PLA (Polylactic Acid) is a biodegradable and compostable thermoplastic polymer that is derived from renewable resources such as corn starch, cassava roots, or sugarcane PLA is a popular material for 3D printing, as well as for manufacturing disposable items such as cups, plates, and utensils.

PLA is considered to be environmentally friendly because it is made from renewable resources and it biodegrades under certain conditions, meaning it can break down into natural components and return to the earth without leaving harmful residues However, it is important to note that the composting process of PLA can be slow and requires specific conditions, such as high temperatures and moisture levels, to break down properly. If not properly disposed of, PLA can still contribute to waste accumulation in the environment.

PLA is made from renewable resources: PLA is derived from natural resources such as corn starch, cassava roots, or sugarcane, which are renewable and can be regrown after harvest.

PLA has a lower carbon footprint than conventional plastics: The production of PLA generates fewer greenhouse gas emissions than the production of conventional petroleum-based plastics.

PLA is biodegradable and compostable: PLA can break down into natural components and return to the earth under certain conditions, such as high temperatures and moisture levels This means that it does not contribute to long-term waste accumulation in the environment.

PLA is versatile: PLA can be used for a wide range of applications, including 3D printing, food packaging, and disposable utensils. This versatility means that it can potentially replace conventional plastics in various industries, reducing the environmental impact of those industries

Fermentation:

The first step in the production of PLA is to ferment the renewable resource, usually corn starch, with microorganisms such as bacteria or fungi. The microorganisms convert the sugars in the corn starch into lactic acid.

Purification:

The lactic acid produced in the fermentation process is then purified and concentrated to produce a high-quality product Polymerization: The purified lactic acid is polymerized, which means that the individual molecules are linked together to form long chains. This process is typically carried out using heat and a catalyst, which encourages the lactic acid molecules to bond together.

Pelletization:

The resulting polymer is then pelletized, which means that it is turned into small pellets

PLA can also be composted in a commercial composting facility In this process, the PLA is broken down by microorganisms and turned into compost, which can be used as a soil amendment. However, it is important to note that PLA requires specific conditions to biodegrade, and it may not biodegrade properly in a home composting system.

It is important to note that not all recycling facilities accept PLA, so it is important to check with your local recycling program to see if they accept it. Additionally, it is important to properly label PLA products as compostable to prevent them from contaminating recycling streams, as well as to ensure that they are disposed of properly.

Limestone is a sedimentary rock that is primarily composed of calcium carbonate (CaCO3). It is formed over millions of years from the accumulation of organic and inorganic materials such as shells, coral, and marine debris that have settled on the sea floor and been compacted by the weight of the overlying sediment.

Limestone is a common rock found all over the world, and it can vary in color from white to gray to yellow. Some types of limestone are more durable and resistant to weathering than others

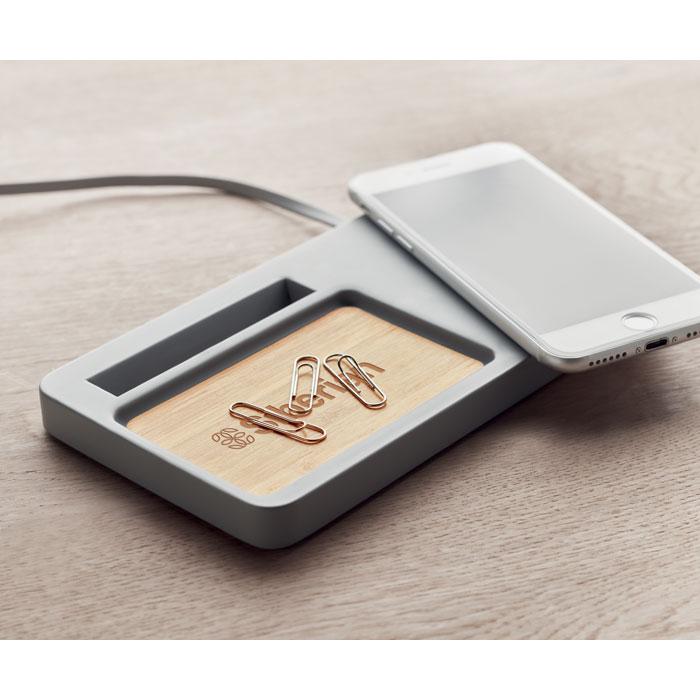

Limestone is not commonly used in the production of promotional products, as it is a heavy and bulky material that can be difficult and expensive to transport. However, there are some products that may incorporate limestone as a decorative element or as a component of a composite material Here are a few examples: Coasters, Desk Accessories and speakers

Limestone is considered a sustainable material for several reasons:

Abundant and renewable: Limestone is a naturally occurring material that is abundant and widely available. It is formed over millions of years from the accumulation of organic and inorganic materials such as shells, coral, and marine debris that have settled on the sea floor and been compacted by the weight of the overlying sediment This means that limestone is a renewable resource that can be continually replenished through natural processes.

Low energy and emissions: The production of limestone requires relatively low energy inputs compared to other materials, such as concrete and steel Additionally, the emissions associated with limestone production are relatively low, as the process does not involve high-temperature kilning or the release of large amounts of carbon dioxide.

Recyclable: Limestone can be recycled by crushing it into aggregate for use in construction materials, such as concrete and asphalt.

Limestone is a type of rock that forms from the accumulation of sediment, such as the shells and skeletons of marine organisms. Over time, this sediment becomes compacted and cemented together to form a solid rock. The process starts with the accumulation of sediment in a marine environment, such as a coral reef or shallow sea floor. As more sediment accumulates, the weight of the overlying material compresses and solidifies the sediment below Over time, minerals such as calcium carbonate can precipitate out of the pore fluids and fill the spaces between the sediment grains, creating a solid rock. This process is known as cementation. The resulting rock is known as limestone, and it is an important natural resource with many practical uses, including construction materials, fertilizer, and industrial applications

Limestone is a natural rock that is formed over millions of years, and it cannot be recycled like plastic or paper However, there are ways to reuse and repurpose limestone products to reduce waste and promote sustainability.

Limestone products can be repurposed for use in gardening or landscaping. Crushed limestone can be used to make a type of soil amendment called lime, which can be added to garden soil to make it more fertile Limestone chips can also be used to create paths or walkways in a garden or park.

So, while limestone products cannot be recycled in the traditional sense, they can be reused and repurposed in ways that promote sustainability and reduce waste.

Natural wood is a sustainable and renewable resource that is obtained directly from trees without any modification or treatment. It is widely used as a raw material in the production of various promotional products like pens, keychains, phone cases, and drinkware. These products are popular because they offer an eco-friendly option as wood is a renewable resource and is more sustainable than materials like plastic or metal.

