A

Th e

Component Manufacturing dverti$ dverti $ er

Don’t Forget! You Saw it in the

Adverti$$er

November 2023 #15292 Page #47

Truss Plants Meet 90’s Rap – Welcome to Hammer Time!

T

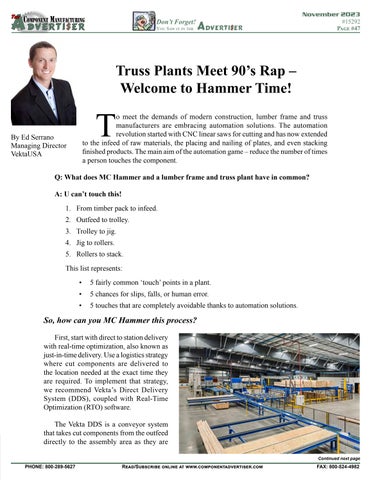

o meet the demands of modern construction, lumber frame and truss manufacturers are embracing automation solutions. The automation revolution started with CNC linear saws for cutting and has now extended to the infeed of raw materials, the placing and nailing of plates, and even stacking finished products. The main aim of the automation game – reduce the number of times a person touches the component.

By Ed Serrano Managing Director VektaUSA

Q: What does MC Hammer and a lumber frame and truss plant have in common? A: U can’t touch this! 1. From timber pack to infeed. 2. Outfeed to trolley. 3. Trolley to jig. 4. Jig to rollers. 5. Rollers to stack. This list represents: •

5 fairly common ‘touch’ points in a plant.

•

5 chances for slips, falls, or human error.

•

5 touches that are completely avoidable thanks to automation solutions.

So, how can you MC Hammer this process? First, start with direct to station delivery with real-time optimization, also known as just-in-time delivery. Use a logistics strategy where cut components are delivered to the location needed at the exact time they are required. To implement that strategy, we recommend Vekta’s Direct Delivery System (DDS), coupled with Real-Time Optimization (RTO) software. The Vekta DDS is a conveyor system that takes cut components from the outfeed directly to the assembly area as they are Continued next page

PHONE: 800-289-5627

Read/Subscribe online at www.componentadvertiser.com

FAX: 800-524-4982