October 2022 | Issue #13 DeMOLITION HUB MAGAZINE UK, European & worldwide demolition matters British Demolition Awards 2022 Special Edition Forever Promoting British Demolition INDUSTRY AWARDS 2022 British Demolition Awards & the CN Specialists Awards DEMOLITION DISCUSSION With Melvyn Cross Total Reclaims Demolition NO TIME WASTED Featuring leading waste companies Find out more at Bauma 24-30 October 2022 BOOTH A1.451 - FM .711/4 LEADING THE WAY WITH BRAND NEW INNOVATIVE SOLUTIONS

info@liugong.co.uk 02392 123 392www.liugong.co.uk FROM 1.8 TO 95 TONNES THE ALL NEW F-SERIES BREAKS THE MOULD. SCAN THE QR CODE TO DISCOVER THE DIFFERENCE GROUND BREAKING DESIGNTOUGHNESSCONTRÔLINTELLIGENCE

Quite honestly it’s been a brilliant, busy and seemingly quick couple of months in which an awful lot of good and interesting stuff occurred and (of course) got knocked down.

It goes without saying that the key event for us was proudly staging the fourth British Demolition Awards, sponsored by LiuGong Direct UK, which we organise quite simply to champion demolition.

This was the best and most celebrated British Demolition Awards yet, with the aftermath continuing for the majority of September on the socials and with attendees clearly having had a really enjoyable, and beneficial, time.

Congratulations to all the winners and thank you to all those that supported the event. The King Power Stadium did us proud, so now it’s over to London for 2023.

Our industry raised many thousands of pounds on the night for our chosen charity Mates in Mind and with an ongoing donation page still open, we will be announcing the full amount raised in the next issue.

To add to the donations please go to: https://justgiving.com/ fundraising/britishdemolitionawards.

Our awards started September and we ended the month with my invite to the Construction News Specialists Awards, which we used to report on all the many British demolition successes.

Away from our well-used tuxedos – work boots-wise I was on site in Plymouth to meet Welsh based Pritchard’s for the ongoing demolition of gas holders and I am eagerly awaiting a WhatsApp to go back to see the final demolition of the gargantuan remaining holder.

Paul was in Kirkby on Merseyside with Austin Wilkinson Demolition for the removal of a railway bridge over County Road and you can read about INMALO delivering a concrete cracker to a new hotel development site in Clerkenwell. With the Hammersmith and City line only metres below, the developer turned to INMALO to use innovative methods to break up existing concrete foundations. We were also with Salford-based Connell Brothers completing the demolition of Mosley Hill Hospital and in Switzerland for the demolition of a Swiss bank by Eberhard.

It would be remiss of me not to mention the passing of Queen Elizabeth II, which we marked here at the Demolition Hub offices.

I really hope you enjoy this issue,

Ben Chambers Publisher, Demolition Hub ben@chambers.media

published six times a year.

subscription rate is £60 per year. Subscription

at

Articles and information contained in this

are the

and

photographs or manuscripts.

to,

DemolitionHUB Magazine | 3 PUBLISHER Ben Chambers ben@chambers.media 01903 952 648 EDITOR Toby Wilsdon toby@chambers.media 01903 952 645 DEMOLITION EDITOR Paul Argent paul@chambers.media 07813 064 590 COLUMNISTS Jacqueline O’Donovan Terry Lloyd SALES Ben Chambers ben@chambers.media 01903 952 648 Luke Chaplin luke@chambers.media 01903 952 643 DESIGN Nicki Chambers nic@chambers.media Alex Jarrett PRODUCED & PUBLISHED BY Global News Media Ltd Suites 5 & 6, Chapel House, 1-6 Chapel Road, Worthing, West Sussex BN11 1EX ben@chambers.media 01903 952 640 Demolition Hub are proud supporters of the National Demolition Association Demolition Hub are proud supporters of National Federation of Demolition Contractors Demolition Hub are the media partner for the European Demolition Association Demolition Hub is

The

records are maintained

Global News Media Ltd, Suite 5 & 6, Chapel House, 1-6 Chapel Road, Worthing, West Sussex BN11 1EX.

publication

copyright of Global News Media Ltd

may not be reproduced in any form without the written permission of the publishers. The publishers cannot accept responsibility for loss of, or damage

uncommissioned

demolitionhub.com

The CEA’s response to the government’s minibudget by Chief Executive, Suneeta Johal

creates more than 150 new jobs with £8m investment in careers programme

submitted to kick start demolition works at Fiddler’s Ferry

EUROPEAN DEMOLITION ASSOCIATION NEWS

newest member – Metal

Company

Tank 2022 virtual

NATIONAL DEMOLITION ASSOCIATION NEWS

Casey-Bertram

of 100,000 m3

CASE STUDY

by

DEMOLITION DISCUSSION

With

STUDY

WASTE FEATURE

SUPPLIER TALK

With Alexander Sturm, Business Unit

Sennebogen

40

Demolition of

demolitionhub.com 82 4 | DemolitionHUB Magazine 18 CONTENTS 6 NEWS

JCB

Plans

12

EDA welcomes

Collection

EDA Think

conference 16

Outside the box

Paul Argent 18

Melvyn Cross, owner of Total Reclaims Demolition 28

Demolition Hub presents: • Anglian Demolition and Asbestos • Ward • The British Metals Recycling Association • Total Metal Recycling • Collard Group • O’Donovan Waste Disposal 24 CASE

Banking on Eberhard by Paul Argent 14

begins demolition

distribution centre40

Demolition

•

Promove

Trevi Benne CS Series supplied by Robustrack

•

• Rotar RG

by Worsley

Doosan

Eggborough

Group

Bobcat reveals

demolitionhub.com Magazine | 5 Industry leaders in design and manufacture of bespoke excavator equipment and modifications Kocurek Excavators Ltd. 24 Arkwright Road Hadleigh Road Ind Est, Ipswich, Suffolk IP2 0UB t: +44 (0) 1473 217477 e: sales@kocurek.co.uk www.kocurek.com ALWAYS IN REACH 46 EVENTS • The British Demolition Awards winners • ConExpo 2023 – Drones • bauma preview • Construction News Specialists Awards –AR Demolition crowned twice at a big night in London 72 CASE STUDY An (in)firmary foundation by Paul Argent 96 INDUSTRY

demolition excavator takes down historic factory Five ways technology is improving Health & Safety for construction workers

power station blowdown caught on camera by Sky Revolutions Rye

runs Sandvik QJ241 on HVO

super compact telehandler and company’s most powerful compact loaders Diesel power disappearing from Cawarden sites 112 CONTRACTS Builders’ Conference CEO Neil Edwards reports back on the UK construction sector for August 120 OPINION Jacqueline O’Donovan Terry Lloyd 76 ATTACHMENT FEATURE

Hub presents: • LaBounty MSD4000R Legend Shear, supplied by BPH Attachments • Epiroc • Inmalo • OilQuick •

srl •

Rototilt

Steelwrist

Series supplied

Plant 92 CASE STUDY Breaking tracks by Paul Argent

CEA responds to government’s mini-budget by CEA Chief Executive, Suneeta Johal

news NEWS

demolitionhub.com6 | DemolitionHUB Magazine

Our industry has welcomed the chancellor, Chancellor Kwasi Kwarteng’s, announcement to overhaul planning restrictions, get rid of EU regulations and environmental assessments. The chancellor said the new bill will “unpick the complex patchwork of planning restrictions and EU-derived laws”. Further announcements are expected in the coming weeks, we hope as an industry he will stick to his pledge of prioritising infrastructure projects and energy – speeding up building.

This announcement is, however, reminiscent of government announcing fast-track planning reforms back in December 2020 –therefore the jury remains out until we have concrete reform plans in place.

The announcement of government setting up investment zones across 38 areas in the UK is also welcome as it will encourage new growth with offers to new businesses of zero business rates and stamp duty waived.

The decision to make the Annual Investment Allowance, which gives 100% tax relief on investments in plant and machinery to be permanently set at £1m is what manufacturers and association representatives have been requesting for some time, so this is most welcome – it’s good to have stability, which will allow forward planning and encourage investment. We also welcome the £500m to support new innovative funds in UK tech and science scale-ups, which will further encourage investment.

The reversal of the national insurance rise and the cancellation of the planned rise in corporation tax has been well received. The corporation tax rise had not yet been implemented so freezing something that hasn’t happened yet does

not encourage growth – so there’s no reduction – the situation remains the same. The standard income tax rate deduction to 19p in 2023 is encouraging – but we would have liked to see business rates reduced.

The Energy Bill Relief Scheme and wholesale energy prices to be capped for just six months was very disappointing. There is an offer of a review in March 2023 for struggling businesses, however, this is not enough, business should have been afforded the two-year freeze granted to domestic energy users .

This has been hailed as a bold budget for business –we can only hope that this is not a budget of smoke and mirrors from government –but a growth plan to release the huge potential in our sector.

news

demolitionhub.com DemolitionHUB Magazine | 7

More than 150 new jobs created with £8m talent investment

on challenging and rewarding careers.”

JCB has created more than 150 new jobs for apprentices and graduates with an £8m investment in its industryleading early careers programme.

The new recruits started their jobs in early September as JCB focuses on training the next generation of manufacturers, engineers, and business specialists.

JCB CEO Graeme Macdonald said: “JCB’s future growth and success depends on recruiting and training new talent. JCB always plans for the long term and that is more important than ever as the business goes through a period of rapid growth. We are delighted to welcome our new apprentices and graduates as they embark

Among the apprentices joining JCB are Fynn Churton, aged 18, of Upper Tean, near Cheadle, Staffs, and Freya Barkas, 21, of Uttoxeter. Fynn, who is starting a four-year Finance Apprenticeship at JCB’s World HQ in Rocester, said: “I wanted to do an apprenticeship simply because of the scale of JCB; it is a global business and there are so many opportunities available. I am quite an ambitious person and it appears to me that if you put the work in, you can move higher and higher in your career.”

Freya is starting a Customer Service Apprenticeship after giving up a full-time job to take up her new role at JCB’s World Parts Centre in Uttoxeter. She said: “It was hard giving up a job, but I have always wanted to work at JCB because of the scale of the company. I wanted to wait for the right opportunity

though, and that is just what has come along now with my apprenticeship because customer service is something I’m passionate about.”

JCB Group HR Director Max Jeffery said: “Competition for places on the JCB apprenticeship and graduate schemes is always fierce and this year we had more 2,000 applications. We set the bar very high when we recruit people and many JCB apprentices in recent years have gone on to win national awards, which is testament to the quality of the schemes we run. Our new intake of apprentices and graduates will play a fundamental role in shaping this business in the future.”

demolitionhub.com

Fynn Churton (l) and Brodi Wright

New JCB apprentices (left to right): Libby Hodge, Lexi Anderson and Freya Barkas

8 | DemolitionHUB Magazine

When the demand is high.

Concrete busting

Our CB Concrete Busters are designed for primary demolition of wide reinforced concrete structures. The two powerful hydraulic cylinders deliver virtually constant closing force, while the 360° endless hydraulic rotation allows optimal positioning and precise handling. Concrete Busters are ideally suited for high-reach demolition jobs. Epiroc UK & Ireland Ltd Email : hat.uk@epiroc.com Tel : 07971 650455 www.epiroc.com United. Inspired.

news Plans submitted to kick start demolition works at Fiddler’s Ferry

Plans have been submitted to commence demolition works at the Fiddler’s Ferry Power Station in Warrington to help regenerate the area and create new opportunities for investment, jobs and housing.

New owners Peel NRE, Peel L&P’s natural resources and energy company has provided documents to Warrington Borough Council to prepare the first phases of

development at the northern part of the Widnes Road site, which will include the demolition of the four northern cooling towers, nearby admin buildings and clearance of the former coal stockyard and machinery.

The former fossil-fuel dependent power station, which sits on the boundary of Warrington and Halton, was decommissioned in 2020 and

Peel NRE acquired the 820-acre site in July this year from SSE.

It has been an important part of Warrington’s history and economy for the past 50 years and Peel NRE’s 10–15-year masterplan for the brownfield land marks a new era for the site with proposals for industrial use and a new sustainable community.

Plans will also create extensive

demolitionhub.com10 | DemolitionHUB Magazine

new parkland and wildlife areas to enhance the environment in partnership with Peel L&P’s homebuilder, Northstone.

Controlled demolition techniques will be carried out to demolish the four, 115 m-high concrete cooling towers and as much material as possible from the first phase demolition will be re-used on the site as engineering material for the

re development of the site.

If approved, the demolition is expected to start later this year and take up to a year to complete.

The Fiddler’s Ferry site, which also includes agricultural land, was identified in the 2021 version of the Warrington Local Plan for the development of around 250-acres for employment use and a minimum of 1,760 new homes.

Kieran Tames, Development Director for Peel NRE said: “The submission of these plans takes us a step closer to starting work to regenerate the former power station site and secure future investment for Warrington, Halton and the wider region including new family homes, improved

facilities and more jobs.

“The first phase of demolition will take place at the northern part of the site, and we will be working with contractors and the community to ensure this is carefully planned and managed to the highest safety and environmental standards.

“We recognise that the demolition programme will be of significant interest to many local people, and we will be ensuring we keep residents informed throughout the process. A public consultation on the first phase of our proposed development will also be taking place later in the year and we look forward to liaising closely with the local community to help shape our plans.”

For more information about the plans, visit www.fiddlersferry.com.

For more information about Peel NRE, visit Natural Resources and Energy (peellandp.co.uk)

news demolitionhub.com DemolitionHUB Magazine | 11

EDA Think Tank 2022 virtual conference

The EDA Think Tank 2022 will be held on 5 October on videoconference. This event, titled End of life of industrial facilities, is organised by the European Demolition Association in partnership with the European Decontamination Institute.

The two sessions, starting at 09:30 CEST (GMT + 2), will be separated by a 15-minute break.

The objective is to foster direct communication between stakeholders, to chat and share experiences, common challenges, risks and possible solutions when planning for and preparing to retire an industrial facility.

It will also serve to officially present the technical guide about this topic, aimed at facility owners (chemical, oil and gas, nuclear, etc.).

Both sessions will include roundtable discussions with contractors, engineering companies and asset owners, as well as a Q&A session for attendees.

After the great achievements at past events, we are confident that this will be of interest to professionals in the demolition industry.

Sessions will be moderated

EDA welcomes newest member: Metal Collection Company

The Metal Collection Company is an international company of Saudi Arabian origin, which is active in metal assembly. Now, it is also a member of the European Demolition Association.

The company has specialised in metal collection since 1997 in Saudi Arabia. It has a range of functions including ship dismantling and wrecking; demolition and removal of buildings; and wholesale iron, scrap and recycling materials.

Its nearly quarter century

long experience in the scrap metal trading field has provided it with great opportunities to participate in public and sealed bid auctions with Aramco, SABIC, Saudi Electricity Company, Saudi Telecom Company, Saline Water Conversion Corporation, government trusts and municipalities and other public and private sector companies.

Its success and achievement of goals is based on partnership, job satisfaction, quality, transparency and trust.

by Jose Blanco, EDA SecretaryGeneral.

09:30 – 10:30 Session 1 – Before the end-of-life

Presentation of guide on endof-life of industrial facilities by Kate Bester

Panelists: Kate Bester, Contract Manager, JET DEMOLITION, Kurt Van Stappen, Senior Project Manager Demolition, TRACTEBEL

Themes:

• What are the main challenges when planning the end of life of assets?

• Which steps should be taken during the normal operation of a facility to prepare for its end of life?

• Should external experts be engaged in the end of life planning and bidding process?

• Who should be involved in the decommissioning and closure activities?

• Highlights of lessons learned

10:30 – 10:45 – Break

10:45 – 11:45 Session 2 – During and after the end-of-life

Panelists:

Stefano Panseri, CEO, DESPE, Simon Carroll, Senior Advisor

VATTENFALL, Ángel Fudili, Project Manager, NATURGY, Erik Sandonis, Project Manager, LEZAMA DEMOLICIONES

Stéphane Ponet, CEO, CURIUM.

Themes:

• What are the most frequent issues encountered in the demolition of industrial plants?

• Is the planning of the demolition project often done jointly by the owners and the companies involved?

• Is it common to find an inventory of equipment and materials found in the facility? How much can be recovered/ recycled?

• How can clear communication between the parties affect the success of the project?

• Highlights of lessons learned.

Conclusions by EDA President, Stefano Panseri

To attend the event, visit: www. europeandemolition.org/ activities/thinktank/edathink-tank-2022-end-of-life-ofindustrial-facilities.

Demolition Hub is the media partner for the European Demolition Association

demolitionhub.com12 | DemolitionHUB Magazine

Congratulations to Demolition Hub on its first issue including the Americas. We hope you enjoy the article on Casey-Bertram’s demolition of a 100,000 m3 distribution centre in Plainfield, Indiana.

At NDA, through best practices and sharing of information, we help our members succeed in business. If you’re doing business in North America, if you know someone who is not a member or you are not a member, now is the time to join NDA. There is nothing more valuable than a peer-topeer connection and education. Membership provides access to safety resources, demolition best practices, educational content, a company listing in our public Membership Directory and much more. Contact me directly at jlambert@demolitionassociation. com or apply for membership online at demolitionassociation. com/Membership/Join-or-Renew.

Jeff Lambert Chief Executive Officer

Demolition Association

Demolition Association

Casey-Bertram begins demolition of 100,000 m3 distribution centre

The day after a March fire engulfed a large distribution centre, local authorities called Casey-Bertram to provide immediate support to the fire department. The Indianapolisbased demolition contractor travelled to Plainfield, Indiana, to drag semi-truck trailers away from the 100,000 m3 building, which allowed firefighters to concentrate their efforts on areas that were previously inaccessible and safely mitigate the fire.

After the fire was extinguished, Casey-Bertram was tasked with the teardown of several concrete pre-cast panels near key utility systems. Casey-Bertram’s proven track record over the last 30 years made it the perfect candidate for this project.

Teardown challenge

Removing the pre-cast panels was challenging for two unique reasons: they were 14 m tall and within 10 m of critical utility systems that supported an adjacent distribution centre with over 1,000 employees. These utility systems included two 1,100 m3 tanks, a three-storey battery recharging station for the centre’s

forklifts, and multiple electrical transformers. It was imperative to remove the pre-cast panels within their footprint to avoid disrupting operations at the nearby distribution centre.

Normally, the CAT 330 and two Komatsu PC300s in CaseyBertram’s fleet are enough to support a safe demolition project. However, in this situation, Casey-Bertram’s co-owner and president, Scott Casey, knew he needed a high-reach excavator to meet the unique challenges of this job.

Acquiring a high reach Casey contacted Company Wrench, a specialty equipment dealership headquartered in Carroll, Ohio, to inquire about renting a high reach excavator. The company offers a variety of high-reach fronts ranging from 15 to 30 m.

Doyle Burgess, Company Wrench’s territory sales manager, recommended a Kobelco SK300 with a 30 m high-reach front with a LaBounty multi-demolition processor (MDP 20R). Casey stressed the importance of getting the machine on-site as

National

demolitionhub.com14 | DemolitionHUB Magazine

quickly as possible to avoid critical damage to the utility systems.

“Doyle bent over backwards for us,” Casey says. “I told him what the situation was and I sent him some information. He selected the machine, the tool and the height. Then he arranged trucking and the machine was delivered within a few days. He went above and beyond to get it on site as soon as possible.”

Executing the plan

Once the high-reach excavator was delivered, Casey-Bertram initiated its plan to safely remove pre-cast panels from the building within their footprint. This process required all four machines and metal bracing to ensure the panels would collapse as intended.

The high reach used the MDP 20R to crush the top concrete segments of the panel while the bracing held the panels in place. The other three machines used their buckets to support and reposition the bracing as the high reach continued to make cuts with the MDP 20R. Once debris accumulated on the ground, Casey-

Bertram’s excavators used shears, processors and buckets to clear a path to allow the high reach to continue moving forward.

The process took about a week, avoided damage to the utility systems and did not interrupt the operations at the neighbouring distribution centre. Without this timely teardown, the unstable precast panels may have fallen off the building, potentially creating large utility costs and impacting more than 1,000 employees.

“Our operators raved over

the high reach and LaBounty MDP,” Casey says. “They said the equipment worked perfectly and that the controls were very precise. Doyle sent out a machine that had the height we were looking for and to be far enough away from danger to work safely.”

Next steps

It was ultimately determined the entire building needed to be demolished due to the damage caused by the fire.

The next step is to remove the remaining pre-cast panels, which span approximately a mile in length. This process will not require the same pinpoint accuracy that was used previously because the remaining sections are not close to utility systems.

The timetable on the complete demolition of the building is unknown due to several outside factors, but this first step of the process was considered a success by all parties involved.

Demolition Hub are proud supporters of the National Demolition Association and credit to this article goes to the NDA. Thank you for working with us.

Article: https://bit.ly/3SFcxaT

demolitionhub.com DemolitionHUB Magazine | 15

case study

Outside the box

by Paul Argent

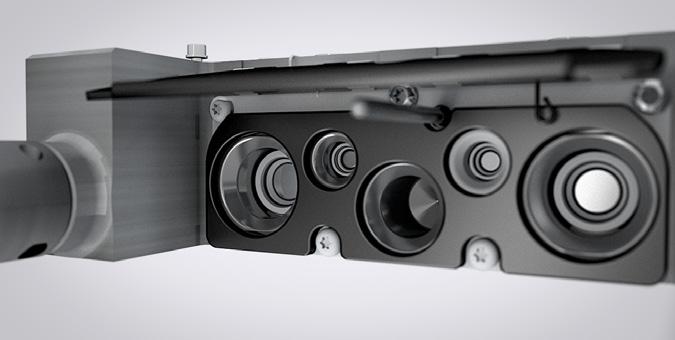

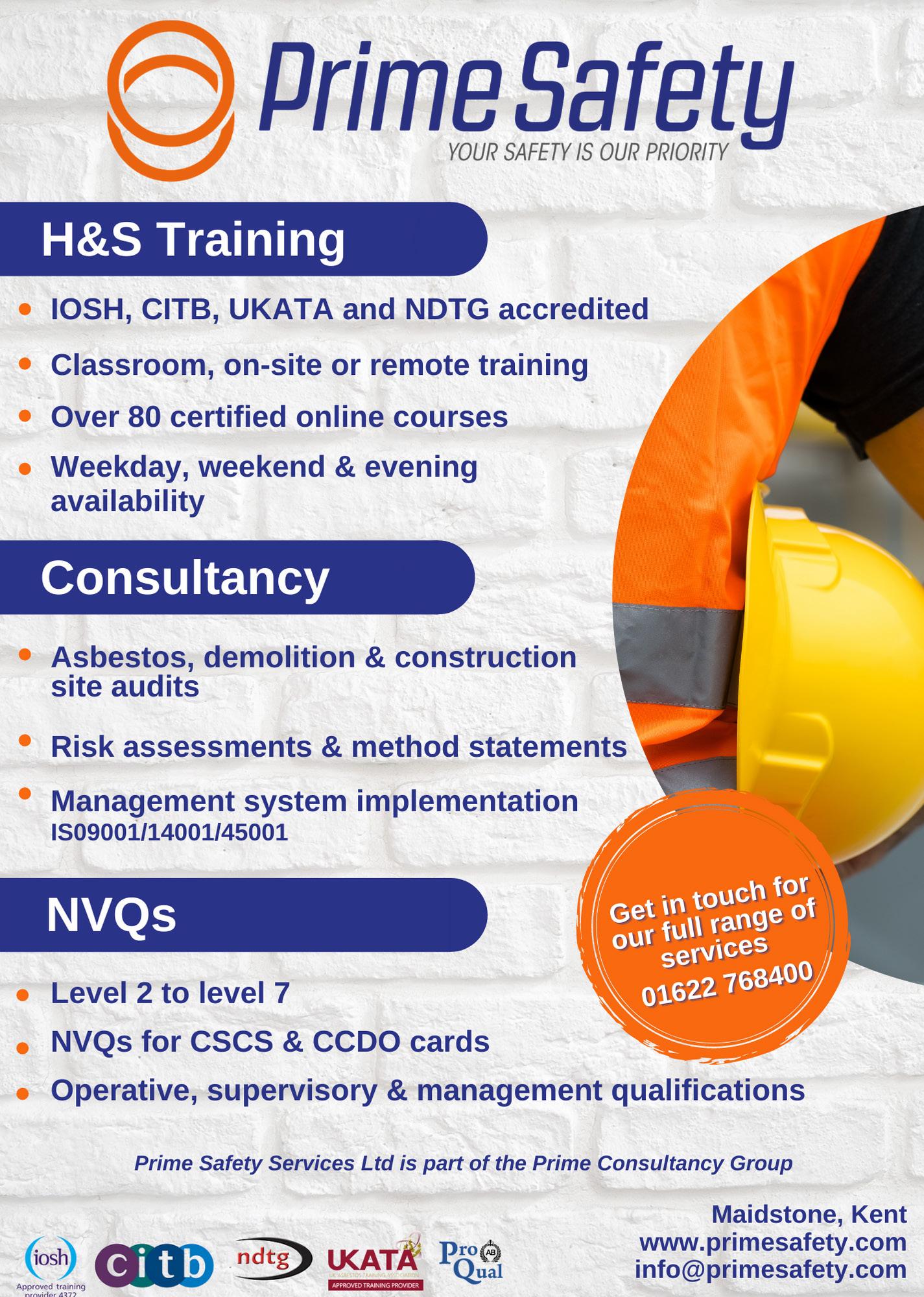

Inmalo has been supplying demolition attachments from Italian manufacturer Mantovanibenne for more than two decades with great success. Company director Charles Polak says: “The attachments are well known for their simple yet robust design and are well liked within the industry for their reliability.”

The issue faced by the developer of a new hotel in Clerkenwell was that the Hammersmith and City tube line sat just a couple of metres below its project, which meant the more traditional method of using hydraulic breakers to remove any below ground structures was immediately prohibited.

Inmalo’s Mike Wright takes up the story: “We were asked to look at ways of demolishing some large concrete foundations in situ. These blocks varied in size up to 1.6 m in width, almost 2 m in depth and varied in lengths reaching 4 m in places. They were also heavily reinforced too as they were designed to hold up a former multi story car park that once sat on the site.

The issues of the size of the blocks were exacerbated by the fact that they could only be processed in stages as the construction teams were immediately starting their piling operations from one end of the job.

“We spoke about wire sawing the blocks in situ, but this would

Winchester based attachment and engineering specialist Inmalo has recently delivered one of the UK’s largest concrete crackers to a project in central London

demolitionhub.com16 | DemolitionHUB Magazine

have taken far too long to complete,” Mike explains. “The contractor also looked at lifting the blocks out in larger sections, but this would have caused time and access issues to the remaining works.

“Our logical option was a large cracker mounted on a big excavator but again, access and weight issues made us think again. Our solution was to bring in a CR80 cracker and boom mount it onto a smaller machine.”

With a plan in place, Mike, Charles and the rest of the Inmalo team set about the preparation of the 50-t carrier excavator, a Hitachi Zaxis 490LCH. “Once we had ensured the flows and pressures on the Hitachi were sufficient to work the attachment productively, we carefully measured the boom and cylinder in order to fabricate a bespoke hanger for the cracker,” Mike says. “We have an experienced team of fabricators capable of undertaking this work in-house so we knew our hanger was going to work.”

With the arrival on site of the 8.25-t cracker, the team set about attaching it to the newly manufactured headstock and running tests on the kit to ensure that it met with the client’s

requirements. With this done, it was dispatched to site to start work.

The CR80 boasts a jaw opening width of 1,750 mm so was working at almost its maximum capabilities on some of the ground beams. Designed to be dipper mounted on excavators in the 70–90 t weight range, the Hitachi was also working close to its physical limits for both carrying capacity and hydraulic power as the shear requires a working pressure between 320 and 350 bar and an oil flow of between

500 and 600 litres per minute.

While not a quick job, even the hardest and largest beams were dealt with by the combination. The chamfered design of the jaw tips aided the cracking of the concrete, but the almost constant work meant regular rebuilding and refacing of the jaws was required.

Thanks to the outside the box thinking from the Inmalo team, the work was able to carry on with no disturbance to the tube lines running below the project.

case study demolitionhub.com DemolitionHUB Magazine | 17

interview DEMOLITION DISCUSSION Interviewee: Melvyn Cross Role: Owner Company: Total Reclaims Demolition Above left to right: Gary Cross (Director), Melvyn Cross MIDE (Managing Director), Martin Cross (Director), Ricky Cross (Project Manager) Inset right: Melvyn Snr demolitionhub.com18 | DemolitionHUB Magazine

QTell us about the evolution of Total Reclaims Demolition

A couple of my brothers, Mark and Gary and I formed a company called MGM. We mainly worked as subcontractors to the likes Malcolm Brydon of Matrixgrade in Nottingham, who is sadly missed and we remain eternally grateful to for giving us our first chance.

After a while my older brother Gary, who is one of the best machine drivers I know, was offered good

money to work directly as a machine driver. The security of being on the books and the warmth of a cab lured him.

Mark, my dad Melvyn Snr (who we all looked up to) and I formed Total Reclaims Demolition in 1993, becoming a limited company in 2000. The early years were tough, but back then Mark and I hadn’t grown up with much so had little to lose. After a few years of subcontracting and doing the work for others, we started to venture into pricing our own work, which was daunting at first. Some projects would lose money, and some would make. However, with the reclamation of bricks, timber and an eye for scrap metal the business grew to what it is now.

I consider that we are the leading demolition company within the East Midlands and one of the largest in the Midlands. We work throughout the UK and have also recently completed a couple of projects in the Republic of Ireland.

QHow did you get involved in business?

We were very much working class growing up and my five brothers, one sister and I all vehemently looked up to our dad. He always worked hard and although things were tight he ensured we were all provided for.

It was my dad’s work ethic and my drive to earn that saw my first

entrepreneurial ventures. On the way to school I would buy multipacks of sweets and chocolate bars and sell them individually for a tidy profit. Then on the way home from school I’d buy the latest film with the proceeds, back then on VHS. I’d be the first to watch it and then I’d rent them out around the estate for a £1 per night. I was always looking for a gap in the market.

My favourite subjects at school were maths and PE. Adding, subtracting, multiplying and dividing became second nature when dealing with money and I always loved playing football.

For as long as I can remember Mark and I worked for our dad on Saturdays and Sundays, either cleaning bricks or de-nailing timber. He paid us on a piece work basis and we earned about £7 a day. We often got friends to help, some of them still work for us to this day. It was simple, the more you did the more you earned.

Just about my entire family and extended family are involved in demolition in some way. I grew up knowing nothing else, well apart from renting videos.

QTell us about any memberships or accreditations you or the company have

We are proud members of the National Federation of Demolition Contractors (NFDC). The Directors and many of the senior management team are members of the

interview demolitionhub.com DemolitionHUB Magazine | 19

Institute of Demolition Engineers, which I proudly represented as Midlands and Welsh regional chair in 2014. We hold ISO 9001, 14001, 18001 and 45001 accreditations.

QTell us about your team and working culture

The one word that sums up the culture of the business is, family. I like to think of the business and everyone that works for it as one big family. Indeed, many of the employees are extended family.

I believe you get the best of someone by giving inspiration and independence, which is certainly what my mum and dad gave to me.

QWhat kind of projects do you work on most frequently?

As you can imagine the core of our business is demolition. However, as the company has grown, so has the breadth of experience and expertise. True to our roots, we are still involved in straightforward demolition, even on a domestic scale, but we are also now very experienced in high-reach demolition. We have completed countless multi-storey projects including the 17-storey, 50 m high Lenton Flats and more recently the Bonded Warehouse, which was associated with Imperial Tobacco.

Our portfolio also covers ground remediation, asbestos removal, strip out, façade retention and the production and supply of recycled aggregate.

We hope to expand the remediation arm and continue building on our already strong public sector work such as with HS2.

There’s nothing too big or small. I’ve just signed off two invoices that demonstrate the diversity of our work. One is addressed to a domestic client for £250 for some asbestos we removed. The other is the final account for our contract with HS2, which is over £5.8 million and has involved everything from demolition, separation, remediation and latterly the reclamation of a Grade II listed farmhouse. I like to think that our teams have shown the same level of care, skill and professionalism regardless.

have specialised in for many years. Given that asbestos was a common building material up to 1999/2000, our scope often includes its removal and disposal.

Increasingly over the years as local authorities, the Environment Agency and clients have become more savvy, land remediation and reclamation has been scoped within our remit. Recently while completing the demolition of a large storage and distribution centre in Northampton, we were tasked with the removal of several large underground fuel storage and the remediation of the surrounding ground and water table.

QWhat are the standout projects from Total Reclaims’ history?

Our roots are very firmly in demolition, especially when it involves the reclamation and recycling of material, which we

Most notably was the demolition of the former Odeon Cinema, Angel Row, Nottingham. The structure was built in the 1930s, sandwiched between two historic buildings and backed onto one of the country’s only private subscription libraries. Positioned in the city centre it involved everything from high-reach demolition, burning, lifting and excavation. It was a real test of our skills and expanded our knowledge.

Other projects that spring to mind include the demolition of the five tower blocks that formed Lenton Flats, which were 17 storeys high. The demolition of the Bonded Warehouse and more recently the Heart of the City project, Sheffield and Heartlands Parkway, Birmingham were all of a very large scale, which helped expand the business.

QTell us about other services you provide. How do they relate back to your core demolition focus?

interview

NPBA Family of the Year Finalist 2019: Martin Cross (Director), Gary Cross (Director), Ewan Cross (Estimator, Melvyn Cross’ son); Melvyn Cross MIDE (Managing Director)

demolitionhub.com20 | DemolitionHUB Magazine

WHEN EVERY HIT COUNTS, COUNT ON RAMMER.

The world’s best-known and most respected brand of hydraulic hammers offers a comprehensive range of powerful, productive and durable attachments that are suitable for carriers in the 0.6 to 100 tons operating weight class.

The Rammer hydraulic hammer range is unsurpassed in its innovation and reliability and offers class-leading power-to-weight characteristics.

www.rammer.com

QWhat makes Total Reclaims different?

We are, at our core, a family business and I see all of our employees as members of that family. Our staff attrition is next to nothing and those that leave often return. Many of our staff have been with the business for over 20 years and a couple, have been with Mark and I since 1993.

QHow do you gain business and spread the word about your services?

Over the years we have built excellent working relationships with the many of the leading national contractors such as Willmott Dixon, Bowmer and Kirkland, Laing O’Rouke etc. and many local and national developers bring repeat custom. Other work is often secured in competitive tender or via frameworks.

QTell us about any trainee schemes for new recruits

Over the years we have supported and sponsored many employees through various apprenticeships, whether site based or office based.

We are very proud of one particular member of staff who excelled during his apprenticeship and was awarded National CITB Apprentice of the Year award.

Closer to home, I’m proud to see my eldest son Ewan showing an interest in the business. I can sense his keenness to learn and his confidence to question things.

really appreciate how hard it is to make ends meet, especially given the current cost of living crisis, in part spurred on by high fuel prices.

Q

Do you undertake any ongoing training or Continuous Professional Development?

Training and staff development are fundamental to the business. Every member of the team features on our training matrix to maintain existing skills and qualifications as well as benchmark and signpost additional training, qualifications for personal development. This benefits not only the individuals but business as a whole.

QTell us about any engagement Total Reclaims Demolition has in the community Having come from nothing myself, I

As well as continually reviewing rates of pay, we offer a hardship fund should anyone have a genuine need or concern. Our management team is focused on spotting anyone showing signs of concern about financial issues, which can be referred to me.

In the wider community, we sponsor a number of local football teams, which isn’t really about getting your name out there, it’s more about support for grassroots football and my passion for the game.

Through our work with HS2 we have supported two reformed offenders and have provided employment and training upon their release from prison. We have also been engaged in support of “Suited for Success” which is a Birmingham based charity that assists those out of work with clothing and interview preparation.

interview demolitionhub.com22 | DemolitionHUB Magazine

As a Nottingham based, family run business that employs over 80 members of staff, it’s essential that these representatives of the business are courteous, kind and outstanding members of society.

I actively encourage and support all employees to be involved with their local community, whether that be having time off to attend meetings, training or support financially or otherwise.

A recent example of this is our support to Caythorpe Cricket Club, which a member of our team plays for. They needed to install additional drainage, which we were bowled over [!] to help with. We supplied them with the plant needed to complete the work free of charge. Other examples include time off to attend Parish Council meetings and time to train and manage a junior football team.

QWhat are the biggest technological developments you have seen in the industry and what do you envisage will be the future game changers?

I vividly remember watching my older brother, Martin and my dad operating a ball crane. Although, it’s still a recognised technique, I’d be surprised to see anyone doing it nowadays.

Like with the ball and crane, our current technology will inevitably be superseded, making what is already an incredibly safety conscious industry even safer.

QDo you have any notable projects in progress or in planning?

We have just completed the demolition of the Broadmarsh Shopping Centre in Nottingham, which as an eyesore was iconic for all the wrong reasons. We are also in the process of completing the demolition of the third and final tower of the Bonded Warehouse, which was key to cigarette manufacturing in Nottinghamshire.

QHow do you envisage Total Reclaims in 5 to 10 years?

I’d like to see the expansion of our remediation portfolio. I envisage that with the use of brown field sites increasingly common for residential purposes that specialist remediation will be required.

QAnd what about you in a few years?

I’d like to think that I’ll be able to take a back seat and become less hands on in the future, handing over the running of the business to the management team that I have faith and trust in. However, it will be hard for me to give up working completely, or at least thinking about the business that I cherish.

And finally

Who is your favourite artist?

I’m currently listening to Miley Cyrus’ album Bangerz, as it features a track called Wrecking Ball.

Who do you most admire?

My wife, Tammy, mainly for putting up with me, for support, understanding and being there through the ups and downs.

When and where are/were you happiest?

Looking back it was mucking about, as you could back then, with my brothers, Steven, Martin, Gary and Mark on site, working for our dad Melvyn Snr. That’s where we all learned our trade.

What’s the most expensive non-essential you’ve ever bought? While out pricing a job up about six months ago with my eldest son, Ewan, we cheekily parked in the new Nottingham Aston Martin dealership carpark and I noticed a British Racing Green DB11 in the showroom. A few minutes later I found myself on a test drive. Following a relatively decent year for the company, I’m now the very proud owner of said Aston Martin.

What’s your ideal weekend?

I love to get home on a Friday and put my feet up with a glass of wine and Tammy. If Forest are playing at home, I’m usually there on a Saturday. Sundays are spent watching our football team, Total Reclaims Demolition Vets, who play in the East Midlands Veterans League.

What’s your favourite food or cuisine?

When I can, I’m partial to a sausage meat sandwich from my favourite cafe, Mill Cafe at Bobbersmill. It brings back memories of going there for breakfast with my dad.

QWhat do you think responsible companies need to be doing in regard to their communities?

interview demolitionhub.com DemolitionHUB Magazine | 23

study

Banking on Eberhard

by Paul Argent

One of the most well-known names in the construction sector of Switzerland is that of Eberhard. The family-owned company can trace its history back over 65 years and is one of the largest specialist suppliers of demolition, recycling, and earthmoving services in the country.

Not that its specialities lie solely in these disciplines as the company also has a huge specialist haulage fleet to assist its day-to-day activities, including land and rail transport.

The third generation of the family owned company is now stepping up to take charge of the various

divisions of the business and in a series of features I will look at some of the areas the company operates in across Switzerland. I would like to extend my thanks to Marco Basile, Urs Peyer and Silvan Eberhard for their help and hospitality during my visit.

I visited a project on the outskirts of Zurich near the small town of Dübendorf, where Eberhard was tasked with the demolition of a former office block for a wellrespected Swiss bank. The bank had moved to new premises, leaving the huge concrete structure ready for demolition and redevelopment. The two buildings were being soft stripped with workers removing the fixtures and fittings from the building. Suspended floors, parts of the stone slab facing, AC-units and a full commercial kitchen were stripped out carefully for potential reuse. Other fixtures such as suspended ceilings, windows, doors, built in furniture and all nonconcrete walls were removed and sent away for recycling. Using several Kubota mini excavators equipped with demolition grabs, the material was quickly removed and passed to the outside of the building where a CAT M315D wheeled excavator from Baskarad AG was sorting and loading the material into roll-on-off containers.

The two huge seven-storey buildings also incorporated a basement car park outside the building perimeter. This meant that a large amount of structural propping was required to allow the demolition works above ground to commence safely. Working to structural engineer’s details, a series of round timber props were cut and placed throughout the basement outside the building perimeter to ensure the structural stability of the roof was always maintained. This allowed Eberhard to bring in two large demolition machines with a combined weight of around 170 tonnes to work safely above.

The two Caterpillar machines were a relatively standard 352F XE joined

case

demolitionhub.com24 | DemolitionHUB Magazine

study

by the company’s largest dedicated demolition machine, the CAT 395F high reach.

For readers not in the know, Caterpillar has never actually manufactured a 395F excavator – it was Eberhard that rebranded this machine to relate to the base machine’s increase in weight following its conversion. Fitted with a tilting cabin, increased counterweight, hydraulic extendable undercarriage and three-piece demolition arm capable of carrying its 6.5 t Egli crusher to a height of 30 m, the combination made steady progress through the tough concrete structure.

Situated within a couple of metres of the boundary, Eberhard used a large mobile crane carrying a drop-down protective mat to stop any material dropping onto the public highway. This is a common method of working in Switzerland and is far more cost effective and suitable than building a full scaffold enclosure. With the material dropping to the ground, the 352F was used to fill the basement with

material for a safe workbase. Like almost every demolition machine in the country, OilQuick hitches are fitted to the excavators. This allowed the 352F to swap from Rammer hammer to Egli crusher and back to its bucket in seconds to demolish the basement ceiling and fill up the basement. Supplied through Egli, the OilQuick coupler has revolutionised the way companies such as Eberhard operate by allowing them to utilise less machines and reducing the cost of attachment and hose damage.

Manufactured in Switzerland, the four Egli crushers with operating weights of 1,170 to 6,100 kg are designed for demolishing heavy concrete quickly and effectively. Their open jaw design allows the concrete to pass through, leaving regular sized material. The cutting edges on both jaws also slice through rebar leaving shot pieces instead of large strands lying around a site.

As one of the most experienced recycling contractors in Switzerland, Eberhard operates state of the art facilities in Rümlang and Oberglatt (more of which in a future issue)

and will take all of the concrete rubble from this project to the site to be recycled and used up for new concrete.

Marco Basile, Eberhard’s Project Manager says: “We take our recycling obligations very seriously at Eberhard. Apart from a very small amount of hazardous material, we aim to recycle everything we can from a demolition project.”

With a buoyant economy in Switzerland and, like most countries, spare land at a premium, the demolition division of Eberhard should be kept extremely busy for the foreseeable future.

case

demolitionhub.com26 | DemolitionHUB Magazine

Full perimeter protection, giving you access on five separate levels all at the same time. An innovative external access solution for high-rise demolition. More efficient than traditional methods, Demolition Screens are quick to install and provide complete perimeter protection and debris containment. BENEFITS • Pre-assembled • Lifted directly from trailer onto the building • Minimal installation time compared with traditional solutions • Full height, wrap around protection • Other trades can work around screens • Self-climbing hydraulics • Aluminium perforated sheet allows combined wind relief, working protection, sunlight and ventilation INTRODUCING TITAN DEMOLITION SCREENS HEAD OFFICE: Ischebeck House, Wellington Road, Burton upon Trent, DE14 2AP www.www.ischebeck-titan.co.uk | 01283 515677 | sales@ischebeck-titan.co.uk

Waste Feature

Anglian Demolition and Asbestos Ltd

Anglian Demolition and Asbestos is the largest and most reputable demolition and asbestos contractor in East Anglia. Anglian was established in 2007 specialising in demolition and asbestos throughout the region and has been evolving ever since, gaining a reputation for

its exceptional industry knowledge and high standards. Anglian currently operates 65 vehicles with 110 employees across all divisions. With an already impressive portfolio of clients and jobs that range from RAF bases to castles and a preferred contractor to many, its services are trusted by some of the country’s most well-known contractors.

Anglian’s services also extend to recycling and remediation projects – preparing brownfield sites for ongoing redevelopment; ensuring planning conditions are fully satisfied, all complying with Environmental Permitting Regulations and in accordance with the regulator-approved site remediation strategy and CLAIRE Code of Practice.

The Anglian Group has been associated with the waste sector for over 14 years due to the nature of its industry and services. Over the last

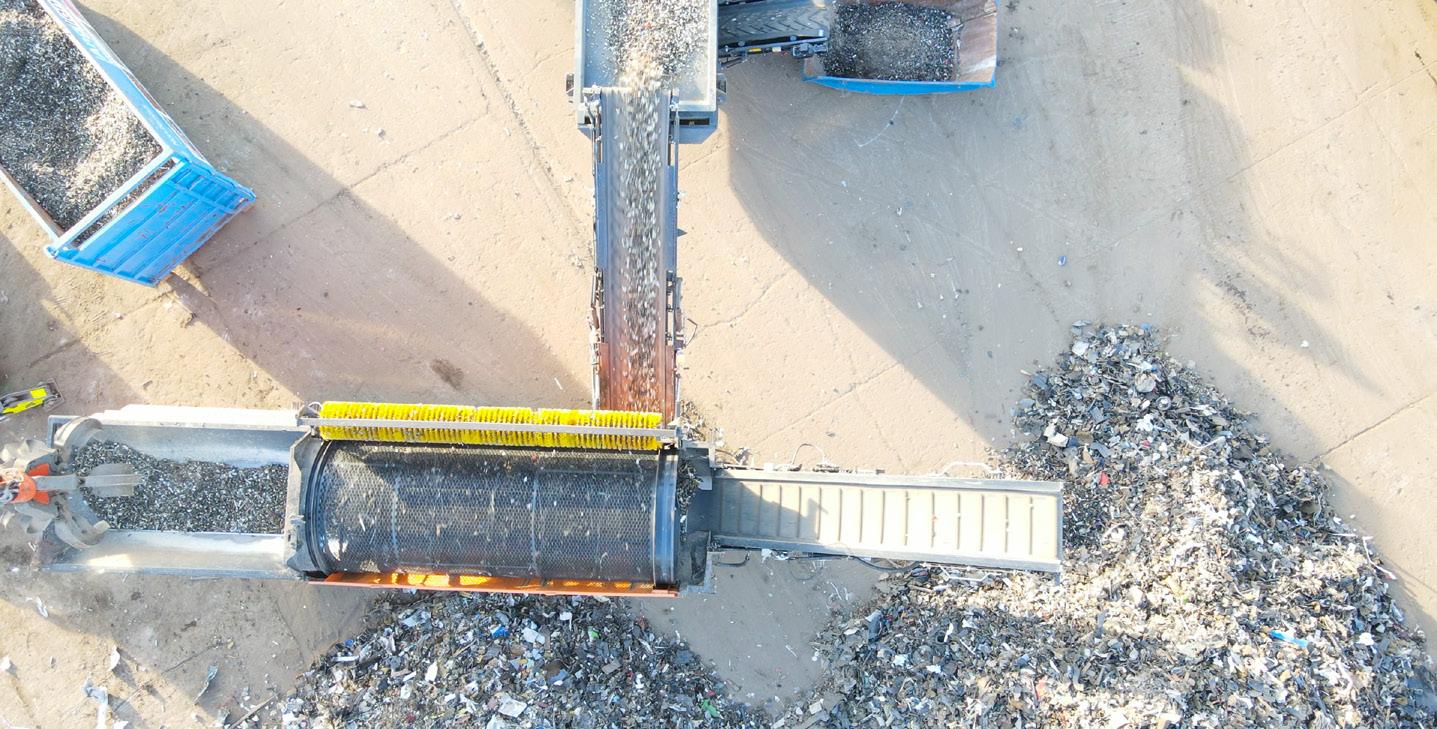

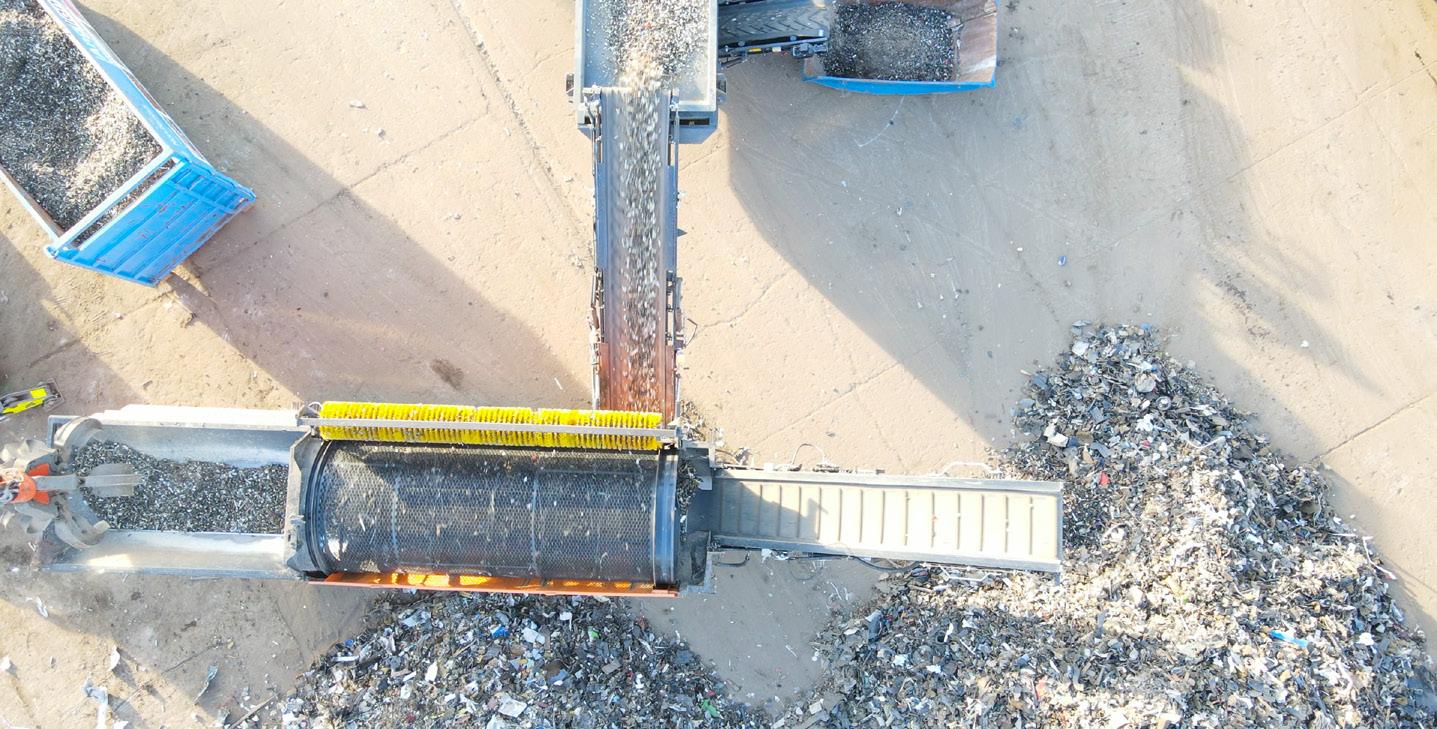

18 months, Anglian has developed its own standalone waste division that provides full waste management services to its customers. It operates East Anglia’s fastest growing metal recycling facility, buying, processing and selling over 20,000 tonnes of both ferrous and non-ferrous metals per year from its licenced 10-acre site in Attleborough, Norfolk.

The significant growth of the waste division has resulted in the investment of further equipment including vehicles, containers and wheelie bins, as well as processing equipment such as the ARJES 950 and 250 shredders.

Anglian’s commercial waste

feature

demolitionhub.com28 | DemolitionHUB Magazine

refuse trucks are already a regular sight on the roads of East Anglia and you will see its bins located in shops, pubs, hotels, factories and holiday parks. With recycling at the heart of its operations, waste streams include food, glass, DMR, paper and cardboard, all of which is 100% recycled.

In September 2022 Anglian agreed a significant contract to become the exclusive supplier of feedstock into the newly built anaerobic digestion facility in Attleborough. With a 100,000-tonne capacity annually, Anglian is quickly becoming one of the leading service providers of food and organic wastes in East Anglia. Unique to the site, 100% of the gas generated

from the facility is being used locally to support the gas demand direct to the local community. The digestate from the facility is then used as fertiliser on local farms, providing a high-quality fertiliser. This service will offer Anglian’s clients an alternative to out of region disposal or processing and contribute to a large reduction in their carbon footprint.

Anglian’s recycling mission is to responsibly dispose of waste and metal produced by the company, eventually reaching a zero to landfill goal, reducing its carbon footprint and ameliorating climate change.

Our mission extends to

taking care of the surrounding environment and providing a service to ensure other businesses and individuals have access to a responsible waste recycling solution with an advice hotline for reassurance.

Anglian offers regular environmental audits to clients in which they can analyse their waste data and identify areas to meet and improve upon their environmental targets. By offering a one stop shop, Anglian makes the perfect waste management partner to clients that are serious about helping to repair our planet.

feature

demolitionhub.com DemolitionHUB Magazine | 29

O’Donovan Waste Disposal

O’Donovan Waste Disposal is one of London’s leading waste management companies, with a turnover of £20m, a fleet of 100 HGVs and a workforce of 185. A dynamic business specialising in construction and demolition waste, O’Donovan has earned an excellent reputation as a trusted company that crosses a number of sectors, offering total waste management and recycling solutions.

The award-winning family run company champions a range of ongoing innovative initiatives that prioritises staff wellbeing, health and safety, training and environmental excellence, demonstrating a topdown commitment to best practice and is widely regarded within the sector as an industry leader.

The company is passionate about the waste industry and working as safely and sustainably as possible. It has an array of impressive accreditations demonstrating its competent and ethical practices. The company is a Construction Logistics and Community Safety (CLOCS) Champion and Fleet Operator Recognition Scheme (FORS) Gold operator (held for more than eleven consecutive years).

O’Donovan has invested heavily in waste processing and ensures the maximum is reused or recycled. Recycled aggregates are produced using state-of-the-art equipment, as per the WRAP quality protocol before going on to be reused in construction and infrastructure projects. All of its recycled materials come with a British Standard quality certification demonstrating excellence and commitment to the circular economy and achieving zero waste to landfill.

The company has now made the bold move to switch its entire fleet to Hydrotreated Vegetable Oil (HVO). This is a huge step for the business, which operates a fleet of 100 HGVs, serving the construction and demolition sectors throughout London and the Home Counties.

HVO is a sustainable and 100% renewable fuel that eliminates up to 90% of net carbon dioxide emissions. The green alternative fuel reduces nitrogen oxide (NOx) by up to 30%, particulate matter (PM) by up to 86% and carbon monoxide (CO) emissions by up to 90%.

The business is undoubtedly committed to its aspiration of achieving Net Zero carbon by 2035, having refined its environmentally focused waste management processes, recycling over a million tonnes of construction and demolition waste annually and diverting 100% from landfill.

O’Donovan is the first waste management company to make the switch to using solely biofuel.

Jacqueline O’Donovan, Managing Director of O’Donovan Waste says: “We are acutely aware that our biggest impact on the environment is our vehicles and along with other initiatives already in place, we are delighted to be able to commit to

using HVO on all HGV road vehicles by October 2022.

“This bold move has a huge positive effect in terms of our environmental impact. We are clearly demonstrating that we are in line with our clients’ needs and requirements to adopt more sustainable processes and services, as well as the worldwide need to act now to prevent further global warming.

“I know that existing clients will be thrilled at this enormous change and I sincerely hope that new clients appreciate a real commitment in this immense global challenge and support us as a business by adopting our service offerings.

“As a leader in our sector, I feel we have a duty to lead by example and moving to solely HVO has an immediate positive impact on our carbon footprint and we would encourage others to follow suit. As a business, we are passionate about sustainability and this is a huge step towards our net-zero objectives.”

feature

demolitionhub.com30 | DemolitionHUB Magazine

Looking for the world’s most powerful & reliable shears and demolition attachments? BPH is the exclusive dealer of LaBounty in the UK and Ireland. BPH is a family-run nationwide supplier and attachments specialist. Founded in 1972, we have extensive demolition and recycling experience, and offer knowledgeable help and advice to ensure your project is at maximum productivity and profitability. LaBounty’s unrivalled and market leading MSD range of steel shears sits alongside BPH’s vast collection of attachments. BPH are carrying out refurbishment and servicing on LaBounty and all other hydraulic attachments. shears and demolition alongside LaBounty Demolition and Scrap Shears Hire Sales Parts Repairs Head Office/South-East 0845 017 6972 Midlands 01530 553788 London 0203 988 2255 South-West 01761 239213 sales@bph-uk.com | bphattachments.com Made in the USA London & Bristol NEW DEPOTS

Ward

Metal recycling and waste management specialist Ward has been trusted partner of demolition contractors for decades. Despite year-on-year organic growth in the demolition sector, not all firms are aware of our abilities and geographical reach. Over 80% of our business is bulk metal recycling, a large portion of this comes from the demolition sector.

At Ward, we collect and process scrap metal, which is sold globally. We also offer a complete waste recycling package to nationwide customers. Unlike many of our competitors, we handle and process both waste materials and scrap metal. Therefore, we can offer a total recycling solution.

Over the years, we’ve become a multi-award-winning business and have received ongoing recognition for our contributions to innovation, investment, teamwork and excellent service, most recently winning the Queen’s Award for Excellence

in International Trade for our consistent growth in metal exports. We process c.1,000,000 tonnes of materials annually and recycle

products including metals, plastics, glass, cardboard, wood, textiles, soils and hardcore to ensure our customers fulfil environmental regulations and commitments.

With an extensive range of waste management, land clearance and metal recycling services, Ward deals with major demolition contractors in diverse, nationwide locations. Ward can now count demolition contractors headquartered in London through to locally in Ilkeston as regular customers. Jobs ranging from power stations to service stations contribute to the demolition business.

Our core business is the processing and recycling of metals from a variety of sources. Demolition projects provide metals as well as other materials, which we handle in other parts of the company.

The business has progressed

feature

demolitionhub.com32 | DemolitionHUB Magazine

over several years from collecting and receiving scrap from demolition projects near our original site in the Midlands. We now receive enquiries from all of the UK, Europe and the Far East – a testament to the business being increasingly seen as the most progressive and innovative partner for demolition companies with sizeable jobs to complete.

Last year Ward handled in excess of 350,000 tonnes of materials from demolition projects. The business was fortunate enough to work in many sectors of the demolition industry, from inner city technical works and general demolition, to pharmaceutical, oil and gas sites.

Our special projects team has built up an extensive knowledge to deliver excellent results on the largest projects, such as steelworks and power stations. These are two sectors in which Ward has grown more recently thanks to our on-site processing capabilities.

We would like to think that following the years of development, Ward is considered by the companies we trade with as a first choice partner. While we’ve achieved significant growth, we do try to retain family values and a focus on customer service.

Ward’s one stop approach for all demolition arisings makes it the specialist solution for partnering on all demolition projects. It can process ferrous or non-ferrous metal as well as the various other material streams that demolition projects produce – minimising the requirement for multiple suppliers on site, and maximising recycling, reuse and diversion from landfill where appropriate.

By investing heavily in infrastructure, processes and employees, and by prioritising the reinvestment of profits, Ward has built a sustainable business. We have chosen not to seek external funding, such as private equity, to ensure that we retain the core values and culture of our family-run business. Our investment strategy supports our principal objectives to sustainably grow our operational capacity, export volumes and turnover in the coming years.

Ward’s nationwide fleet of 140 modern vehicles is FORS Gold accredited with the Fleet Operator Recognition Scheme, reducing emissions and promoting excellence in driver training. When demolition contractors choose Ward as their supplier, they are guaranteed a low carbon footprint, high standards of sustainability, safety and a great level of service.

Like many other businesses, we have faced significant challenges in the last 18 months. These range from plummeting prices in the global market, to shortages in haulage, shipping and labour, as well as the impact of both COVID-19 and its resulting lockdowns on the health and wellbeing of our employees. And now inflation and energy prices are spiralling.

We have been able to withstand these so far thanks to a resilient and agile, business model and a dedicated team.

feature demolitionhub.com DemolitionHUB Magazine | 33

The British Metals Recycling Association

The British Metals Recycling Association (BMRA) is the trade association representing the £7bn UK metal recycling sector. Its overarching mission is to promote the metals recycling industry while safeguarding the interests of its member companies. The BMRA keeps members informed about upcoming issues and regulations, while helping them overcome problems and challenges related to running a metal recycling business.

Today, the UK’s metal recycling industry comprises an estimated 2,500 businesses and employs some 10,000 people. The sector trades and processes over 10m tonnes of ferrous and non-ferrous metals every year, including steel, aluminium and copper.

The metals recycling industry is a significant net contributor to UK balance of trade and contributes more than any other sector to UK end of life targets, such as vehicles, packaging, batteries, electrical and electronic equipment. In short, metals recycling protects the environment, saves energy and supports a huge workforce.

Metal, unlike some other recyclable materials, is in the enviable position of not only being endlessly recyclable with no loss of quality, but it also has an intrinsic economic value. A steel or aluminium metal drinks container can be back on a shelf in 60 days. Metal from cars can become reinforcing bars for skyscrapers or metal parts for computers, or any number of components for another car. Recycled steel like all other recycled metals has no end of uses

The BMRA represents over

feature

demolitionhub.com34 | DemolitionHUB Magazine

290 organisations made up of businesses of all sizes, including small family-owned businesses and large international companies.

Member activities include collecting, sorting, shearing, baling, shredding, media separation, as well as re-use, casting, and fabrication.