Natural wood has a unique texture and character that can add warmth and personality to any product Moreover, wood products can be recycled or repurposed, making them an even more sustainable choice. However, it is important to manage forests responsibly to ensure that they are not depleted or damaged by harvesting. By promoting the sustainability and eco-friendliness of natural wood products, we can help reduce waste and protect our environment

Natural wood is considered a sustainable material for several reasons Firstly, it is a renewable resource, as trees can be grown and harvested repeatedly. Proper forest management practices can ensure that forests are not depleted or damaged by harvesting, making natural wood a sustainable option.

In addition, natural wood is biodegradable and can be easily recycled or repurposed, reducing waste and promoting sustainability Wood products can also have a lower carbon footprint than other materials like plastic or metal, as they require less energy to produce and transport.

Furthermore, natural wood has a lower environmental impact than materials like plastic or metal, as it does not release harmful chemicals or pollutants during production or disposal This makes it a more eco-friendly option for promotional products and other applications

Overall, the renewability, recyclability, and low environmental impact of natural wood make it a sustainable and responsible choice for various products, including promotional items.

When you source FSC-certified wood, you are supporting responsible forest management practices that protect natural habitats, prevent deforestation, and support the rights and wellbeing of workers and local communities

The Forest Stewardship Council (FSC) is an international organization that sets standards for responsible forest management and certifies products that meet these standards. FSC-certified wood comes from forests that have been independently verified to meet strict environmental and social criteria, such as protecting endangered species and indigenous peoples' rights, avoiding the use of hazardous chemicals, and promoting responsible forest management practices.

By choosing FSC-certified wood for promotional products, businesses can demonstrate their commitment to sustainability and responsible sourcing This helps to promote the responsible use of natural resources and support the well-being of people and the planet.

Wooden promotional products can be recycled or repurposed in various ways to reduce waste and promote sustainability. Here are some options for recycling wood promotional products:

Composting: Wooden products like keychains, coasters, and phone cases can be composted after use. They can be broken down into organic material that can enrich soil.

Recycling: Wood products can be recycled into wood chips or other wood-based products, like particleboard or mulch. Check with your local recycling center to see if they accept wood for recycling

Upcycling: Wooden promotional products can be repurposed into new products or given a new life. For example, wooden keychains can be turned into plant markers, and wooden coasters can be used as trivets or in craft projects.

Donating: If the wood products are still in good condition, they can be donated to a local charity or thrift store for someone else to use

Wheat fiber is a natural, renewable material made from the stalks of wheat plants. It is a byproduct of the wheat farming industry and is typically sourced from wheat straw, which is the residue left over after the grain has been harvested

Wheat fiber is commonly used as a sustainable alternative to plastics and other non-renewable materials. It is often used to make a variety of products, including food packaging, tableware, and other household items.

Wheat fiber is eco-friendly because it is a renewable resource that does not require additional land or resources to produce. It is also biodegradable, meaning it can be broken down by natural processes and will not contribute to long-lasting waste or pollution. Additionally, wheat fiber is often produced using a closed-loop manufacturing process, which reduces water and energy use and minimizes waste

Wheat fiber is considered sustainable for several reasons:

Renewable Resource: Wheat fiber is made from the stalks of wheat plants, which are a renewable resource. Unlike nonrenewable materials, wheat plants can be grown and harvested repeatedly, making it a more sustainable option.

Biodegradable: Wheat fiber is biodegradable, meaning it can be broken down by natural processes and will not contribute to long-lasting waste or pollution.

Reduced Environmental Impact: Producing wheat fiber has a lower environmental impact compared to many other materials. The production process of wheat fiber involves using a closed-loop manufacturing process, which minimizes waste, water, and energy use

Byproduct of Wheat Farming: Wheat fiber is a byproduct of the wheat farming industry, specifically from wheat straw, which is the residue left over after the grain has been harvested. This reduces the amount of waste produced during the farming process and provides an additional source of revenue for farmers

Wheat fiber is made from the leftover stalks of the wheat plant after the grain has been harvested. The stalks are cut into small pieces and then soaked in water to soften them Next, the fibers are separated from the rest of the plant material and dried out The dried fibers are then compressed into the shape of plates, cups, and bowls using heat and pressure. Once the products have been formed, they are ready to be used!

So, instead of throwing away the leftover parts of the wheat plant, we can turn them into something useful like dishes that we can eat from This way, we are using all parts of the wheat plant and not wasting anything.

Wheat fiber promotional products can often be recycled by placing them in a commercial composting facility. Composting facilities provide the right conditions, such as heat, moisture, and air, to break down organic materials like wheat fiber products into nutrient-rich soil

When disposing of wheat fiber products, it's important to check if the product is compostable and if there are any specific instructions for composting or recycling. If there is no commercial composting facility available, the product can also be disposed of in a backyard composting bin, but it may take longer to break down.

In addition to composting, some wheat fiber products can also be repurposed or upcycled. For example, wheat fiber plates or bowls can be used for arts and crafts projects, or as holders for small items like keys or coins.

Overall, recycling wheat fiber promotional products can help to reduce waste and contribute to a more sustainable future

Jute is a natural plant fiber that is commonly used to make a variety of products, including bags, rugs, and clothing. It is a long, soft, shiny vegetable fiber that can be spun into coarse, strong threads

Jute is a sustainable and eco-friendly fiber that is biodegradable and compostable. It is also a renewable resource, as the jute plant grows quickly and requires little fertilizer or pesticides. Jute is known for its durability and strength, and it can withstand heavy use and wear.

When jute is unprocessed and used in its natural state, it is referred to as "natural jute." Natural jute has a warm, earthy tone and a slightly rough texture that is wellsuited for rustic or natural decor styles. It can be used in a variety of applications, such as rope, twine, and burlap sacks.

Renewable resource: Jute is a plant-based material that is grown mainly in tropical regions. The jute plant is relatively easy to grow and has a high yield per acre, making it a renewable resource Additionally, the cultivation of jute requires minimal irrigation and fertilizers compared to other crops

Biodegradable: Jute is 100% biodegradable, which means it can be easily decomposed in the environment without causing harm. This makes it an environmentally friendly alternative to synthetic materials that take a long time to decompose

Low carbon footprint: Jute has a low carbon footprint as it absorbs large amounts of carbon dioxide during its growth. In contrast, synthetic materials require high levels of energy and fossil fuels in their production, contributing to greenhouse gas emissions.

