1 minute read

What’s the Current View on Digitalization?

Digitalization is sweeping through the industry but is the change happening quickly enough?

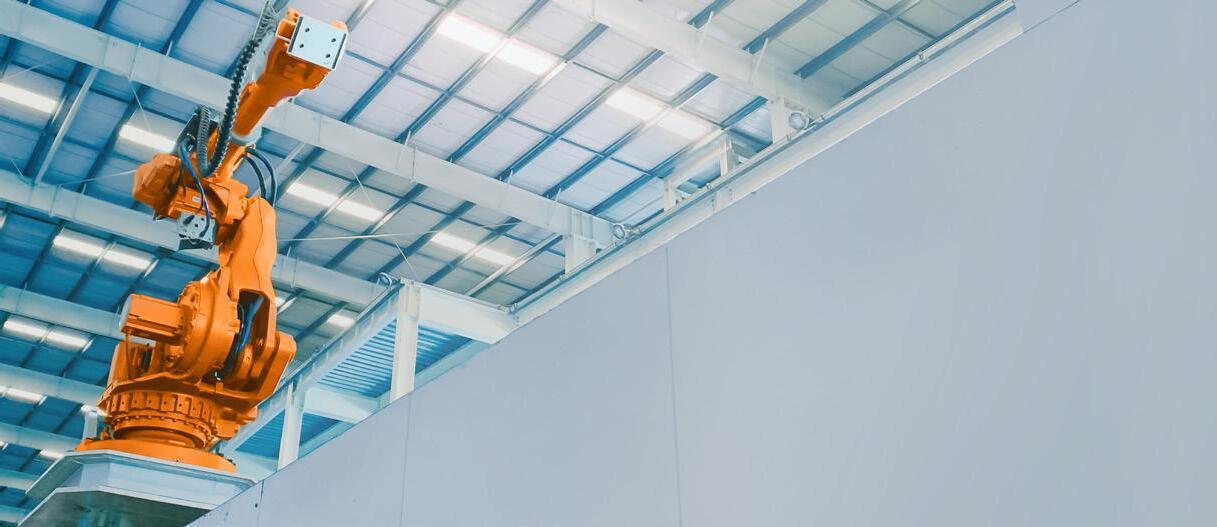

The fourth industrial revolution is here and it’s all about realising the full potential of data connectivity. Connect the systems on your manufacturing shop floor and benefit from consolidated data, AI and real-world modelling - all of which can help you to develop new strategies across the entire business, from product conceptualisation and design right through to end-user consumption and after-sales service provision.

Advertisement

Essentially, it’s making the most of new tools and strategies to add value to what your business does and make your employees’ lives easier.

This is what digitalization should look like for the industry. But, the approach to ‘going digital’ has been very gradual, mostly because “it’s based on an immediate need or customer demand”, according to Kevin Bull, our Product Strategy Director. If you want to fully exploit the opportunities presented by digitalization, you need a broader, more strategic view of your business.

Tip from Our Advisors

Just because you’re “going digital” doesn’t mean you must implement the entirety of that strategy in one huge step. Analysis and score-carding of the areas of highest expected value of return in comparison to expected effoart, cost or risk can be used to drive these decisions.

Bull recommends looking at your entire value chain. “Look deeply, often imaginatively, for opportunities to use data to drive improvements,” he says. At the simplest level, that might mean data integration – reducing waste by eliminating data entry activities which then frees up your employees’ time to focus on other tasks.

This is what office furniture manufacturer Orangebox did by installing Microsoft Dynamics 365 Field Service. At the highest level, it might mean consuming data being streamed from a multitude of sensors and using data analytics and machine learning to make predictions and suggest remedial actions.

“Or, it might mean developing computerised models of production environments, the so-called ‘digital twin’”, Bull continues. “This allow us to conduct “what if” scenarios before committing them to the real world.”