Rising from Adversity: Joshua Clauss’ Journey to Rebuild

MAGAZINE Issue 6 - 2023

Clauss Construction

The Cat® Card is the fast, easy way to pay for parts, service, rentals and more, wherever the job takes you. And the more you spend, the more Cat Card Rewards* you earn. It’s that simple. Apply today! PUT IT ON YOUR CAT ® CARD Earn 1% back*on every qualifying purchase you make with your Cat® Card *Terms and conditions apply. See cat.com/catcardrewards for details and eligibility. © 2023 Caterpillar. All Rights Reserved. CAT, CATERPILLAR, LET’S DO THE WORK, their respective logos, “Caterpillar Corporate Yellow”, the “Power Edge” and Cat “Modern Hex” trade dress as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission. www.cat.com / www.caterpillar.com The Cat Card is accepted at all Cat dealers and Cat Rental Stores in the U.S., and you can also use it to shop on Parts.Cat.Com. Contact your California Cat dealer today or visit catcard.com for details. SINCE 1956 hawthornecat.com San Diego County 800-437-4228 quinncompany.com Central & Southern California 888-842-2155 SINCE 1919

E V E N T H E M O S T N EE D IT’S WHY WE OFFER JOHN DEERE PROTECT™ Let us handle your scheduled maintenance and machine inspections to help prevent work-stopping, budget-breaking issues. Equipment COASTLINE Long Beach, CA (562) 272-7400 Santa Ana, CA (714) 265-5500 Oxnard, CA (805) 485-2106 Sylmar, CA (818) 890-3353 Jerome, ID (208) 324-2900 Las Vegas, NV (702) 399-2700 Bakersfield, CA (661) 399-3600 Santa Maria, CA (805) 922-8329 Meridian, ID (208) 888-3337 McCall, ID (208) 634-3903 Elko, NV (775) 777-7070 www.coastlineequipment.com/extended-service-plans

CLAUSS

PUBLISHER: Kerry Hoover khoover@calcontractor.com

EDITOR: Brian Hoover, Senior Editor

GRAPHIC DESIGNER: Aldo Myftari

FOR ADVERTISING INFORMATION: Please call: (909) 772-3121

On the Cover: Front cover photo by John Martorano Photography. 08 20 24 28 20 PAVEMENT RECYCLING SYSTEMS, INC. Caltrans Utilizes Partial Depth Recycling for the Sustainable Pavement Rehabilitation of State Route 127 near Shoshone and Death Valley National Park 24 BROKK, INC. Cutting Inefficiency, Not Corners 3 Ways Demolition Robots Increase Efficiency in Concrete Demolition Applications 28 VOLVO CONSTRUCTION EQUIPMENT & SERVICES (VCES) Holds Electric Open House Events in San Leandro and Corona – Featuring Voltstack e-Charger

CONTENTS

Demo & Recycling 06

NOTE Assessing the Current Status of Demolition Projects in California’s Civil General Engineering Construction Industry 08

2023

EDITOR'S

CONSTRUCTION

Adversity:

CalContractor is published twelve times each year by Construction Marketing Services, LLC. Copyright © 2023. All rights reserved. Reproduction in whole or in part without permission is prohibited. P.O. Box 892977, Temecula, CA 92589 www. CalContractor . com CALCONTRACTOR .COM DEMO & RECYCLING / 2023 4

Rising from

Joshua Clauss’ Journey to Rebuild Clauss Construction

VCES has served customers in the construction industry for more than 50 years. Match that experience with full-service Volvo dealerships now positioned throughout the state of California, and we’re ready to help solve your toughest problems. From new or used equipment and rentals to parts and service, we have you covered. Contact your nearest VCES location today. Dependable Service. Expert Experience. Bakersfield, CA 661.387.6090 Corona, CA 951.277.7620 Fresno, CA 559.834.4420 Lakeside, CA 619.441.3690 Redding, CA 279.201.4869 Sacramento, CA 916.504.2300 San Leandro, CA 510.357.9131 Turlock, CA 209.410.6710 vcesvolvo.com Find us on social media: facebook.com/volvoces VolvoCES volvoces volvoces

Assessing the Current Status of Demolition Projects in California’s Civil General Engineering Construction Industry

The civil general engineering construction industry in California is a dynamic sector that constantly evolves to meet the state’s growing infrastructure needs. As part of this industry, demolition projects play a crucial role in clearing space for new developments, retrofitting existing structures, and ensuring safety and progress. California’s population continues to grow, and urban areas experience the need for rejuvenation and expansion. As a result, the demand for demolition projects has witnessed a steady rise. Demolition projects encompass various facets, including removing obsolete structures, seismic retrofitting, site preparation, and environmental cleanup. With aging infrastructure and evolving regulatory requirements, demolition has become a necessary precursor to new construction endeavors.

In recent years, there has been a notable shift towards sustainable practices in the construction industry, including demolition projects. California’s stringent environmental regulations and focus on sustainable development have prompted the adoption of eco-friendly demolition techniques. Contractors now employ strategies such as selective dismantling, salvaging reusable materials, recycling construction waste, and minimizing environmental impact during the demolition process. This emphasis on sustainability aligns with the state’s broader goals of reducing waste, conserving

resources, and mitigating climate change.

The civil general engineering construction industry has also witnessed significant technological advancements, which have permeated the field of demolition. Innovative tools and equipment, such as high-reach excavators, robotic machines, and precision demolition methods, allow for more controlled and efficient demolition processes. Additionally, Building Information Modeling (BIM) and advanced 3D scanning technologies aid in accurate project planning and minimizing disruptions to surrounding structures.

Safety is also a paramount concern, given the inherent risks involved. Contractors and regulatory bodies in California have prioritized the implementation of stringent safety protocols to protect workers and the public. Comprehensive safety plans, hazard assessments, proper training, and the use of personal protective equipment (PPE) are now standard practices in the demolition industry. The adoption of advanced monitoring systems and real-time data analysis has further enhanced safety on demolition sites.

While the demolition sector in California continues to thrive, it also faces several challenges. One significant hurdle is the disposal of construction and demolition waste. To combat this, efforts are being made to increase recycling and reuse rates, reducing the amount of waste sent to landfills.

Furthermore, ensuring compliance with complex regulatory frameworks and obtaining necessary permits can pose logistical challenges. These challenges also present opportunities for innovation and growth. The demand for specialized demolition services, such as the removal of hazardous materials, asbestos abatement, and deconstruction for historical preservation, has created niche markets. This has allowed smaller, specialized firms to flourish in California’s demolition industry, contributing to a diverse and competitive landscape.

The demolition sector within California’s civil general engineering construction industry is witnessing a period of growth and adaptation. The rising demand for demolition projects, coupled with the emphasis on sustainability, technological advancements, and enhanced safety measures, has transformed the way demolition is approached. While challenges persist, they have opened avenues for innovation and specialization. As California continues to evolve, the demolition industry will play a crucial role in shaping its infrastructure landscape, enabling progress and sustainable development. Cc

Brian Hoover, Senior Editor

Editor’s Note CALCONTRACTOR .COM DEMO & RECYCLING / 2023 6

BARE AND OPERATED HEAVY EQUIPMENT FOR THE SOUTHERN CALIFORNIA DEMOLITION INDUSTRY • Dozers - GPS ready • Scrapers • Rollers/Compactors • Blades - GPS ready • Mini excavators • Track excavators - Breakers - Pulverizers - Thumbs - Compaction Wheels - V Buckets • Skip loaders • Rubber tire loaders • Rubber tire backhoes - Breakers - Swivels - Vibe Plates - Compaction Wheels - V Buckets EQUIPMENT AVAILABLE WBE/MBE 16402 Construction Circle East Irvine, CA 92606 26340 Lester Circle Corona, CA 92883 YEARS SERVING: LOS ANGELES, VENTURA, SAN DIEGO, ORANGE, SAN BERNARDINO & RIVERSIDE COUNTIES 24 HOUR EMERGENCY SERVICE (800) 672-8252 / (949) 552-1859 www.savala.com

Rising from Adversity: Joshua Clauss’ Journey to Rebuild Clauss Construction

By Brian Hoover, Senior Editor /

Photos by John Martorano Photography

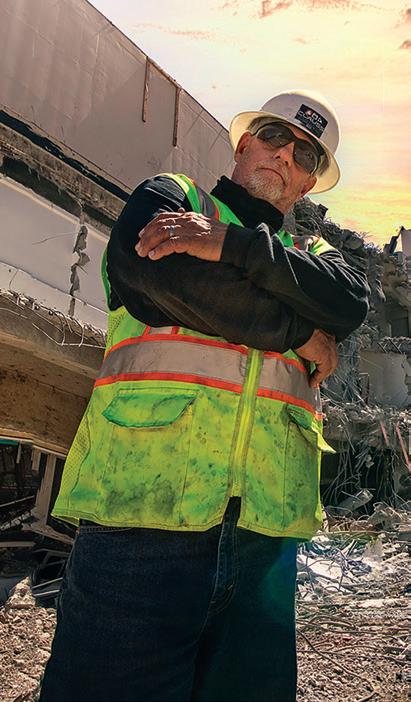

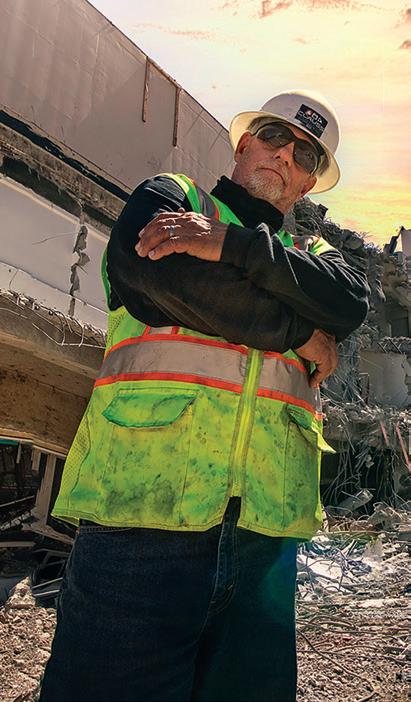

Joshua Clauss, President/CEO, Clauss Construction.

Above: Clauss Construction utilizing one of their many Link-Belt excavators for removal of demolition debris from the old San Jose Jail demolition project.

By Brian Hoover, Senior Editor /

Photos by John Martorano Photography

Joshua Clauss, President/CEO, Clauss Construction.

Above: Clauss Construction utilizing one of their many Link-Belt excavators for removal of demolition debris from the old San Jose Jail demolition project.

Clauss Construction is owned and operated by Joshua Clauss, who acquired the company from his uncle, Patrick Clauss, in 2017. Joshua Clauss’ upbringing in the California demolition industry paved the way for his involvement in the family business from a young age, commencing at 15 when he obtained his worker’s permit. Clauss Construction was founded by Patrick

Clauss in 1991, and under his leadership, the company enjoyed years of success and prosperity. However, like most family enterprises, there is a backstory that illustrates both the challenges and rewards of operating a demolition business in California.

During the late ‘70s, Patrick (Pat) Clauss held a position as a sales representative for Hilti Corporation, where he supplied tools and other

products to the construction, manufacturing, and building maintenance sectors. Through countless interactions with his customers, many of whom were involved in the demolition industry, Patrick amassed a wealth of knowledge about this particular field. Enthralled and inspired by the demolition industry, he embarked on his first entrepreneurial venture in the early ‘80s, partnering with

Background: Volvo EC480E high-reach excavator making quick work of the demolition at the old San Jose Jail.

Above: Volvo high-reach and Link-Belt excavator working in tandem with dust control crew members in San Jose.

another individual to establish a small demolition company called Diamond Pacific. This experience provided invaluable lessons on the dos and don’ts of business, ultimately enhancing his acumen as an entrepreneur when he eventually founded Clauss Construction in 1991.

Initially, Clauss Construction operated with just Patrick and his brother Joe Clauss. Their modest headquarters was a one-bedroom apartment located in La Mesa, with Patrick overseeing the administrative and project management aspects while Joe managed the field operations. Their primary focus at the time revolved around demolishing residential properties and small apartment buildings. However, the true turning point came when Patrick made the decision to venture into the government sector. This endeavor, though

easier said than done, involved navigating a demanding and bureaucratic submission process. Undeterred, Patrick persevered and successfully expanded the company, leading to an influx of new hires and the acquisition of additional machinery.

JOSHUA CLAUSS TAKES OVER THE REINS

During the company’s formative years, Joshua Clauss diligently absorbed all the knowledge and experience his father and uncle gained from their work both on and off the jobsites. In those earlier times, regulations were more lenient, and Joshua had the opportunity to work with a permit. Initially starting as a laborer, he gradually progressed to the role of foreman under his father’s guidance, who served as the field operations manager. Joshua then advanced further, assuming the

position of superintendent and later becoming an accomplished equipment operator. However, a significant turning point occurred in 2001 when Joe Clauss chose to depart from the business, feeling a calling to relocate to Oregon and assist in constructing and establishing a church. Joe’s absence spanned nearly a decade, during which his brother, Pat, encountered health challenges. Consequently, the company faced a period of adversity, necessitating urgent measures to restore its former prosperous state.

Recognizing the need for a strategic change, the decision was made in 2014 to appoint Joshua Clauss as Vice President, granting him responsibility for overseeing all daily operations. Demonstrating unwavering dedication, Joshua tirelessly managed the company’s day-to-day activities, both within

{ Continued on page 12 }

CALCONTRACTOR .COM DEMO & RECYCLING / 2023 10

Above: Clauss Construction works day and night to serve their customer’s needs now and into the future.

