16 minute read

5. Contamination management

5.1 Overview

This section details the procedures for the management of contaminated media (soil, groundwater and surface water) during the Mt Eden Enabling Works. It includes control measures for reducing human exposure to contaminated soils and water and minimise contaminated discharges to air, land and/or water. These measures must be established prior to commencing and maintained during earthworks associated with the Mt Eden Enabling Works. The Council (Team Leader Central Monitoring) is to be notified at least two working days prior to any of the earthworks.

5.2 Excavation of contaminated soil

While the protocols below can be applied to all earthworks associated with the Mt Eden Enabling Works, contamination has only been identified within fill. The following is most relevant to disturbance within fill:

Erosion and sediment controls shall be implemented in accordance with the ESCP prepared for the Mt Eden Enabling Works before earthworks commence; Excavated spoil shall be placed directly into a truck for immediate off-site disposal, where practicable; Excavated spoil classified as contaminated fill (refer Section 5.3) retained on site as part of contingency storage shall be placed within erosion and sediment controls and covered when not being worked and weather conditions dictate so as to minimise dust and runoff(additional details for management of stockpiles detail in the Air Quality DWP (AQ DWP) prepared for the Mt Eden Enabling Works); Spillages of soil during placement in trucks shall be cleaned up as soon as practicable following the spillage. Spillages shall not be left unattended as contaminated soil could be trafficked by trucks and transported off-site; and The earthworks shall be observed by the CLS. If unexpected contamination is encountered during works, the works shall cease in the immediate vicinity and the procedures documented in Section 7 of this C DWP shall be followed.

5.2.1. Additional requirements for asbestos contaminated soils

The management of asbestos in soils is regulated under the Health and Safety at Work (Asbestos) Regulations 2016 (Asbestos Regulations). In order to help achieve compliance with the Asbestos Regulations, WorkSafe New Zealand has prepared an Approved Code of Practice (ACoP): Management and Removal of Asbestos (September 2016). The ACoP refers readers to the NZ Asbestos in Soil Guidelines.

The key requirements of the Asbestos Regulations and ACoP are that works involving asbestos contaminated soils must be undertaken with appropriate asbestos controls in place and that contaminated soil removed from site must be taken to an approved disposal site.

Table 5-1 provides a summary of the controls indicated in the NZ Asbestos in Soil Guidelines for different concentrations of AF/FA and ACM. The results of the limited asbestos in soil investigations undertaken specifically within the South Pacific Timber site indicate the presence of trace asbestos in fill soils. Disturbance of surficial fill material on the South Pacific Timber site shall be undertaken, as a

minimum, as Unlicensed Asbestos Works as defined in NZ Asbestos in Soil Guidelines, unless further testing is undertaken to justify that the controls are not required.

If a higher concentration of asbestos fibres is detected as part of any additional testing, then the relevant level of controls outlined in Table 5-1 shall be implemented. This C DWP is to be reviewed and updated to confirm the controls to be implemented on receipt and review of any additional soil results.

Table 5-1: Summary of asbestos requirements as detailed in the NZ Asbestos in Soil Guidelines

Scenario

Additional documentation/ notification requirements

Oversight by a licensed removalist

Personal protective equipment (PPE)

Minimum respiratory protective equipment

Dust/asbestos fibre suppression Class A works –non-friable Class B works –non-friable Asbestos-related works Unlicensed asbestos work

>0.1% w/w AF+FA in soil >0.01% w/w AF+FA in soil >1% ACM >0.001% w/w AF+FA in soil >0.01 % w/w ACM

≤0.001% w/w AF+FA in soil <0.01% w/w ACM

Asbestos removal control plan and WorkSafe notification for asbestos removal Asbestos removal control plan and WorkSafe notification for asbestos removal No additional notification required No additional notification required

Required Required Not required Not required

Disposable coveralls rated type 5, category 3, nitrile gloves, steel toe capped gumboots or safety footwear with disposable overshoes.

Full-face P3 respirator with particulate filter.

Water and polymer spray via localised points before and during works. Disposable coveralls rated type 5, category 3, nitrile gloves, steel toe capped gumboots or safety footwear with disposable overshoes. Disposable coveralls rated type 5, category 3, nitrile gloves, steel toe capped gumboots or safety footwear with disposable overshoes. No asbestos-specific PPE as concentrations are unlikely to exceed trace levels in air.

Half-face P3 respirator with particulate filter. Disposable P2 dust mask

Water and polymer spray via localised points before and during works. Water spray via localised points. No asbestos-specific requirements as concentrations are unlikely to exceed trace levels in air

Water spray via localised points.

Scenario Class A works –non-friable Class B works –non-friable Asbestos-related works Unlicensed asbestos work

>0.1% w/w AF+FA in soil >0.01% w/w AF+FA in soil >1% ACM >0.001% w/w AF+FA in soil >0.01 % w/w ACM

≤0.001% w/w AF+FA in soil <0.01% w/w ACM

Air monitoring Air monitoring required Air monitoring not required but can be undertaken depending on the site setting and to confirm that concentrations are below 0.01 f/ml Air monitoring not required but can be undertaken depending on site setting to confirm that concentrations are below 0.01 f/ml Air monitoring not required

Decontamination facilities

Vehicle (truck) protection

Vehicle Washing Facilities

Finishing surfacing/cap Dedicated wet decontaminatio n area or trailer. Consider powered and plumbed unit Dedicated decontamination area and foot wash Dedicated decontamination area and foot wash Foot wash and used PPE collection area.

200 µm heavygauge polythene wrapped soil/lined trays and truck covered. 200 µm heavygauge polythene wrapped soil/lined trays and truck covered. Truck lining/soil wrapping depends on the receiving landfill. All trucks should be covered. Truck lining/soil wrapping depends on the receiving landfill. All trucks will be covered.

HEPA filter system fitted for all occupied vehicles filter replaced or clean down with HEPA vacuum cleaner post work HEPA filter system fitted for all occupied vehicles where friable ACM on site (lagging, insulation, etc). Standard air conditioning. Standard air conditioning.

Visual assessment plus swab and air sampling inside the cab by an independent assessor Visual assessment plus swab (if friable) by an independent assessor or independent competent person* or SQEP following brush and or wash down Visual assessment by a competent person* or SQEP following brush and or wash down Visual assessment by a competent person* or SQEP following brush and or wash down

No special finishing/cover requirements if soils are confirmed to meet health criterion (0.001% w/w). Otherwise: Hard cap - No depth limitation, no controls. Soft cap –at least 0.2 m and should be delineated by a permeable geotextile marker layers between the cap and underlying asbestos/contaminated material.

Scenario Class A works –non-friable Class B works –non-friable Asbestos-related works Unlicensed asbestos work

>0.1% w/w AF+FA in soil >0.01% w/w AF+FA in soil >1% ACM >0.001% w/w AF+FA in soil >0.01 % w/w ACM

≤0.001% w/w AF+FA in soil <0.01% w/w ACM

Ongoing management If validation testing shows any soil at the base of any excavation contains asbestos, even at <0.001% w/w, the Asbestos Regulations require the location of these to be recorded in an asbestos management plan. * A competent person must meet the requirements of regulation 41(3) of the Asbestos Regulations.

5.3 Soil material classification

The spoil generated as result of the Mt Eden Enabling Works will require off-site disposal. In the context of this C DWP, spoil generated shall be classified as per the following three categories to define disposal requirements:

Cleanfill

Cleanfill material is defined in the Auckland Unitary Plan –Operative in Part (AUP) as:

Means natural material such as clay, gravel, sand, soil and rock which has been excavated or quarried from areas that are not contaminated with manufactured chemicals or chemical residues as a result of industrial, commercial, mining or agricultural activities. Excludes:

Hazardous substances and material (such as municipal solid waste) likely to create leachate by means of biological breakdown; Product and materials derived from hazardous waste treatment, stabilisation and disposal practices; Materials such as medical and veterinary waste, asbestos, and radioactive substances; Soil and fill material which contain any trace element specified in Table E30.6.1.4.2 at concentration greater than the background concentration in Auckland soils specified; Sulfidic ores and soils; Combustible components; More than 5 % by volume of inert manufactured materials (e.g. concrete, brick, titles); and More than 2 % by volume of attached biodegradeable material (e.g. vegetation).

Managed fill

Managed fill comprises:

Soil containing metal contaminants above the published background concentrations in the Auckland region. Soil containing low level hydrocarbon compounds. Soil containing low level asbestos in soil concentrations (depending on disposal facility). o Note: there are currently no managed fill tip sites within the Auckland Region that can accept asbestos. Soil that does not contain hazardous substances or materials in the form of household and industrial waste or organic waste.

Contaminated fill comprises:

Soil with concentrations of contaminants exceeding managed fill acceptance criteria. Household and industrial waste. Asbestos in soil and/or ACM.

5.4 Spoil disposal

Surplus spoil requiring offsite disposal shall be managed according to the location and nature of the material, as follows:

Surficial fill materials • Fill is present across the site varying in depth but typical present between 0.4 m and approximately 4.0 m bgl; • Based on the available results, fill materials will require disposal as either managed or licenced landfill; • Disposal to managed fill is subject to compliance with the spoil meeting the acceptance criterial of the disposal location; • Any contaminated fill (as defined in the previous section) will be disposed of to a licenced landfill; and • Trucks taking spoil for disposal offsite must be lined/ wrapped if required by the receiving managed fill facility and in accordance with Table 5-1.

Natural materials

Following removal of all fill material, the underlying natural material, if free from staining or odour, is suitable for disposal as cleanfill; and The receiving facility may require confirmatory testing, which should be undertaken in accordance with the soil sampling procedures detailed in Section 5.10.

In all cases: • Truck transporting spoil for disposal offsite will be covered; • The necessary permits from the disposal site operator will be obtained to confirm that the facility can receive the materials prior to off-site transportation; and • All weighbridge dockets and/or a summary sheet will be retained for inclusion in validation reporting at completion of the works (refer to Section 8).

There is limited opportunity for reuse of spoil. If spoil is to be re-used the appropriate environmental controls (if any) are to be advised by the CLS. Such controls may include encapsulating the soil (refer finishing surface/cap requirements in Table 5-1).

5.5 Transportation of spoil

The following measures shall be implemented to prevent spoil from being dispersed onto roads or transported to another site (excluding transport to a disposal facility) as well as to minimise generation of dust:

Any excess soil on vehicle tyres shall be removed before vehicles leave the works area. A wheel wash will be established on site and vehicles that have tracked over exposed soils will

be required to exit the works area via the wheel wash;

Excess soil shall be removed from vehicles and plant before they leave the works area; All trucks transporting excavated spoil to the selected disposal facility shall be covered to prevent the spillage of spoil and dust emissions; and Additional controls (refer vehicle protection and vehicle washing facilities in Table 5-1) are required for the disturbance of asbestos contaminated fill material on the South Pacific Timber site, unless further testing is undertaken to justify that the controls are not required. Such controls include: o Visual assessment by a competent person following cleaning of vehicle before leaving the works area. o Depending on the requirements of the receiving site truck lining/soil wrapping of fill material during transport may be required.

If a higher concentration of asbestos fibres is detected as part of any additional testing or discovery of unexpected contamination, then the relevant level of controls outlined in Table 5-1 shall be implemented.

5.6 Water management

Separation and diversion of clean stormwater away from areas of ground disturbance is standard practice for any earthworks activity but becomes more important where contaminants are present. To minimise the potential for clean stormwater to encounter contaminated soil the stormwater and sediment controls detailed in the ESCP for the Mt Eden Enabling Works shall be implemented.

