Shaping the future

ENTERPRISE

IS ALL ABOUT

building things, and we at Consat are passionate about working together to create solutions consisting of various parts that can be connected like Lego pieces, thanks to our way of working. Creating each new piece makes us grow, and all the pieces are genuinely important.

Let’s take Engineering and IoT as an example. We have built up capabilities based on our solid expertise in developing special-purpose machinery and, above all, our deep understanding of our customers’ business. To this we add our expertise in IoT to create added value for customers with the help of digitalisation. The more customers we meet, the more we realise how unusual it is for colleagues in the industry to take such broad responsibility.

This attitude is common to all our companies. Consat Telematics’ supply commitment spans everything from hardware installation to subsystem integration combined with further development and adaptation in a continuously expanding product portfolio. Customers may have requirements and requests, but at the end of the day what is most important is achieving a well-functioning comprehensive delivery. Consat SES’s strength lies in its ability to understand system perspectives such as what technical measures generate the greatest savings and how to take joint responsibility with our installation partners for the con–struction contract based on trust. Many of SES’s customers have their own organisation for optimising energy efficiency, and it is at this point, if not ear-

EDITORIAL

future together

lier, that it becomes especially clear how much value our deliveries create. Many of Consat Data’s customers choose to fully outsource their IT support. Detailed management and control requires many divisions of responsibility, which takes energy and time – things that are in short supply for most players.

However, performing large assign–ments is not easy and makes high demands on organisation, work processes and individual employees, whose efforts have a direct impact on the overall result in many cases.

If we stop and look at what we’ve achieved together, we can only be incredibly proud and happy. There’s no doubt that we’re creating value and success through partnership – with more to come.

Consat Telematics recently won new contracts in Australia, including with Ventura, one of the country’s largest bus operators with over 500 buses in Melbourne. We’ve landed a contract in the city of Fredricton in eastern Canada, and there’s a distance of over 5,580 km between this customer and British Columbia in western Canada!

Consat Engineering is expanding with more employees and new projects both in Sweden and in India. Our team in Stockholm is developing and delivering installation equipment for Scania’s production units at an impressive rate, and in Partille, we are in the final negotiations regarding one of our biggest machine projects ever!). We also have a wide range of software projects including a telematics system for Actia in, an IoT system for Eberspächer and software integration for Lotus in the UK, among many others.

Consat Data is growing, not least in the events sector. Although there are many organisers in this sector, few of them are able to offer a stable IT environment.

All our companies are affected by component delivery delays and, not least, rising costs. Consat SES, which operates in the construction sector, has been negatively impacted by the industry’s rapid downturn, which has resulted in customers postponing projects at short notice. Meanwhile, there is an increased need to streamline energy use in response to surging energy prices. Some real estate companies have the

muscle power to continue investing. SES has begun expanding its customer base towards sectors such as industry and breweries, where we are now helping essentially sound businesses to cut their energy costs.

It is always difficult to predict the future, but in times like these it is important to keep up the pace, spread risks and, of course, be extra responsive to rapid changes.

Although the transition needs to happen faster, it is driving a need for development in many of the areas where we are active today. Both as a company and for humanity as a whole, it is, quite simply, important to have the courage to keep the momentum going even when the going gets tough.

Or in the words of Mario Andretti, winner of F1, Indycar and Indy 500: “If everything is under control you’re just not going fast enough.”

Thank you for your exceptionally good work.

Martin Wahlgren

For many, this may be the first time you read ConText. ConText is the magazine that takes the time to tell in more detail about our innovative and challenging projects and not least what it is like to work at Consat. Our ambition is to use interesting articles and good visual material to describe and highlight in which contexts Consat operates.

Publisher: Martin Wahlgren

Editor in Chief: Jenny Fredér

Text Editor: Mattias Johnson

Editing Assistant: Gabriella Wendt

Design: Happy Camper Reklambyrå

Graphic Design: Andreas Eklöf

Min 12mm hög

Print: Billes Tryckeri

After working as a consultant at Consat Engineering AB for many years, Frida Williamsson has stepped into a leadership role as technical area manager in Embedded Design. Her ambitions are to strengthen the strong corporate culture that Consat already has and ensure that everyone has the necessary conditions to achieve both the company’s and their own individual goals.

WILLIAMSSON HAS BEEN A CONSULTANT at Consat for eleven years, working on projects at major corporations as well as startup companies. In recent years, she has become increasingly involved in the various working methods employed by teams and has developed a growing interest in leadership and team dynamics. When she was offered the role of technical area manager, she naturally accepted.

“As a consultant at Consat, I’ve seen many different aspects of the work. It’s been an instructive journey that’s prepared me for my new role. For me, it’s important to maintain and strengthen our culture at Consat. Our culture is based on our enjoyment of cooperating, taking care of and helping each other. At Consat we have an innovative streak that is really tangible. We welcome new ideas from employees and do our best to put them into practice.”

She is responsible for Embedded Design, where just over 20 software and electronics engineers work. Their work currently focuses on developing products such as smart lighting, measuring instruments for nuclear power stations and electrification of future vehicles.

“This is an important team for Consat and our business, and I’m proud to be working with them. It’s an excellent team of engineers.”

As technical area manager, Williamsson is responsible both for HR and for marketing services to new and existing customers. Because the majority of her staff work on projects out in the field and only a handful work in-house at Consat, one of her greatest challenges is making sure everyone feels part of Consat.

“Consat should be a workplace where employees are happy and feel they have scope for development and creativity. As technical area manager, I need to be sensitive to employees’ requests and input in order for them to have the best possible conditions to carry out their work and for us to achieve our established goals together,” she says.

About

FRIDA WILLIAMSSON

Age: 39 years

Family: Partner and two daughters

Home: Påvelund

BEING A CONSULTANT UNLOCKS OPPORTUNITIES

Ingrid Bogdanovic has been a consultant at Consat for five years. She has worked on site at Volvo during this entire period. What is it really like working at a customer’s premises as a consultant?

WHEN BOGDANOVIC graduated from Chalmers University of Technology in 2017 and joined Consat, she got her first consulting assignment after just a month. The customer she was assigned to was no other than the automotive giant Volvo Trucks.

“As a systems engineer, my job entailed working with integration testing and Volvo’s own tools. I tested Volvo’s different systems, performed regression testing and made sure everything was OK. It was particularly satisfying because this gave me the opportunity to learn more about building system rigs.”

Since then, Ingrid has been on parental leave and subsequently returned to Volvo Trucks, this time working with cybersecurity. Although she now works in a different field, she knows many of the staff because of having worked with them on previous assignments.

“Of course it feels a bit different working on long-term consulting assignments since my closest colleagues aren’t the people I work with at Consat. But Consat feels like a secure base to come back to. It’s good to

know that I always have their backing if an unclear situation arises when I’m at a customer’s site,” says Bogdanovic. She adds: “Although I’m an external consultant, I’m treated as part of the team at Volvo and get invited to after-work events and other activities. They make sure consultants aren’t treated any differently to regular employees. We’re all part of the organisation because we all work towards the same goal of delivering high-quality products.”

Bogdanovic spends 99 percent of her time at the customer’s premises, but she occasionally works at Consat’s office. She feels her role as a consultant gives her freedom and choices, two aspects she values in a role. If she became interested in working in a different area, she would have many options as a consultant.

“I chose to work as a consultant because it unlocks opportunities. Right now I’ve found a satisfying job with Volvo that I love, which offers me maximum opportunity for development. My reason for continuing to be a consultant with Consat is that it gives me so much scope for working in different areas or for different clients in the future.”

INGRID BOGDANOVIC About

Training: Degree in Electrotechnology at Chalmers University of Technology, 180 credits.

Assignments while working at Consat: Systems engineer, system rig engineer and currently system tester in the area of cybersecurity.

Key aspects that make the job fun: Being in a team with high expertise and good team spirit.

TEXT ANNA LARSSON [BORG O WILLI] PHOTO MATTIAS JOHNSON

TEXT ANNA LARSSON [BORG O WILLI] PHOTO MATTIAS JOHNSON

30 YEARS IN TELEMATICS – ROLAND MOBERG TALKS ABOUT THE JOURNEY OF PUBLIC TRANSPORT

MOBERG’S TELEMATICS JOURNEY began at Göteborgs Energi, where he worked in the department that designed traffic signals for the Traffic and Public Transport Authority. After a couple of years he decided to embark on further studies at Chalmers University of Technology, but when the time came to do his dissertation project he returned to Göteborgs Energi. He continued working there with public transport solutions.

