Keeping safe is a continuous challenge and one we believe is worth taking on. We believe in ZERO HARM.

Copyright© 2024 Bullivants Pty. Ltd. All Rights Reserved

Shackles Grade S Shackles

Shackles Stainless Steel Grade 316 Dee

Superbuckles Jaw & Jaw Galvanised

Superbuckles Eye & Eye Galvanised

Superbuckles Jaw & Eye Galvanised

Turnbuckles Hook & Hook Stainless Steel

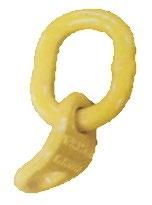

Concrete Lifting Clutch

Zinc Eyenut Range

RUD – Starpoint VRM Eyenut

Weld On Lifting Point Grade 100

Weld On Lifting Point Grade 80

RUD – VLBS Load Ring for Welding

RUD – VRBS Load Ring for Welding

RUD – W-ABA Lifting Ring for Welding

Gunnebo - De-Centred Lifting Point DLP Metric

Gunnebo - De-Centred Lifting Point DLP Imperial

Gunnebo – Rotating Eye Lifting Point RELP Metric & Imperial

Gunnebo – Rotating Lifting Point RLP Metric & Imperial Threads

RUD – VLBG-PLUS

RUD – Starpoint VRS-F Eyebolt

RUD – VWBG Loading Right for bolting

RUD – ACP-TURNADO

RUD – INOX-ABA

Link Brackets

A shackle is used for interconnecting components in lifting, tensioning and staying systems. A shackle consists of a body, a removable pin and a locking device (where applicable).

Grade S Shackles generally comply with Australian Standard 2741 with approximately twice the working load limit of Grade M Shackles. All Bullivants shackles are destruction and proof load tested prior to sale in the Australian market.

Features & Benefits:

• Alloy Steel material is more compact and lightweight than Grade M shackles

• 6:1 Safety factor provides confidence in strength when used in the correct application

• Galvanised finish for corrosion resistance for longer life span

• Identification markings for traceability, manufacturers identification, grade of material, batch number and working load limit in accordance with AS2741 Australian Standards

Shackle Types:

Bow Shackles:

Can be used on either single or multi-leg applications. Screw pin closing method. Note: Screw pins need to be checked for tightness prior to each lift.

Dee Shackles:

Only used for single leg applications - never multi leg as the body and pin may distort. Screw pin closing method. Note: Screw pins need to be checked for tightness prior to each lift.

Safety Pin Shackles:

Preferable for long term or permanent applications or where the load may slide on the pin causing rotation to the pin. Also used on equipment that may vibrate to ensure pin does not become dislodged.

Available in Bow and Dee shackle body styles

Bow Screw Shackle Specifications:

Bullivants

WSS-0850-SA-

Identification markings for traceability, manufacturer’s identification, size, grade of material, batch number and working load limit in accordance with AS2741 Australian Standards

Main Features:

• Grade 316 stainless steel

• High corrosion resistance

• Suitable for harsh corrosive applications and marine and coastal environments

• Not suitable for lifting

Specifications:.0

Main Features:

• Hot dipped galvanised steel

• End fittings are quenched and tempered; bodies heat treated by normalising

• Turnbuckles recommended for straight on in-line pull only

• Proof load 2.5 x WLL

• