6

Anna Stamm – Advertiser Forum: Fall is for Follow-Up

Joe Kannapell: The Development of the Truss Plate, Part III: The Ingenuity of Carol Sanford and Cal Jureit

Wendy Boyd – Spida USA: BCMC 2022—What an Awesome Event

Todd Drummond Consulting, LLC: Including Meaningful Process Improvement on Your Capital Investment Checklist

Glenn Traylor: Are You Counting Your Teeth Correctly?

Tracy Roe – Eagle Metal: Perseverance and Success in the Components Industry

Edmond Lim, P.Eng. –LimTek Solutions: The Most Automated, Most Toured Truss Plant

A dverti $ er Component 72 77 80 86 90 95 98 103 106 122

Rob Bellian – Vekta: A Model of a Show at BCMC

Eide Machinery Sales Team: From Minneapolis to Columbus with Eide

Tim Kassa – Panels Plus: Going Platinum at BCMC with Panels Plus

Rod Wasserman – Wasserman & Associates: Displaying Our Family Pride at the Show

Steve Shrader – Hundegger USA: Getting Started with CNC Automation

Carl Villella – Acceptance Leasing: Added Value From Your Funding Source

MSR Lumber Producers Council: Because Good Ingredients Matter

Thomas McAnally – From the Road: The Best Laid Plans

Geordie Secord – The JobLine: Are We Selling Trusses or Lumber?

Michael Fagan – A-1 Industries: Building a 100-Year Company

Craig Webb – Webb Analytics: LBM’s Pace of Deals Hasn’t Slowed But Fewer Yards Are Involved

Randy Shackelford – Simpson

Strongtie: Hurricane Andrew — a 30-Year-Old Learning Experience

Joe Kannapell – The Last Word: The First Trade Show

From plans, to walls, to panels, and everything above. Introducing a new level of design tools, built from the ground up.

31,121

17,86,87

48,100

22,68

8,56

4,42,88

17,31,45,66,97

36,112

13,97

15,78

9,27,39,80,87

28,44,50

12,141

30,55,64,72

13,97

14,94,122,128

1,18,19,46,70,74

9,37,93,99

17,41,45,49,59,61,95,98,109,113

32,110

16,24

38,108,144

2,60,96

7,21,27,53,57,59,62,71,75,76, 77,85,101,105,109

49,89

21,23,29,37,39,40,41,47,49,53,54,55,57,58,59,61, 63,65,69,71,75,79,84,85,87,109,111

Thomas McAnally twm@componentadvertiser.org

Anna L. Stamm 800-289-5627 x 3 anna@componentadvertiser.org

Via e-mail subscription Download PDF or Read on line at www.componentadvertiser.com

News of Interest and Advertising inquiries can be submitted to: anna@componentadvertiser.org An Open Forum for many sources.

Deadline 20th of each month. Articles, Trade Names, and Logos are the property of their respective owner or creator unless otherwise noted

Disclaimer: We reserve the right to refuse any advertisement or material that we deem not in the interest of the industry or the Advertiser. Permission to use content is the responsibility of the contributor including permissions to use any likeness of persons.

The Advertiser is provided “As Is” including typographical errors, omissions, and mistakes both intentional and unintentional. Believe it at your own risk! 30,55,64,72 Copyright 2008-2022

Component Manufacturing

The Advertiser 411 Walnut Street #12250 Green Cove Springs, FL. 32043 no reproduction in whole or in part without

from the

advertiser

Archive Copies Available On Line www.componentadvertiser.com

Director of Communications and Marketing Component Manufacturing Advertiser.

Director of Communications and Marketing Component Manufacturing Advertiser.

As a follow-up to last month’s article, September is for Celebrating, I’ve realized that October should be the sequel. Indeed, as you’ll see from this month’s authors, there are many reasons to regard October as the perfect month for follow-up.

By all accounts, BCMC 2022 in Columbus last month was outstanding! Wendy Boyd from Spida describes it as “awesome” in her article. Tracy Roe from Eagle calls it “the best BCMC in almost two decades.” In the eyes of Rob Bellian of Vekta, it was a “bumper year,” and Tim Kaasa at Panels Plus had many “encouraging” conversations. The team from Eide Machinery thanks everyone for visiting both of their booths, and Rod Wasserman from Wasserman & Associates reminds us all how our industry is like a big extended family.

If you were fortunate enough to attend the show last month, be sure to prioritize your following up with the friends and colleagues you saw there or missed seeing there! Whether you have new business to conduct or simply want to catch up and stay in touch, October presents your best opportunities to do so before we begin the rapid approach into the holiday season.

Now that it is officially fall, it’s also time to consider the things we have intende d to accomplish “before the end of the year.” We all know that Thanksgiving and Christmas always arrive much more quickly than we think they will, immediately followed by the new year. Do you have a mental list of things you’ve been expecting to accomplish in 2022? Are there a few more goals to attain or targets to hit? Whether we’ll be relieved that 2022 is ending or sorry to bid it adieu, we have one quarter of 2022 left—let’s see if we can make the most of it!

• Automated (Truss Design Software Download) or SemiAutomated (Touch Screen Entry) Operation

• All Movements are Computer & PLC Controlled

• Comprehensive Setup Screens

Display Each Piece with Setup Data

• 22” x 40 Tooth Blade on PAE Cut 1 or 2 Boards up to 20’ (2 Second Plunge Cut)

• Cut Chords, Webs, Rafters, Wedges & Stair Stringers

• Cut Long Scarfs by MultiPlunging

• Servo Positioning on Infeed, Angle & Outfeed Pusher

• Over Travel Protection

• Ink Jet Printer

• Lumber Optimization Program

• Belt Waste Conveyor

• 480 Volt / 3 Phase / 60 Amp

• Includes 5 Day Onsite Installation & Training

• Optional Monet DeSauw Live Deck, Bunk Feeder & Incline Belt Waste Conveyor

FOB MO

Call For Pricing

• Touch Screen User Interface with Backup Mechanical Controls

• 3 Operating Modes: Auto, SemiAuto & Manual

• All 20 Axes of Movements are Computer & PLC Controlled

• Comprehensive Setup Screens

Display Each Piece with Setup Data

• Anti-Collision & Optimizing Programming

• Auto Calibration Productivity & Time Tracking

• Maintenance Diagnostics

• Variable Speed Conveyor (0-50 Flights per Minute)with Powered Hold Downs

• (1) 30” x 80 Tooth Blade (27 3/4” Scarf on PAE)

• (4) 16” x 40 Tooth Blades (13 1/2” Scarf on Centerline)

• Pneumatic Blade Brakes on all 5 Blades

• 16 1/2” to 20’ Length Capacity (11” Minimum on Square End Blocks)

• Vibrating Waste Conveyor Under Saw

• 480 Volt / 3 Phase

• Includes 4 Day Onsite Installation & Training

• Add $2,900 for Extra Set of Blades

• Optional Live Deck, Label Printer, Ink Jet Printer, Catcher Display & Incline Belt Waste Conveyor.

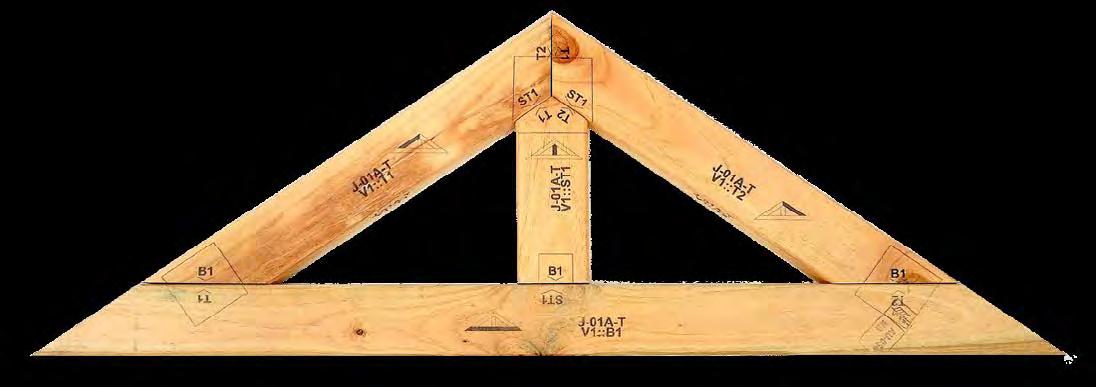

By Joe Kannapell

By Joe Kannapell

CarolSanford’s invention didn’t equal Cal Jureit’s, but he made up for it with his head start and his aggressive marketing. Sanford had filed for his patent in March 1954, two years ahead of Jureit’s September 1956 filing, and had a plate design that was relatively simple to mass produce. Though his plate required extensive hand nailing, it was the best wood connector available at the time and an instant hit. By July 1958, Sanford was operating a huge stamping plant and had developed extensive engineering manuals, declaring on their covers that his company was “The World Leader in Roof Truss Connectors.” This claim was undoubtedly true, as Sanford had no real competition until Jureit entered the scene.