Versatile: Jute can be used for as bags, rugs, and textiles, mak can replace synthetic alternati

Affordable: Jute is a relatively i

Jute is considered a sustainable option for several reasons: material compared to synthetic alternatives, making it an accessible choice for manufacturers and consumers.

Jute is made from the fibers of the jute plant (Corchorus olitorius and Corchorus capsularis), which is primarily grown in Bangladesh, India, and other tropical regions. The process of making jute typically involves the following steps:

Harvesting: The jute plants are harvested when they are about 8-10 feet tall The stems are cut close to the ground and then bundled together.

Retting: The bundled stems are soaked in water for several days to soften the outer bark and separate the fibers from the woody core. This process is called retting and can be done in either fresh or saltwater

Stripping: After the retting process, the fibers are stripped from the stems by hand or by using a machine. The fibers are then washed to remove any remaining impurities.

Spinning: The cleaned fibers are then spun into yarns or threads using a spinning wheel or a machine.

Weaving: The jute yarns or threads are woven into fabrics or other products, such as bags or rugs.

Finishing: Finally, the jute products are finished by cutting, dyeing, and/or printing according to the desired specifications.

Overall, the process of making jute is relatively simple and can be done with minimal machinery, making it an accessible and affordable material for many communities.

Jute is a natural fiber that is biodegradable and compostable, which means it can break down in the environment without causing harm. However, jute can also be recycled and repurposed to extend its lifespan and reduce waste. Here are some common ways to recycle jute:

Reuse: Jute bags, sacks, and other products can be reused for multiple purposes, such as storage or shopping bags

Composting: Jute products can be composted along with other organic materials, such as food scraps or yard waste. As a natural material, jute can break down quickly and add valuable nutrients to the compost.

Recycling: Jute fibers can be recycled and turned into new products, such as paper or insulation The fibers can also be blended with other materials, such as plastics or rubber, to create composites for various applications.

Upcycling: Jute products can be upcycled into new and creative items, such as wall hangings, rugs, or even furniture Upcycling gives jute a second life while reducing waste and promoting creativity

Cork is a natural, renewable, and sustainable material that is harvested from the bark of cork oak trees. The cork oak tree is primarily found in the Mediterranean region, particularly in Portugal, Spain, and Italy Cork is widely known for its unique properties, including being lightweight, compressible, durable, and impermeable to liquids and gases.

Cork is commonly used for a variety of purposes, including wine bottle stoppers, flooring, insulation, and bulletin boards. It is also used in the construction industry as a sustainable and eco-friendly alternative to traditional building materials like concrete and wood Additionally, cork has some special acoustic properties, which make it an excellent material for sound insulation and reduction.

Cork is considered a sustainable material because of the following reasons: like plastics, metals materials that have impact on the envir

Renewable resource: Cork is harvested from the bark of cork oak trees, which can regrow the bark every 9 to 12 years without harming the tree This makes cork a renewable resource

Low carbon footprint: The production process of cork has a low carbon footprint, as it requires minimal energy and does not release any harmful pollutants into the environment.

Biodiversity preservation: Cork oak forests are home to many species of plants and animals, and they play a crucial role in preserving biodiversity in the Mediterranean region

Recyclable and biodegradable: Cork is a recyclable material, and it can also biodegrade naturally without releasing any harmful substances into the environment.

Durable and long-lasting: Cork is a durable material, and it can last for decades, reducing the need for frequent replacements and minimizing waste

Eco-friendly alternative: Cork is used as a sustainable and eco-friendly alternative to other materials

Cork promotional products are manufactured using various processes, depending on the specific product and its intended use. However, the basic steps involved in manufacturing cork promotional products are as follows:

Harvesting: Cork is harvested from the bark of cork oak trees in a process that involves carefully removing the outer bark layer without damaging the tree This process is typically done by hand and is performed every 9 to 12 years.

Sorting and boiling: The harvested cork is sorted by quality and then boiled to remove any impurities, such as dirt and bark fragments.

Pressing and molding: The cork is then compressed and molded into the desired shape and size using heat and pressure. This process can involve using a variety of machines and tools, depending on the specific product.

Finishing: The cork product is then finished with various coatings and treatments, such as varnishes or waxes, to enhance its appearance, durability, and functionality

Printing or engraving: Some cork promotional products are then printed or engraved with branding or messaging using various techniques such as screen printing or laser engraving.

Packaging: The final step in manufacturing cork promotional products is packaging them for distribution The products may be packaged individually or in bulk, depending on the specific product and the intended use.

Cork promotional items can be recycled, and there are several ways to do so. Here are some options:

Cork recycling programs: Some organizations and companies have cork recycling programs in place that allow individuals to recycle cork products These programs collect used cork products and process them into new materials or products.

Composting: Cork is a biodegradable material, which means it can be composted. If you have a compost bin or pile, you can add your cork products to it Cork will break down over time and enrich the soil

Creative reuse: Cork promotional items can also be repurposed or creatively reused. For example, wine corks can be used to make cork boards or coasters, while cork flooring can be turned into bulletin boards or trivets.

Upcycling: Another option is to upcycle cork promotional items into new and useful products For example, a cork wine stopper can be turned into a keychain or a decorative vase stopper.

Bamboo is a type of fast-growing grass that is native to Asia, but can also be found in other parts of the world, such as South America and Africa. Bamboo is known for its strength, durability, and versatility, and has been used for thousands of years in various cultures for a wide range of purposes.

Bamboo is one of the fastest-growing plants in the world and can grow up to 91 cm (3 feet) in a single day, making it a highly sustainable resource. It is also an eco-friendly alternative to other materials like wood and plastic, as it is biodegradable and does not require any pesticides or fertilizers to grow

Bamboo is commonly used for a variety of purposes, such as building materials, furniture, paper, textiles, and even as a food source. In recent years, bamboo has become increasingly popular as a material for sustainable and eco-friendly products, such as bamboo straws, bamboo toothbrushes, and bamboo utensils

Rapid growth: Bamboo is one of the fastest-growing plants in the world, with some species growing up to 91 cm (3 feet) in a single day. This rapid growth means that it can be harvested more frequently than trees, making it a highly sustainable resource.

Renewable: Bamboo is a renewable resource because it regenerates quickly after being harvested Unlike trees, which can take decades or even centuries to grow back, bamboo can be harvested every 3 to 5 years without causing any harm to the plant or the environment.

Low environmental impact: Bamboo is a low-impact crop that requires very little water, pesticides, or fertilizers to grow It also helps to prevent soil erosion and can improve soil quality.

Biodegradable: Bamboo is a biodegradable material, which means that it can decompose naturally without causing harm to the environment.