“They were just about to start a big project to improve the public transport network in the city. At that time there was no wireless communication, so we were tasked with finding technologies that would enable communication between buses and trams.” Moberg recalls.

A solution was arrived at involving underground circuits capable of detecting the public transport while enabling the vehicles to communicate.

THE ROAD TO CONSAT

Before joining Consat Telematics, Moberg worked briefly for Volvo Buses after the vehicle giant acquired the department at Göteborg Energi where he was working. At Volvo Buses, he and his colleagues were tasked with developing a vehicle software system in-house.

“In 2004 Volvo deemed the system to be fully developed and ready to start selling off-the-shelf. So Volvo started looking for a partner to outsource the actual development to. We met with Hogia and Wireless Car before establishing contact with Consat. We met with Consat’s founder Jan-Bertil Johansson. We really clicked with the Consat Group and it seemed a perfect place for us to be because we got to continue working with the product. So on 1 April 2005 our development team moved from Volvo to Consat,” Moberg says.

Roland Moberg has worked in telematics for over 30 years. During this time he has seen public transport become increasingly smart, progressing from simple systems to high-tech solutions. He has been R&D Manager at Consat Telematics since 2005.

THE DEVELOPMENT OF TELEMATICS

Looking back on his 30 years in the industry and the development of telematics, he points out the growing requirements of the public and buyers:

“Our work was initially about improving access for public transport. It gradually also became important to give passengers real-time information about buses’ and trams’ actual arrival times. Today, it’s commonplace to have an app on your phone and information displays at bus stops informing passengers of the current status of the service. Meanwhile, it’s become more important for operators to manage the traffic according to the rules of the responsible authority. Otherwise they risk hefty fines.”

The equipment on board buses has become increasingly advanced. Buses today contain equipment worth hundreds of thousands of SEK, such as ticket machines, passenger counters, TV screens and CCTV cameras, as well as the vehicle computer system and the driver terminal. In addition, the system controls bus stop signs, on-board announcements, traffic management applications and much more.

“The technology has constantly improved. About ten years ago, it was far too expensive to carry out exact passenger counts. Only

very few vehicles were equipped with passenger counters and the total number of passengers was estimated based on the results from the few vehicles that had the equipment. Now the technology is so advanced that passengers can even be categorised according to whether they are adults or children and if they have suitcases, wheelchairs, pets or bicycles with them. This means that today we can inform passengers on the display board if the bus is full to capacity,” he explains, and adds:

“When I started working at the Traffic and Public Transport Authority in the 1980s, we had no guidelines to follow and were given a free rein. Today both society and buyers have clear requirements for how public transport should work. It’s been very exciting to be part of this transition.”

“Now the technology is so advanced that passengers can even be categorised according to whether they are adults or children and if they have suitcases, wheelchairs, pets or bicycles with them.”

CONSAT ENGINEERING

TEXT ANNA LARSSON [BORG O WILLI] PHOTO MATTIAS JOHNSON

With solid experience in modern automotive technology, Claes Sernevi has stepped in next to Lars Olsson as Consat’s new Manager sharing the responsibility for Engineering Services. His ambition is to keep the company’s expertise up-to-date while attending to employees’ interests.

SERNEVI WAS AS GOOD as destined to become an engineer. He grew up in a family of engineers in Karlshamn where the latest technology was constantly discussed at the dinner table. And he was no exception:

“Since childhood I’ve been taking things apart – everything from earphones to cycles and mopeds. Nothing bugs me as much as not understanding how something works. I love tackling problems and delving into technological rabbit holes.”

Since graduating in mechanical engineering and product development from Chalmers University of Technology, Sernevi has worked as a consultant in various organisations and constellations. He has primarily focused on heavy and light vehicles, working with both concepts and production. He has been involved in one of Volvo Cars’ self-driving pilot projects and in developing Volvo’s electric trucks.

“I’ve managed to stay at the leading edge of technology, which is where I want to be. Glimpsing the future, shaping society’s direction and making meaningful contributions to a more sustainable world are the things that drive me,” he says.

In January 2022 Sernevi became

Manager Engineering Services at Consat. He describes the role as being a hub for competence in mechanics at the company. His duties involve securing and supplying the necessary resources for customer projects and internal projects.

“I had a similar role in my previous job and enjoy the combination of HR development, business development and building customer relationships. What attracted me to Consat was their understanding that expertise and human resources are what actually builds an organisation,” says Sernevi. He adds:

“As head of consulting, my work isn’t about what I want to do; it’s about what our employees want to do and how they want to develop. Our consultants are the entire basis of our business.”

Right now there’s a strong focus on recruiting new staff. Several machine projects are coming up in the area of product development. Sernevi also works on developing Consat’s machine design expertise and making the company stronger in automation.

“There’s also a huge amount going on in electromobility and battery technology in the Gothenburg region right now. This is a sphere I feel we should also be moving in,” he says.