Site water including surface water that has been in contact with disturbed ground, groundwater and perched water requiring removal is to be managed via the following methods:

Piped or pumped to a sediment control system or settlement tank(s); Further treatment (i.e. flocculent additives, pH adjustment) in accordance with the procedures detailed in the Flocculation Treatment Management Plan (FTMP) for the works; and Testing in accordance with the Water Quality Discharge Monitoring Programme (WQDMP) included in the Flocculation Treatment Management Plan (FTMP) to confirm compliance with the criteria for discharge to stormwater.

Alternatively, site water will either be disposed by licensed liquid waste contractor to a licenced facility or discharged to sewer (subject to approval by Watercare Services Limited). For discharges to sewer monitoring shall be conducted in accordance with the applicable permit conditions, e.g. trade waste agreement requirements.

5.7 Dust management

To minimise the generation of dust during earthworks (particularly during earthworks within fill), the following controls shall be implemented:

Weather forecasts shall be obtained each day during work to check for predicted high wind conditions and any such predictions shall be notified to relevant construction staff so that dust management procedures are adequately prepared and implemented; In windy conditions, if soils are dry and friable during excavation then they shall be dampened with water; Limit drop heights of soil from the excavator bucket into trucks; Immediately clean up spilled soil from truck loading areas prior to loading additional trucks;

Ensure vehicles do not leave site with excess soils between the tyre tread as this will be distributed on public roads and will generate dust; If dust cannot be controlled during excessively windy conditions, then earthworks shall cease until dust can be managed; and If a dust release occurs, the time, duration, location and cause is to be recorded in the daily report as well as remedial action performed.

Further dust management and monitoring requirements are set out in the AQ DWP prepared for the Mt Eden Enabling Works.

5.8 Odour management

The contaminants in soil and groundwater, particularly during excavation in the fill, are unlikely to generate odours and vapours. If odorous soil is encountered, then the actions outlined below shall be implemented:

Limit the time that the excavation of odorous materials is exposed and occur; Removing excavated odorous material from site as quickly as possible in covered trucks; The odorous material shall be covered to suppress odour emissions, and work in that area suspended until suitable mitigation measures can be put in place if the odorous material cannot be removed quickly; Install an odour suppressant system if appropriate; and Install a ducted fan or additional mechanical ventilation to reduce vapour concentrations in the area if required.

If odorous material is encounter, the time, duration, location and cause is to be recorded in the daily report as well as remedial action performed, including notifying the CLS.

Further dust management and monitoring requirements are set out in the AQ DWP prepared for the Mt Eden Enabling Works. 5.9 Sampling and testing

Any sampling and testing of soils shall be undertaken by the CLS according to the requirements of the NES Soil Regulations and the MfE Contaminated Land Management Guidelines No.5. Site Investigation and Sampling (revised 2011). Samples for asbestos testing shall be collected in accordance with the NZ Asbestos in Soil Guidelines.

Soil samples shall be collected according to the following procedure:

The materials encountered shall be described in accordance with the NZ Geotechnical Society Guidelines for the classification and field description of soils and rocks for engineering purposes; Hands shall be freshly gloved to collect soil and the samples shall be placed immediately into the appropriate laboratory supplied sample containers; Any equipment used to collect the samples shall be decontaminated between sample locations using clean water and Decon 90 (a phosphate-free detergent) rinses; and Samples shall be shipped in chilled container to an IANZ certified laboratory under chain of custody documentation.

As a minimum, testing shall be for metals and PAH. Any evidence of the presence of asbestos shall trigger testing for asbestos content in soil.

The CLS shall evaluate any analytical results against the relevant human health and environmental discharge regulatory standards/acceptance criteria as appropriate.