Cal Jureit engineered his own business startup with thoughtful aplomb. Before going to market with a product that he knew was better than Sanford’s, he spent a year of R&D perfecting it, drawing from his years running a testing lab. This involved “one-off” fabrication of multiple plate configurations and running dozens of tests. With the data collected, Jureit was able to determine optimal tooth size and arrangement, and the necessity of increasing the plate thickness from 16 gauge to 14 gauge. Finally, with design in hand, he was unable to find an existing stamping facility capable of producing it, as Miami lacked heavy industry. So, he invested further time and effort recruiting manufacturing talent and outfitting a suitable building. And by 1958, Jureit was ready to stake his claim in the truss plate market.

Perhaps Sanford felt the competition was growing and realized he needed to distinguish his plate from Jureit’s, as these 1958 product listings from American Builder Magazine seem to imply. Sanford indicates “Semi-Nailed” in the headline without any mention of the extensive hand-nailing effort required. He seems to hang his hat on the “1,000 lbs. (jigging) pressure” and “each joint placed under 50 tons of pressure” without acknowledging that the truss must be flipped, back-plated, and nailed before being “moved to a roller table.”

Contrarily, Jureit’s promotions immediately seized on his trump card, headlining that the “Gang-Nail plate eliminates hand nailing altogether.” Then, he compounded that advantage by stating that both top and bottom plates are applied while the truss is in the jig.

While both of these listings gloss over the machinery needed to apply their products, this determination was underway. Sanford alluded to a roller table and a vertical press with 50 tons of pressure at each joint, while Jureit referenced a moveable table that rolls through a vertical beam-type press that can simultaneously press two or more truss joints. Jureit was the first to submit a patent application for a vertical press. Two years later, in 1962, Sanford patented a system with a vertical press with finish roller.

Another factor that was not apparent from the early ads, but would eventually be a game changer, was the dramatic difference in the steel makeup of their plates: Sanford’s 20 gauge plate was half the weight and half the cost of Jureit’s 14 gauge plate.

Next Month: Competition Intensifies

Since 1970, Joe Kannapell has worked as programmer, Chief Engineer, Marketing Manager, and Sales VP for MiTek, plus 7 years at truss plants, retiring at the end of 2020.

1995 Koskovich Auto Omni

Component Saw

1995 Koskovich Auto Omni saw, S/N

AO950056 4-blade automated saw includes [1] 29 inch blade and [3] 19 inch blades.

Includes scrap incline. Fully automated setup with full power length and all axis angulation, single sided setup from operator console, 2×3 through 2×12, 12 degree minimum angle to -71.6 maximum angle.

20’ to 2′-4” @ 90°/90°, includes owner ’s manual and any available spare parts including [6] spare blades. 208/240/480 volt, 3 phase, 100 Amp, and 120 volt, 1 phase electrical, 100 Amp electrical required, 90 psi air.

$14,990 FOB SD Wood Tech Systems 765-751-9990

www.woodtechsystems.com

Safety Speed Manufacturing Model 7400 XL Panel Saw

Safety Speed Manufacturing, model 7400 XL*, vertical panel saw, 3 HP induction motor, 64 inch crosscut, 2 1/8" maximum thickness, accuracy within 0.005 inches, 13 foot long welded steel frame with integrated stand and linear V-guides, enclosed counterweight system, adjustable vertical and horizontal rules. Quick changes from vertical to horizontal cutting. Includes machined aluminum material rollers, hold down bar, wheels, quick stop gauges and material hold downs. Dust collection ready. Options available include digital readouts for vertical cuts, automated length measuring, laser guide, stop bar, vacuum and midway fence. 208-230/460 volt, 3 phase electrical (208-230 single phase, 2 HP power optional +$100.00).

$13,149 Base, FOB MN.

Wood Tech Systems 765-751-9990

www.woodtechsystems.com

a blending of excellent services and products, with answers that work...!©

Not producing the results you need or want – getting conflicting info about what to do and the equipment and the systems you may need?

Before you Buy - Ask yourself –do I need a salesman or a guide?

If you want an Independent Guide that has your bottom-line results as the #1 priority, Call Me. If the salesman will do - we'll talk later...

Also, don't let Financing Deals influence your best solution. FitzGroup can arrange – Zero down & No payments for 90 Days!

Please be assured that your investment with any of our selected partners will not cost one penny more with the Fitzgerald Group as your purchasing contact. In addition, you will receive the full advantage of our Partner Relationships and Services NOT offered elsewhere.

RFitzgerald@FitzGroup.com 719.528.5445

www.FitzGroup.com

Used Razer S5 Linear Saw

S5 Razer saw modules configured for either left-to-right cutting and/or “Z” shaped layout. AIT auto infeed tables. Vekta user interface software complete with the full version of the optimization algorithms.

Stack cutting and side by side cutting

Contact for Pricing

Eide Integrated Systems, LLC 612-521-9193

www.eidemachinery.com

– One person rafter cutter can make single or double compound cuts and simple cuts on either end of the rafter. Features twin H.D. Milwaukee worm-drive circular saws, 10’ infeed conveyor, turntable system allows for precise angle cuts and easy set-up, 120 volt, 1 phase, 90 psi air required.

$2,990, FOB WA.

Wood Tech Systems 765-751-9990

www.woodtechsystems.com

•

•

SpeedCut Speed Rafter Cutter Saw SpeedCut model SRC, Speed Rafter CutterMeeting production goals is easier when you can rely on people who understand your business. Our service pros at Simpson Strong-Tie are ready to listen and offer solutions to strengthen your organization. System integration and team collaboration are easy with our open-platform software. And whether your team is in the office, on the production line or at the jobsite, we’re here every step of the way to provide technical support and expert training — so you can stay on track and get the job done.

Let our team support and train yours. Visit go.strongtie.com/componentsolutions or call (800) 999-5099 today.

Simpson Strong-Tie® Component Solutions® | Software and Service for an Integrated Industry

Simpson Strong-Tie

Simpson Strong-Tie® Component Solutions® | Software and Service for an Integrated Industry

Simpson Strong-Tie

The Most Advanced and Up to Date Lean Process and Industrial Engineering Methods to Significantly Improve:

√ Productivity

√ Quality

√ Employee Issues

√ Net Profits

All Areas - Manufacturing, Sales, Design, and Admin.

Cost Savings and Net Profit Gains that Usually take Months or Years, Can be Accomplished in Weeks or Months with TDC

“I’ve been reading Todd’s articles for the last few years and have been intrigued by his view of productivity measures, so I decided to hire him to learn more about his philosophy. It was an investment well spent because I not only learned a completely different way to view labor metrics, but I came out of it with a completely different mindset on pricing, scheduling, and staffing. I highly recommend Todd’s services to take your company to the next level. The most valuable information you can get is the information you don’t know you need.”

Shane Soule, President Bremen, IN

Dozens of clients provided written testimonials on the TDC website.

a show together is no easy feat—organization on this scale doesn’t just happen, rather it takes months and months of planning to have it evolve from planning to a show. Spida is grateful to SBCA for the outstanding event that was BCMC 2022.

What a throwback to BCMCs of old! When the doors opened, there were scores of customers just waiting to come in and see old and new faces and all the Exhibitors had to offer Every attendee came through the door with a huge amount of energy and so many had a specific piece or pieces of equipment in mind to complement their factory and increase their market share.

Spida was able to introduce our new salesmen to the world of BCMC and they were shocked at the attendance and then the spectacle of the Spida Machinery booth machinery demonstrations first-hand. Our newcomers, Bill, Dan and Mike, were in 7th heaven attending to loads of questions and enquiries on the machinery at hand. Tony, our long-standing salesman in Texas, was smiling and shaking so many familiar hands that he said it was just like old home week: “So many friends and faces I haven’t seen for a while, so good to be back doing BCMC.” We also brought our Aussie and New Zealand staff to the booth—what a great way to introduce some of them to the USA!!

Spida again showcased our Wall Framing Line with Sheather, Build Table, and Wall Extruder. Lots of great conversation was had on our Raked Frame Extruder that’s in the market now, making raking and common walls with ease. Our PieceMaker was showcased in its finest form and the interest was outstanding. With so many customers watching our linear saw doing its best to cut the most amazing cuts from long and short length lumber, I even saw some of our customers take bits of lumber as souvenirs from the linear saw outfeed.

This year I was privileged to talk at the Women in Construction forum. It was an honor to sit and talk amongst my peers about how to engage women into this exciting career. Thank you to all those people who came and talked to me afterwards about their mothers’, sisters’, and wives’ journey and to those who now aspire to bring their daughters to work with them. I was in awe of the ladies who spoke on the stage with me, they are outstanding women with fascinating stories to tell.