About

CLAES SERNEVI

Age: 35 years

Family: Married with two children

Home: House in Surte just north of Gothenburg

Hobbies: Mountain biking, cycling, skiing and climbing

TEXT AMY-LEE THOMAS EDITING MATTIAS JOHNSON PHOTO MATTIAS JOHNSON IMAGE PROCESSING ANDREAS EKLÖF

TEXT AMY-LEE THOMAS EDITING MATTIAS JOHNSON PHOTO MATTIAS JOHNSON IMAGE PROCESSING ANDREAS EKLÖF

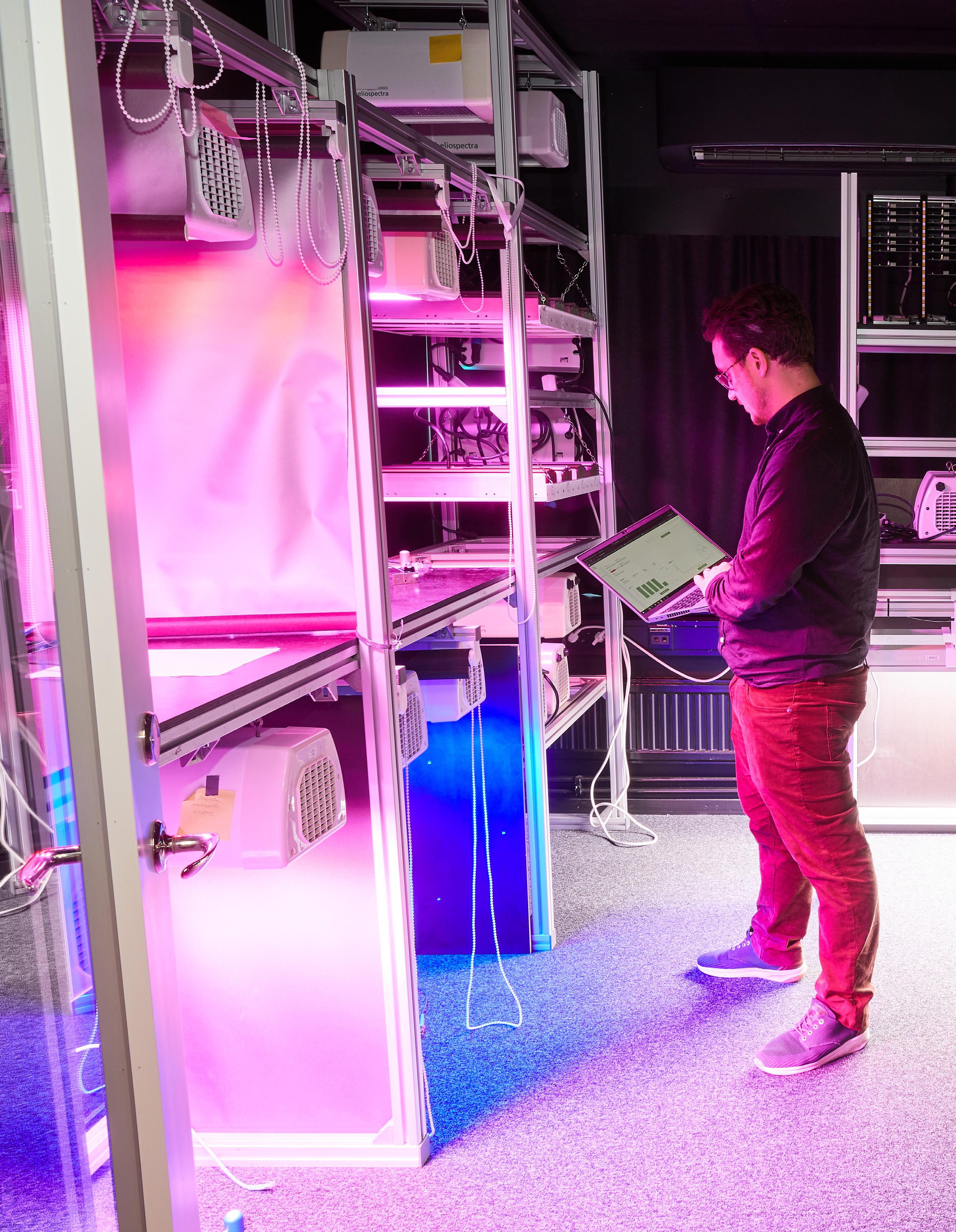

CONSAT LAUNCHES NEW IOT PLATFORM: NEXT

WANT TO SUPPORT OUR CUSTOMERS’ DIGITAL TRANSFORMATION JOURNEY”

On 1 March, Consat Engineering AB launched Next, a new IoT platform designed in partnership with the Indian company Orahi. “Through Next, our customers can start their digital journey at a reasonable pace but with the shortest possible starting distance,” says Pär Forsberg, Manager IoT & Electrification, Consat Engineering.

WITH OVER 35 YEARS OF EXPERIENCE in embedded software, domain, IT, cloud and IoT, Consat and Orahi (read more about the partnership in a separate article in this magazine) designed their new platform to offer exactly what each individual customer needs, almost regardless of who they are.

There is an enormous need for a simple transition to a world where almost everything is connected and constantly accessible. Very soon it will be more the rule than the exception that every thing and every machine shares information both with users and manufacturers.

It doesn’t have to be hugely complicated. Even simple real-time information about how a small machine or household appliance works, right now and over time, can provide enormous added value.

Next makes it possible for customers to connect their devices and view collected real-time data through a simple web dashboard. Then they can process, sort and refine the information using everything from simple rules to complex artificial intelligence.

“With our platform, customers don’t have to start from scratch. We can quickly build the functionality you need to solve the particular business problems you’re experiencing,” says Forsberg.

“WE

“And what makes our platform particularly unique is the implementation speed. With Next, you can actually digitalise your projects and be up and running with simple functionality in four to six weeks.”

SMALL OR LARGE STEPS WITH THE CUSTOMER IN FOCUS

When developing Next, the goal was to have an agile approach to customer challenges, for instance by offering rapid prototype production (minimal viable product scope (MVP)), in order to get started and deliver functions in the shortest possible time. When simple functionality is in place and everyone can see that it works, you can continue adding functions and really increase the added value. Another aim is to constantly maintain transparency in the contact with customers and build a relationship with a long-term perspective right from the outset.

“We aim to maintain a close collaboration with our customers and support them along the way,” Pär explains.

ALREADY UP AND RUNNING

Although the platform was recently launched, it was successfully pilot tested on clients prior to the launch. Now Consat looks forward to helping more customers.

“We can do this in a simple way; we have the tools, the abilities and the experience. By letting us take care of the digital side, our customers can focus on what they do best while we make their lives a little easier,” Pär concludes.

“With Next, you can actually digitalise your projects and be up and running with simple functionality in four to six weeks.”

GREAT PLACE TO WORK conducts the world’s biggest employee survey. It gives organisations data-driven insights into their culture and provides the world’s only certification of outstanding workplaces. No less than 19.8 million people responded to one of their Trust Index™ surveys last year.

Employee satisfaction alone is not enough to meet their criteria for a good workplace. An organisation must also have high levels of fairness, respect, pride and camaraderie, and the man agement must offer inspiration and information, show ap preciation and care, and develop their employees. Organisations that meet these criteria are awarded Great Place to Work® certification, which is valid for 12 months.

The employee survey is carried out via an email link, and employees are asked to rate their experience at work. They are asked to respond to 60 statements grouped into five categories: credibility, fairness, respect, pride and camaraderie. As the final question, the respondents are asked if, overall, they regard their workplace as a great place to work.

The 60 statements are then computed to measure the degree of trust the employees feel. The resulting value is our Trust Index. To be awarded Great Place to Work certification, an organisation must have a Trust Index™ of at least 70 (on a scale of 0–100). Consat got a Trust Index of 80%, which of course we’re extremely proud of. Now each company will work with the results, address areas where improvements are needed and, above all, maintain their good performance in high-scoring areas.

Together we make Consat better and more successful!

CONSAT ENGINEERING

TEXT MATTIAS JOHNSON PHOTO MATTIAS JOHNSONMOVING AWAY FROM PNEUMATICS IN FACTORIES

Short setup times for small series, small energy losses. Many of Consat Engineering’s industrial clients are requesting electric actuators instead of traditional pneumatic solutions in their production lines and machinery.

MATS BERNHARDSON AND DANIEL CARLSSON have been with Consat for many years and have designed many machines. One change they’ve seen in the past ten years is a gradual transition from push-button pneumatics to electric actuators in customers’ machinery and production lines. This transition has been driven by a supply of suitable electrical actuators in the market, as well as by a demand from customers who need to streamline their production.

AIR MAKES LIGHT WORK

The traditional and typical way of moving, holding, lifting, sorting and stopping products on a factory production line is to use cheap, reliable compressed air cylinders to produce simple movements. Electric servo motors have, in principle, only been used in cases where a job simply can’t be done using compressed air, due to a need for precise movement or positioning. Because air can be compressed, it is not possible to achieve precise movements – at least not with simple, cheap cylinders.

So compressed air has been the cheaper, simpler option, with electric servo motors being more expensive and more complicated from a design perspective.

This is despite the fact that compressed air has always been expensive to produce, and a factory with a large compressed air system loses a lot of energy due to all the tiny leakages that typically occur with compressed air. The benefits have simply outweighed the disadvantages.

“Air cylinders are very small, compact, operationally reliable and simple,” Bernhardson explains.

“And although they’re small, they can deliver enormous power – and the speed can be set from one end position to the other.”

He adds:

“If you want to place a pallet on a pallet conveyor, you simply use an air cylinder: It’s either out or in, and you can achieve a pressure of 200 kg in a large cylinder – and it works at lightning speed if necessary.”

ELECTRICAL POWER? YES PLEASE

But the technology is advancing. Electric actuators and cylinders are getting better and cheaper almost by the year, and when the two solutions are compared, electric actuators are increasingly being chosen. Especially when the customer gets to choose. The ongoing energy cost for compressed air is often a compelling argument.

“There are simpler electric cylinders that work and are controlled like their pneumatic counterparts, and there are also more advanced ones that can be controlled with exact precision. And then there are all-in-one units that include the control electronics, which are otherwise in a separate electrical enclosure,” says Carlsson.

“The choice is largely determined by the application, but many people still want to have the control electronics all together in an electrical enclosure, which is handy both from an operating environment and a servicing perspective.”

CHANGING TRENDS

“It was when we were working with SKF in 2013–14 that I first noticed this customer trend towards electrically powered movement,” says Bernhardson.

“The customer said they didn’t want pneumatics, and they also said in a machine project that they wanted to reduce the compressed air pressure from 6 to 4 bar in a machine to reduce leakage and save energy.

“I think we generally still prefer not to use electric actuators or cylinders for a new machine unless a customer requests it, since at the end of the day it’s easier and cheaper to buy an air system. It’s easy to install, but of course there needs to be a compressed air system in the factory,” Carlsson says.

It’s often also a question of how many simple movements a machine or application needs to perform. A compressed air system requires an air conditioning unit which costs about SEK 5,000, regardless of whether the machine is fitted with one or twenty-five air cylinders. If only one or two movements are needed, pneumatics might not be the cheapest or even the simplest solution, the two colleagues point out.

“And you have more design options with electric operation,” says Carlsson.

“If I only need two positions, I’ll obviously choose the simplest, cheapest solution,

which is often air. But if the customer doesn’t want an air cylinder I have to find an electric equivalent – and they’re available now,” says Bernhardson.