SALES | RENTALS | | | FINANCE LOS ANGELES: 562.247.5817 SAN DIEGO: 619.403.9637 VENTURA | SANTA BARBARA: 805.585.3179 LARGE EXCAVATORS • WHEEL LOADERS • MINI EXCAVATORS • SKID STEERS 866.673.8148 WARRIORMACHINERY.COM SALES: 909-566-8276 W H E E L L O A D E R 856 H E BATTERY TYPE LFP RATED STORAGE ENERGY 423 kWh OP RA NG W GHT 21 000 b 46 297 kg BU KE CAPAC TY 4 58 yd³ 3 5 m ORANGE: 949.281.6022 SAN BERNARDINO | RIVERSIDE: 909.585.3179 KERN: 661.237.5496 NOW IN BAKERSFIELD $350,000 Plus Tax $49,500 Plus Tax $64,750 Plus Tax 877H COUPLER - FORKS 9035EZTS 385B

{ Continued from page 10 }

the office and out in the field. Then, in 2017, an opportunity arose for Joshua to assume ownership of Clauss Construction, as his uncle Pat offered him the chance to purchase the family business. Reflecting on this pivotal moment, Joshua shared, “My uncle was incredibly supportive of my decision to take over the company. However, it was a momentous choice for both my wife, Jennifer, and I. With the company undergoing financial turmoil, our attorney cautioned against acquiring a business burdened with substantial debt, particularly for a young couple.” Joshua added, “After much prayer and reflection, we made

the resolute decision to take the plunge and utilize all our assets to assume the burgeoning debt. Through the Lord’s grace and the hard work of every single Clauss team member, we successfully eradicated the debt and amassed a robust backlog of projects in just three years’ time.”

One of Joshua’s initial steps in steering the company toward recovery was cultivating a strong rapport with the bank and the bonding company. Evidently, Joshua’s prior work had not gone unnoticed, engendering trust and confidence within these financial institutions. Since assuming the role of president in June 2017, Joshua has focused on bolstering

what he refers to as the company’s human capital. “I have come to appreciate the immense importance of fostering a thriving company culture. Prioritizing our people is the key to success. A robust company culture drives productivity and enhances customer service,” emphasized Joshua. “What truly sets us apart from our competitors is our emphasis on establishing meaningful connections. It permeates the atmosphere on our worksites, cultivating a team that shares a clear understanding of our vision and direction. It begins with simple acts such as regularly visiting and supporting workers, both on and offsite, acknowledging their talents and

Above: Clauss Construction team members bringing down structure at Scripps Hospital in San Diego.

CALCONTRACTOR .COM DEMO & RECYCLING / 2023 12

Left inset: Volvo EC480E high-reach demoing a tower structure at Scripps Hospital in San Diego.

accomplishments, and ensuring they receive fair compensation for their unwavering loyalty and hard work. These factors have enabled Clauss Construction to achieve sustainable growth, surpassing even our pre-challenging times.”

THE PEOPLE MAKE THE DIFFERENCE

Clauss asserts that his acquisition of the company in 2017 proved fortuitous, as numerous exceptional projects swiftly materialized. “Remarkably, everything fell seamlessly into place,” Clauss affirms. “We secured lucrative contracts with favorable profit margins and expedited turnaround times, accelerating our recovery

process.” Clauss further expresses his gratitude for the return of his father, Joe, to the company after a prolonged absence. Joe promptly assumed the role of General Superintendent, making an immediate and significant impact on our field operations and overall profitability.

In addition to Joe’s contributions, Clauss highlights the pivotal role played by William (Bill) Musbach, who has been instrumental in transforming Clauss Construction throughout the years. Around 25 years ago, Bill became a protégé under Pat Clauss and discovered his niche in the government sector, particularly with the Department of Energy (DOE) and the Department of Defense (DOD). “One of my first

actions upon assuming ownership was to elevate Bill to the position of Senior Vice President, responsible for overseeing all government and public works operations,” Clauss reveals. “Both Bill and my father are indispensable to our company’s continual expansion, and I deeply appreciate their unwavering commitment.” Clauss further expresses profound affection for the employees of Clauss Construction and acknowledges the unwavering support provided by their families. “The team is the lifeblood of our organization, and I am genuinely grateful to have each and every one of them working alongside us at Clauss Construction.”

Above: Volvo high-reach and conventional excavator working together to demo and remove debris from Scripps Hospital.

Right inset: Cleanup crews go to work after the majority of Scripps Hospital structure is brought down.

CALCONTRACTOR .COM DEMO & RECYCLING / 2023 13

EARTHWORK DIVISION –EQUIPMENT MAKES THE DIFFERENCE

Clauss Construction prides itself on self-performing 95 percent of the work involved in its demolition projects. The company’s earthwork division plays a significant role in its comprehensive, fully self-performed packages. Clauss confidently asserts their capability to handle every aspect, encompassing demolition, rough, fine, and finish grading. This is why Clauss Construction was particularly excited about acquiring their new Volvo EC480E excavator, which functions as both a high-reach demolition unit and a standard excavator. “Nothing compares to Volvo’s high-reach technology and the exceptional construction and design of their machines,” states Clauss. “What ultimately sealed the deal for me was the inclusion of the

EC480E conversion kit. This kit allows us to effortlessly transition from the high-reach function to a standard excavator, enabling our crews to continue working on the ground once the higher levels have been brought down. It’s simply more value for our investment, and in the demolition industry, that holds tremendous value.” Clauss further notes that when clients witness the capabilities of their Volvo high reach on demolition projects, they are left astounded. “The machine’s swift demolition of structures while ensuring the safety of those behind it instills a sense of safety, security, and confidence in our clients,” says Clauss. “Our experience with Volvo Construction Equipment & Services and their representative, Danny McCausland, has me now eying the Volvo EC750E HR high-reach demolition excavator. I love the technology, and I know I can count

on the consistent, exceptional customer service I always receive from everyone at Volvo Construction Equipment & Services.”

According to Clauss, achieving the right balance in heavy equipment ownership is critical for a demolition contractor. “A significant portion of a demolition contractor’s fleet consists of multi-million dollar financed machines, and even a single month of inactivity can result in a loss of revenue exceeding $60,000 for the company. We maintain an extensive fleet of machines, ranging from smaller mini-excavators and skid steer loaders to massive excavators,” Clauss elaborates. “At Clauss Construction, we have made the conscious decision to primarily invest in Volvo and Link-Belt for { Continued on page 16 }

Left: Joe Clauss, General Superintendent, Clauss Construction.

Middle L to R: Father and son, Joe and Joshua Clauss on site at Scripps Mercy Hospital in San Diego.

CALCONTRACTOR .COM DEMO & RECYCLING / 2023 14

Right: William (Bill) Musbach, Senior Vice President, Clauss Construction.

BOXES Trench Boxes Slide Rail Competent Person Training Trench Plates Confined Space Equipment Hydraulic Shores Proud Founding Member of Hablamos Español TrenchShoreRentals.com We Deliver World Class Customer Service LOS ANGELES (866) 270-9960 SAN DIEGO (800) 321-5285 SAN BERNARDINO (909) 381-0244 AN ARCOSA COMPANY RAMCO continues to focus on meeting the needs of both its customers and the construction industry, while remaining sensitive and responsive to environmental issues and community relations. Beaumont, CA 951-300-8816 Escondido, CA 909-644-0638 Rialto, CA 818-335-9130 Sun Valley, CA 818-731-9788 Thousand Palms, CA COMING SOON RAMCO.US.COM 805-522-1646 CALCONTRACTOR .COM DEMO & RECYCLING / 2023 15

THE LEADER IN TRENCH

{ Continued from page 14 }

our large, heavy excavators, while diversifying our options for smaller support machines. To manage costs effectively, we opt to rent equipment as needed, including specialty machines such as Brokk demolition robots, which prove invaluable for interior and governmental projects.”

CLAUSS CONSTRUCTION JOINS THE UNION – LAS VEGAS PRESENTS UNIQUE OPPORTUNITIES

In 2004, Clauss Construction embarked on a new chapter by establishing a branch office in Las Vegas. This strategic decision marked the beginning of their operations in this distinctive market, as they undertook high-profile projects. Recognizing the importance of collaboration, Clauss opted to join the Local 12 International Union of Operating Engineers as well as Local 872

Laborers. Reflecting on this choice, Clauss shared, “Many who were familiar with my uncle Pat knew that he was not inclined towards union membership. As a young man, this mindset was instilled in me. However, circumstances evolve, demanding adaptability.” He continued, “In 2004, I relocated and launched our operations in Las Vegas, forging a partnership with the Union. My uncle supported this decision, as we continued to maintain a non-union status in California.”

Clauss recognized the paramount significance of fostering a harmonious relationship with the union in Las Vegas. Approaching the situation with humility and a genuine willingness to learn, the company cooperated seamlessly with its union representatives. Consequently, since 2004, they have successfully executed a multitude of demolition projects within the Las Vegas region.

Several noteworthy endeavors serve as examples, including the dramatic implosion of the Frontier Hotel & Casino, the Desert Inn Hotel and parking garage implosion (which now stands as Wynn), as well as demolition work on the Riviera Hotel east parking garages, MGM Grand, Studio 54, Sahara Hotel and Casino, Bill’s Gambling Hall & Saloon, and a comprehensive transformation of the old Aladdin into Planet Hollywood, to mention just a few projects. Clauss remarked, “Our clientele has predominantly consisted of nonunion entities, which ensured our diversification, along with private contracts and prevailing wage projects. While we already handled a substantial amount of union work for schools under prevailing wage agreements, we were missing out on numerous large-scale, highquality projects,” says Clauss. “Approximately a year ago, I made the pivotal decision to transition

CALCONTRACTOR .COM DEMO & RECYCLING / 2023 16

Above: Clauss Construction maintains the very best late-model fleet of machinery ranging from large high-reach and conventional excavators to smaller compact excavators and skid steer loaders.

the entirety of our operations to a union model in California. This shift has been transformative for our company, alleviating the burdens associated with hiring while presenting numerous advantages in the public works, military, and governmental sectors, as well as with Project Labor Agreements.”

Currently, Clauss Construction’s workload consists of approximately 75% union-affiliated governmental projects and 25% private endeavors. “This dynamic composition necessitates continual adaptability, dependent on variables such as interest rates and prevailing state and national policies,” says Clauss. “Staying flexible and receptive to change is indispensable, enabling us to navigate this ever-evolving landscape with agility and proficiency.”

WE ARE ALL ABOUT DEMOLITION – A FEW RECENT PROJECTS IN CALIFORNIA

Clauss Construction specializes in the meticulous demolition of structures across diverse industries, showcasing its expertise in tackling projects of all sizes. Their comprehensive range of services includes structural, explosive, and tenant improvement demolition, while also encompassing crucial areas such as environmental remediation (hazardous waste removal), earthwork (grading & excavating), and building decommissioning in the government sector. Clauss is well-versed in the art of implosion, proficiently dismantling structures, and boasts proficiency in all forms of interior and conventional structural demolition. Presently, the company is fully engaged in a multitude of demanding projects, particularly focused on implosion and structural demolition ventures for governmental entities such as the DOE (Department of Energy), the DOD (Department of Defense), the Army Corps of Engineers, Navy, and Air Force.

SAN JOSE JAIL DEMOLITION

One of the more recent governmental demolition projects for Clauss Construction was the complete demolition of the old San Jose Jail. “The San Jose Jail was a challenge because it was built with high-density concrete and a substantial amount of reinforced rebar. However, this posed no issue for our professional crews and state-of-the-art equipment,” says Clauss. “We also encountered asbestos during our abatement process but were surprised to uncover a layer of black, felt-like material once the slab was opened. Recognizing the potential hazards associated with such situations, the onsite third-party IH (Industrial Hygienist), well-versed in identifying hazardous materials, conducted appropriate testing. The results confirmed the presence of asbestos fibers, prompting us to safely expose, properly abate, and thoroughly clear the area before proceeding with the demolition.” Following the successful completion of the entire demolition process, Clauss Construction also undertook the rough grading for the forthcoming new building project.

SCRIPPS HOSPITAL DEMOLITION PROJECT IN SAN DIEGO

Clauss Construction was also recently entrusted with the demolition of a parking garage structure, along with a fivestory building space above it, at Scripps Hospital in San Diego. The structure needed to be demolished to make way for a new hospital expansion project. “The demolition was further complicated by the proximity of an active banking institution, a mere 30 feet away from the project footprint,” revealed Clauss. “This is where the expertise of our operators, laborers, and top-of-the-line equipment played a crucial role in our success. We effectively used our Volvo high-reach excavator

and Link-Belt conventional excavators, along with our skilled operators, to safely bring down the structure according to schedule. Additionally, we successfully completed the rough grading for this project.”

Clauss, along with his entire team of dedicated team members, was able to rise to the challenge of breathing life back into an ailing company. “Presently, we find ourselves in an exceptionally favorable position, experiencing continuous growth with each passing year. But we are also all very aware of the challenges that come with owning and running a demolition business,” says Clauss. “We know that the margins remain thin and that we must continue to navigate through all of the old and new state, county, city, and federal regulations. Then there are the continuing environmental, safety, and labor law considerations, rising operating costs, and continuous stiff competition. Even with all of these challenges, we all remain devoted to doing our best every day to make things better for our clients, ourselves, and of course, our families.”

Joshua Clauss also acknowledges the ongoing support he receives from his wife, Jennifer. “Jennifer gets involved whenever we need an extra hand, but her main focus is on our children,” concludes Clauss. “We have three children: Joey and Gwen, who are both currently attending Grand Canyon University in Arizona, and Ethan, who is a junior in high school and recently committed to Texas A&M for baseball. All of us at Clauss Construction do what we do to give our families the best life we know how. With God’s help and direction, the future will bring even greater things for this company and our people.” Cc

CALCONTRACTOR .COM DEMO & RECYCLING / 2023 17

” CSS can place 20 yards of material in just 8 minutes! • BACKFILLING WALLS • FUEL TANK INSTALLS • GRAVEL MULCH • LANDSCAPING • MSE WALLS • SLOPE WORK • TRENCH BEDDING & BACKFILL 559.400.0222 / CAStoneSlingers.com WE’RE HERE TO HELP YOU WITH PRODUCT PLACING

OVERVIEW • Digging Power and Reduced Tail Swing Design • Fuel E ciency Technologies Are Standard Intuitive Controls and 360-Degree Visibility • Built to Last With Convenient Serviceability 800.316.0327 SALES • RENTALS • PARTS • SERVICE MINI EXCAVATORS / SKID STEERS BACKHOES / SKIP LOADERS Serving California For 50 Years! DX235LCR-7 Crawler Excavator ATTACHMENTS • Severe Duty Bucket Heavy Duty Bucket • Angle Tilt Bucket • Ditch Cleaning Bucket • Hydraulic Quick Coupler Thumb SOUTHERN CALIFORNIA’S PREMIER EQUIPMENT DEALER SANTA FE SPRINGS / 562-777-0775 11318 Norwalk Blvd., Santa Fe Springs, CA 90670 TEMECULA / 951-355-3085 NOW OPEN 43136 Rancho Way, Temecula, CA 92590 FONTANA / 909-822-2200 14635 Valley Blvd., Fontana, CA 92335 WORK SMARTER – NOT HARDER Power Through With Confidence. HORIZON UNDERGROUND INC. California - Nevada - Arizona 1595 Mountain Avenue Norco, California 92860 USA Directional Drilling - Hydro Vacuum Excavation - Trenching - Restoration 951.603.0745 CALCONTRACTOR .COM DEMO & RECYCLING / 2023 19

PAVEMENT RECYCLING SYSTEMS

Caltrans Utilizes Partial Depth Recycling for the Sustainable Pavement Rehabilitation of State Route 127 near Shoshone and Death Valley National Park

Route 127 was added to the state highway system in 1933. In 1964, state highway renumbering defined SR 127 from I-15 to the Nevada state line, a designation that has remained unchanged ever since. Route 127 originates northbound, connecting Interstate 15 in Baker to State Route 373 at the Nevada line. It traverses the vicinity of Death Valley National Park’s eastern boundary, passing near California 190 and Death Valley Junction. Classified as a Rural Minor Arterial, this route serves as an integral connection between southeastern California, Nevada, and other rural highways.

Caltrans scheduled specific segments of State Route 127 for rehabilitation, encompassing two sections located approximately

By Brian Hoover, Senior Editor /

seven miles apart in Inyo County. These individual sections were designated by Postmile Marker 21.0 to 34.5 and Postmile Marker (PM) 41.8 to 49.4, respectively.

Caltrans awarded the Partial Depth Recycling project to Hat Creek Construction for $15,409,904, and Hat Creek Construction, in turn, enlisted the services of Pavement Recycling Systems, Inc. (PRS) to carry out the Partial Depth Recycling (also referred to as Cold In-Place Recycling (CIR) by other agency standards). The engineered process recycles 100 percent of 3 to 5 inches of the existing asphalt and combined with an asphalt overlay in the rehabilitation of the pavement.

This is not the first time Caltrans has elected to utilize PDR on State Route 127, and the State has recognized that highways such

Systems, Inc.

as SR 127 offer an ideal setting for maximizing the value of Partial Depth Recycling (PDR). In fact, Caltrans has performed four PDR projects over the past eight years on individual segments of SR 127. A closer look reveals that the PDR work near Shoshone skipped the section of SR 127 between PM 34.5 and PM 41.8. This is because that segment was actually rehabilitated using PDR back in 2016. That same year, PDR was utilized in rehabilitating PM 0.0 to PM 21.0 in Inyo County, the segment leading into the beginning of this project. In San Bernardino County, two segments of SR 127 were also rehabilitated using PDR in 2015, from PM 3.0 to PM 10.5 and PM 37.7 to PM 41.5. In total, approximately 60.7 miles of SR 127 have been recycled using the PDR

Above: PRS CIR Train consists of a cement-spreading unit, followed by a Wirtgen 380 CRi full-lane milling machine, a pugmill recycling unit, and a 26-ton oil tanker truck. The process is efficient and cost effective with the production of two lane-miles per day.

Photos provided by Pavement Recycling

CALCONTRACTOR .COM DEMO & RECYCLING / 2023 20

process since 2015, or nearly 67% of the 91 miles that make up the entire stretch of the highway.

Josh Kennedy, who has been with PRS for over three years, currently holds the position of Branch Manager for the Renew Division in the Western United States. The Renew Division is responsible for promoting and implementing CIR and Roller Compacted Concrete (RCC) Solutions for the company. According to Kennedy, many agencies, including Caltrans, regularly utilize the CIR (Partial Depth Recycling) method when rehabilitating pavements in remote locations. “Because CIR recycles the existing asphalt pavement to perform as an asphalt base course during the rehabilitation process, it is an extremely cost-effective solution,

often resulting in costs that are as much as 40 percent lower than the structurally equivalent pavement section constructed with less sustainable remove and replace methods. CIR reduces and, at times, eliminates the exporting of milled asphalt material to the remote jobsite,” says Kennedy. “Reducing or eliminating the constructionrelated truck traffic associated with remove and replace pavement rehabilitation methods can also reduce GHG (Greenhouse Gas) emissions by up to 80%. Reducing construction-related truck traffic and its interaction with the traveling public in a remote area that is three to five hours away is also a major safety factor to consider.”

Kennedy explained that the State Route 127 Shoshone CIR Project aims to rehabilitate the

pavement by grinding and simultaneously recycling the highway pavement followed by overlaying the segments with hot mix asphalt material. One section of SR 127 was designed to be recycled at a depth of three inches, while the other section required a four-inch recycled depth solution. “The CIR train consists of several units, beginning with a specially engineered cement spreading unit located on a flatbed trailer and pulled by a semi-truck. The selfmade unit contains a water tank and a 25-ton cement silo, and the cement is applied at 0.6 percent by weight. The spreader operation is then followed and pushed by our Wirtgen 380 CRi full-lane (12.5 feet) milling machine. The milling machine uses its conveyor to transport the milled asphalt into the pugmill

Above: Pavement Recycling Systems’ Wirtgen 380 CRi full-lane (12.5 feet) milling machine grinding and conveying existing RAP material into the recycling unit.

Above: Pavement Recycling Systems’ Wirtgen 380 CRi full-lane (12.5 feet) milling machine grinding and conveying existing RAP material into the recycling unit.

CALCONTRACTOR .COM DEMO & RECYCLING / 2023 21

recycling unit, which incorporates screen decks to ensure proper material sizing,” elaborated Kennedy. “The recycling unit handles all the crushing, screening, and injection of the recycling agent, which, per the engineered mix design, is applied at 2 ½ percent emulsion. The last unit in the CIR train is the 26-ton oil tanker that stores and distributes the emulsified recycling agent. The fully recycled asphalt material is finally laid out in a windrow, at which point, Hat Creek Construction crews pick up, pave, and compact the recycled asphalt material. The completed recycled section is subsequently overlain with a three-inch HMA cap and put to service the two-lane highway.”

The State Route 127 Shoshone CIR Project started on April 3, 2023, and was completed on May 9, 2023. PRS’s $3.1 million contract included the use of CIR throughout, except for the bridge decks that had thin areas of HMA. These sections underwent a mill and fill application, while all other pavement sections were recycled. “Because CIR recycles existing asphalt materials through established engineering and construction practices, the process improves safety while reducing construction costs and construction-related community impacts. CIR is utilized throughout the state and beyond

to rehabilitate pavements in both rural and urban areas,” emphasizes Kennedy. “Finally, our 8-person crew performed brilliantly, and it is important to recognize their efforts. We thank everyone for another job well done, with special recognition to our Superintendent, Pat Waldron, and our Foreman, Dave Zewe, as well as to Hat Creek’s field crew and management personnel.”

Pavement Recycling Systems, Inc. is currently involved in multiple CIR projects, including a job in Yellowstone National Park, where they are rehabilitating a roadway located close to Old Faithful. From airport runways to public roadways, Cold In-Place Recycling’s

performance has been tested and proven to be a powerful, economical strategy for rehabilitating asphalt pavement sections. For more information on PRS and its pavement rehabilitation solutions, please visit www.pavementrecycling.com or call 800-966-7774. Cc

Right: PRS using a Wirtgen supplemental milling machine to pre-grind outside edge of asphalt pavement to increase paving width to 16 feet.

Below: Finished recycled pavement section on State Route 127.

Left: Hat Creek Construction following the CIR Train on State Route 127 project utilizing their Bomag MS2 pickup machine and their Terex-Cedarapids 552 Asphalt Paver.

Right: PRS using a Wirtgen supplemental milling machine to pre-grind outside edge of asphalt pavement to increase paving width to 16 feet.

Below: Finished recycled pavement section on State Route 127.

Left: Hat Creek Construction following the CIR Train on State Route 127 project utilizing their Bomag MS2 pickup machine and their Terex-Cedarapids 552 Asphalt Paver.

CALCONTRACTOR .COM DEMO & RECYCLING / 2023 22

Below: Front angle of the PRS CIR Train recycling the asphalt pavement on State Route 127 near Death Valley National Park.

2023 MANITEX 50155HL 55 TON STK# 105076 CALL FOR PRICE PETERBUILT 567 – AUTO TRANS 2018 TADANO GR1600XL 160 TON STK# 75890 $950,000 NEW UNITS IN STOCK 2023 MANITEX 3051T STK# 106098 – CALL FOR PRICE SALE – RENT – RPO “Your Crane and Boom Truck Headquarters” SALES | RENTAL | PARTS & SERVICE 2023 MANITEX 40124SHL STK# 99538 - $495,000 PETERBUILT 567 – 13 SPEED 2023 MANITEX 35124C 35 TON STK# 106087 – CALL FOR PRICE PETERBUILT 567 AUTO TRANS 2023 MANITEX 30112S STK# 109946 – CALL FOR PRICE MACHINE IS IN STOCK 2023 MANITEX 22101S STK# 109945 – CALL FOR PRICE KENWORTH T480 – AUTO TRANS 2023 ELLIOTT L65R STK# 104905 – CALL FOR PRICE MACHINE IS IN STOCK 2022 SHUTTLELLIFT SCD15 STK# 104619 - CALL FOR PRICE SALE – RENT – RENTAL PURCHASE 2018 TADANO GR350XL 35 TON STK# 78047 - $335,000 SALE – RENT – RENTAL PURCHASE (800)966-7774 & Pavement Coatings Co. Pavement Recycling Systems www.pavementrecycling.com Cold Milling | Cold Asphalt Recycling | Soil Stabilization | RAP Slurry | Chip Seal Fog Seal | Asphalt Interlayers | Roller Compacted Concrete | Profile Diamond Grinding & More! 100% Employee Owned PRS Holdings Companies SUSTAINABLE RECYCLING SOLUTIONS FOR ALL STAGES OF THE PAVEMENT LIFE CYCLE CA Lic #569352 CA Lic #303609 CALCONTRACTOR .COM DEMO & RECYCLING / 2023 23

Cutting Inefficiency, Not Corners

3 Ways Demolition Robots Increase Efficiency in Concrete Demolition Applications

Demolition, like every industry, is constantly evolving. To keep ahead of the curve, contractors seek out the machines and methods that increase productivity while decreasing the physical toll on workers.

Concrete sawing is viable option for fast, effective removal. However, savvy contractors are finding that adding remote-control demolition robots to their sawing operation not only increases productivity and safety, but also allows them to reduce bid prices and maximize profits. Here’s how:

1. COMPLETE JOBS FASTER

Take a wall sawing job, for example. To remove a 10-by-3meter wall in a confined space with a saw requires, on average, 25 cuts. Depending on depth, this might take several passes. Once cut, the concrete blocks need to be broken down for easier removal. The whole process would take at least four days with two saws and require a crew of at least three — two to run the saws and at least one more to handle removal.

Using a remote-control demolition robot can cut the time in half. Rates vary based on machine, material and depth, but demolition robots are capable of

extraordinary productivity — up to 5 cubic-meters per hour in some cases. To remove the same 10-by-3-meter wall, the contractor would still require perimeter cuts to avoid transferring vibration to surrounding structures. After that, though, the demolition robot and a single operator could quickly and effectively break up the concrete into small pieces that are easily cleaned up with a skid-steer loader.

Bank Vaults and other heavily reinforced concrete removal applications are another area where a demolition robot can reduce removal time by more than half. The robot works its way across the surface, exposing the rebar for cutting with a torch. This

Concrete sawing contractors are finding that adding remote-control demolition machines to their sawing operation not only increases productivity and safety, it allows them to reduce bid prices and maximize profits.

method greatly reduces diamond costs from standard methods such as core drilling, wire sawing, and wall sawing.

Additionally, demolition robots reduce the need for scaffolding on larger vertical demolition projects since some models can reach up to 5 meters (16.4 feet). This can save up to a week before and after the project, allowing contractors to take on more revenue-producing jobs instead.

2. KEEP OPERATORS OUT OF HARM’S WAY

Machine reach, paired with a 300-meter (984-foot) remote operating distance, also keeps workers away from jobsite dangers such as falling objects, flying

By By Jeff Keeling, Vice President of Sales & Marketing, Brokk Inc. / Photos provided by Brokk Inc.

CALCONTRACTOR .COM DEMO & RECYCLING / 2023 24

debris, weak floors, ledges and silica dust.

Perhaps the biggest safety advantage, though, is limiting the human element in the more manual aspects of concrete cutting. Using a demolition robot minimizes the need for handheld saws, coring equipment or pneumatic breakers. Working with these machines, some of which can weigh 18 kilograms (40 pounds) or more, can easily fatigue workers and the vibrations can lead to long-term injuries. Robotic demolition also creates more manageable rubble that is easily lifted and removed, further reducing strain on workers.

3. VERSATILITY WITH A RANGE OF ATTACHMENTS

Attachments can further increase safety and productivity. A crusher attachment, for example, is quieter than a saw or handheld pneumatic devices and breakers, making the jobsite safer for workers and the public. It also opens up new opportunities in areas where saws would be too noisy — such as near hospitals or schools. Not to mention making waste disposal easier by separating concrete and rebar onsite.

The possibilities go beyond concrete cutting, as well. In addition to crushers and breakers, leading remote-control demolition robot manufacturers offer a range of attachments for cutting pipes, taking down stud walls, sorting debris, digging, and even vacuum lifting slabs. A demolition robot with the right array of attachments can not only increase productivity, but also limit the need for additional support equipment on congested jobsites.