Spida would like to thank everyone who came to say hello to us at the booth. We also would like to thank everyone involved in bringing BCMC 2022 to fruition and all those who we are engaged with in quoting and machinery supply. We had a blast and planning is already underway for a bigger and better show next year!!!

See you in Indianapolis, IN next September for BCMC 2023!

Don’t

The Sprint M600 Saw

Don’t

The Sprint M600 Saw

Price: $209,000

FOB: MN

Don’t just do it, nail it. It’s a brand new day in wall-panel production, with a whole new way of doing things better.

Terminailer®, a revolutionary, event-driven, nailing machine that completely defies any preconceived notions about sub-component assembly

Terminailer all but shatters the stereotypical myth that subcomponent equipment is essentially peripheral – unimportant. And it does so by quickly and accurately driving far more framing nails in your wall panel jobs than ever before. Whether in your shop or in the field, one operator sets the pace for production and quality And that reduces labor costs and other aspects of overhead.

Terminailer is an event-driven, sub-component assembler that will quickly and accurately drive 30% to 70% of the framing nails in any wall panel job. In your shop or in the field, one operator sets the pace for production and quality. The Terminailer functions independent of design software, requires zero set-up time when switching between any configuration, and requires no special operator training.

The Terminailer is easy to move around the shop so it’s location can evolve as your shop evolves. With all of the nailing occurring in the closed main chamber, nail injuries and nail location miss-fires are eliminated, making your plant that much safer.

With nearly ten years of development from people that know machinery it is assembled to exacting standards, well supported, and it is easily maintained with shelf-item parts. Terminailer: vetted, tested, and ready to drive maximum productivity for you. Be sure to check out our videos below for a quick review of this revolutionary machine!

PARTS & COMPUTER

• Used Servo Star CR10251 (3 Available) -$1,100 Each

• Used Servo Star CR06251 (3 Available) - $1,100 Each

• Used Servo Star Master Controller MCSS-08-6410-004 - $4,000

• Used ALS Windows XP Computer - $1,500

• All Parts - $10,900

• Used parts were removed in "working condition" from the ALS 276 during a saw upgrade

FOB AL Wasserman & Associates 800-382-0329

www.wasserman-associates.com

2002 Koskovich Auto Omni 5-Blade Component Saw 2002 Koskovich Auto Omni component saw, 5-blade automated saw includes [3] 20 inch blades, [1] 30 inch blade, [1] 12 inch blade and shaker waste conveyor with factory side pans. Fully automated setup with full power length and all axis angulation, single-sided setup from operator console, 2×3 through 2×12 and 4×2, 20’ to 9” @ 90°/90°, Exair cabinet coolers, remote monitor, no spares.

In operation until Aug. ’21. 208/240/480 volt, 3 phase, 100 Amp saw electrical required. 120 volt, 1 phase PC electrical required.

$13,970 NOW $9,997 FOB OH

Wood Tech Systems 765-751-9990 www.woodtechsystems.com

The L-M Verticut 2000 is a true Precision End Trim (PET) saw that is capable of holding a 1/16th accuracy all day long. Made in the USA, the V2k comes equipped with a 15 HP 460/230 volt High-E three phase TEFC motor driving a Double ended Premium “Stellite” inlaid saw bar with a spring loaded chain tensioner and an automatic oiler to lubricate the .404 pitch custom profile semi chisel saw chain.

Rather than a single pivot-point, the saw assembly is mounted on a mandrel box that is guided by cam followers on a steel frame that is raised and lowered by a hydraulic cylinder. A console with the saw controls moves with the saw assembly along a track positioned using a manual “V” wheel geared drive or optional Hydraulic drive

Safety Speed Manufacturing model 7000, vertical panel

saw, 3 HP induction motor, 64 inch crosscut, 2 inch maximum thickness, accuracy within 1/64th of an inch, 10 foot welded steel frame with integrated stand and linear V-guides, enclosed counterweight system, adjustable vertical and horizontal rules. Quick changes from vertical to horizontal cutting. Includes machined aluminum material rollers, hold down bar, wheels, quick stop gauges and material hold downs. Dust collection ready. Options available include lower frame extensions, digital readouts, laser guide, stop bar, vacuum and midway fence. 208-230/460 volt, 3 phase electrical (208-230 single phase, 2 HP power optional +$100.00). $9,332 Base, FOB MN.

765-751-9990

The V2k is unlike other imported systems that are basically a Portable Yard Saw on a cutting rack with a best cutting accuracy of +/- 1/8″ (meaning up to ¼” accuracy variance between units of lumber). The V2k from L-M provides +/- 40 thousands, assuring consistent PET precision from unit to unit.

Another advantage L-M has over the competition is their commitment to personal service with unlimited phone assistance and technical help. Their team has traveled the country working on crosscut saws for many years and they know their equipment inside and out. L-M is a familyowned business that prides themselves in doing the job right and building long term relationship that is vital to their business: “Built to last as long as our customers since 1946”.

765-751-9990

www.woodtechsystems.com

Timeand time again, TDC has witnessed too many companies spending millions on capital investments to achieve marginal improvements while others spend far less and achieve spectacular results. It may feel obvious that adding a saw or auto-puck table will significantly enhance output, but the reality often falls far short of the promised results. It is far easier for many to risk spending millions on new equipment and buildings, but an investment of a few thousand for formal training in proper process enhancement has been deemed a step too far. Why is investing in meaningful process improvement not part of every company’s yearly checklist?

One might be asking, what is meaningful process improvement? Well, process improvement covers all processes that happen within any company. For example, HR, manufacturing, design, sales, admin, and capital improvement discussions are all part of the process improvement umbrella. Process improvement is at the heart of the continuous improvement philosophy embedded in successful lean manufacturing. For a fraction of the millions spent on capital improvements, the investment in process improvement can be measured in the hundreds of thousands, if not millions. What would the return for your company be for a 3-point gain in net profits year after year? Just FYI, a 3-point increase is a very low bar.

Employer HR practices. Time and time again, many are stating that finding enough talented and dependable employees is becoming a growing problem. That statement is far more accurate than most understand. More people will be leaving the workforce for the foreseeable future than coming into it. In the US, it will be 400k fewer new workers per year for the next nine years. As a percentage, Canada’s demographics are even worse. (Source: Peter Zeihan, The Trade Breakdown | Upfront Summit 2020)

Todd DrummondLean manufacturing has two sides to the proverbial coin. One is lean tools, such as 5S and Just-In-Time, and the other side of the proverbial coin is that it requires excellent employee and management practice. Without good employee and management practices, lean manufacturing will fall apart. Over the coming decade, the companies that survive and prosper will only be those with strong and healthy HR management practices. Employees will have far better bargaining strength when choosing who to offer their services as an employee. Talented and skilled individuals will have multiple offers from multiple companies to make their choice.

Case Study for HR Process Improvement. During our lean training, TDC spends considerable time explaining best practices of HR and management principles. One client, who must remain confidential, had chronic turnover and vacancies in a very prosperous area with an extremely low unemployment rate. While their competitors were experiencing healthy net profits, they struggled to break even. Fast forward three years later, while implementing best practices for HR and management, and with no investment in new equipment, the company has virtually no turnover or vacancies. Their net profits are now among the high percentage of their peers. HR and management practices are part of process improvement and need to be remedied too. The best practices of HR and management principles are just as important as any new equipment.

With so many areas included under the meaningful process improvement umbrella, all of them cannot be covered in this article.

The one thing that needs to be mentioned – the most significant barrier to implementing or investing in a formal process improvement program is pride or ego.

Case Study for Manufacturing Process Improvement. One client brought me into their location without his co-owner’s consent.

His partner could not believe that he did not think that they were undoubtedly the experts. They certainly did not need an outsider coming into their location to point out what the consultant believed were areas of deficiencies and how they could make improvements.

He thought they already knew where they needed improvement and did not need anyone explaining what they already knew. Long story short, each day spent showed just how many areas where they could make adjustments and improve, and that both owners had blind spots. It was a typical case of not knowing what you do not know. The services’ cost was paid back within the first hour on location. The returns garnered by the better practices in every department kept filling their bank account every month, just like an investment in new equipment. Yet this investment was not even close to what new equipment cost. Client quote: “Damn Drummond, you are certainly a straight shooter and a hell of a cheap investment for the return. I like how you work.”

TDC is Now Scheduling the Fall and Winter Months for New Consultations. The team of TDC is your best source for learning about proven and practical lean manufacturing best practices combined with industrial engineering principles to keep your company at the leading edge of competitiveness. No one is better at providing your team with proven results for process improvement of employee practices, pricing, truss labor estimation, and so many other best-in-class practices. TDC’s tailored solutions are for the client’s specific needs. Go beyond the typical software and equipment vendor recommendations for your operations and do what many have dared to do. Embrace the Drummond Method, and your company can experience cost savings, and net profit gains that usually take months or years can be accomplished in weeks or months, resulting in an average of 3 to 6 point net profit gains for CMs. All areas are addressed, not just the manufacturing. Please do not take my word for TDC’s services, though. Read the public testimonials many current and past clients with decades of expertise and experience have been willing to give: https://todd-drummond.com/testimonials/.