5.10 Imported material requirements

It is not anticipated that soil materials will be imported as part of the Mt Eden Enabling Works. In the event that soil materials are imported these shall originate from:

A site which has been determined by a suitably qualified contaminated land professional to have had no known history of potentially contaminating activities, as detailed on MfE’s Hazardous Activities and Industries List (HAIL); or A site which has been adequately investigated by a suitably qualified contaminated land professional, in accordance with MfE’s Contaminated Land Management Guidelines No. 5 Site Investigation and Analysis of Soils (revised 2011), to meet the ‘cleanfill material’ definition as prescribed in the AUP (refer Section 5.3).

Soil materials imported will typically be tested at a rate of 1 in 500 m3 for metals and PAH and any evidence of the presence of asbestos shall trigger testing for asbestos content in soil. The CLS will determine the required rate and analytes based on the source site. It is preferable that the fill is tested at its source prior to its use at the site. However, if not, then the imported soil materials shall be stockpiled on site with appropriate controls until test results are available.

Additional, engineering materials may be used including clean quarry materials and recycled crushed concrete aggregate that is site won or sourced from a quarry or supplier. The supplier of these materials are to provide documentation to confirm suitability for use.

For crushed concrete aggregate the additional information is required:

Sourced from the site: address of the source site, copies of pre-demolition asbestos surveys,

copies of asbestos clearance certificates prepared prior to demolition and asbestos testing at a rate of 1 in 500 m 3 .

Sourced from a supplier: confirmation of processing procedures and asbestos testing at a rate of 1 in 500 m 3 of product is to be provided by the supplier. The CLS shall review the supplied

information prior to acceptance or the material stockpiled on site until available.

5.11 Sealing excavation service trenches

If contaminated material is encountered and sealing of excavation service trenches is required to prevent them from acting as a conduit for migration of contaminated groundwater away from the site, a pipe dam shall be installed at the site boundary. The pipe dam shall be either concrete or another impervious material to be specified by the drainage design engineer. The dam shall encase the pipe and extend up the trench to just below the paved surface as shown in Figure 5-1 below.

The locations of pipe dams will be recorded on as-built drainage drawings and included in the validation reporting at completion of the works (refer to Section 8).

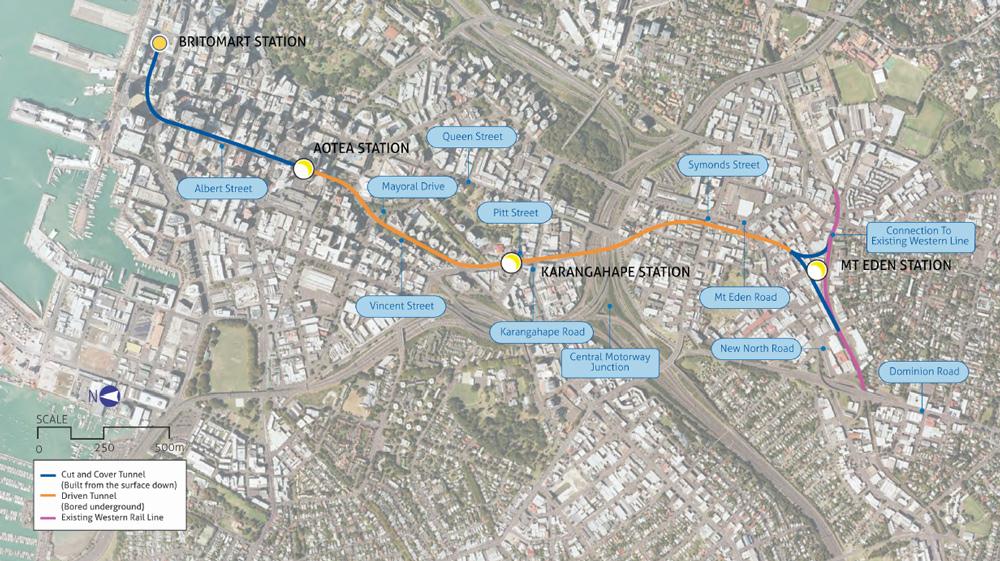

Figure 5-1: CRL Route and Location