Carbon sequestration: Bamboo is an excellent carbon sink, as it absorbs more carbon dioxide from the atmosphere than other plants. This means that bamboo forests can help to mitigate the effects of climate change by reducing the amount of greenhouse gases in the

atmosphere. material that can be wide range of purpo

Versatile: Bamboo is

Bamboo is a type of fast-growing grass that is used to produce a variety of products, including bamboo fiber. Bamboo fiber, on the other hand, is a textile material that is made from the pulp of bamboo plants While they are related, there are some key differences between bamboo and bamboo fiber:

Source: Bamboo is a plant, while bamboo fiber is a textile material that is made from the pulp of the bamboo plant.

Production: Bamboo is harvested, cleaned, and processed to create bamboo fiber The process involves breaking down the bamboo stalks into a pulp, which is then spun into a fiber that can be used to make textiles.

Properties: Bamboo is a strong and durable material that is also lightweight and flexible. Bamboo fiber, on the other hand, is soft and silky, with a texture that is similar to cotton or silk Bamboo fiber is also moisture-wicking, breathable, and hypoallergenic

It's important to note that while bamboo is considered a sustainable material, the production of bamboo fiber can be more resource-intensive than other natural fibers like cotton or linen. The process of breaking down the bamboo pulp requires the use of chemicals, which can be harmful to the environment if not properly managed However, there are ecofriendly methods of producing bamboo fiber that minimize the environmental impact of the process.

Bamboo is a sustainable and eco-friendly material that can be recycled and repurposed in a number of ways Here are some ways to recycle bamboo promotional products:

Composting: Bamboo products can be composted along with other organic materials When composted, bamboo products break down into nutrient-rich soil, which can be used to fertilize plants and gardens.

Reusing: Bamboo products can be reused for different purposes. For example, a bamboo utensil set can be repurposed as a makeup brush holder, a pen holder, or a plant marker

Recycling: Some bamboo products can be recycled, depending on the local recycling facilities. It's important to check with the local recycling center to see if they accept bamboo products and to follow the guidelines for recycling.

Upcycling: Bamboo products can be upcycled into new and useful items. For example, bamboo flooring can be upcycled into furniture or wall art.

Recycled ABS, or recycled acrylonitrile butadiene styrene, is a type of thermoplastic that is made from recycled ABS plastic. ABS is a common type of plastic that is used in a variety of applications, including automotive parts, toys, and electronic housings Recycling ABS plastic reduces the amount of waste that ends up in landfills and conserves natural resources by using existing materials to create new products.

Recycled ABS plastic has similar properties to virgin ABS plastic, including high impact resistance, good heat resistance, and good chemical resistance Recycled ABS plastic can be used in a variety of applications

It's important to note that the quality and properties of recycled ABS plastic may vary depending on the quality of the original plastic waste and the recycling process used. However, using recycled ABS plastic can be an effective way to reduce waste and conserve natural resource

Recycled ABS is considered a sustainable material for several reasons:

Reduces waste: Recycling ABS plastic reduces the amount of plastic waste that ends up in landfills or oceans. This helps to minimize the negative impact of plastic waste on the environment and wildlife

Conserves resources: Recycling ABS plastic conserves natural resources by using existing materials to create new products. This reduces the need for virgin plastic, which requires the extraction and processing of raw materials.

Energy-efficient: The production of recycled ABS plastic is less energy-intensive than the production of virgin ABS plastic. This is because the recycling process requires less energy than the extraction and processing of raw materials.

Cost-effective: Recycling ABS plastic can be cost-effective compared to producing virgin ABS plastic. This is because the recycling process is often cheaper than the extraction and processing of raw materials

Overall, using recycled ABS plastic is a sustainable option that helps to reduce waste, conserve resources, and minimize the negative impact of plastic waste on the environment that the sustaina ABS plastic depe of the original pl and the recyclin

Recycled ABS is made by collecting, cleaning, and processing post-consumer or post-industrial ABS plastic waste. The collected ABS plastic waste is sorted by type and color, then cleaned to remove impurities. After that, the cleaned ABS plastic waste is shredded into small pieces and melted down using high temperatures Additives such as colorants, stabilizers, and flame retardants may be added to the molten ABS plastic to enhance its properties. Finally, the molten recycled ABS plastic is extruded into pellets or flakes, which can be used to create new products. The process of making recycled ABS helps to reduce waste, conserve natural resources, and minimize the negative impact of plastic waste on the environment

Recycled ABS and RPET are two different types of recycled materials made from different types of plastic. Recycled ABS is made from recycled acrylonitrile butadiene styrene (ABS) plastic, while RPET is made from recycled polyethylene terephthalate (PET) plastic

Recycled ABS is known for its high impact resistance and heat resistance, making it suitable for use in automotive and consumer products. RPET is known for its strength, clarity, and barrier properties, making it ideal for use in packaging for food and beverages.

Recycling ABS and PET plastics requires different processes ABS plastic waste is collected, sorted, cleaned, shredded, melted down, and extruded into pellets or flakes. PET plastic waste is collected, sorted, cleaned, shredded, and melted down before being processed into new products.

Recycling recycled ABS promotional products is similar to recycling any other ABS plastic product Here are some steps you can take to recycle recycled ABS promotional products:

Check if your local recycling facility accepts ABS plastic Some facilities only accept certain types of plastics, so it's important to check beforehand.

Clean the recycled ABS promotional product. Remove any labels or stickers and wash the product with soap and water to remove any dirt or residue.

Separate the different parts of the product If the product has multiple components made of different materials, separate them and recycle them separately.

Drop off the recycled ABS promotional product at a recycling facility. If your local recycling facility accepts ABS plastic, drop off the product there. If not, try to find a recycling facility that does

By recycling recycled ABS promotional products, you can help reduce waste and conserve natural resources.

RPET stands for recycled polyethylene terephthalate. It is a sustainable material that is made from recycled PET plastic, which is commonly used in water and soda bottles, food packaging, and other products. RPET is made by collecting, sorting, and cleaning postconsumer PET plastic waste, and then processing it into a new material that can be used to make a wide variety of products.

RPET has become increasingly popular as a sustainable alternative to virgin PET plastic, as it helps reduce waste, conserve natural resources, and minimize the negative impact of plastic waste on the environment RPET can be used to make products such as clothing, bags, packaging materials, and other consumer products.

RPET (recycled polyethylene terephthalate) is considered sustainable for several reasons

Reduces waste: RPET is made from post-consumer PET plastic waste, which reduces the amount of plastic waste that ends up in landfills or oceans This helps to conserve natural resources and reduces the negative impact of plastic waste on the environment

Conserves resources: RPET reduces the need for virgin PET plastic, which conserves natural resources such as crude oil and reduces greenhouse gas emissions associated with the production of new plastic.

