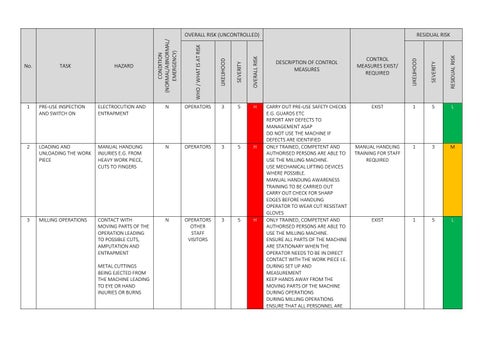

OVERALL RISK

ELECTROCUTION AND ENTRAPMENT

N

OPERATORS

3

5

H

2

LOADING AND UNLOADING THE WORK PIECE

MANUAL HANDLING INJURIES E.G. FROM HEAVY WORK PIECE, CUTS TO FINGERS

N

OPERATORS

3

5

H

3

MILLING OPERATIONS

CONTACT WITH MOVING PARTS OF THE OPERATION LEADING TO POSSIBLE CUTS, AMPUTATION AND ENTRAPMENT

N

OPERATORS OTHER STAFF VISITORS

3

5

H

HAZARD

METAL CUTTINGS BEING EJECTED FROM THE MACHINE LEADING TO EYE OR HAND INJURIES OR BURNS

DESCRIPTION OF CONTROL MEASURES

CARRY OUT PRE-USE SAFETY CHECKS E.G. GUARDS ETC REPORT ANY DEFECTS TO MANAGEMENT ASAP DO NOT USE THE MACHINE IF DEFECTS ARE IDENTIFIED ONLY TRAINED, COMPETENT AND AUTHORISED PERSONS ARE ABLE TO USE THE MILLING MACHINE. USE MECHANICAL LIFTING DEVICES WHERE POSSIBLE. MANUAL HANDLING AWARENESS TRAINING TO BE CARRIED OUT CARRY OUT CHECK FOR SHARP EDGES BEFORE HANDLING OPERATOR TO WEAR CUT RESISTANT GLOVES ONLY TRAINED, COMPETENT AND AUTHORISED PERSONS ARE ABLE TO USE THE MILLING MACHINE. ENSURE ALL PARTS OF THE MACHINE ARE STATIONARY WHEN THE OPERATOR NEEDS TO BE IN DIRECT CONTACT WITH THE WORK PIECE I.E. DURING SET UP AND MEASUREMENT KEEP HANDS AWAY FROM THE MOVING PARTS OF THE MACHINE DURING OPERATIONS DURING MILLING OPERATIONS ENSURE THAT ALL PERSONNEL ARE

CONTROL MEASURES EXIST/ REQUIRED

RESIDUAL RISK

SEVERITY

PRE-USE INSPECTION AND SWITCH ON

TASK

SEVERITY

LIKELIHOOD

1

No.

RESIDUAL RISK

LIKELIHOOD

WHO / WHAT IS AT RISK

CONDITION (NORMAL/ABNORMAL/ EMERGENCY)

OVERALL RISK (UNCONTROLLED)

EXIST

1

5

L

MANUAL HANDLING TRAINING FOR STAFF REQUIRED

1

3

M

EXIST

1

5

L