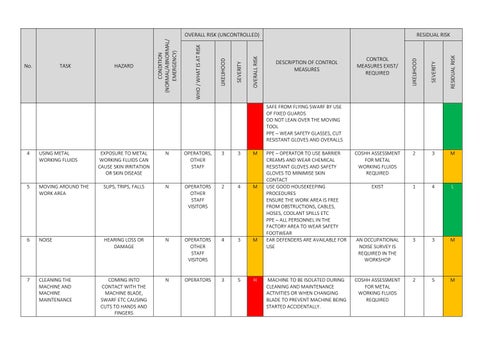

CONTROL MEASURES EXIST/ REQUIRED

SEVERITY

RESIDUAL RISK

RESIDUAL RISK

LIKELIHOOD

OVERALL RISK

SEVERITY

HAZARD

LIKELIHOOD

TASK

WHO / WHAT IS AT RISK

No.

CONDITION (NORMAL/ABNORMAL/ EMERGENCY)

OVERALL RISK (UNCONTROLLED)

PPE – OPERATOR TO USE BARRIER CREAMS AND WEAR CHEMICAL RESISTANT GLOVES AND SAFETY GLOVES TO MINIMISE SKIN CONTACT USE GOOD HOUSEKEEPING PROCEDURES ENSURE THE WORK AREA IS FREE FROM OBSTRUCTIONS, CABLES, HOSES, COOLANT SPILLS ETC PPE – ALL PERSONNEL IN THE FACTORY AREA TO WEAR SAFETY FOOTWEAR EAR DEFENDERS ARE AVAILABLE FOR USE

COSHH ASSESSMENT FOR METAL WORKING FLUIDS REQUIRED

2

3

M

EXIST

1

4

L

AN OCCUPATIONAL NOISE SURVEY IS REQUIRED IN THE WORKSHOP

3

3

M

MACHINE TO BE ISOLATED DURING CLEANING AND MAINTENANCE ACTIVITIES OR WHEN CHANGING BLADE TO PREVENT MACHINE BEING STARTED ACCIDENTALLY.

COSHH ASSESSMENT FOR METAL WORKING FLUIDS REQUIRED

2

5

M

DESCRIPTION OF CONTROL MEASURES

SAFE FROM FLYING SWARF BY USE OF FIXED GUARDS DO NOT LEAN OVER THE MOVING TOOL PPE – WEAR SAFETY GLASSES, CUT RESISTANT GLOVES AND OVERALLS 4

USING METAL WORKING FLUIDS

EXPOSURE TO METAL WORKING FLUIDS CAN CAUSE SKIN IRRITATION OR SKIN DISEASE

N

OPERATORS, OTHER STAFF

3

3

M

5

MOVING AROUND THE WORK AREA

SLIPS, TRIPS, FALLS

N

OPERATORS OTHER STAFF VISITORS

2

4

M

6

NOISE

HEARING LOSS OR DAMAGE

N

OPERATORS OTHER STAFF VISITORS

4

3

M

7

CLEANING THE MACHINE AND MACHINE MAINTENANCE

COMING INTO CONTACT WITH THE MACHINE BLADE, SWARF ETC CAUSING CUTS TO HANDS AND FINGERS

N

OPERATORS

3

5

H