Energy-efficient: The production of RPET requires less energy compared to the production of virgin PET plastic, resulting in reduced greenhouse gas emissions and a smaller carbon footprint.

Recyclable: RPET is itself recyclable and can be used to make new products, which further reduces waste and conserves natural resources

Eco-friendly: By using RPET, companies can demonstrate their commitment to sustainability and reduce their impact on the environment.

Overall, RPET is conside because it reduces wa natural resources, is en efficient, and is recycla It is a good option for c looking to reduce their environmental impact promote sustainability

RPET is made from post-consumer PET plastic waste through a process of collection, sorting, cleaning, and processing. Here is a brief overview of the process:

Collection: PET plastic waste is collected from various sources such as recycling bins, landfills, and waste management facilities.

Sorting: The collected PET plastic waste is sorted according to its color, type, and quality. The sorting process ensures that only high-quality PET plastic is used in the production of RPET

Cleaning: The sorted PET plastic is then cleaned and washed to remove any dirt, residue, or impurities. This ensures that the resulting RPET is of high quality

and purity.

Processing: The cleaned and sorted PET plastic is then processed into RPET through a series of mechanical and chemical processes. The PET plastic is first shredded into small flakes, which are then melted down and extruded into pellets or fibers.

Production: The resulting RPET pellets or fibers can be used to make a wide variety of products, including

clothing, bags, packaging materials, and other consumer products

Here are some best ways to recycle RPET promotional items

Reuse: If possible, reuse the RPET promotional items instead of throwing them away. For example, reusable shopping bags can be used for grocery shopping or carrying items

Recycling bins: Dispose of the RPET promotional items in recycling bins designated for plastic. This ensures that the items will be collected and processed for recycling.

Upcycling: Upcycle the RPET promotional items into new products. For example, an old RPET tote bag can be cut and sewn into a new makeup pouch

Donation: Donate the RPET promotional items to charity or organizations that can use them. This can extend the lifespan of the items and reduce waste.

By using these best ways to recycle RPET promotional items, we can reduce plastic waste, conserve natural resources, and protect the environment

Recycled milk carton, also known as High-Density Polyethylene (HDPE), is a type of plastic made from used milk or juice cartons that have been recycled. Milk cartons are made from a combination of paper, plastic, and aluminum, and can be difficult to recycle without separating the materials. However, the HDPE plastic layer can be separated and turned into a new product.

Recycling milk cartons helps to reduce waste and conserve natural resources. It also helps to reduce the amount of plastic that ends up in landfills or oceans. The recycled HDPE plastic can be used to make a variety of products, including outdoor furniture, decking, playground equipment, and plastic lumber.

Milk cartons can be considered sustainable for a few reasons:

Made from renewable resources: Milk cartons are made primarily from paperboard, which is a renewable resource that comes from trees

Lightweight and efficient: Milk cartons are lightweight and space-efficient, which means they require less fuel to transport than heavier alternatives, such as glass bottles.

Recyclable: Milk cartons are recyclable, which means they can be turned into new products instead of ending up in landfills or oceans The paperboard can be recycled into new paper products, while the plastic and aluminum layers can be recycled into new plastic and metal products.

Alternative uses: Milk cartons can also be repurposed for other uses, such as building materials or as planters for gardening.

Overall, the use of milk carton help reduce the environment packaging, as long as the ca repurposed.

Coffee fiber is a byproduct of the coffee production process It is the fibrous material that surrounds the coffee beans within the coffee cherry, also known as the coffee fruit. During coffee production, this material is typically removed and discarded as waste, but it has potential as a sustainable and environmentally-friendly material

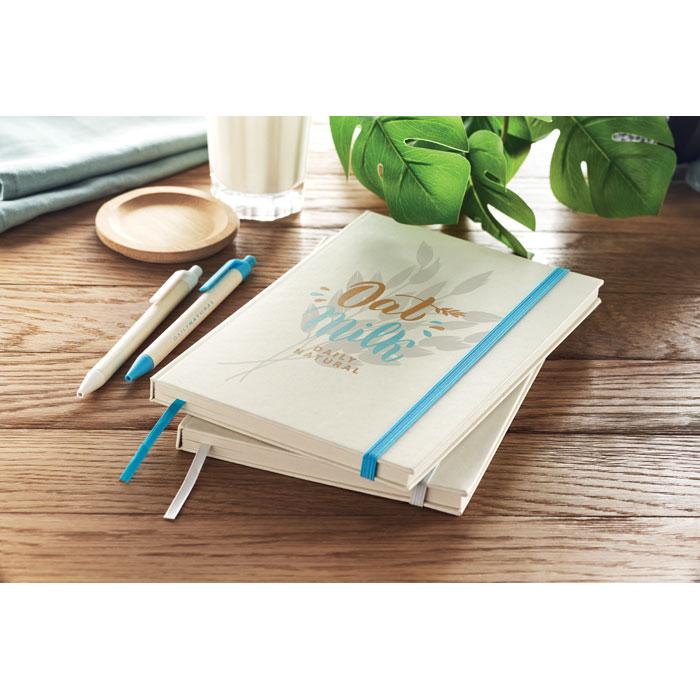

Coffee fiber can also be used in the production of promotional products such as pens and notebooks These products can be made using paper that incorporates coffee fiber into the pulp, which gives them a unique texture and appearance.

Some companies are also exploring the use of coffee fiber as a sustainable alternative to traditional plastic packaging materials. For example, coffee cups made from coffee husks (the outer layer of the coffee cherry) are becoming increasingly popular as a sustainable alternative to singleuse plastic cups.

Coffee fiber is considered a sustainable option in the promotional products industry for several reasons: sustainable materials into their product lines.

Renewable: Coffee is a widely grown crop that can be harvested multiple times a year. The use of coffee waste products, such as coffee husks or coffee grounds, to create coffee fiber reduces waste and provides a new purpose for a byproduct of the coffee industry.

Biodegradable: Unlike synthetic materials like polyester or nylon, coffee fiber is a natural material that is biodegradable. When disposed of properly, it can break down into organic matter without harming the environment.

Low carbon footprint: The production process for coffee fiber requires less energy and emits fewer greenhouse gases compared to the production of synthetic materials Using coffee fiber instead of non-biodegradable materials like plastic can significantly reduce the carbon footprint of promotional products.

Versatile: Coffee fiber can be used to create a variety of promotional products, including textiles, stationery, and packaging This versatility makes it a useful material for companies looking to incorporate

Coffee husk is a waste product generated during the processing of coffee beans. It is the outer layer of the coffee cherry, which is removed during the milling process. Coffee husk is usually brown in color and has a fibrous texture.