Website: www.todd-drummond.com

Phone (USA): 603-748-1051

E-mail: todd@todd-drummond.com Copyrights © 2022

Driven

Conveyor

• Rea Ink Jet Printer (does not work)

• 24' Capacity Outfeed Table

• 6 Arm Storage Deck (adjacent to saw outfeed table)

• Waste Conveyor (under saw, parts to the rear)

• Excludes Incline Waste Conveyor

• A/C System for Control Cabinet

• 480 Volt / 3 Phase

• Saw will need a tune up when installed at buyers location for 100% cutting accuracy

• Video available upon request

One month after installing a Double Lumber PickLine to feed two TCT Linear Saws:

"We are getting 3,000 to 5,000 bdft more each saw, than we were getting before the install.

We have shut down one Cybersaw and one TCT chord saw.

This equals about 3 less people 10 hours, and 2 less forklifts 10 hours.

Overall, it is a major improvement to our operation. We hope to have the chance to run it two shifts to further accelerate the payback.”

Tom Hollinshed, Ownermode,

powered movements,

network

depths and internal brakes are standard. Options include enhanced servo controls featuring autocalibration, catcher's display and either shaker or belt scrap conveyor and incline. 440 volt, 3 phase

The Panels Plus 3-Table Line is also known as a Full Production Line. It has the largest footprint and the highest production output in comparison to the other system lines. The 3-Table Line frames and sheathes wall panels. This production line consists of a Framing Station, Squaring Station, Sheathing Station, Subcomponent Tables and Roller Conveyors.

FRAMING STATION

FRAMING STATION

and

ProCut™ UC Linear Saw Series offers many variations to suit your plant and

line. Let

design a system for

The truss industry relies on 3rd party quality assurance services to provide random visits to review the plants Quality Assurance program along with their operations. If your plant needs to comply with the IRC, IBC and to those who depend on solid, experienced QA expertise, we ask you to consider selecting Timber Products Inspection, Inc. (TP) as your choice for 3rd party inspections.

Proudly serving the forest products industry for over 50 years, TP brings the expertise you need to ensure your business is successful. As a responsible partner, TP delivers to clients, employees, and the industries we serve the confidence to drive value through the effective use of our diverse professional team.

TP would like to welcome the following authorized agents to our inspection team, each of whom have many years of experience in the truss industry!

• Al Coffman

Jean Hart

Curt Holler

Chuck Ray

Glenn Traylor

Elliot Wilson

If you have questions about how you can make this selection, please contact your authorized agent above or Glenn Traylor at 919-280-5905 or trusguy@gmail.com.

https://www.tpinspection.com/ https://www.tpinspection.com/auditing-services/truss

Onoccasion, we are required to utilize a detailed tooth count to qualify a connection on a metal plate connected wood truss. Fortunately, we have several tools that can assist us. My June article, “Which is Better: Plate Placement Method or Tooth Count Method?”, includes a point-by-point comparison of two of these tools, showing how neither is the perfect solution for all situations. In addition, we should include two more items on this list of tools for counting teeth:

1. Plate Placement Method (PPM) – Critical plate inspection template

a. This is generated by the plate manufacturer’s software

b. Software settings allow any or all plates to be generated

a. Available to SBCA members at no charge for the software

b. Utilizes electronic devices with camera and wireless connection to connect to your system database

a. This is generated by the plate manufacturer’s software

b. A compilation of connectors, with 4, 6, or 8 per page that can printed to accompany the job

4. A combination of PPM and TCM.

Except for TCM, these tools consider the conditions and requirements that must be followed. It is built into the software. Sometimes, it’s up to an old-fashioned tooth count to make the determination, but there are several rules that need to be understood. Based on a recent inspection challenge conducted at BCMC 2022 in Columbus, it was observed that many in the industry may not be aware of this particular rule that is dictated in part by the American Wood Council’s National Design Specification® (NDS®) for Wood Construction

Let us look at a typical example. In this analysis, we are not going to consider defects in the plated area.

In the first photo, a particular joint is illustrated. Teeth are counted for each member considering all teeth in the web member. This is a simple process – but that does not automatically make it a correct process.

As we apply the NDS® rule reflected in ANSI/TPI 1–2014, 3.7.7.2.2 Ineffective Teeth End and Edge Distances, the second photo shows the actual effective teeth. The NDS® rule dictates that lumber within ½” of the end of the member and lumber within ¼” of the edge of the lumber (the margins shown with the orange lines) cannot be counted as effective.

Thus, the table demonstrates the difference between simply counting ALL teeth versus counting effective teeth. When the teeth located in the ½” end distance and the ¼” edge distance are eliminated from the count, the reduction can be striking. The percentages will differ from case to case, but in this example the result varies from roughly 60% to 70%.

When it comes down to which teeth to count when you’re counting, TCM is the most precise method. With TCM, you can verify the effective tooth holding with your own eyes. As long as you take into account the edge and end distance considerations, TCM will prevail over PPM in this challenge.

An ANSI/TPI 1 3rd Party Quality Assurance Authorized Agent covering the Southeastern United States, Glenn Traylor is an independent consultant with almost four decades of experience in the structural building components industry. Glenn serves as a trainer-evaluator-auditor covering sales, design, PM, QA, customer service, and production elements of the truss industry. He also provides project management specifically pertaining to structural building components, including on-site inspections and ANSI/TPI 1 compliance assessments. Glenn provides new plant and retrofit designs, equipment evaluations, ROI, capacity analysis, and CPM analysis.

Glenn Traylor

Structural Building Components Industry Consultant http://www.linkedin.com/in/glenntraylor

Don’t Forget!

Saw it in the

Hardened, Ground and Polished Steel and Billet

Length: 5 feet (60”) to 60 feet (720”)

Height: 12 inches Depth: 12 inches

If you are looking for the fastest, most consistent way to measure and cut your product, then the Hain Measuring System (MEA) is your answer. The MEA changes from one length t any length instantly, up to 60’, without changing the operator’s position on the line. It is also highly accurate (+/- .010) and quickly moves from one length to the next in seconds. The MEA is designed for quick and easy setup and is simple to use. Even a first time user will be productive with little or no training required. It can adapt to any saw and can be mounted to any surface so that you can integrate the MEA with your existing setup. The MEA is versatile allowing “left” or “right” handed operation and measurement in “feet and inches” or “inches” depending on your preference. The MEA is also available in a “Skid Mounted” version.

The Spida Apollo saw with Automation is a computerized, pull-arm type saw used for cutting either wood truss components or wall panel cutting and represents the lowest-cost way to add an automated single-blade saw to your operation. Features include angle cutting from 10 to 170 degrees, 36 inch scarf cuts, patented variable stroke limiter for safety, solid frame and arm design, 17 inch industrial touch screen with enclosure, 7.5 HP motor, plug and play wiring making installations easier and includes cowls for adding a dust extraction system.

Available options include software is available for both trusses and wall panel cutting, laser guide showing exactly the path of the blade before the blade moves, Safe Grip™ Clamp for cutting smaller pieces, clamping table, Plate Marker template providing automated set up for marking joint locations (studs, sub-component locations, etc.) on top/bottom plates, Chop Saw Table for adding another saw for miter/compound or end cuts, prior to feeding the Spida Apollo saw, Portable Dust Extractor and spare blades.

Saw is available in 240 volt, 20A or 460 volt, 15A 3 phase electrical. Computer requires 110 volt, 1 phase, 20A.

Wall Heights:

Wall Lengths: 16', 20'

Pre-Stage Area: 16', 20' or

The new field-tested Triad PreStage Framing Table, designed and built with customer input, can bring increased productivity to your panel shop.

Triad's exclusive and unique design merges a pre- layout material-staging area with a fast and efficient framing station -- into a single unit that can assist with rapid throughput in your plant.

A powerful, built-in continuous track system lifts and conveys components and material to framers and then the finished panels to your next station.

Initial customer field production, from a Texas plant, has shown an average of 3600 linear feet per day (8 hr shift) of framed walls in their facility!

(matches wall length)

to change without notice

New, DeRobo linear saw by Monet organizes "fill" boards to increase optimization of each board, can produce unlimited scarf cuts, cuts 1 or 2 boards at a time and cuts webs, chords, wedges, rafters and open-stair stringers. Works with all major connector plate manufacturer's software. Features include 22 inch blade, left-to-right feed direction standard, lumber push and pull grippers for more accuracy, ink marking on the 1 1/2" face of the incoming boards and small piece capture and delivery to the front of the saw for easy access. Infeed deck and bunk feed are shown as options only. 480 volt, 3phase. Call for pricing, FOB MO.