Like many such industries, the metal recycling sector is heavily regulated. There is a raft of environmental-based regulations to abide by as well as licencing and regulations under the Scrap Metal Dealers Act 2013 and the Air Weapons and Licensing (Scotland) Act 2015.

Reflecting its mission to be an effective voice for the metals recycling industry in the UK, the BMRA works closely with government, local authorities, the police services and other key stakeholders on behalf of its members on a range of different issues affecting the industry and to steer legislation both in the UK and in Europe.

BMRA membership is open to UK

companies that have been in business for at least two years, and have the correct and valid licences and permits to process

metal for recycling.

An application form can be downloaded from the BMRA website: www.recyclemetals.org.

feature demolitionhub.com DemolitionHUB Magazine | 35

Total Metal Recycling

Total Metal Recycling Ltd is a young, vibrant, family-run, modern metal recycling company operating from two facilities in Surrey.

Since opening our gates at our Walton on Thames site in 2012, TMR has grown to become one of the leading metal recyclers in London, Surrey, Hampshire, Berkshire, Sussex and the south of the UK.

Buying, recycling, processing and exporting all grades of ferrous and non ferrous metals, computer floor tile recycling and end of life recycling, TMR offers an efficient one stop service for all your metal needs and operates a large FORS accredited fleet of trucks, consisting of roll-onoff bins, skips, Hiab lifting trucks and articulated bulkers for reliable, cost

effective collections.

In 2022, TMR has opened the gates of an additional modern metal recycling facility in Guildford, Surrey. This new state of the art facility will

feature

demolitionhub.com36 | DemolitionHUB Magazine

handle and process ferrous and nonferrous metals, ELVs, raised computer floor tiles and provide export facilities. Equipped with Liebherr LH40 material handlers, Lefort shear, metals shredder, balers, cable granulator, depollution bays, Niton analysers and metal handling equipment ensures this additional site can cater for both trade and public customers. Operating both 50 t weighbridge and 3 t non-ferrous scales means we can accept all vehicles and quantities, no matter the size.

Nathan Pidgley, MD of Total Metal Recycling Ltd says: “At TMR, we put the environment at the very heart of our business, by providing continuous investment to target net zero emissions and environmental sustainability. Our dedicated young, vibrant team of metal recycling experts ensures your recycling journey is compliant, efficient and cost effective, while our experienced in-house team of global metal traders provide accurate and precise market information to our customers.”

While trading on the London Metal Exchange LME and having a large network of global refiners, smelters, steel works and foundries, our offices in central London and Turkey work around the clock studying global economies, growth, supply and demand and currency exchange.

These have become the main factors when trading on an international level.

Both TMR sites operate export hubs for processed scrap to be loaded into shipping containers, road bulkers for European destinations and use of our short sea dock for material to be loaded onto vessels.

TMR is an official member of the British Metal Recycling Association (BMRA), National Federation of Demolition Contractors (NFDC), Fleet Operator Recognition Scheme (FORS), Bureau of International Recyclers (BIR) and Road Haulage Association (RHA).

feature demolitionhub.com DemolitionHUB Magazine | 37

Collard Group

Since 1994 our family-run business has grown, adapted, and evolved to reflect the many changes in the construction and waste sectors, providing expert solutions for complex projects, nationwide.

Our unique capability to repurpose virtually all construction and demolition waste from site helps our public sector, local authority, commercial and residential clients achieve zero-tolandfill targets.

We demolish, process the arisings and return the same material in a different format back to site for an alternative use. This ensures landfill and virgin material cost savings for clients and, most importantly, reduces the carbon footprint of their operations.

We’re passionate about sustainability so we’ve invested significantly in plant and equipment to enable us to process C&D waste to make it useful again. We call this ‘recycling the past for the future’.

Our premium grade recycled

aggregates are used for future construction projects along with our award-winning ready-mix concrete that’s made using recycled aggregates.

With the capacity to process over a million tonnes of waste a year at our nine licenced waste transfer stations, we separate, process and recycle materials using state-ofthe-art equipment and processes. We divert almost all of the waste we handle from going to landfill, helping our clients achieve their sustainability targets.

Over the past 25 years we’ve seen the opportunity to expand our operations significantly to become an end-to-end enabling partner for construction projects and a onestop-shop for our clients.

We work with clients from site survey through to soft strip, and asbestos removal before full structural demolition, remediation and earthworks, hauling waste from site and recycling it into products used by the construction industry.

The recycled aggregates we produce include:

• Various grades of recycled crushed concrete including Type 1 & 6f5,

Shingle from 10 to 40 mm,

20 mm ballast,

Sharp and building sand,

12 mm screened soil and British Standard topsoil.

feature

•

•

•

•

Collard’s capability doesn’t end with demolition; it hauls C&D waste and processes it for re-use in construction projects

demolitionhub.com38 | DemolitionHUB Magazine

We produce a range of BSEN206 8500 ready-mix concrete using construction and demolition waste.

Our 90 m3 per hour concrete plant is one of our most significant investments to date. Our concrete is checked by our UKAS accredited, on-site laboratory to make sure it meets BSI standards.

By investing over £5m every

year in R&D, plant and equipment and attracting the very best strategic and operational team members, we’ve become one of the largest privately owned

national demolition contractors and waste management businesses in the south, employing 400 people and turning over more than £60m.

feature

Collard’s award-winning ready mix concrete is made using high-grade recycled aggregates produced at its urban quarry

This £2.5m waste plant was installed at Collard’s Andover licenced waste transfer station this summer

demolitionhub.com DemolitionHUB Magazine | 39

SUPPLIER

QTell us briefly some background on Sennebogen as well as its history in the UK

For more than 70 years

Sennebogen has offered machines for material handling, cranes, multi loaders, machines for the wood industry and as you know for demolition. Sennebogen is a traditional and 100% family owned company and has extended its product portfolio continuously since the beginning. We focus on the market and on our customers and depending on that, we develop and improve our machines continuously.

We have also delivered machines in the UK for more than 20 years. For us it’s a very important, and also growing market. Sennebogen distributes the machines through its strong dealer network and especially in UK, we have dealers who do a great job.

interview

Interviewee: Alexander Sturm Role: Head of Business Unit Demolition Company: Sennebogen

TALK 40 | DemolitionHUB Magazine demolitionhub.com

QHow did you start out in the industry, what attracted you to it and how has your career developed to where you are now?

Since I was a small child I have been fascinated by machines and technology. Accordingly, after school I did an apprenticeship as a mechatronics engineer and then studied mechanical engineering. Sennebogen is a great, globally known company with innovative products, so I began to work there after finishing my study.

I started in sales and now manage the demolition machinery sector globally. Here, sales of the machines is just as much a part of the job as the further development of the products. I work a lot with customers and dealers, as well as with our production, design, development and marketing department.

interview

DemolitionHUB Magazine | 41demolitionhub.com

QTell us about the range of demolition products Sennebogen provides and your relationship with clients Sennebogen offers demolition machines from 17 to 117 tonnes. This is a wide range and offers customers the opportunity to find the right machines for each job.

Customers buy machines from our dealers, in more than 180 countries. This is a further point that distinguishes Sennebogen – an excellent dealer network.

QWhat makes Sennebogen different?

Sennebogen became successful with special machine construction and that is still what we offer our customers. For us the customer comes first. Of course, we have basic machines with basic specifications. We try to fulfil all the special wishes of our customers so almost no machine is the same that comes out of production.

The service of the machine is also very important for Sennebogen. We offer our dealers training courses at the Sennebogen Academy in order to be able to offer our customers good service.

QAre there any standout supply contracts, projects or product developments from your time at Sennebogen?

Yes there are. A few weeks ago we presented a fully hydraulically

detachable counterweight for our demolition machines. This gives the customer the opportunity to reduce the transport weight of the machine. Within a few seconds the 10-tonne counterweight can be removed by a remote control.

At bauma 2022 we also will present a new kind of machine for demolition, a 23-m demolition machine with a changeable boom and other options.

QHow does Sennebogen gain business and spread the word about its services?

Sennebogen machines are globally known as very stable, robust and reliable machines. Furthermore our machines are made in Germany and this is what we are very proud of.

In some countries we are even the market leader for material handling machines and other products.

Through our dealers, we then have sales as close to the customer as possible and, of course, customers have direct contact with us at trade fairs or factory visits.

QWhat are the biggest technological developments you have seen in the demolition plant industry and what do you envisage will be the future game changers?

Demolition machines often stand for large machines with maximum power and reach. I believe that for various reasons there is also a certain rethinking taking place in the

industry. Transport is becoming more and more complex and complicated, environmental regulations are becoming stricter and structures of buildings change. I think the machines have to become more flexible and of course the topic of electric drives also plays an important role. Sennebogen has been offering machines with electric motors for several years and this year also presented the first battery-powered excavator at IFAT. This will soon also be available as a demolition machine and I think we have taken a trendsetting step into the future here.

QHow do you see the outlook for the demolition plant industry generally?

As we have noticed over the last few years, the demolition industry has become more and more important. The construction industry has boomed and more and more buildings have been built. At some point, the demolition of buildings becomes inevitable. Our planet

interview demolitionhub.com42 | DemolitionHUB Magazine

does not have unlimited space. In the future, the issue will become even more important as not only the type of demolition (selective deconstruction) changes, but also the building structures become more complex. The machines and technology have to keep up with this. Accordingly, I think the demolition industry will become even more important in the future and the machines will also experience a high demand.

In general, Sennebogen is very broadly positioned with its products and is therefore represented in various industries. From material handling in scrap, waste disposal and ports, our cranes are used in building construction and special civil engineering, our loaders in agriculture and industry. Our timber machines have become indispensable in tree care and sawmills. It remains to be seen which other sectors will open up in the future, but Sennebogen is always open to new markets.

PRODUCTS

QTell us about one of your key demolition-relevant products

This is a difficult question because all our demolition machines are key products. Besides our 36-m high reach machine, I think the 830 Demolition is also one of our most widely used machines.

QOutline the key functions of the product

We are talking about a 45-t machine with various equipment up to 23 m and with various options such as the liftable and tiltable cab, telescopic undercarriage and detachable counterweight. The machine is easy to transport and an allrounder on every construction site.

QHow is it critical for demolition contractors?