Coffee husk is an abundant waste product in the coffee industry, with millions of tons produced each year. Historically, coffee husk has been discarded as waste or used as a low-value fuel source. However, in recent years, there has been growing interest in using coffee husk for other purposes, such as animal feed, compost, and as a raw material for the production of sustainable products

Coffee husk promotional items can be considered sustainable for a few reasons:

Use of a waste product: Coffee husk is a waste product of the coffee industry and repurposing it for promotional items means using a resource that would otherwise go to waste This reduces the overall waste generated by the coffee industry.

Biodegradable: Coffee husk is a biodegradable material, meaning it can decompose naturally and won't contribute to landfill waste or ocean pollution if it ends up in the environment

Renewable: The coffee industry is constantly producing new batches of coffee, so the supply of coffee husk is considered renewable.

Lightweight: Coffee husk is a lightweight material, making it easy and efficient to transport, reducing the carbon footprint of transportation

Overall, the use of coffee husk in promotional items can be a sustainable choice as it repurposes a waste product, uses a renewable resource, is biodegradable, and lightweight.

Coffee husk promotional products can be made by compressing the coffee husk fibers into various shapes and forms using heat and pressure The process typically involves the following steps:

Collection: Coffee husks are collected from coffee farms or coffee processing facilities.

Cleaning and drying: The collected coffee husks are cleaned and dried to remove any dirt, debris, or moisture.

Grinding: The dried coffee husks are then ground into a fine powder

Mixing: The coffee husk powder is mixed with a binding agent, such as starch or resin, to help hold it

together.

Compression: The coffee husk mixture is Finishing: The finished coffee husk

then placed into a mold and compressed using heat and pressure to form the desired shape

product is sanded or polished to create a smooth surface and may be coated with a protective finish or dye.

The recyclability of coffee husk promotional products depends on the specific product and the recycling capabilities in your area. Some coffee husk products, such as pens or keychains, may be made from a composite material that is difficult to recycle However, other coffee husk products, such as coffee cups or plant pots, may be compostable or recyclable if they are made from a single material like biodegradable plastic.

If you are unsure about the recyclability of a specific coffee husk promotional product, check for recycling symbols or labels on the product or contact the manufacturer for information

Coconut is a natural material that has gained popularity in the promotional products industry for its sustainability and versatility. It can be used to create a variety of promotional items such as:

Drinkware: Coconut shells can be hollowed out and turned into unique and eco-friendly cups or mugs.

Bags and totes: The fibers of the coconut husk can be used to create durable and reusable shopping bags and totes

Keychains and accessories: Coconut shells can be carved and painted to make keychains and other accessories.

Stationery: Coconut husk fibers can be processed into paper and used to make notebooks, journals, and other stationery items.

Coconut is a renewable and biodegradable material that is widely available in tropical regions. It requires minimal processing to turn it into usable materials, making it a low-impact and sustainable choice for promotional products. Additionally, using coconut in the promotional products industry supports local economies in regions where coconuts are grown and harvested.

Renewable resource: Coconuts are a renewable resource that can be harvested every year This means that the production of coconut-based products can be sustained without depleting natural resources.

Biodegradable: Coconut products are biodegradable, meaning that they will naturally break down over time and won't contribute to the buildup of waste in the environment.

Low-impact production: The production of coconut-based products typically requires minimal processing and energy, which reduces the environmental impact of the manufacturing process.

Versatility: Coconut can be used to create a wide range of products, from drinkware to bags to stationery, which makes it a versatile and sustainable material choice for the promotional product industry

Recycled nylon, also known as rylon or regenerated nylon, is a type of synthetic fiber made from post-industrial or postconsumer waste materials It is created by taking discarded nylon products, such as fishing nets, carpets, and industrial waste, and breaking them down into small pellets. These pellets are then melted and spun into new fibers to create a durable, highperformance material.

Recycling nylon helps to reduce waste and conserve resources, as it diverts waste materials from landfills and reduces the need for virgin nylon production. It also requires less energy and fewer resources to produce than virgin nylon, making it a more sustainable option for the fashion and textile industries.

Rylon, or recycled nylon, is a sustainable option in the promotional products industry for several reasons

Reducing waste: Rylon is made from post-industrial or postconsumer waste materials, such as discarded fishing nets and carpets. By using these waste materials, Rylon helps to reduce the amount of waste that would otherwise end up in landfills or oceans.

Conserving resources: Rylon requires fewer resources, such as water and energy, to produce than virgin nylon This helps to conserve natural resources and reduce the environmental impact of nylon production.

Durability: Rylon is a high-performance material that is strong, durable, and resistant to wear and tear. This means that promotional products made from Rylon are likely to have a longer lifespan than those made from other materials, reducing the need for frequent replacements and minimizing waste.

Versatility: Rylon can be used to create a wide range of promotional products, from bags and backpacks to apparel and accessories. This versatility makes it a popular choice for companies looking for sustainable promotional products that can be used in a variety of contexts

Recycled aluminum is made from used aluminum products, such as beverage cans, household items, and construction materials, that have been melted down and reprocessed The recycling process involves melting the aluminum at high temperatures to remove any impurities, then adding alloys to improve the strength and durability of the final product.

Aluminum recycling is an important process because it helps to conserve natural resources and reduce the energy and emissions associated with mining and refining new aluminum Recycled aluminum also requires less energy to produce than new aluminum, which makes it more environmentally friendly.

Recycled aluminum is considered sustainable for several reasons:

Conservation of natural resources: Recycling aluminum helps to conserve natural resources because it reduces the need for mining and extracting new bauxite ore, which is the primary raw material used to produce aluminum. This helps to preserve natural habitats and ecosystems, which are often affected by mining activities.

Energy savings: Recycling aluminum requires significantly less energy than producing new aluminum from raw materials. According to the Aluminum Association, recycling aluminum requires only 5% of the energy needed to produce new aluminum from bauxite ore. This leads to significant energy savings and reduces greenhouse gas emissions associated with energy production

Reduced waste: Recycling aluminum helps to reduce the amount of waste that ends up in landfills, which in turn helps to conserve space and reduce the environmental impact of waste disposal.

Economic benefits: Recycling aluminum can provide economic benefits by creating jobs in the recycling industry and reducing the cost of producing new aluminum

Recycled aluminum can be used to create a variety of promotional products, such as keychains, water bottles, and pens The process of creating these products from recycled aluminum typically involves the following steps:

Collection and sorting: Used aluminum products, such as beverage cans, are collected and sorted according to their grade and quality.

