Bulk carriers

Rolling hatch covers Side-rolling hatch covers are commonly used on the weather decks of larger bulk carriers, such as Panamax and Capesize types. For ore bulk oil carriers (OBOs) and ore oil carriers, hatch covers are designed to withstand internal liquid loads. Side-rolling hatch covers stow in a transverse direction. For open hatch bulk carriers (OHBCs), rolling covers of the piggy-back type (page 30) are preferred if the deck allows little or no free space for stowing the covers when the hatches are open. A traditional side-rolling cover consists of two panels per hatch, each panel rolling sideways on a pair of transverse ramps. This minimises obstacles to be considered by the shore crane or other loading/unloading device operator when loading and unloading. When air draft is limited, both panels can in some cases be stowed together on one side. This makes it possible to carry out loading operations from the coaming level. This alternative allows access to one half of the hatch

opening, while the other half remains covered by the stowed hatch cover. A single-panel type is mainly used on very large ore carriers (VLOCs) with a sufficiently free deck area. In this hatch cover size range, coordinated design and manufacturing is crucial. MacGregor has a proven record of supplying hatch cover designs and steel structures for VLOCs. Side-rolling hatch covers can have a variety of different drive systems. The two main options are rack and pinion or chain drive. Specially developed sealing and securing systems and a superior structural design ensure that the rules and regulations of all classification societies and international authorities are met. The ship’s hull and hatch coamings will deform in both harbour and sea conditions. These variables must be taken into consideration when selecting the type of hatch cover. Rolling hatch covers with an open web structure and a flat or inclined top plate are superior to a doubleskin structure because they allow for torsion of the coaming. Also, their thermal deflections are minimised. The main variables in side-rolling hatch cover designs are the drive system, the lifting system and the cleating system, which usually depends on the specified lifting system. MacGregor’s early involvement in a project and its extensive knowledge enables it to suggest the best combination of these systems and hatch cover arrangements to match an operator’s requirements.

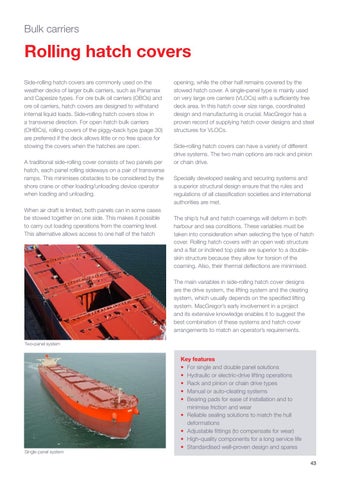

Two-panel system

Single panel system

Key features • For single and double panel solutions • Hydraulic or electric-drive lifting operations • Rack and pinion or chain drive types • Manual or auto-cleating systems • Bearing pads for ease of installation and to minimise friction and wear • Reliable sealing solutions to match the hull deformations • Adjustable fittings (to compensate for wear) • High-quality components for a long service life • Standardised well-proven design and spares 43