Bottom Line

Concrete sawing contractors who supplement their operation with remote-control demolition robots can do jobs faster, safer, and with less overhead. It’s that simple. What used to take a week with a large crew can now be done in just a few days with a small crew and a single machine. Once the first job is done, they can quickly move on to the next, doubling their productivity. Labor and diamond savings add up, as does the profit margin with each extra job they can take on. Not to mention the savings from a healthy, happy workforce.

Demolition robots won’t replace concrete sawing, but as part of a versatile operation, it can easily

In addition to crushers and breakers, leading remote-control demolition machine manufacturers offer a range of attachments for cutting pipes, taking down stud walls, sorting debris, digging, and even vacuum lifting slabs.

open up doors — or bank vaults — to increased profits.

About the Author

Jeff Keeling is the vice president of sales and marketing for Brokk Inc. He works closely with regional sales managers to develop and grow the Brokk brand in key segments across the United States and Canada. He is also responsible for educational initiatives aimed at helping customers maximize their Brokk machines’ potential.

About Brokk

Brokk has been the world’s leading manufacturer of remotecontrolled demolition machines and attachments for over 45 years. Through continuous innovation in engineering and design, Brokk is able to offer unique solutions to multiple industries worldwide, including construction, demolition, mining and tunneling, cement and metal processing, nuclear and other specialty applications. For more information: Brokk Inc., 17321 TYE Street SE, Suite B, Monroe, WA 98272; 800-621-7856; info@brokkinc.com; www.brokk. com;

Facebook; YouTube; LinkedIn and Twitter. Cc

Reach, paired with a 300-meter (984-foot) remote operating distance, keeps workers away from jobsite dangers such as falling objects, flying debris, weak floors, ledges and silica dust.

CALCONTRACTOR .COM DEMO & RECYCLING / 2023 25

Remote-control demolition machines can cut demolition times in half. These machines are capable of extraordinary productivity — up to 4 cubic-meters per hour in some cases.

WORK SMARTER – NOT HARDER www.scottequip.com Serving California For 50 Years! Model: SK30SR-6E Program: 0% for 54 months and 90 Day deferral options for qualifying customers COMPACT YET TOUGH MINI Full-Size Performance, Short-radius Agility and Quiet Operation SANTA FE SPRINGS / 562-777-0775 11318 Norwalk Blvd., Santa Fe Springs, CA 90670 TEMECULA / 951-355-3085 – NOW OPEN 43136 Rancho Way, Temecula, CA 92590 SALES • RENTALS • PARTS • SERVICE MINI EXCAVATORS / SKID STEERS BACKHOES / SKIP LOADERS FONTANA / 909-822-2200 14635 Valley Blvd., Fontana, CA 92335 SOUTHERN CALIFORNIA’S PREMIER EQUIPMENT DEALER CALCONTRACTOR .COM DEMO & RECYCLING / 2023 26

V isit u s a t h tt ps ://d ot.c a.g ov/ or e ma il s mall bu s i n ess advo cat e@d ot.c a.go v for mo re in fo rma t ion Use c ell p h on e ca me ra t o s ca n Q R cod e a b ov e t o a ccess in for ma t ion a b ou t Ca lt ra n s u p comin g opp ort u n it ies CONT RACT ING OPPORTU NIT IES AV AILABLE FOR SMALL BU SINESS! INCL U DI NG MI NO RI TY, WO MEN, A ND DI SAB L ED V ETERA NS TRENCH SHORING COMPANY SLIDE RAIL ROLLING STRUT SHORING SYSTEM Compton - Corporate Office - 310-327-5554 Bakersfield Banning Corona Fresno Fullerton 661-396-9160 951-849-1611 951-734-4290 559-691-4123 714-879-1005 949-454-0858 805-529-4614 858-530-2500 510-900-0595 Lake Forest Moorpark San Diego San Leandro 702-651-0920 Las Vegas 5 0 Y E A R S TrenchShoring.com CALCONTRACTOR .COM DEMO & RECYCLING / 2023 27

VOLVO CONSTRUCTION EQUIPMENT & SERVICES (VCES) BECOMES

FIRST VOLVO CONSTRUCTION EQUIPMENT DEALER TO RECEIVE PORTABLE ELECTRIC’S VOLTSTACK E-CHARGER

VCES Holds Electric Open House Events in San Leandro and Corona

Volvo Construction Equipment & Services (VCES) has long been at the forefront of battery-electric construction equipment. Having actively participated in several pilot programs in California, VCES now offers a range of battery-electric units for sale. Recently, they organized Electric Open House events in San Leandro and Corona, showcasing their electric equipment alongside their conventional diesel machines. The Electric Open House in San Leandro spanned May 16 and 17, while the Corona event took place on April 18 and April 20.

Ed Galindo is the E-Mobility Product Manager for VCES and helped to set up and oversee both Electric Open House events. “We wanted to bring our customers in to see and demonstrate our electric offerings, along with our full inventory of conventional diesel machines. We wanted our

customers to see everything we have to offer right now in the zeroemission space. We had our Volvo ECR25 Electric compact excavator running and on display, along with our Volvo L25 Electric compact wheel loader. Additionally, our customers were treated to our newest electric offering, the EC230 Electric, Volvo’s first electrified larger (50,000 lb.) excavator,” says Galindo. “We were also very excited to show off our new Voltstack 30k e-Charger, equipped with 30 kilowatts of power with 80-kilowatt hours of battery capacity. Then we had another new electric offering at the events, our Bergmann 804 electric dumpers. There were lots of questions from contractors and officials from Caltrans and other city and municipal agencies. Everyone seemed surprised and excited about just how efficient, productive, and quiet these electric machines were as they demoed them onsite.”

Voltstack e-Charger Now Available

at all Eight Volvo Construction Equipment & Services Locations

VCES recently became the first Volvo Construction Equipment dealer in the United States to become a certified distributor for Portable Electric’s Voltstack e-charger offerings. The Voltstack e-Charger is a rugged, reliable, offgrid mobile charging solution that allows customers to recharge their electric equipment on any job site. By providing a complete solution for electric equipment charging, the Voltstack e-Charger closes the power loop on electric equipment being utilized out in the field. The Voltstack e-Charger ensures uptime for electric machines while also offering power services only found in the past from conventional gas and diesel generators.

“Electrification is a key enabler for sustainable construction, and Volvo is taking a leadership role in

Above: Volvo ECR25 electric compact excavator, L25 electric compact wheel loader and Bergmann 804 electric dumper on display at VCES Electric Open House.

CALCONTRACTOR .COM DEMO & RECYCLING / 2023 28

By Brian Hoover, Senior Editor / Photos provided by Volvo Construction Equipment & Services

the industry to drive this transition,” says Ed Galindo. “We’re proud to offer a range of electrified products to help customers reduce their carbon footprint and meet their sustainability goals. By combining innovative technologies like the Voltstack ecosystem with our deep expertise in construction, we’re working to create a cleaner, more sustainable future for everyone.”