Shredding and melting: The collected aluminum is shredded into small pieces and melted down in a furnace This process removes any impurities and prepares the aluminum for further processing

Casting: The melted aluminum is cast into molds to create the desired shape of the promotional product. The molds can be customized to include specific logos or designs.

Finishing: Once the promotional product has been cast, it can be finished with various techniques, such as polishing, sandblasting, or anodizing This helps to give the product a smooth and attractive appearance

Packaging and distribution: The finished promotional products are packaged and distributed to customers, who can use them for various marketing and branding purposes.

The main difference between recycled aluminum and recycled stainless steel is the composition of the materials Aluminum is a lightweight, soft metal with a low melting point, while stainless steel is a heavier, harder metal that is resistant to corrosion and high temperatures.

The process of recycling these materials also differs. Recycled aluminum is typically melted down at a lower temperature than stainless steel, and the resulting metal can be used to create a variety of products

Recycled stainless steel, on the other hand, is often used in the production of higher-end products. The recycling process for stainless steel involves melting the metal down at very high temperatures to remove any impurities and create a highquality product

In terms of sustainability, both recycled aluminum and recycled stainless steel offer environmental benefits by reducing the need for new raw materials and reducing waste. However, the specific environmental impact will depend on the specific production processes and the end-use applications of the recycled materials.

Recycled leather is a material that is made from leather scraps and waste that are processed and reformed into new usable leather The scraps are collected from various sources, such as leather factories, furniture manufacturers, and leather products that are discarded or no longer in use.

The recycling process involves grinding the leather scraps into a fine powder, which is then mixed with a binding agent to form a pulp The pulp is then pressed into sheets, which can be cut and shaped into various products, such as bags, wallets, belts, and shoes. Recycled leather can also be embossed or printed with designs, and dyed in various colors.

Recycling leather scraps into new products helps to reduce waste and conserve resources, as it minimizes the need for new raw materials and reduces the amount of leather waste that ends up in landfills In addition, the production of recycled leather typically requires less energy and water than producing new leather from animal hides, which makes it more environmentally friendly.

Recycled leather is considered a sustainable material because it offers several environmental benefits:

Reducing waste: Recycling leather scraps and waste reduces the amount of material that would otherwise end up in landfills, contributing to the problem of waste disposal.

Conserving resources: By using existing leather scraps, the production of recycled leather requires less energy, water, and other resources than producing new leather from animal hides.

Lower carbon footprint: The production of recycled leather has a lower carbon footprint than producing new leather, as it reduces the need for resource-intensive processes such as raising livestock, transportation, and processing of raw animal hides

Increased durability: Recycled leather is often combined with other materials to improve its durability, making it last longer and reducing the need for frequent replacements.

Versatile: Recycled leather can be used for a wide range of applications, including clothing, bags, shoes, and furniture, which allows for more efficient use of the material and reduces waste.

Recycled glass is a material that is produced by processing used glass products and waste into new usable glass The process of recycling glass involves crushing the used glass into small pieces called cullet, which are then melted down in a furnace to produce new glass products.

The glass waste used in recycling can come from a variety of sources, including discarded bottles, jars, windows, and glass packaging materials This waste is collected, sorted by color, and then transported to recycling facilities where it is processed into new glass products

Recycling glass offers several environmental benefits, such as reducing the need for new raw materials and conserving energy. Glass is 100% recyclable and can be recycled an infinite number of times without losing quality, which makes it an ideal material for sustainable production practices In addition, recycling glass reduces the amount of waste that ends up in landfills, which helps to conserve natural resources and protect the environment.

Here are some fun facts about recycled glass:

Glass can be recycled endlessly without losing its quality or purity. This means that a glass bottle or jar that you recycle today can become a new glass product over and over again.

The production of recycled glass uses significantly less energy compared to producing new glass from raw materials Recycling one glass bottle can save enough energy to power a 100-watt light bulb for four hours

The use of recycled glass in manufacturing can help to reduce greenhouse gas emissions. Every six tons of recycled glass used in manufacturing can save one ton of carbon dioxide emissions.

Recycling glass also helps to conserve natural resources For every ton of glass that is recycled, over a ton of raw materials like sand, soda ash, and limestone are saved.

Some cities have unique recycling programs that turn recycled glass into beautiful works of art. For example, in Seattle, Washington, a recycling program called "Artful Glass" creates unique pieces of glass art from recycled glass bottles and jars

RRPET felt is a type of felt made from recycled plastic bottles RPET stands for Recycled Polyethylene Terephthalate, which is the material used to make many plastic bottles.

The production process of RPET felt involves collecting used plastic bottles, cleaning and shredding them into small pieces, and then melting and reforming them into felt sheets The felt can then be used for a variety of applications, including clothing, accessories, and home decor.

RPET felt is a sustainable alternative to traditional felt, as it reduces waste and conserves resources. Recycling plastic bottles into felt helps to reduce the amount of plastic waste that ends up in landfills or oceans. It also reduces the need for new raw materials, such as petroleum, which is used to produce virgin polyester felt

Here are 3 reasons why clients should consider purchasing RPET felt promotional products.

Eco-Friendly: RPET felt is an eco-friendly material that is both durable and versatile. It has similar properties to traditional felt, but is made from recycled materials. By choosing RPET felt promotional products, clients can show their commitment to sustainable practices and reduce their carbon footprint.

High-Quality: RPET felt is a high-quality material that is durable and long-lasting. It can withstand wear and tear, and maintain its shape and form over time. This makes it a great choice for promotional products that will be used repeatedly.

Customizable: RPET felt promotional products can be customized with logos, designs, and colors to meet the specific needs of the client. This allows businesses to create unique and personalized items that promote their brand and message

Hemp belongs to the Cannabis sativa plant family and is cultivated as an industrial crop for its fiber, seeds, and oil. It has been utilized for its therapeutic and medicinal properties, as well as for making textiles, paper, and construction materials in various cultures for thousands of years.

Hemp is a versatile material that is popularly used in creating promotional products Some examples of how hemp is used in the promotional products industry include making durable bags for shopping, travel, or outdoor activities, producing clothing that is sustainable and breathable, creating ecofriendly stationery products like journals and notebooks, crafting unique accessories such as hats, lanyards, and wristbands, and producing beauty products that use hemp oil or other hemp-derived ingredients By using hemp, promotional products are marketed as eco-friendly and sustainable options, as hemp is considered a renewable resource that requires less water and pesticides compared to other crops like cotton.

Requires less water: Hemp requires less water than other crops like cotton. It is a drought-tolerant crop that can grow in a wide range of climates with minimal irrigation.