“But I still don’t think there’s an electric alternative that’s quite as simple, cheap, strong and fast as an air cylinder for small movements,” he adds.

Carlsson agrees: “No, you still don’t get exactly the same maximum power or speed from today’s electrical cylinders.”

SIMPLY TOO SIMPLE

But simple isn’t always an advantage. Adjusting the flow in air cylinders in situ using restrictor valves can sound like a simple, practical and beneficial solution, but Bernhardson and Carlsson don’t agree.

“It can actually be a drawback. In real-life situations in the workshop, an operator on one shift might decide to adjust the valve to improve its performance, but then the team on the next shift adjusts it back again – even though we’ve already fine-tuned the machine to perform in a certain way. So the fact that everybody knows how an air cylinder works can actually be a disadvantage, compared with electrical cylinders that need to be adjusted by a programmer,” Bernhardson points out, laughing.

“On the other hand, a broken air cylinder is easy to replace simply by screwing a new one in place, whereas an electric cylinder might need to be reset to zero or parameterised when replacing it, which can be much more complicated,” he says..

“Sometimes you can use a memory card with stored parameters, which can be moved to the replacement unit. That makes replacement a bit easier,” Carlsson interjects.

A COMBINATION IS OFTEN USED

“We made ten assembly machines for SKF a while back. They said they didn’t want compressed air at all, but in the end a few cylinders were used anyway,” says Bernhardson.

“When you have conveyors and pallets to manage, electricity can be a expensive solution. A small air cylinder with a sensor costs maybe SEK 1,500, whereas an electric equivalent costs upwards of SEK 10,000. If 6 to 8 small cylinders are needed, it adds up to a huge expense. It’s a balance between purchase and operational costs,” he points out.

SHORT SETUP TIME WITH ELECTRIC ACTUATORS

Energy savings are important, but probably the biggest and strongest argument for electric actuators is the short setup time – precisely because of the actuator’s precise positioning and electronic control system. Where a line with only pneumatic cylinders requires manual replacement of tools, blocks, adjustment, etc. to handle a specific product, which takes perhaps 30 minutes, an electrically controlled line can, in principle, be prepped just by pressing a button. This is a huge advantage when you’re producing small series of products are produced just-in-time, as opposed to mass-producing goods to store in a warehouse, Bernhardson and Carlsson explain.

CONSAT

TELEMATICS TEXT MATTIAS JOHNSON PHOTO MATTIAS JOHNSONConsat Telematics has helped to set up five new continuously connected electric ferries in the Oslofjord. Consat’s passenger counting solution keeps track of passenger numbers, while no less than twelve on-board display screens provide passengers with information.

Acouple of years ago, public transport operator Boreal Sjø won a contract to provide new ferry transport in the Oslofjord. Their five brand new electric ferries serving the islands in the Oslofjord mark a step towards the target of making Oslo’s public transport emission-free by 2028.

Providing real-time passenger information is seen as a matter of course in public transport today. Consat Telematics, which dominates the Norwegian market for real-time systems, got the job of connecting the new ferries, which were built at the Sefine Shipyard in Turkey.

As mentioned earlier, the five ferries, Oslofjord I to V, are electrically powered. They are charged up in Aker Brygge in Oslo between journeys, using the same type of “pantograph” that has become standard on electric buses. When the batteries are empty, diesel generators are used as a back-up.

The ferries were designed by the Norwegian company Multi Maritime A/S. They are 35 metres long and have a capacity for 350 passengers.

Joakim Sällberg is a project manager at Consat Telematics. He is in charge of the Consat project that provides the ferries with a solution for passenger counting, passenger information and connection of vessel and weather data to Boreal’s traffic management and office on shore, and to the responsible authority, Ruter, which procures and monitors public transport for Oslo Municipality.

This is not the first time Consat’s system is used on ferries. The system has been in use for many years in the Gothenburg archipelago. However, many things in the Oslofjord project are new. Not least the large amount of data from the vessel that is collected and transferred in real time.

“Each vessel has a large number of sensors that monitor drivetrains, temperatures etc. This information is loaded into Consat’s system via a protocol called Modbus, which we are using for the first time,” explains Sällberg.

“Information is also supplied from a weather station without moving parts, where the wind speed is measured by ultrasound (believe it or not). We also get in-

“Providing realtime passenger information is seen as a matter of course in public transport today. Consat Telematics, which dominates the Norwegian market for realtime systems, got the job of connecting the new ferries.”

CONSAT TELEMATICS

formation from the gangways and about the ferry’s direction of travel – the vessel is symmetrical and doesn’t have a specific bow or stern.” He adds:

“And we have passenger counter sensors installed above each gangway.”

All this data is sent through the Consat system to Ruter or Boreal, who can constantly monitor the status of their vessels.

EVERY PASSENGER IS COUNTED

Although Consat has extensive experience of passenger counting in buses and trams using sensors from various manufacturers, the ferries’ challenging environment and larger dimensions required certain modifications to be made.

“The problems associated with passenger counting in this case were largely due

to the fact that the entrance is so wide – over 2.5 metres – much wider than the doors of a bus or tram,” says Sällberg.

“Prams, bicycles, etc. also need to be detected and classified. At present there is a requirement to distinguish between adults and children, but we also want to be able to detect prams and wheelchairs.

“We previously intended to use two communicating sensors to cover the entire width of the gangway, but the manufacturer we were working with didn’t have the function ready in time so we contacted Hella, a different manufacturer than we had originally planned to use.

“They seem very good and their sensors can cope with the large width. We’ll probably expand our partnership with them going forward. These passenger counter sensors use cameras and visible light, not IR like many other passenger counter sensors,” Sällberg says.

He explains that one of the most important functions associated with automatic passenger counting is that it allows both the operator and authorities to constantly monitor how many people are on board. This can save lives in an emergency situation. Consat has equipped its web application Fleet Studio (see the article on Fleet Studio in this issue of Context) with a display that allows users to constantly track the number of passengers on each ferry.

And as mentioned before, it’s not only the operator and authorities that Consat provides with information.

“Every ferry has twelve information screens, far more than on a bus or tram. We actually had to adapt our system to handle such a large number of screens in a single ‘vehicle’,” laughs Sällberg.

LEARNING CURVE

Although not much new development was needed to adapt the Consat system to the Norwegian electric ferries, many practical problems arose during the project. This was not least because the Turkish shipyard that built the ferries was unaccustomed to installing cables and the type of electrical equipment that Consat’s real time system is

“The problems associated with passenger counting in this case were largely due to the fact that the entrance is so wide –over 2.5 metres – much wider than the doors of a bus or tram.”

“He explains that one of the most important functions associated with automatic passenger counting is that it allows both the operator and authorities to constantly monitor how many people are on board. This can save lives in an emergency situation.”

based on. This meant that both Consat and Sefine Shipyard had to learn on the job while building and installing the system.

“The requirements differed from our on-shore projects,” Sällberg says.

“For example, earth faults have greater consequences on a boat because they cause corrosion, and some of the cables are unusually long – upwards of 80 metres – so we had to keep a check on the cable resistance in a completely different way than for even the largest trams.

“Installing our equipment at a shipyard is also very different to working in a nice, clean bus factory. The shipyard staff weren’t used to installing the type of connectors we use, so we had to modify some of the installations. But it was a great learning experience,” says Sällberg.

Sometimes there were also setbacks in the project. The ferries, which were delivered from Turkey to Norway on the decks of large cargo ships, were delayed.

“Some of the installations weren’t finished before the ferries were delivered to Oslo, so we had to complete them, even after the ferries were commissioned,” Sällberg says.

SPECIAL MARINE FUNCTIONALITY

The project is largely complete at the time of writing, although some planned functionality still remains to be added. And there have also been requests for some interesting marine-specific functions that other Consat customers are likely to be interested in.

“We’ve planned to add manual adjustment of the passenger count,” Sällberg explains.

As an added precaution, the passengers are still being counted by hand until the passenger counter system is trusted to take over completely, and we know there will be times when the numbers need to be adjusted slightly.

“Although the sensor is good, with a specified accuracy of about 99 percent, it can still make mistakes, for instance if an adult is carrying a child. A decksman has to keep a lookout for such situations and ask the captain to make corrections in our interface if needed.