As I said, the way of working in demolition has changed for the most part. From total demolition, there is an increasing shift towards selective dismantling. In other words, one tries to separate the material at the construction site in order to save time and money. To do this, however, you need a suitable machine that not only has the necessary power and reach for demolition, but also the necessary properties for sorting and loading. This is exactly what the 830 Demolition does. It offers the customer the possibility to do all the work on the construction site with only one machine. The customer is faster on site

interview demolitionhub.com DemolitionHUB Magazine | 43

because he can work more efficiently with the machine. While he has sufficient reach and enough engine and hydraulic power for big tools, he also has the perfect machine for sorting and loading with the material handling equipment and lifting cab. At the same time, he saves the transport of another machine to the construction site and can thus achieve maximum cost efficiency.

QHow have you found takeup among demolition contractors?

We now have the machine in use with numerous customers. As the machine concept is unique and new, we wanted to give the customers the opportunity to test the machine without obligation and to get honest feedback.

Here I can tell a funny story that sums up the whole thing. A customer rented a machine for a demolition job for four months. After about half that time he returned the machine. Shocked, I called him to see if he was not satisfied. The customer replied that the site was already completed and he’d finished much faster than expected. He was more than satisfied with the machine and was able to finish the site faster than planned because of the flexible and efficient machine.

Q

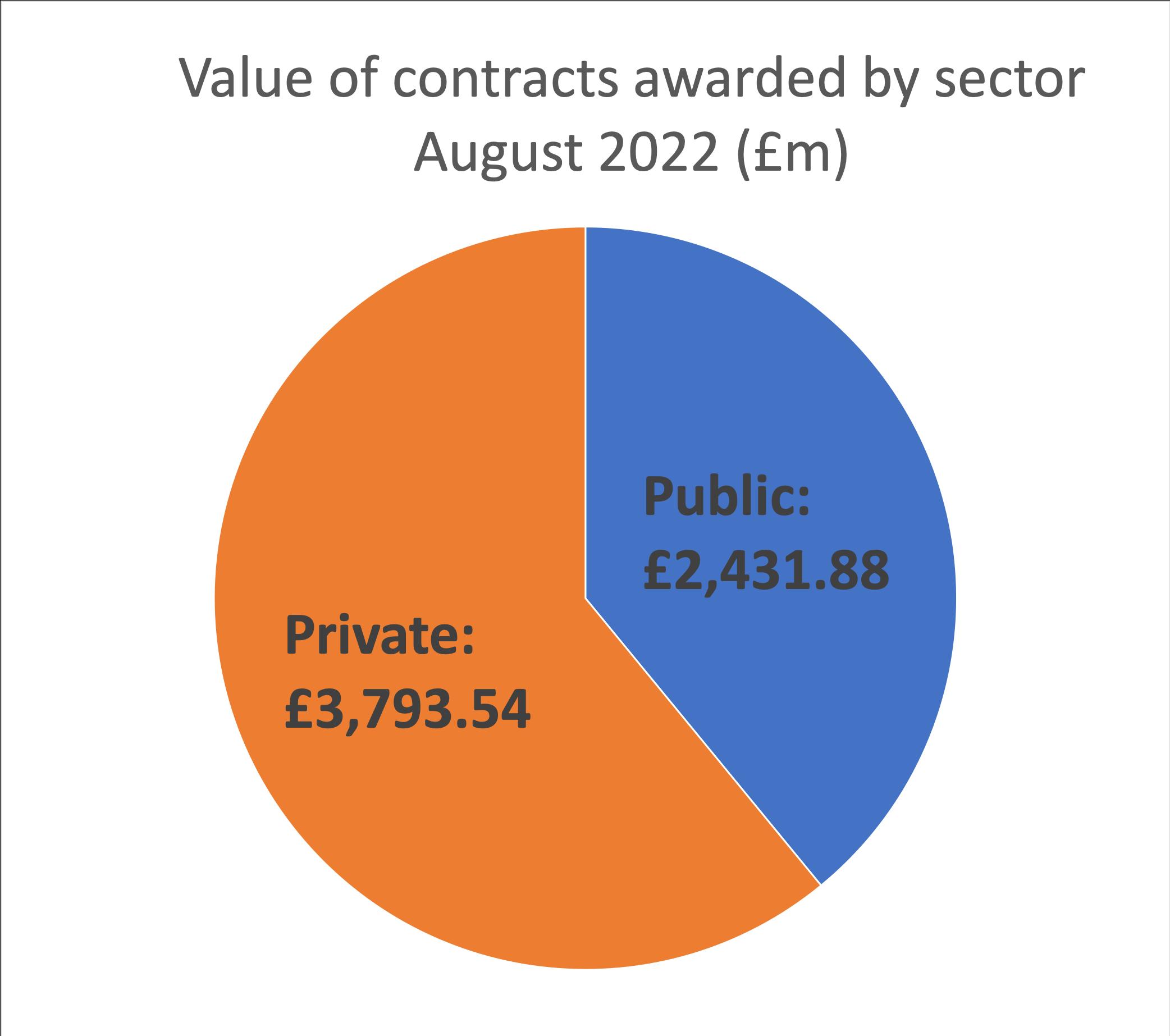

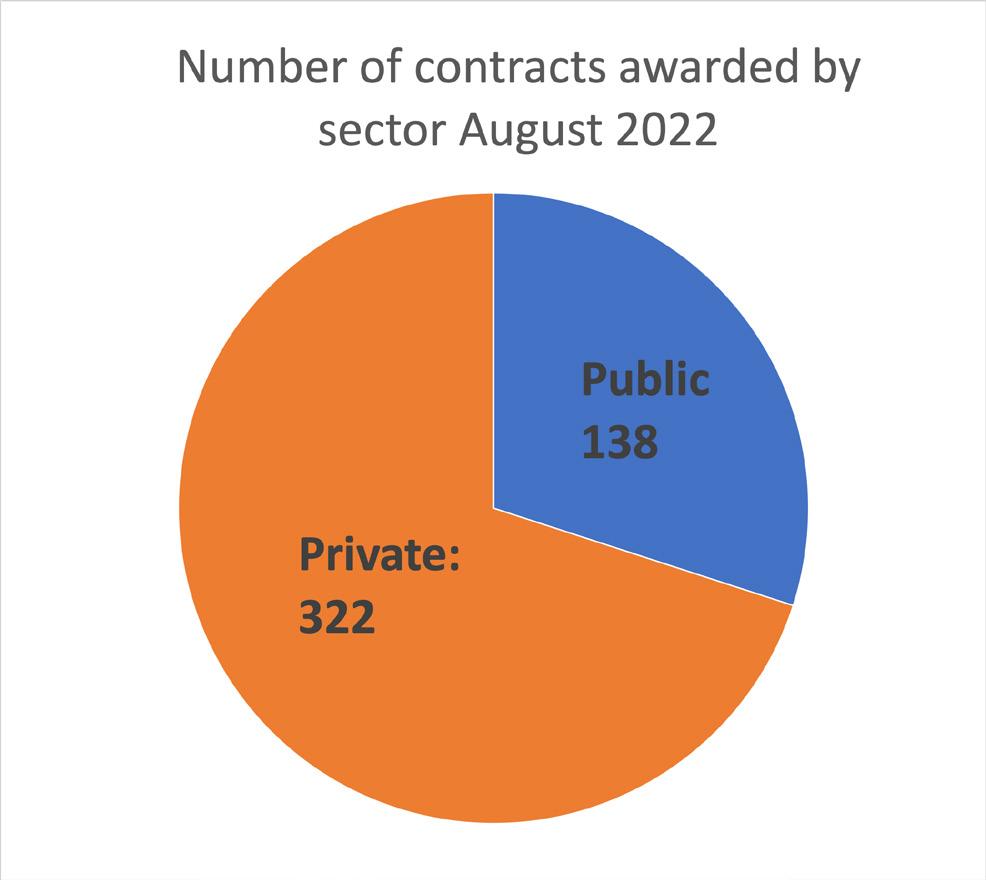

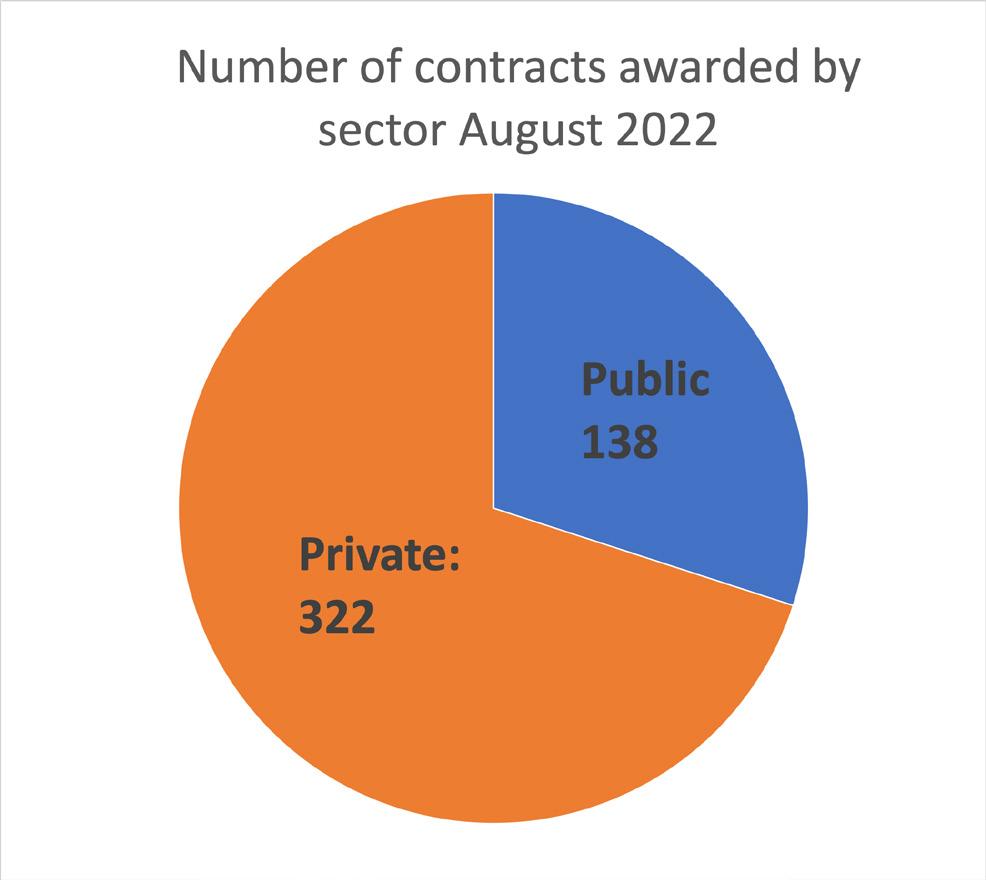

How do you see its further development?