2 minute read

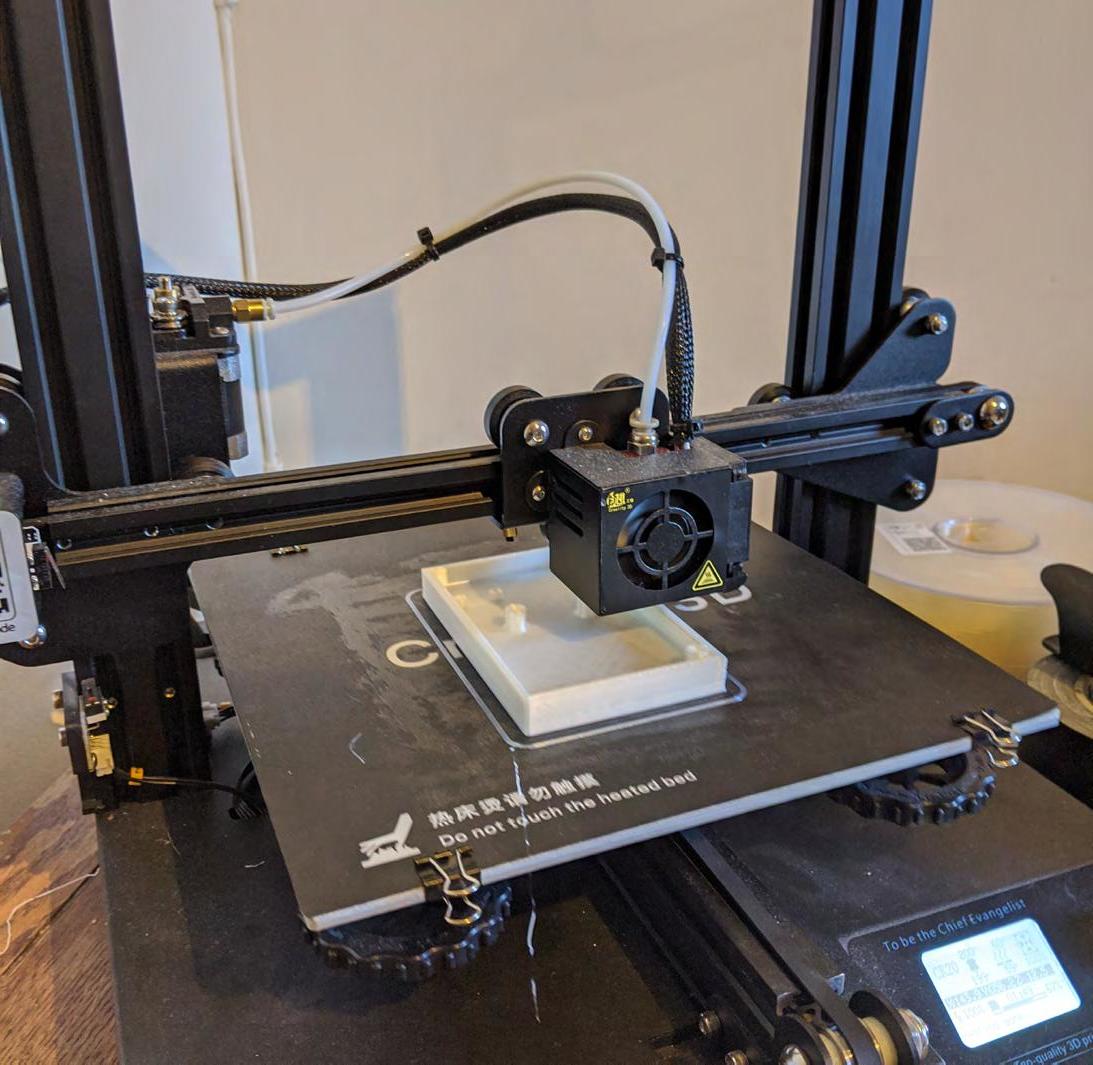

final design material choice

From initial costing work, it was clear that previously proposed methods of metal manufacture were not suitable: • Blanking and forming - too high set up costs at a production run of 1000 units. • CNC routing - too high per unit costs as process takes a lot of time and has low yield. Due to this, metal casting was to be used as the main metal manufacture process. I wanted to keep a type of metal as it would give the product a premium look and feel, as well as be more durable than alternative polymers such as ABS. In order to decide on the metal to be considered, I used CES to compare different materials. Limits were used to filter process usage to casting, recyclability and resistance to common substances. I wanted to optimise price per unit volume, as this was the main concern in manafacture. I created graphs of price against yield resistance, CO2 created in production and recycling, as well as a graph of the overall price per unit volume. This left me with 3 materials with the desired properties: • Stainless Steel • Cast Iron • Aluminium From looking at the data sheets for these materials, I eliminated cast iron due to its rough surface finish, as well as high density, as this would have made the product less aesthetically pleasing, as well as significantly heavier - meaning more costs in shipping. From this I was left with aluminium alloys and stainless steel. Both had similar resistance to yield, meaning similar losses from shipping damage and similar general robustness. However, the stainless steels had a lower CO2 output both in creation and recycling compared to aluminuim alloys. However both had significantly less than a polymer alternative. Due to its lower cost and density whilst, compared to polymers, low amounts of CO2 produced in production and recycling I chose to stick with aluminium alloys (specifically 5000 grade - datasheet included).

Limit Value Reason

Advertisement

Metal Casting Excellent This would mean the fewest wasted casts, maximising the yield of the process and minimising costs.

Recycle Yes At the end of the product lifecycle, the casing can be sustainably recycled.

Water (fresh), weak acid, UV radiation, light abrasion Acceptable, Excellent Resistance to common substances that the product would encounter in daily use.