“We’ve also discussed the possibility of checking to make sure the ferry captains don’t drive too fast when approaching the jetty. We could quite easily check this and also issue a warning if a certain speed was exceeded on the way towards the jetty,” he says.

“Earth faults have greater consequences on a boat because they cause corrosion, and some of the cables are unusually long – upwards of 80 metres – so we had to keep a check on the cable resistance in a completely different way than for even the largest trams.”

congrats! congrats! congrats!

• Daniel Carlsson who welcomed a daughter on 10/3

• Emanuel Lundqvist who welcomed a daughter on 4/5

• Victoria Peterson who welcomed a son on 10/6

• Kirill Kravtsov who welcomed a son on 6/9

• Dawid Johansson who turned 50 on 21/3

• Ingemar Carlsson who turned 60 on 29/3

• Patrik Bengtsson who turned 30 on 4/4

• Daniel Almestål who turned 40 on 7/5

• Kenan Pacavar who turned 30 on 26/5

• Emil Brandt who turned 50 on 30/5

• Nicklas Reitz who turned 30 on 17/9

• Martin Olsson who turned 50 on 21/9

• Marika Särnblom who turned 50 on 25/9

• Ian Hostetter who turned 50 on 26/9

• Lulu Cui who turned 30 on 1/12

TOGETHER WITH ORAHI, Consat is strengthening its offering to the Swedish market at a time when digitalisation is enabling increasingly advanced solutions. With the joint venture Consat Orahi, Consat can secure steady access to expertise that consolidates the company’s position as one of the leading engineering companies in Sweden.

“Orahi delivers important expertise in the internet of things. We’re also seeing how electrification and digitalisation require more and more of both embedded development and system development in IT. We want to gain even greater access to these areas of expertise to win even more projects in the field,” says Pär Forsberg, Manager IoT & Electrification, Consat Engineering.

LONG EXPERIENCE OF SWEDEN

Orahi, which has its operations in Gurgaon just southwest of the capital region of Delhi, has extensive experience of Sweden and Swedish corporate culture. Its employees and management have backgrounds at large Swedish companies. Consat has had a project-based collaboration with Orahi for over a year.

“The work has included the development of Consat’s new IoT platform, Next. With it, customers can easily start their digital journey, focus on their business needs and create insights, while we manage the technical parts around device connectivity, data management and smart applications. We’ve built a number of customer solutions on the platform, including a system for the operation and maintenance of vehicle chargers and one for predictive maintenance on mobile cooling systems,” says Forsberg.

SECURING SKILLS NEEDS

With the joint venture, the collaboration is being formalised, which guarantees complete deliveries to the market with security and cutting-edge expertise even in large, development-heavy projects.

“This joint venture will make our customers feel confident that skills needs are being met. The skills situation is extremely strained in Sweden. Through Consat Orahi, we will strengthen our delivery capability even in the most demanding projects. Moreover, with their knowledge of the Swedish market, Orahi has a corporate culture that is similar to ours,” says Ragnar Hallgren, Vice President, Consat Engineering.

A CULTURE WHERE PEOPLE CAN GROW

A long-term perspective and a work environment where competence can grow and be utilised are central to the joint venture. That’s why common core values have been crucial from the outset for a functioning collaboration, Hallgren emphasises.

“Consat has a clearly defined corporate culture that we are careful to maintain. It’s about having a good atmosphere, a flat organisation where everyone can have their say so that people can develop. We’ll continue building this culture at Consat Orahi in India,” says Hallgren.

Consat Engineering and Indian Orahi have formed the joint venture Consat Orahi. As a result, Engineering will strengthen its offering in areas such as the internet of things (IoT).

“This joint venture unites excellence and good corporate culture,” comments Ragnar Hallgren, Vice President, Consat Engineering.

CONSAT ENGINEERING

EKLÖFFROM DRAWING BOARDS TO 3D MODELS

When Dan Gustafsson and Claes Ottosson joined Consat in the 1980s, the company had a small handful of employees and its premises were filled with drawing boards, drawings and a fair amount of cigarette smoke. Today Consat is an international group and its tools are workstations, 3D CAD and 3D printers. And its employees are entitled to wellness allowance. It’s been a long and exciting journey!

TEXT ANNA LARSSON [BORG O WILLI] EDITING MATTIAS JOHNSON

TEXT ANNA LARSSON [BORG O WILLI] EDITING MATTIAS JOHNSON

CONSAT ENGINEERING

IN 1986, the year Consat was founded, Dan Gustafsson became the company’s fourth employee. Ronald Reagan was in his second term as US president and the average Swede drove a Volvo 240, or a 740 if their finances allowed it. A computer cost the same a good second-hand Volvo 240.

Today, 36 years later and with retirement in sight, Gustafsson can look back on a career packed with engineering experience, primarily from the automotive industry. He has spent most of this time as a consultant at Volvo, constantly at the cutting edge of the engineering profession. “In a purely technical sense there’s been enormous development,” he says.

“When I started at Consat, we used a drawing board and pens. Actually, pencils were used at Volvo, although other companies, such as Ericsson, made India ink drawings. Drawing in ink was almost a profession in its own right. But ink was already on the way out by then,” he recalls. A drawing is a drawing, although standards vary between industries and companies. But the digital tools that have been introduced since then have evolved and

changed significantly over the years. Cadam, CATIA, Autocad… Many solutions – initially extremely expensive and specialised –have come and gone. Some are consigned to history while others live on and continue evolving.

“Consat started working with 2D computer drawing in the early 1980s, but everything was still checked, saved and delivered on paper,” remembers Gustafsson.

“I actually encountered 3D CAD at Volvo even before starting at Consat, and [the CAD software] CATIA with 3D was introduced at Volvo in 1986, so everything wasn’t only drawn on pen and paper,” he says.

“But everything was done in black and white on big tubes (monitors with cathode-ray tubes) and the equipment was really difficult to work with. UNIX stations were exorbitantly expensive, and for a while Consat had a single CATIA station which we all shared.”

SMOKE AND DRAWING BOARDS

Another “old-timer” who was one of Consat’s first employees is Claes Ottosson. A colleague at his previous job had spoken highly about Consat, and shortly after that Claes got a job as one of Consat’s designers.

“When I joined Consat in 1987– or maybe it was1988 – the company had twelve employees and we only worked with industrial design solutions. The office was on Backa Bergögata at Stigs Center. We had seven drawing boards – two in the smoking room and five outside it,” laughs Ottosson.

“One of our colleagues smoked so much that he had to work in

a separate room with another chain smoker,” he recalls.

The large drawings could be copied with an enormous electrostatic printer, and there was a huge drawing board in the middle of the room. Everything in the automotive industry was drawn on a 1:1 scale, including large trucks. The chassis drawings could be enormous.

“The vehicle was sectioned every hundred millimetres and the cross sections were drawn separately, as if the vehicle had been sliced from end to end at ten centimetre intervals. The model builder with the task of making the vehicle in clay based the model on each cross section in the drawing to ensure absolute precision,” Ottosson and Gustafsson explain.

LIZARDS AND LIGHT PENS

Ottosson also recalls the early CAD workstations.

“Today you can sit at a screen without feeling discomfort. But the screens back then were a different matter. You got practically blinded by this big, thick screen with white lines shining straight in your face. If you worked too much at a computer in those days, you started looking a bit like monitor lizard, all gnarled and scaly,” he jokes.

“And the first workstations had a light pen that you had to click on the screen with, which meant you had to sit really close. I don’t think that was very healthy either,” adds Gustafsson with a smile.

A drawing board seems appealing by comparison.

“When you stand opposite or next to each other, you can talk to each other and maintain contact while drawing. That’s not as

“The large drawings could be copied with an enormous electrostatic printer, and there was a huge drawing board in the middle of the room. Everything in the automotive industry was drawn on a 1:1 scale, including large trucks. The chassis drawings could be enormous.”

easy when everyone’s huddled over their computers,” Ottosson observes.

A MIX OF 3D MODELS AND PAPER

“Volvo started doing certain things in 3D CAD in the late 1980s, but you still couldn’t send a 3D model to a supplier. You created the 3D model, then you chose a view to create a specific drawing. Then you set the dimensions in a different program and printed a paper copy of the drawing, which you sent to the supplier,” says Gustafsson.

“Consat switched completely to working on the computer in the 1990s. Volvo used 3D technology early on, of course, but when I was at FlexLink in 1995 we were still drawing in 2D in Autocad on ordinary PCs,” says Ottosson.