According to Galindo, the Voltstack e-Charger is available in 5k and 30k and Mobile EV Charger capabilities. “We offer the Voltstack e-Charger units for sale or for rent. The 30k units take approximately 11 hours to recharge from a 240V/50A outlet. The fully charged Voltstack 30k e-Charger is capable of providing four full chargers to the Volvo ECR25 electric compact excavator and two full charges for the Volvo L25 compact wheel loader,” says Galindo. “Customers can rent our Voltstack e-Chargers as an economic solution for keeping their machines consistently charged out in the field. We offer clean, silent power for rent for standby or

service applications. We bring the unit to your jobsite for on going operations or just a one-day event”

VCES very recently received delivery of several Voltstack e-Charger units, with some already spoken for and another half-dozen going directly into their rental fleet.

“Electric power providers in Northern California are showing interest as fire season quickly approaches,” continues Galindo. “Voltstack e-Chargers are also ideal for indoor construction projects that require zeroemission-generated power. These units are completely silent and are the ideal solution wherever auxiliary power is needed.”

Galindo says that it is important to remind everyone about the Clean Off-Road Equipment Incentive Project (CORE), which is a $273 million voucher incentive program intended to encourage California off-road equipment users to purchase or lease current zero-emission off-road equipment.

“The CORE voucher incentive program helps to offset the cost of zero-emission technology with

a point-of-sale discount. These programs are available right now. There is another new round of funding that will be starting on July 18, and you just have to apply by visiting californiacore.org for more details.”

Volvo CE and VCES are fully committed to the continuing development of zero-emission equipment and charging solutions. Along with their Voltstack e-Charger offerings, VCES also offers full solar charging stations for sale or rent. “At VCES, we pride ourselves on offering a full lineup of equipment for the construction, mining, municipal, and industrial industries. Our electric offerings are just another tool in our toolbox as we continue to strive to meet and exceed our customers’ equipment, parts, and service needs,” concludes Galindo.

For more information about Volvo Construction Equipment and Portable Electric, please visit www.volvoce.com and www.portable-electric.com. Cc

Left: Voltstack 30k e-Charger and Voltstack 5k e-Charger units.

Left: Voltstack 30k e-Charger and Voltstack 5k e-Charger units.

CALCONTRACTOR .COM DEMO & RECYCLING / 2023 29

Above: VCES Electric Open House guests check out the new Volvo EC230 50,000 lb. electric excavator.

ADVERTISER INDEX Caltrans ......................... 27 California Stone Slingers ............ 18 Clairemont Equipment .............. 26 Coastline Equipment ................ 3 Coastline Equipment Crane Division. ... 23 Graniterock ...................... 27 Hawthorne CAT .................... 2 Horizon Underground, Inc. ........... 19 Nixon-Egli Equipment Co. .... Back Cover Pavement Recycling Systems ......... 23 Quinn CAT ........................ 2 Ramco ......................... 15 Savala Equipment Rentals . . . . . . . . . . . . 7 Scott Equipment ............... 19, 26 Sonsray Machinery ................ 31 Terry Equipment, Inc ...............30 Trebor Shoring Rentals .............. 15 Trench Shoring Company ............ 27 Volvo Construction Equip. & Services. ... 5 Warrior Machinery ................. 11 BIG POWER and Performance in Compact Packages The TK 70 IS IDEAL FOR LARGER AGGREGATE CONCRETE PUMPING AND SHOTCRETING APPLICATIONS • Specially designed hopper • Electric cycling • Proven reliable S-Valve • High-strength trailer • Easy filling and operation • Inexpensive maintenance • Fast setup • Smooth pumping • Simple cleanup • Long-term dependability Las Vegas, Nevada (800) 350-9230 Stronger, Tougher, Wider, Smoother Safer, Easier Your authorized Putzmeister distributor for California, western and southern Nevada, and the Hawaiian Islands. Bloomington, California (909) 879-1438 Sacramento, California (916) 388-2480 CALCONTRACTOR .COM DEMO & RECYCLING / 2023 30

IRON RULES

Sonsray offers industry leading machines for TEAR-DOWN and CLEANUP

Demo structures and clear the path for new beginnings with unstoppable power and your crew at the controls.

hablamos español

sonsraymachinery.com TO DEMOLITION

MOB I R E X MR 130i EVO 2

The mobile impact crusher MOBIREX MR 130i EVO2 can be deployed universally as an all-rounder and produces rst-class nal grain quality. With a crusher inlet width of 52 in., it achieves a production rate that until now was only associated with considerably larger crushing plants. This is made possible by outstanding cost e ectiveness and performance with a variety of technical highlights. Thanks to its compact design, the plant is easy to transport and can be assembled and disassembled quickly.

California’s L argest General Line Construction and Municipal Equipment Dealer. So. California: 2044 S. Vineyard Ave., Ontario, CA 91761 • (9 09) 930 -1822 No. California: 80 0 E. Grant Line Rd., Tracy, CA 95304 • (209) 830 - 860 0 Nevada: 2750 Marion Drive, Las Vegas, NV 89115 • (702) 342-8100 ww w.nixonegli.com California‘s source for Kleemann Crushing & Screening Equipment Rental, Sales, and Service.

Simple and intuitive SPECTIVE control concept

E cient and powerful D-DRIVE diesel direct drive

High-performance post screening unit with oversize grain returning (option)

•

•

•

> TH E P OW E R FU L A L L-R O UNDE R

By Brian Hoover, Senior Editor /

Photos by John Martorano Photography

Joshua Clauss, President/CEO, Clauss Construction.

Above: Clauss Construction utilizing one of their many Link-Belt excavators for removal of demolition debris from the old San Jose Jail demolition project.

By Brian Hoover, Senior Editor /

Photos by John Martorano Photography

Joshua Clauss, President/CEO, Clauss Construction.

Above: Clauss Construction utilizing one of their many Link-Belt excavators for removal of demolition debris from the old San Jose Jail demolition project.

Above: Pavement Recycling Systems’ Wirtgen 380 CRi full-lane (12.5 feet) milling machine grinding and conveying existing RAP material into the recycling unit.

Above: Pavement Recycling Systems’ Wirtgen 380 CRi full-lane (12.5 feet) milling machine grinding and conveying existing RAP material into the recycling unit.

Right: PRS using a Wirtgen supplemental milling machine to pre-grind outside edge of asphalt pavement to increase paving width to 16 feet.

Below: Finished recycled pavement section on State Route 127.

Left: Hat Creek Construction following the CIR Train on State Route 127 project utilizing their Bomag MS2 pickup machine and their Terex-Cedarapids 552 Asphalt Paver.

Right: PRS using a Wirtgen supplemental milling machine to pre-grind outside edge of asphalt pavement to increase paving width to 16 feet.

Below: Finished recycled pavement section on State Route 127.

Left: Hat Creek Construction following the CIR Train on State Route 127 project utilizing their Bomag MS2 pickup machine and their Terex-Cedarapids 552 Asphalt Paver.

Left: Voltstack 30k e-Charger and Voltstack 5k e-Charger units.

Left: Voltstack 30k e-Charger and Voltstack 5k e-Charger units.