765-751-9990

www.woodtechsystems.com

New Square 1 Rolsplicer, splices 2"x3", 2"x4" and 2"x6" lumber with a 3 to 4 second cycle time. Presses the lumber together prior to imbedding plates. Embeds plate lengths up to 19 inches. Features two, recessed, simultaneous-activation buttons, guarded motor and sprockets, external lubrication points, 3 HP motor and a footprint of 59" long x 42" wide. Optional 20' infeed and 10' outfeed conveyor available. 480 volt, 3 phase electrical. Other voltages available.

765-751-9990

www.woodtechsystems.com

2002 Auto Omni 5 blade automated component saw includes shaker waste conveyor with factory side pans, [3] 20 inch blades, [1] 30 inch blade and [1] 12 inch blade. Fully automated setup with full power length and all axis angulation, single sided setup from operator console, 2×3 through 2×12, 22’ to 3′ @ 90°/90°, and spare blades. 208/240/480 volt, 3 phase, 100 Amp and 120 vac, 90 Amp electrical required.

Price: $19,990 FOB PA

Wood Tech Systems 765-751-9990

www.woodtechsystems.com

2008 Alpine PF 90 wall panel cutting and marking syste m. 3.5″ x 12″ m aximum cutting profile, Inkjet option, cuts to 16 ft long. From the OEM’s literature, “Effortlessly handles two of the most critical and difficult processes in any wall panel operation – plate cutting and panel layout. At the rate of 1,000 linear feet per hour or more, uses data from the design software and accurately marks stud, cripple and jack locations, job and panel number, subcomponent and window/door locations, and even sheathing locations on both top and bottom plates simultaneously with ink-jet printing.

MORE INFORMATION HERE

$8,499 FOB NY

Wood Tech Systems 765-751-9990

www.woodtechsystems.com

Safety Speed Manufacturing model 6400 vertical panel saw, 3 HP worm drive motor, 64 inch crosscut, 1 3/4" inch maximum thickness, accuracy within 1/64th of an inch, 10 foot welded steel frame with integrated stand and linear V-guides, enclosed counterweight system, adjustable vertical and horizontal rules. Quick changes from vertical to horizontal cutting. Includes machined aluminum material rollers, hold down bar, wheels, quick stop gauges and material hold downs. Dust collection ready. Options available include lower frame extensions, digital readouts, laser guide, stop bar, vacuum and midway fence. 120 volt. Starting at $5,169 FOB MN.

765-751-9990

www.woodtechsystems.com

765-751-9990

2008 Alpine PF90 Wall Panel Saw

2002 Koskovich Auto Omni 5 Blade

Component Saw

2008 Alpine PF90 Wall Panel Saw

2002 Koskovich Auto Omni 5 Blade

Component Saw

Havingjust returned from the best BCMC in almost two decades, I want to share some reflection. Our industry was deemed essential during the pandemic, and we outperformed many other sectors. Demand for wood components continued to stay strong through it all.

By Tracy Roe

By Tracy Roe

Today, defeating the odds of recession has strengthened and enhanced our industry. Now more than ever we are coming together as one and displaying perseverance, drive, and dedication like no other. As we continue to soar above the facts and percentage of our declining economic affairs, the future is what we remain focused on.

BCMC 2022 attendance was within reach of record breaking. Attaining such an accomplishment has proven to everyone that this industry is valued and capable. The wood component industry expansion has conquered the diminished recession that our country has entered. Focusing on the future, and staying true to who we are, has set us apart and the world is taking notice.

The demand in our industry continues to rise, as we continue to showcase how essential we are. With the statistics of our economy working against us, the push for our industry remains in our favor. As we remain hopeful, we look forward to surpassing the projections of attendance and growth in the years to come. Our industry is changing and shaping this world as well as the young minds that are patterned closely behind. Reframing the world’s perspective on our industry allows us to represent ourselves as a part of the future. This gives us the opportunity to adjust the world viewpoints.

BCMC has presented endless possibilities within our industry that help us secure success and advancement. As we progress, we will prevail sustaining gratitude and gratefulness. Thank you for those who attended, bravo to those who were recognized with awards, and most of all congratulations for all those involved in this industry. This is an exciting time to be in such a close-knit and friendly business. We are proud to be a part of it.

thick,

reduce noise, dust, and improve operator safety; automated via downloaded sheathing cutting files from wall design software. Includes 8 foot long idler infeed conveyor and outfeed conveyor with pop-up skate wheels, (1) spare blade and all available spare parts. 220v/440v, 3phase electrical saw, 120v, 1 phase electrical PC. 100 PSI at 14 CFM

3″. Fully enclosed

angulation axis of movement for cutting and

(both faces, one edge).

Ph, spare blade. The WoodRunner Air Pick automated lumber retrieval system includes a single picking head with 10 bunks and 2 magazines. Includes manuals, all available spare parts and spare servo cards, and WoodRunner software source code. Available March 2022.

Safety Speed Manufacturing, model 7400 XL*, vertical panel saw, 3 HP induction motor, 64 inch crosscut, 2 1/8" maximum thickness, accuracy within 0.005 inches, 13 foot long welded steel frame with integrated stand and linear V-guides, enclosed counterweight system, adjustable vertical and horizontal rules. Quick changes from vertical to horizontal cutting. Includes machined aluminum material rollers, hold down bar, wheels, quick stop gauges and material hold downs. Dust collection ready. Options available include digital readouts for vertical cuts, automated length measuring, laser guide, stop bar, vacuum and midway fence. 208-230/460 volt, 3 phase electrical (208-230 single phase, 2 HP power optional +$100.00).

765-751-9990

www.woodtechsystems.com

Since 2006, we've been helping businesses of all kinds build their online presence. We make websites and software for the construction industry to empower companies to reach a wider customer base and engage their audiences. Companies all around the world work with us to make websites and apps that people actually want to use. Reach out to Wolf X Machina if you're a business and you want a website that actually drives results.

www.wolfxmachina.com info@wolfxmachina.com

Highly confidential position, Regional Manager opportunity. Experience with operations in the $20-50M range. Responsible for all areas of Truss and Wall Panel Manufacturing operations, safety, inventory control, delivery, and customer service at 3 locations producing $10-15M each. The facilities produce Roof and Floor Trusses.

Compensation $100k+ base range plus substantial bonus based on your performance. Very competitive benefits package. Relocation package is negotiable if not in the region. Please inquire to discuss details. Strictly Confidential! Let's talk to see if this is a perfect opportunity for you.

visit: www.thejobline.com email: mail@thejobline.com

Monet DeWall 90/90 wall panel marking saw is a computer numeric controlled wall panel saw with touch screen user interface. Cuts and marks up to 2 boards at a time using 2x4 through 2x8 or cuts and marks one board at a time. Call for pricing, FOB MO

765-751-9990

www.woodtechsystems.com

In my humble opinion, since 2014, United Truss of Innisfil, Ontario, Canada has unofficially held the titles of “The most automated truss plant” in North America and “The most visited truss plant in North America.” United Truss was the un-named but featured truss plant in my May 2022 article, “Debunking the ‘Automation Takes Too Much Space’ Myth.”

Edmond Lim, P.Eng. LimTek Solutions Inc.

United Truss has been visited by a “Who’s Who” of the US truss industry, including ProBuild, Builders FirstSource, 84 Lumber, USLBM, S.R. Sloan, Ridgway Roof Truss and Toll Integrated Systems, just to drop a few names that made the trip to United to see how they Feed the Beast! In Canada, it is easier to ask who has not yet visited United Truss. As mentioned in last month’s article, “Incremental CapEx ROI and Plant Tours," United Truss is a textbook study just like R&K. United Truss started with a fully loaded RetroC automatically fed lumber from a Lumber PickLine to auto-fill carts which funded future investments and optimized investments in table automation. United Truss will tell you that they could not have achieved their goals if they did not invest in material handling and sawing first — yes, they knew how they were going to Feed the Beast!

United Truss incorporates traditional truss plant automation, such as automated saws to cut the lumber, auto jigging to set up the truss perimeters, and overhead lasers to help position the truss plates. Traditional automation is not why people come to visit United Truss. People come to see the efficiency and simplicity of United Truss cutting lumber for multiple jigs with just one human picking lumber and one human saw operator with auto-fill lumber carts which is all part of their

complete in line lean manufacturing system. The collated lumber and collated truss plates (per joint) arrive at the tables organized for left and right of truss, which results in an average of 2–3 minutes per truss build time, optimizing United’s investment in traditional truss building automation.

For United Truss, this is a standardized day-in and day-out of 2–3 minute per truss, not just for a run of benchmark trusses as described in Joe Kannapell’s November 2020 article, “60 Years of Machines, Part XII: Best of Both.” Material has to arrive in front of the truss build tables organized so that truss builders just keep building trusses, not wasting time and energy finding and/or sorting material for every truss.