MOVING IN STEP WITH TECHNOLOGY

Of course, the huge technical advances mean that the work has become more precise. Today, Consat’s engineers can easily send a 3D model to customers and suppliers over the Internet and show exactly what the product will look like and how it will work.

But while the tools have improved, the products that are designed, such as vehicles, have become increasingly complex.

Gustafsson’s work gradually changed from designing engines to designing vehicle batteries. In 2009, he was working on a project to examine solutions for what were then the electric vehicles of the future when Consat and another consulting firm were contracted by Volvo to design a fully electric C30.

In the last decade, he has increasingly switched to working as a project manager.

“These days I serve as a communication link between the customer’s designers and our designers at Consat,” he explains.

“The work is still technical but the role also requires you to be a ‘people person’, which I definitely am. So you could say that the tools, vehicles and I have all developed enormously over the years,” he says with a smile.

During his decades at Consat, Ottosson has mainly worked with process development, both as a designer and a project manager. What he enjoys most is problem solving, the actual heart of the job.

Although a lot has changed in the industry and at the company, many things remain the same:

“Our niche in engineering is still relatively similar. Everything has evolved of course – we have better engines and control systems – but a nut is a nut and a bolt is a bolt, so the basics are still very much the same,” says Ottosson.

Although the company has grown from a small, young consulting firm to the group Consat is today, Ottosson and Gustafsson both agree that the company has succeeded in maintaining its original culture.

“The helpful, open, family atmosphere is firmly established here. Although many of us are out working with customers, we always have our Consat family to return to,” says Gustafsson.

“While the tools have improved, the products that are designed, such as vehicles, have become increasingly complex.”TEXT AMY-LEE THOMAS PHOTO MATTIAS JOHNSON

Consat expands to Stockholm –

CTS SOLUTION TO TRANSDEV

Consat Telematics deepens its partnership with Stockholm-based Transdev. In late summer, the transport operator went live with Consat’s solution, CTS, which has been adapted to cover requirements regarding on-board systems and traffic management

“We’re delighted that Transdev chose us as a partner for the traffic contracts in Stockholm and are looking forward to the collaboration,” says Oscar Rosenstam, Product Manager, Consat Telematics.

THE TRANSPORT SECTOR is undergoing a paradigm shift. What used to be primarily about transporting people from A to B is today characterised by high IT requirements. Given this change, transport operator Transdev has sought new solutions to meet the requirements of SL (Stockholm Public Transport Authority) in Stockholm. Previously, SL installed its own equipment in the buses to cover its needs. This is no longer the case, and bus operators are now responsible for providing the corresponding information from the buses. The parties initiated their partnership shortly after Consat Telematics launched its innovative solution last November, and the services went live in August. This delivery will be the first of CTS’s new web-based driver interfaces that can be displayed on screens controlled by third parties. “As customers impose higher technical requirements, transport operators need to maintain high quality; CTS is part of the chain that delivers the data that SL requests. As suppliers we have worked with this type of data stream for decades, while these are new requirements for bus operators,” says Oscar Rosenstam.

Even if technical requirements are changing, it is always passengers’ experience that is at the heart of public transport.

“It’s extremely important for us to have full control of our service deliveries to clients. Here we’re seeing, among other things, that the monitoring services in CTS together with Transdev’s real-time platform help us get more information right down to the component level in the buses, while also enabling fast, efficient troubleshooting in the event of malfunction. It can give us an even better service for our passengers,” says Adam Fall, CIO at Transdev.

AN INNOVATIVE SOLUTION

Consat Telematics’ solution suits players on both the client and operation side. It is scalable in both size and functionality, with many different interfaces that make it adaptable to the customer’s existing platforms both on board the veichle and in the back end. The fact that Transdev is now starting to use Consat’s solution is a milestone for the telematics company, which has not previously provided its CTS system to the Stockholm region.

“We’re very excited to see how the delivery will be received by Transdev. The project also includes on-demand traffic, which is a very exciting area in public transport and something that is being introduced in several of our markets. We’re really looking forward to developing a solution for it together with Transdev,” says Rosenstam.

“It’s fabulous to work with Transdev. They’ve got many enthusiastic people there and it really feels like we’re building something cool together.”

CONSAT BRASIL

TEXT AMY LEE THOMAS PHOTO MATTIAS JOHNSON, ADOBE STOCK 3D-IMAGE PROCESSING ANDREAS EKLÖFCONSAT CONTRIBUTES TO CLEANER, SMARTER PUBLIC TRANSPORT IN BRAZIL

In late 2021, Consat continued its expansion journey by establishing operations in South America through the launch of Consat Brasil Ltda with its head office in the metropolis of São Paolo. Statistics from Renavan (National Register of Motor Vehicles) show that there are over a million diesel-powered buses in Brazil, something that Consat wants to change.

“There’s great potential for change, and we at Consat look forward to being part of the journey,” says Esbjörn Lif, Sales & Marketing Manager, Consat Brasil Ltda.

PUBLIC TRANSPORT TAKES HIGH PRIORITY on the societal agenda today, and more and more cities are investing in their infrastructure to increase accessibility for citizens and improve the environment by reducing the number of diesel vehicles on roads. Consat’s core business is to develop, deploy and maintain state-of-the-art public transport systems for vehicle manufacturers, public transport operators and public transport authorities.

“Our timing for establishing Consat in Brazil is perfect as the country has recently begun making the journey towards electrifying its public transport. As a forerunner in innovative, smart solutions for electrified public transport, Consat will be an attractive partner for players in the Brazilian public transport market. We’re a few years ahead of the local competition thanks to our experience of smart solutions for electric buses in Scandinavia, Canada and Australia,” Lif points out. He continues:

“Needless to say, a population of over 200 million and the large number of buses in the country result in significant negative climate impact. The introduction of electric buses will contribute to reducing CO2 emissions, noise and negative impact on human health.”

ONE IN FIVE BUSES TO BE ELECTRIFIED

Shortly after Consat launched its venture in Brazil, the company contacted Leandro Sodré, who has worked in the Brazilian bus industry for over 20 years. Sodré and Lif began penetrating the market in the first half of 2022. As a result of this, the company now sells its systems to the bus manufacturer Eletra, which makes electric buses with 100 percent Brazilian components. The mayor of São Paolo recently set a target for 20 percent of the city’s buses to be electrified by 2024, and Consat wants to contribute to meeting this target.

“This is a project that’s in line with the times. Transitioning away from fossil-fuelled transport is a necessary step towards long-term climate sustainability. We’re delighted that our solution has been received so favourably. It feels like the Brazilian authorities have realised the necessity to overhaul public transport to contribute to a better climate. Electrification has moved forward worldwide and Brazil must keep up with this development,” says Lif.

BRASIL

CONSAT

ENGINEERING

IN-DEPTH TESTING

When a number of large electrical enclosures are installed on the sea bed at a depth of 1,000 metres in an enormous natural gas field, it’s essential to know that they’ll work – for a long time. Once they’re in place you can’t make repairs or modifications, and hundreds of millions of dollars are at stake.

Consat Engineering spent several weeks in the summer of 2022 performing costly testing to verify the calculations carried out by our Netgroup colleagues at FS Dynamics regarding the temperature development and environment in these electrical enclosures. A job with “NASA-level” requirements.

THIS IS YET ANOTHER STORY that confirms how Netgroup – a group of technology companies that collaborate in order to take on big jobs for big clients – can generate good jobs for its members, who have mutually complementary skills and expertise.

This time it was Consat who got an exciting job from our colleagues at the calculation company FS Dynamics –which in turn had obtained an exciting job from Aker Solutions of Norway, a company with billions of NOK in sales and 14,000 employees, which develops and manufactures oil and natural gas extraction technology. This technology is largely located on the sea bed, one of the most demanding and unforgiving environments imaginable.

In this project, Aker Solutions delivers equipment to Chevron, which is building a compressor station in an enormous gas field off the coast of Australia.

Martin Hogander at Consat Engineering describes the compressor station as ‘the size of Ullevi stadium’.

Installing the compressor station on the sea bed makes it possible to maximise the efficiency of the gas production. It minimises losses when transporting the gas to the surface, which results in big financial and environmental benefits.