Low pesticide use: Hemp is naturally resistant to pests and diseases, so it requires fewer pesticides and herbicides than other crops This reduces the environmental impact of farming and protects the health of farmers and consumers.

Reduces soil erosion: Hemp has a deep root system that helps to prevent soil erosion and improve soil health. This makes it an excellent crop for sustainable agriculture and promotes the long-term health of the land

Carbon sequestration: Hemp is an excellent carbon sequester, meaning it absorbs more carbon dioxide from the atmosphere than other crops. This helps to reduce the amount of greenhouse gases in the atmosphere and mitigate climate change.

Tea leaves are the young leaves and leaf buds of the tea plant (Camellia sinensis) that have been harvested and processed for use in making tea. The tea plant is an evergreen shrub or small tree that is native to East and Southeast Asia, and is cultivated in many other parts of the world

Tea leaves waste refers to the discarded tea leaves that are generated during the production and consumption of tea. In the promotional products industry, tea leaves waste can be repurposed to create a variety of eco-friendly products.

By repurposing tea leaves waste, companies can reduce their environmental impact and promote sustainability in the promotional products industry. These products also have a unique story behind them, which can help to engage and connect with customers who are interested in eco-friendly products.

silicone is made from sand, which is primarily composed of silicon dioxide. The process of making silicone involves extracting silicon from the sand and combining it with other elements such as oxygen, carbon, and hydrogen to create a synthetic polymer This process is called the "silicones process " and involves several steps, including purification of the silicon, reaction with other chemicals, and processing into a final product.

The use of sand as a raw material in the production of silicone is considered more sustainable than the use of petroleumbased materials, which are often used to make other types of plastics Sand is a naturally occurring and abundant resource, and its use in the production of silicone can help to reduce the environmental impact of manufacturing.

Unlike many other plastics, silicone can withstand high temperatures and does not break down easily, which means that it can be reused multiple times. Additionally, silicone does not leach harmful chemicals or toxins, making it a safe and non-toxic option for products that come in contact with food or skin.

Elephant dung paper is a type of recycled paper made from the dung (or poop) of elephants. The process of making elephant dung paper involves collecting the dung, washing it, and then boiling it down to create a pulp. The pulp is then mixed with other recycled materials such as newspaper or office paper and pressed into sheets

This process not only creates a unique and sustainable paper product, but it also helps to reduce waste and promote conservation efforts for elephants. Additionally, the paper is often sold by fair trade organizations, providing economic opportunities for communities that live near elephant habitats.

Elephant dung paper has a rough texture and a natural, earthy scent, and can be used for a variety of purposes such as stationery, notebooks, and gift wrapping. It is also an environmentally friendly alternative to traditional paper made from wood pulp, as it requires fewer chemicals and energy to produce.

Elephant dung paper is odorless: Despite the fact that it's made from elephant dung, the resulting paper is completely odorless thanks to the thorough cleaning process.

It takes a lot of dung to make a little paper: It takes about 1520 pounds of elephant dung to make just one sheet of paper!

The paper is eco-friendly: Elephant dung paper is completely eco-friendly and sustainable, making it a great choice for environmentally conscious consumers.

It provides an economic benefit: Elephant dung paper production provides a source of income for many local communities, particularly in Africa and India, where elephant populations are high.

The paper is strong and durable: Due to its high fiber content, elephant dung paper is actually stronger than regular wood pulp paper, making it great for stationery and other paper products

It supports elephant conservation: By buying elephant dung products, consumers are helping to support conservation efforts aimed at protecting elephant populations and their habitats.

Elephant dung products come in many forms: In addition to paper, elephant dung can be used to make a variety of other products, such journals, and even jewelry.

100% cotton refers to a fabric or material that is made entirely from cotton fibers. Cotton is a natural fiber that comes from the seeds of the cotton plant, and it is a popular choice for clothing and other textiles due to its softness, durability, and breathability. When a product is labeled as 100% cotton, it means that there are no other synthetic or artificial fibers mixed in with the cotton, and it is made entirely from natural cotton fibers

100% organic cotton is cotton that has been grown without the use of synthetic fertilizers or pesticides, and is free from genetically modified organisms (GMOs). Organic cotton is typically grown using natural methods, such as crop rotation, composting, and natural pest control. Organic cotton is considered a more sustainable alternative to conventionally grown cotton, as it has less impact on the environment and is healthier for farmers and workers who are exposed to the chemicals used in conventional cotton farming. Additionally, organic cotton is often produced under fair trade conditions, which ensures that farmers are paid a f i i f h i and are treated fairly in their work

Recycled cotton is a type of sustainable textile made from preor post-consumer cotton waste, such as fabric scraps or discarded clothing. The recycling process involves breaking down the cotton fibers, removing any impurities, and spinning them into new yarn to create new fabrics. Recycled cotton helps to reduce the amount of textile waste in landfills and conserves water and energy that would be used in the production of new cotton textiles It also reduces the need for virgin cotton production, which can have a high environmental impact due to its heavy use of pesticides and water. Recycled cotton is often used in the production of eco-friendly and sustainable clothing, accessories, and other textile products.

Fairtrade cotton is a type of cotton that is produced by farmers who are certified by Fairtrade International, an organization that works to promote sustainable and ethical trading practices. Fairtrade cotton ensures that farmers receive a fair price for their crops, have safe working conditions, and receive other benefits such as access to healthcare and education Additionally, fairtrade cotton is produced using environmentally sustainable fa the use of harmful chemicals a Fairtrade cotton is often used i sustainable clothing and textile

The choice of cotton you purchase can have an impact on the environment, as well as the social and economic well-being of people involved in its production. Here are some reasons why it matters:

Environmental impact: Traditional cotton farming can have a negative impact on the environment due to the use of pesticides, fertilizers, and intensive water usage Organic cotton is grown without the use of harmful chemicals, which helps to reduce the environmental impact. Recycled cotton also has a lower environmental impact compared to virgin cotton as it reduces the amount of textile waste.

Social impact: Fairtrade cotton ensures that farmers receive fair prices for their cotton, and have better working conditions This helps to support their livelihoods and improve their social and economic well-being.

Health impact: Traditional cotton farming involves the use of harmful chemicals, which can have negative impacts on the health of farmers and workers. Organic cotton is grown without the use of harmful chemicals, which helps to protect the health of farmers and workers

Sustainability: Choosing organic or recycled cotton can help to reduce the environmental impact of cotton production, while choosing fair trade cotton can help to support the sustainability of cotton farming communities.

In summary, choosing a more sustainable and ethical cotton option can help to reduce the negative impact of cotton production on the environment and people involved in its production, while also promoting sustainability and fair trade.