Truss plants are the original off-site construction component manufacturers. The sheer volume and size of trusses, along with the variability of lumber and complexity of truss shapes, is just beginning to be addressed on scale with industrial robotics. Interestingly and economically, with all of United’s automation they do not need full-time maintenance personnel, and trusses can be produced at volume and complexity with just one lumber picker, one sawyer, three truss builders, and one forklift operator. To produce even more trusses, all they need to do is add truss builders (if and when they can find them!).

When hosting visitors, Allan Inglis likes to praise the significant reduction in paperwork and the ease of cross-training, especially when businesses just can’t find people. To David Sandke, it is the continued operatingcost savings that have funded annual CapEx improvement projects that have enabled them to continue to look after their loyal and growing customers.

What’s next for United Truss? Ed DeBiasio has already approved a building addition to put the entire Lumber PickLine under roof. Ed has a vision and he continues to implement a profitable plan.

We at Enventek and LimTek are proud that Ed DeBiasio relied on us to help him and his team execute his plan. We are grateful for United’s continual hospitality of hosting plant tours that have resulted in many additional sales for us and we would like to take this opportunity to thank Allan, David, and Ed! On behalf of Larry Dalson, Dave Dalson, and myself, thank you, and it was nice to catch up with everyone at BCMC this year.

Tom Kurowski, Director of Manufacturing, USLBM (center) with Dave Dalson (left) and Larry Dalson (right) at BCMC 2022

United Truss visiting the Enventek booth: (left to right) Ed DeBiasio, Owner of United Truss; Ed Lim, LimTek Solutions; David Sandke, GM of United Truss; Allan Inglis, Plant Manager of United Truss

Tom Kurowski, Director of Manufacturing, USLBM (center) with Dave Dalson (left) and Larry Dalson (right) at BCMC 2022

United Truss visiting the Enventek booth: (left to right) Ed DeBiasio, Owner of United Truss; Ed Lim, LimTek Solutions; David Sandke, GM of United Truss; Allan Inglis, Plant Manager of United Truss

2006 Alpine AutoMill SC, model 348B, five-blade component saw Servo controlled computerized saw sets up in 2 to 19 seconds and downloads from a network or by using a touch screen for ease of operation. Five-head automated component saw works in both automated (downloading files) and semi-automated control via touchscreen input. It has 23 axes of automated movement, enhanced diagnostics, and auto management reporting. The SC cuts from 9″ 90/90 blocks to 2′-6″ to 20′-0″ long angled material, in sizes ranging from 2×3″ through 2×12″, and 4-angle floor webs from 3′-4″. Includes [3] 18″, [1] 20″ and [1] 32″ blades with air brakes, under-saw shaker conveyor and a scrap incline conveyor. Includes owner’s manual, all available spare blades and all available spare parts. 480v/ 60Hz/ 3 phase electrical required. $69,997

765-751-9990

www.woodtechsystems.com

New, Monet five-head, floor truss web saw, cuts 4-angle, 4x2 floor truss webs from 16 inches and 90-90 blocks from 12 inches to four foot long maximum length. Features 10-board magazine feed, powered, fixed-quadrant angulation, manual carriage standard, shaker-pan scrap conveyor with short incline conveyor and cut-off blade. Option for longer carriage length, single-sided setup (shown in pictures, but not standard), dust hood and horizontal scrap conveyor 480 volt, 3 phase. Call for pricing, FOB MO.

765-751-9990

www.woodtechsystems.com

The Light Gauge Steel Sheathing Station offers flexibility in wall height, sheathing thickness, and screw spacing and screws sheathing to steel wall panels to ensure quality panels every time.

This model can be stand-alone or integrated into a full production line.

Various sizes and configurations are available.

• Ergonomic working height

• Single person operation

• Flexibility with fastener spacing

• Fastens consistently and accurately

1-866-726-7587

of mind

unique “uni-body” construction creates a ridged machine that does a final press of the connector plates for complete embedment into lumber, saving wear on your floor assembly machine. 12” diameter rolls, 7 1/2 HP motor, 80# chain, 114 FPM speed, emergency photoelectric shut-off, chain and sprocket guards, integrated brake. Available options include: other roller widths, Heavy-Duty upgrade, gear motor drive, and soft start controls. 480 volt, 3 phase electrical. Other voltages

Designed for high-volume floor truss web output with even greater safety, the Monet DeSauw FWA-500 AC (for “automated controls”) offers the very latest in operator-friendly saw technology. Perfect for manufacturers running floor trusses in large volumes with variable web design, the 500 AC features automation for all blades, including the fixed cut-off blade for minimal waste. And without any need to open the saw motor cabinets, except for periodic service, you’ll benefit from enhanced safety as well. You might say that with the fully automated FWA-500 AC, Monet DeSauw has set a new standard. Again. Contact us today to discuss how this exceptional machine can positively impact your production goals.

Wood

visit: www.thejobline.com

email: twm@thejobline.com

STRICTLY CONFIDENTIAL!

Model HVS, Two Unit, 2-Zone, 14’ Horzontal Stacking System. Two lifting units (one master and one slave) with integral electrics. A truss sensing system consisting of adjustable laser sensors mounted on slide rails. One indoor electric control enclosure & panel w/PLC and manual controls. A stacker-conveyor interface package comprised of (1) mounted 3-push button enclosure and (1) remotely mounted 2-push button enclosure (pause/ emergncy stop). Hand-held Wampfler Remote Control System. 8 stacking rails and 4 stripping posts. Stack 1 5/8” thick x 14’ tall trusses up to 30 high. Stack a truss in approximately 40 seconds (cycle time). Stack up to 55’ or longer trusses on each side of the conveyor with minor assistance for truss sag, shorter lengths can be stacked unassisted. Excludes 77’ Walk Through Conveyor System. Two systems available at $25,000 NOW $19,900 Each. FOB NE. Wasserman & Associates 800-382-0329

www.wasserman-associates.com

•

•

•

•

•

from

• Truss Flip-Over

• Side or End Ejectors

• Bui lt-In Camber

Clamping on Both Sides

• Air Cylinders Under Table

• 2 Contr ol Valves

Clamping

•

Control Vlave

Diameter

• 10 HP / 3 Phase Gear Motor

• Front & Rear Emergency Shut-Off

• Joystick Control

• 2' per Second Travel Speed

800-382-0329 | www.wasserman-associates.com

General Manager

Must

P&L management experience in $10-15M range of Roof and Floor Truss manufacturing facilities. Produces components for Tract, Single Family Custom, Small-Medium Multifamily, and Mega-Multifamily projects. Responsible for Sales, Design, Production, P&L. Long time facility with potential for more output.

Compensation: $100k+- base, bonus potential to match base if metrics are met. Base is based on skills and experience. Relocation assistance available. Benefits details are available to qualified applicants.

Give

800-289-JOBS (5627)

visit: www.thejobline.com

email: mail@thejobline.com

New table-guided (NO rail) gantry system by Spida, side-eject or end-eject options, with continuous production tables built to length. Available in steel, plastic or combination table top options. Can be fabricated to receive automated jigging such as “Wizard” brand. 24″ diameter gantry heads feature raised operator platform, heavy-duty steel roll with 4″ shaft, baffles and heavy-duty spherical bearings, dual 7.5 HP braking gear motors for a total of 15 HP, easy adjusting bogie wheel assemblies, safety bars, Wampfler “finger safe”, under-table-mounted electrical supply and optional soft start drive. Spida can provide the combination of powered transfer rolls, sloping ejectors, receivers, idler conveyors and powered conveyors required to meet your configuration needs. 440 volt, 3 phase electrical. Other voltages available. FOB IN.

765-751-9990

2007 Clark Industries Horizontal Truss Stacker

By

all accounts, it was a bumper year for BCMC 2022, and we were glad to see the significant increase in interest from not only attendees but also exhibitors across the industry

We appreciated the number of enquiries we had on our Direct Delivery Solution and there was significant interest in our PackFeeder solution too. To help everyone visualize how our systems can help improve their company processes, we even brought a 3D model for hands-on discussions.

The winner of the Dundee Style Genuine Croc Akubra Hat was (drumroll, please) — Steve Strom of The Truss Company in Eugene, OR.

Pictured here with me and Ryan Burtenshaw is Aaron Bahner, our GM of US Operations, modeling the hat before the drawing.

Thank you to everyone who visited the Vekta booth at BCMC Columbus. Thanks so much for stopping by, we really enjoyed the conversation and we promise to bring more hats next time!