MODELLING BACKED BY PRACTICAL TESTS

For Consat, the project involved verifying FS Dynamics’ theoretical model of the temperature development and inter-

CONSAT ENGINEERING

nal environment in a number of multi-storey underwater electrical enclosures to be installed at a depth of just over 1,000 metres in the natural gas field’s compressor stations.

Each of these electrical enclosures (or “electrical tanks”) contains powerful motor control electronics for the natural gas compressors, as well as various other control electronics.

Motor control in this power class generates significant energy losses in the form of heat, even with the best technology currently available, and the heat needs to be closely and accurately monitored when such costly equipment is installed on the sea bed. As mentioned earlier, once it’s installed there, nothing can be done to fix faults or irregularities. Once in place, the enclosures will never be opened or brought back to the surface, so they need to work for their entire planned lifetime. This means the project has similar requirements to a space project.

The fact that the enclosures will be filled with dry nitrogen adds to their high-tech nature. The electronics heat the nitrogen, which in turn transfers the heat to the inside of the enclosures, which contain a heat sink. The sturdy steel wall of the enclosure then transports the heat out to the cold sea bed.

Backed by Consat’s practical tests, FS Dynamics can be absolutely sure that their theoretical calculation model is accurate and that they can mathematically model exactly what will happen inside the full-scale electrical enclosures under varying loads. This in turn enables FS Dynamics’ client, Aker Solutions, to build a perfectly dimensioned electrical enclosure, which their client, Chevron, will be very happy about.

BIG TEST ON A SMALL SCALE

Martin Hogander and Lars-Åke Johansson at Consat Engineering are real veterans at the company, and were entrusted with completing the project.

There were initially some issues with organisation, before it became clear that this unexpectedly demanding project called for senior designers like Hogander and Johansson. Once they were on board and tackled the problems, things really took off.

“We felt like it was us against the world. We said, ‘Now let’s go for it,’” says Hogander.

“There were no specs... the tank size, the input power. We had to work it all out as we went along.”

And time was very scarce. FS Dynamics needed results, quickly.

“I’ve never experienced a schedule like that. It felt like they were calling us every two hours,” Hogander says.

The start was shaky for a while. All parts of the test had to be discussed and decided, and it soon became clear that the requirements were so high that the planned budget for the project would need to be increased manifold.

“We quickly realised we couldn’t do this for a fixed price – an extremely costly project would suffer if we cut corners in the wrong places,” Johansson explains.

“We felt like it was us against the world. We said, ‘Now let’s go for it.’”

CONSAT ENGINEERING

STRONG FOCUS ON TEMPERATURE

It was defined during discussions with FS Dynamics exactly how the scaled down “electrical enclosure” for the test would be designed and cooled in order for the theoretical models to get exactly the right data for the verification process. A constant temperature in the outer shell was absolutely crucial. An ice-cold water jacket was used to simulate the surrounding sea (see the pictures to the side).

“For a while we considered using a solution to achieve a stable temperature with active components, but that would have been far to expensive, even for this project,” says Johansson. The water for the water jacket – or actually water jackets since the enclosure was divided into two parts – was kept at a constant temperature by continuously melting ice in large open tanks. This was a simple, physical, self-regulating method of temperature control.

Ordinary submersible pumps delivered a controlled flow of ice-cold wa-

ter from the tanks, through the water jackets and back again. Carefully specified insulation round the tanks minimised external temperature impact.

“To calculate the number of litres of water delivered per minute by each pump in a real application, we tested them individually by pumping water into a 200L oil drum suspended on a hanging scale at the same height as the receptacle used in the test, for 30 seconds. This produced a realistic and exact flow value,” the two colleagues explain.

It also turned out that the two pumps delivered almost exactly the same water flow.

The ice melting method worked well, although vast amounts of ice were used during the test period – 5 metric tons (!). Hogander and Johansson carried the ice in sacks from a freezer container outside the workshop and topped up the tanks as the ice melted in the summer heat.

“The melting ice in the tanks made the water temperature in the system

self-regulating as long as ice remained in the tanks,” Johansson explains. The water in the water jackets stayed stable at 0.5 degrees Celsius.

“The temperature doesn’t have to be exactly the same as in the actual marine environment in order for the test to work, but it does need to be stable,” adds Hogander.

“Of course we logged the temperatures, and they never rose above 0.7 degrees,” says Johansson.

EXACTLY THE RIGHT PAINT

For practical reasons, the tank needed to be divided into two parts. It was made of stainless steel exactly like the full-scale “electrical enclosure”. The same heat sinks were installed on the inside and it was coated with a paint with carefully adapted properties. Everything was done to make the test as realistic as possible.

“We put the two halves of the tank on rails to facilitate assembly and handling. The tank was designed by us. There was talk about designing the

“To calculate the number of litres of water delivered a minute by each pump in a real application, we tested them individually by pumping water into a 200L oil drum suspended on a hanging scale at the same height as the receptacle used in the test, for 30 seconds. This produced a realistic and exact flow value.”

opening like the door of a bank vault, but in the end we decided to put the parts on rails and it worked very well,” says Hogander.

“The paint used in the tank had to have specific conductivity and emissivity, so we had to send it to the RISE [research institute] for testing,” he adds.

And they needed to know the exact thickness of the layers of paint sprayed on the inside of the tank.

“Paint thickness gauges capable of measuring paint on stainless steel are unusual, but the people who painted the tank in Tidaholm had one, so they came here to do the measuring after the paint had cured thoroughly,” Hogander says.

“I made a drawing of exactly where we measured the paint thickness… we had to document absolutely everything.”

AIR INSTEAD OF NITROGEN

In the initial discussions with FS Dynamics, there were plans to have a realistic test tank filled with nitrogen. However, the safety aspects – nitrogen is invisible and risks causing suffocation because people think they’re breathing air – would have required Consat’s workshop to be converted for this purpose. So for this and other practical reasons, the tank was filled with dry air instead, which proved to work very well.

“We used large bags of silicon to dry the air in the tank. This produced equivalent air circulation and characteristics as the dry nitrogen in the real electrical enclosures,” explains Hogander.

“And we constantly monitored the air environment in the tank – relative

humidity and temperature,” adds Johansson.

“We handled the overpressure and underpressure in the tank by using two facing non-return valves.” says Hogander.

ARTIFICIAL HEAT LOSS

To simulate the power losses in the full-scale electrical enclosures, purpose-built aluminium cubes of different sizes containing heating elements were installed at six different levels in the tank.

FS Dynamics specified exactly how the cubes should be designed and positioned. The cubes were made from aluminium, which was given a black anodised finish in order to emit heat in a strictly controlled way. Thermally conductive paste between the heating elements in the cube and the actual aluminium cubes ensured controlled heat emission.

Hogander and Johansson had to order a certain type of heat-resistant but insulating plastic from the United Kingdom to make spacers in order to fit the cubes so that that they were thermally insulated from the cut-out panels used to install the heating elements and sensors in the tank. This was necessary to prevent the test results from being distorted by heat from the actual mounting panels.

“We gave FS Dynamics the drawing of the spacer so they could calculate the amount of heat conducted through the plastic, and it was a factor 100 so nothing serious,” says Johansson.

For precise, stable control of the emitted power in each of the heating elements installed at six levels in the

“ Once in place, the enclosures will never be opened or brought back to the surface, so they need to work for their entire planned lifetime. This means the project has similar requirements to a space project.”

tank, Johansson chose to use traditional rheostats (wirewound variable resistors). They provided an even, precisely controllable current.

“To enable the input power to be monitored exactly, it couldn’t be controlled with a triac (semiconductor control). Instead we had to use old-fashioned rheostats,” he explains.

The heating elements at each level were parallel connected, and a sturdy knob was used at each level for adjusting the power manually.

“The analogue control was surprisingly accurate. The resistance of the resistor changes when it heats up, so we needed to finely adjust the rheostats once they had been heated [by the current]. The settling time for each individual test was 3.5 hours,” says Johansson.

CAREFUL MEASUREMENT

Of course it was important to use reliable temperature sensors for the test.

Considering the tight schedule, Johansson and Hogander opted for the most fail-safe choice.

“The temperature sensors we chose were specifically selected for extreme precision,” Hogander says.

First the sensors were fitted with metal radiation shields to prevent the heat radiation from distorting the readings (these are the slitted sleeves seen in many of the pictures in this article), but this quickly proved a bad idea.

