs and experience modification rate is a good way to start the prequalification process.

Stan Liang

Tetra Tech

Never Assume Anything

Maintain some level of oversight. That’s not to say you have to oversee contractors and subs every minute of every day, said Braun. Periodic observation of the job site is key, he believes.

Notify the contractor, in writing, of any violations and tell them when you expect them to be fixed, he suggested. Have them reply, in writing, when they are taking care of the issues and verify it.

Spot check who is operating equipment and match that up to the records you have on file. Are the contractors diligent about their people being qualified to do what they are being asked to do?

“The process of observing your contractors runs the length of the project,” he said.

One final note from Braun: “Don’t be an enabler.”

A company that performs poorly from a safety perspective is bound to get somebody hurt or killed eventually, he said.

And remember, your primary goal is to keep everyone from getting hurt on your project.

“But if somebody does, you want to be confident that you have done everything you could to prevent it,” he added.

If you are a controlling employer of a worksite, you will want to be careful about which subcontractors you hire, be intentional about the safety practices you enforce at your worksite and perform frequent inspections, concluded Liang.

If you are a subcontractor at a site, make sure you meet all safety requirements and make reasonable efforts to prevent your employees from being exposed to hazards, stressed Liang.

“Even if they are not hazards you created, you will also want to make sure you do not create hazards for employees of other employers at the site.” CEG