2007 VIKING 16' X

WITH SHEATHING BRIDGE

• 16' x 12' Squaring Table with Powered Width Adjustment & Powered Chain Conveyor

• Wall Panel Lengths up to 16', Wall Panel Heights from 4'-0" to 12'-2"

• Swing Gates at Both Ends of Squaring Table

• Automated Field & Edge Nailing Driving by Panel Pro Event Software & Your Programmed Nailing Patterns

• Simple Touchscreen Controls

• 2 Tool Carriages for Sheathing Nailing with Tilt Function for Seams

• 2 Paslode Nail Guns with High Load Coil Tray

• Auto Sheathing Bridge Return

• Includes 4 Pallets of Magnum Coil Nails (2 3/8 x .113)

• 480 Volt / 3 Phase $29,900 FOB KS. Wasserman & Associates 800-382-0329

www.wasserman-associates.com

2021 Triad Router Bridge & Portion of V-Track

2021 Triad Routing Bridge with approximately (20) feet of v-track. Fits over tables that build up to 12′ nominal he ight wall panels. Includes powered automatic bridge return, powered vertical router movement, manual fine adjustment wheel, manual vertical router travel with chain drive and (1) Milwaukee router, catalog #5625-20 120 volt, 1 phase, 15 Amp electrical required. No table included. $28,970 NOW $12,000 FOB BC Wood Tech Systems 765-751-9990

www.woodtechsystems.com

FOB: MN

IBS Tool Bridge & Router Bridge IBS multi-tool bridge with (24) tool stations. Bridge features auto-return, button controls and laser guide mount. Fits up to 12′ nominal rail centers. IBS router bridge features (1) router, laser guide mount and lever-switch button controls. Fits up to 12′ nominal rail centers Sold as a pair Includes all available floor mounted, v-rail. Both bridges missing laser sub-assembly. 120vac, 120psi air. $15,975 FOB UT Wood Tech Systems 765-751-9990

www.woodtechsystems.com

New Panels Plus floor framing machine, supports the structural members creating floor sections from 2" x 6" LVL through 2" x 10" to 2" x 12" dimensional lumber, 20" deep wood floor trusses or engineered wood / I-joists. Standard footprint of floor panels (cassettes) up to 12' wide x 45' long. Table consists of a fixed section and a track-guided, moveable section controlled by either a foot switch or push-buttons.

twm@thejobline.com

New Wall Panel Lift

• 8'

• 1,000 Lb

• Weight: 120 Lbs

• Excludes: Electric Hoist & Freestanding Bridge Crane $1,850 FOB NE Wasserman & Associates 800-382-0329

www.wasserman-associates.com

Includes a series of color-coded locator pins at 16", 19.2 and 24" on-center spacing and clamping with squaring feature including foot pedal control. The locators individually flip down if a joist comes out on top of them. After the floor is complete and unclamped, the floor section can be raised up on skate-wheel conveyors and rolled out or lifted off the table using an overhead crane. Table height is 24.5", OAL 45.5 ft, OAW 14.5 ft. 120 volt, 1 phase, 15 Amp electrical required. 90 to 120 PSIG at 15 CFM air required.

2016 Triad exterior and interior wall panel lines with conveyors and terminal stations. Builds 2×4 and 2×6 walls up to 16’ in length with wall heights from 6’-9” to 10’-2” and includes Component Nailer model FTN and panel lift model XPL1000:

Exterior line includes (2) sets of Rough Opening Assembly tables model RO-CAT, framing table model Gen II with manual nail-gun tool dollies each side & stud locators at 16” and 24” o.c., squaring and sheathing table model Gen II with staple & routing combo bridge & side shift for seams @ 3” & 6” o.c. fasteners, top & bottom plate gun mounts for 6” o.c. fasteners, auto stop & tilt features, (3) 10 ft skatewheel conveyors, (4) 20 ft x 36″ roller conveyors and (4) powered infeed conveyors with chain track.

Interior line includes Rough Opening Assembly table model RO-CAT, framing table model Diamond Quad with manual nail-gun tool dollies each side, pop-up rollers & stud locators at 16” and 24” o.c., (2) 10 ft skatewheel conveyors, (4) 20 ft x 36″ roller conveyors.

System sold for over $223,000 new. Sold as one system only. 110 volt, 1 phase electrical required. 100 PSI air required.

Used Triad wall assembly equipment includes 16 ft x 12′-3″ max height framing station, model G2, with (2) two-tool dollies, squaring/ sheathing combo table, model G2 SH-SQ, with multi-tool mount nailing bridge and separate manual-drive router bridge, quantity of (6) 10 ft long x 2 ft wide idler roller conveyors with (4) legs, and Triad model FTCN component nailing station with four Hitachi NR83A nail tools.

Framer includes 16″ and 24″ color-coded stud locators, pop-up skate wheel conveyors, tool dollies have two tool mounts each (no tools) and powered height adjustment. Sheathing bridge includes joy-stick controls, tool offset, tool tilt, laser guide, power return and mounts for up to (23) Hitachi nail tools. Router and all available spare parts included. 120 volt, 1 phase, 30 Amp electrical required. 100 PSI air required.

765-751-9990

www.woodtechsystems.com

Wall Panel Work-Station (Green)

Custom fabricated, heavy-duty table ideal for producing rough openings, rake-walls, even interior walls. Table features a squaring lip, double-row pneumatic liftouts, duplex 110v outlet for hand tools.

Table dimensions: 16’ 4 1/2” long, 9’ 5” wide, 30 1/2” high.

$9,490 FOB KY

Wood Tech Systems 765-751-9990

www.woodtechsystems.com

Wall Panel Work-Station (Blue)

Custom fabricated, heavy-duty table ideal for producing rough openings, rake-walls, even interior walls. Table features a squaring lip, double-row pneumatic liftouts, duplex 110v outlet for hand tools.

Table dimensions: 17’ 8 3/4” long, 9’ 5” wide, 25 1/2” high.

$9,490 FOB KY

Wood Tech Systems 765-751-9990

www.woodtechsystems.com

PANEL EQUIPMENT

PANEL EQUIPMENT

New Component Table with Skatewheel Conveyors

Lift & Extend Skatewheel Conveyors. 10' x 10' Work Area with Squaring Lip. Gun Holster & Nail Tray.

$11,900 FOB NE

Wasserman & Associates 800-382-0329

www.wasserman-associates.com

Triad model PSRB Sheathing/Routing bridge builds minimum 3′ 9″ and maximum 12′ 3″ walls. includes: staple/nail bridge (no tools included) with auto return, 24 tool mounts, Porter-Cable Router, laser sight & joystick control. Bridge only, no table included. 120v, 100 PSI air required.

$8,490

Wood Tech Systems 765-751-9990

www.woodtechsystems.com

Consider Panels Plus wall panel assembly equipment for manufacturers of wood or steel wall panels, floor-panels, and related framing components. Panels Plus is an employee owned, ISO certified, manufacturing company that builds state-of-the-art equipment featuring durable construction, with fit and finish second to none in the structural building component industry The referenced base framing table allows you to assemble from 7-12 foot wall heights, at industry standard 16 foot lengths, at a working height of 29 to 32 inches. This framer design includes controls at each end of table, squaring stops and pneumatic clamping for consistent wall panel quality. Frames 2x4 or 2 x 6 walls, with color-coded, steel stud locators at 16 and 24 inches O.C. spacing. Includes pop-up skate wheels for easy transfer of completed wall frame. Framing table can be configured to receive wall framing light bars, other options include custom buildable wall heights, lengths and auto-indexing of optional 2 or 3 tool carriages.

Additionally from Panels Plus are sheathing tables with features that include foot pedal control at squaring end of table, with squaring stops, roller conveyors at both sides, single pendant controls for bridge, tool spacing at 6 inch centers with 3 inch bridge shift for offset nailing. Tool bridges can accommodate from 2 x 4 to 2 x 8 walls, with seam tilt being standard equipment Panels Plus Tool Bridges are available with single beam or dual beam design for two different tool mounts on one bridge. Squaring stations, sub-component tables, conveyors and panel lifts are also available to complete the configuration of the wall panel assembly line. Price includes factory installation and training. 50 CFM at 120 psi air. 120 or 230 volt, 1 phase electrical.

765-751-9990

IBS/Comsoft Wall Panel Light Bars

Reconditioned dual 16’ foot long light bars, includes spare light board. Light bars are compatible with all light-bar equipped or ready IBS/Comsoft, Panels Plus, etc. wall panel equipment driven by ITW (IBS) or other compatible design software. 110 volt, single phase electrical. $18,890 NOW $16,550 FOB MN.

Wood Tech Systems 765-751-9990

www.woodtechsystems.com 765-751-9990

New Spida fully-automated CNC controlled sheathing station, fastens sheathing to wood frame wall panels from 2×3″ to 2×8″ nominal, in wall heights from 7′ to 12′. Straightens studs from the underside of the panel prior to firing fasteners. Fixed bridge fires fasteners into sheathing as wall panel passes under bridge. Works with tools firing up to 3 1/2″ nails. Features touch-screen controls, (4) high-speed nail tools, automated tilting of tools at seams and powered transfer of panels. Approximate size is 18 ft wide x 27 ft long. 230 / 460 volt, 3 phase electrical required. 100 PSI at 28 CFM.

www.woodtechsystems.com

Thanks

for the awesome show! We’ve just returned to Minneapolis after attending BCMC 2022 in Columbus – and we can’t thank you enough for visiting our booths and reminding us of all the terrific people who work in this great industry.