“We initially installed radiation shields. But this didn’t work because the radiation shields themselves heated up and radiated heat towards the sensors, and they also obstructed the air flow around the sensors. So the shields had to be removed,” says Johansson.

FS Dynamics calculated the air flow around the radiation shields and confirmed that the warm air was circulating around the shields even though the slits were close to the sensor tips

(see pictures), so it wasn’t heating the sensors as intended.

Without radiation shields and with the sensors thermally insulated from the mounting panels, the measured values improved significantly. But theory and practice still didn’t completely coincide.

What was missing was the exact positions of each sensor in the tank.

“I measured all the sensors’ exact positions, and then FS Dynamics could see greater conformity with their model,” Johansson explains.

“Simply put, theory and practice coincided.”

In hindsight this test series showed that the expensive, specially selected sensors were actually too good.

“The calibrated sensors we had chosen were, in fact, not necessary, because the fluctuations in the system were a factor 10 greater than the sensor precision,” says Johansson.

“They considered this a normal way of working, but we’d never encountered anything like it. They’d say, stop! where’s the risk analysis!? … But we’re only switching on a water pump, we’d reply. We weren’t allowed to start until we’d performed the risk analysis specifying everything that could happen while the pump was running.”

“We measured to an accuracy of a tenth of a degree, whereas the fluctuation was in whole degrees.”

All the sensors – carefully numbered with their exact position and direction in the tank – were connected to rented data loggers for the subsequent test series.

“We rented the loggers because buying new ones would have been far too expensive,” says Hogander.

Finally everything was ready for the tests.

TEN TEST CASES

FS Dynamics had specified ten separate test cases – different power settings for the six levels of the heating elements.

“A test might be carried out as follows: Use maximum power at the bottom level and no power at all the levels above it, or medium power at all levels… etc.,” Johansson says.

“It took three and a half hours before the system was stable and the results of each test could be logged.”

Johansson and Hogander kept a continuous check of the amount of ice in the tanks, the water jacket temperature and the relative humidity in the tank.

They sent all the measured data from the ten tests, which they compared to their theoretical model. The reality coincided very well with the theoretical model and showed that it was completely correct.

DOCUMENTATION AT A HIGHER LEVEL

An aspect of the project that Hogander and Johansson were not prepared for was the extreme requirement to document every tiny detail and to perform risk analyses of every stage of the work. It came as something of a shock. With their off-shore operations, Aker Solutions understandably focuses strongly on HSE (Health and Safety En-

vironment), from the initial concept right through to delivery of the products. HSE is included in everything the company does to prevent people getting injured at their own premises or the premises of their customers or suppliers.

Hogander and Johansson weren’t only required to document drawings and hardware specifications. There were also requirements for test pressurisation, material certificates and data sheets showing the cables’ insulation and thermal conduction properties. The non-return valves limiting the pressure in the tank needed to be classified and precise to allow their function to be verified.

“They considered this a normal way of working, but we’d never encountered anything like it. They’d say, stop! where’s the risk analysis!? … But we’re only switching on a water pump, we’d reply. We weren’t allowed to start until

we’d performed the risk analysis specifying everything that could happen while the pump was running.

“Every part of the work required a risk analysis – even carrying bags of ice up the steps to the water tanks,” says Hogander.

“They had to supply us with templates and documents, and they thought we were very primitive… but things started getting better once they realised we had everything under control and were even ahead of schedule,” he says.

“No matter what question they asked, we immediately had the answer.”

MONEY IS TIME

Perhaps the toughest aspect of the entire project was the tight schedule.

“We were actually really stressed,” says Hogander.

“They said, ‘If you don’t get finished, you’ll have to work during your holidays!’ That added extra pressure,” he says.

“Our contact with the subcontractors got very intense. They had to work double shifts when the schedule was tight.”

It happened several times that Hogander and Johansson had to pay extra to get their jobs prioritised, but it was worth it.

“Aker Solutions and FS Dynamics appreciated that we were quick. They wanted a small plastic cap to put on the sensors. We went to a subcontractor who said, hmm, it’s Friday and we’re busy… But we said, what if cost is no object? And that did the trick. We had a new test ready the following Monday! They were impressed by that,” Hogander says.

“It’s very satisfying to work on a project that so clearly prioritises quality over cost,” he adds.

“But working without specs was less fun,” Johansson points out.

“The hardware proved more expensive than they [Aker Solutions] expected, but the analysis cost less – and in the end they were delighted! During a physical meeting they said, in front of the representatives from Chevron, that we’d done an amazing job and they were really satisfied,” says Hogander proudly.

“They said, ‘the parts and design are of the same high quality as the electrical enclosures we’re installing on the sea bed.’

“It’s actually the same quality that we deliver to SKF and other customers. The only difference is the documentation and all the risk analyses,” says Johansson with a smile.

CONSAT ENGINEERING

“During a physical meeting they said, in front of the representatives from Chevron, that we’d done an amazing job and they were really satisfied.”

Lindholmen Open Day 2022 Open2022 Days

THIS YEAR’S LINDHOLMEN OPEN DAY was a fantastic event. After two years of being held online, Gågatan at Lindholmen Science Park came to life again and Älvrummet was packed with wonderful seminars all day. The theme of the event was Innovation – the way to a sustainable society!

Orvar Hurtig, Amir Skangic and Ulrika Lin held a seminar on DATA BASED DEPOT

CHARGING – the smart sustainable city described in a small context.

At our booth we presented our Geiser greywater heat exchanger, which attracted keen interest.

CDE was there with us presenting the workplace of the future. We demonstrated how a transport controller can sit and work with correct ergonomics, sound and lighting that adapts to your comfort. The Consat Telematics public transport system was shown on the screens at the workplace.

In addition, Martin Wahlgren presented the Collaborator of the Year award to Fredrik Sandblom from Zenseact.

European Dragon Boat CHAMPIONSHIPS Banyoles 2022

MANY OF YOU Many of you have no doubt heard about – and perhaps even took part in – the Dragon Boat Festival in Gothenburg last year, where teams and companies competed in a big race on the canal outside Feskekyrkan. Interestingly enough, there’s also a more serious side to the sport where people compete in races of different distances in 10-person or 20-person dragon boats.

The European Dragon Boat Championships took place in Banyoles, Spain on 1–4 September. Ten countries competed for the titles in various classes. The race distances were 200 m, 500 m and 2,000 m. The races are held on a buoyed course. The 200 m and 500 m races are held on straight courses, while the 2,000 m race takes place on an oval course marked by buoys which the the contestants must navigate round.

Sweden did well, taking home five medals. One silver and one bronze in the U24 class, two bronze, and Sweden also successfully defended its gold medal in the 200 m mixed class.

I have been doing dragon boat racing since autumn 2018, and this was my first international championship. The preparation consists of training on the water and in the gym. Training camps are held in various places in Sweden about 6–7 times a year. The sport is very small in Sweden, with only 200–300 active participants, but it’s big in other parts of the world.

CONSAT

TELEMATICS

TEXT MATTIAS JOHNSON PHOTO MATTIAS JOHNSON, ADOBE STOCK IMAGE PROCESSING ANDREAS EKLÖF ILLUSTRATION ANDREAS EKLÖF

Fleet

Studio:

THE BIRTH OF A STELLAR APP

From a hobby project to a function-packed but modern and user-friendly web application. Fleet Studio is Consat Telematics’ “Swiss army knife”; it can be used in everything from mobile phones to wall-mounted giant screens.

AS THE GREY EMINENCE Mr. Dryden said in the blockbuster movie Lawrence of Arabia: “Big things have small beginnings.” This truism often applies to the product company Consat Telematics, where numerous smart functions and solutions have been born over the years in the form of small experimental ideas and private projects created outside working hours by developers who are passionate about their work.

In case you’re unfamiliar with this Consat company, here is some information: Consat Telematics develops and supplies systems for vehicle management, passenger information and traffic management in the public transport sector for a large number of customers worldwide.

And when a veteran employee at Consat Telematics, Torbjörn Bäckström, started putting together a modular software platform for applications with a web interface in May 2017 in his free time, he sowed the first seed for a project

that has since grown to become Consat Telematics’ latest application, Fleet Studio.

At the time, Bäckström merely viewed it as a fun open-source project that everyone could use to build their own larger, modular web applications, after he had provided the basic building blocks.