Over the past 95 years, our company has grown and expanded to keep pace with the everchanging woodworking and fabricating industries. We were pleased to bring our best equipment to this year’s tradeshow. We featured our WizardPDS®. This automated perimeter definition system is what gives our tables their speed, accuracy, and setup efficiency.

Add as much or as little WizardPDS® automation as you need. It can be used for the entire table line or a 40’ section to capture the bulk of your schedule.

New table installations and/or retrofit table systems for existing lines are available.

Eide Machinery’s New Product Booth displayed our Universal™ Table and Machinery Exchange Program. The Universal™ Table is designed exclusively for adding to and extending WizardPDS® Automation to your existing table line, even discontinued models.

Our Machinery Exchange Program offers complete upgrade and reconditioning services for your existing truss manufacturing equipment. It can add years of life to older or discontinued lines, and our warranty on exchanged equipment meets or exceeds the original OEM warranty. Everything mechanical is new – including the controls, electrical, and drive systems. You can keep your old machine working until your new machine arrives, and installation and operator training is available for any equipment exchange.

In addition, we brought the ProCut™. This linear saw series is configurable to any assembly line and provides a safe, accurate way to cut your lumber – while keeping your materials moving on your line.

If we saw you in person at the show, thank you for stopping by! If you were unable attend, please contact us to hear more about what we brought to the show…and what we can bring to your plant to improve your material handling, cutting, jigging, and more. In business since 1927, we’ve learned many things about what our customers want and need.

You’re welcome to visit us the next time you’re in Minneapolis, or you can call us anytime at 612-521-9193. See you in Indianapolis for BCMC 2023!

Drive your truss plant into a

company, and

ITW Company,

future.

of Design,

teamed together to bring you the latest in

solutions. Solutions that increase your plant’s production

while helping solve labor concerns and improve employee safety. Contact your local Alpine Sales Representative to learn more.

60

Triad in 2021. Maximum panel height clearance 12′-3″.

for (3) tool mounts along

middle beam, top & bottom plate tool mounts, tilt-tool option, joy-stick controls, power bridge return, e-stop button, all available Paslode tool mounts, manual and all available spare parts. 120 volt, 1 phase electrical required. 100 PSI air required.

765-751-9990

Triad squaring table with two bridges and one Viking power conveyor. Either bridge fits on the squaring table. Builds from 6′-9″ to 12′-3″ tall wall panels to 16′-0″ long. Triad squaring table, model G2SHSQ, has powered clamp / unclamp controls on either end of the fixed side of table.

Triad nailing bridge, model PSTT, has (24) tool mount locations with Paslode tool mounts, auto return and bottom plate laser sight mount. Changed by owner from staple tools to nail tools. Router bridge is manual travel. Viking powered conveyor 23 ft long with support platforms alongside both chains. Forward powered drive only. Foot pedal controls for drive motors. 120 volt, 1 phase electrical required. 100 PSI air required.

765-751-9990

2016 Triad wall assembly equipment, model Diamond Quad Framer, Panel Nailer Bridge and Flow Thru Nailer. Builds from 6′-9″ to 9′-3″ panel heights to 16′-0″ long. Framer includes power height adjustment, (4) Hitachi nail tools, squaring stops, manual dollies and parking sections. Nailing bridge includes (18) Hitachi nail tools, laser pointer, 3″ tool shift function and plate fire. Flow Thru Nailer includes (4) Hitachi nail tools. Handle bar router and all available skatewheel conveyors are included. 120 volt, 1 phase electrical required. 100 PSI at 10 CFM air required at nail bridge and Flow Thru Nailer.

www.woodtechsystems.com

By Tim Kaasa

By Tim Kaasa

The2022 BCMC show was a very good one for Panels Plus. Our Platinum Series Automated Sheathing Station was a big hit, with a steady stream of people coming into the booth to ask questions about it or get a demo. In fact, the equipment at the show never made it back to our manufacturing facility in Minnesota—it went directly from Columbus to one of our customers.

One of the highlights every year at BCMC is getting to see old friends and current customers as well. Panels Plus has been exhibiting at the show for nearly 20 years and we have been very fortunate to work with so many great people. We always enjoy getting to see so many of them during the show.

It was encouraging to have so many conversations with builders that are expecting to grow their business. You can’t turn on the news without hearing reports of an economic slowdown, but the vast majority of people we spoke with at BCMC expressed optimism about the health of their business. Panels Plus is pleased to play a role in helping so many builders achieve their business goals.

Thanks to everyone who stopped to see us at the show, and here’s to a great 2023 and beyond!

Don’t Forget!

Don’t Forget!

Saw it in the

tool dollies builds

to 16 ft

from 4 ft to 12 ft in height with 2×3″ through 2×8″ material. The framer clamps and squares components with push button activation before nailing. The trident tool dollies use a single tool per dolly and can be set up to accommodate the nail spacing and quantity of nails. Pop-up skate wheel conveyors assist with moving the wall or components. 110 volt, 1 phase electrical required.

The concept of the Spida Extruder is to bring materials to a central location as the product is extended or “extruded” to create the framed wall panel. A single operator in one central location, feeds the studs and sub-components in-between the plates, while the Extruder does the nailing. The Extruder features (4) servo-controlled, indexing, bracket-mounted tools that can be coil or stick fed, hands-free clamping of plates and is adjustable for wall heights starting from 5’-11”, with options to build walls to 12‘3”, from 2×4″ to 2×8″ lumber.

An option is available to add an intermediate tool mount, for fastening blocking between studs, a notoriously slow process in wall panelization that usually reduces production. The Extruder design makes this connection much easier for the operator, keeping your wall production high.

The support stations are adjacent to the Extruder and operators at those stations build the sub-component openings, sub-assemblies (like ladders) which are conveyed to the central operator’s station, where they are dropped and nailed into the panel in sequence.

Conveyors and transfer tables of various configurations are used to bring the parts to the Extruder. Each design takes advantage of curved or raised conveyors to efficiently bring materials to the Extruder and fit within your plant’s material flow in the most efficient way possible.

Once the wall panel is framed, it proceeds by conveyor to a squaring station and a sheathing station for completion. Here too, the sheathing is fastened as the panel passes by the sheathing bridge with its’ (4) four, high-speed tools. There are options for router bridges and automated ply loading. The Spida Sheather is a fully automated, CNC machine that features touch screen controls and tilt nailing at seams.

Over ten years in development and use in Australia and Asia, there are now several locations using the Extruder here in North America. A typical system can be installed in about (5) hours thanks to the modular, “plug-and-play” design of the Spida wall equipment. 120 volt, 1 phase, 15 Amp electrical required and 110 PSI air @ 6 CFM required for each Extruder and Sheather station.

Wasserman & Associates is proud to be a small family-owned company, and we’re equally proud to be a member of this structural building components industry family. Every fall, attending the BCMC show is like a family reunion – so many old friends and family come together in one location to swap stories and share advice. We wouldn’t miss it!

At our booth in Columbus this year, we emphasized how we always strive to personally address your needs. Wasserman & Associates is a representative for new truss, wall panel, stair, door, and finger jointing equipment, and we also offer the option of used or reconditioned equipment.

In particular, our booth emphasized how we can assist with all your wall panel manu facturing needs. On display was the Single Tool Programmable Panel Bridge. Even though it wasn’t dis played with the complete framing table, attendees were able to get a good sense of its capabilities and ease of use.

When you’re looking for reasonably priced equipment with long-term reliability and performance as well as installation support, call us at 800-382-0329 or sales@wasserman-associates.com. As a partner in your equipment selection process, we promote the equipment that best suits your individual requirements, not the equipment that optimizes our commission. Partnering with Wasserman & Associates will result in competitive pricing, support before and after the sale, and the care that you deserve. After all, you’re part of the family!

Developed in a commercial wall panel production facility this is the remarkable ProStack, fully automated wall panel stacker. The ProStack relieves your build team from creating a stack of wall panels and keeps them building walls instead. Stacks 2×4 through 2×8 walls up to 20′ in length and up to 12 feet in height. The ProStack automatically centers each layer including multiple wall segments on the same layer, and the ability to “create” fork lift pockets for ease of loading in your yard or on the build site. (Please see video for more.) 208 volt, 3 phase, 45.3 full Amp load electrical required. No air required. Footprint is 26′-5″L x 19′-3″W.

Here are some of the features of the ProStack Wall Panel Stacker:

• Wall Length Max – 20’

• Wall Height Range – 8’ to 12’

• Material 2×4″ through 2×8″

• Total Weight capacity – 6,000 lbs.

• Total stack Height Max – 6’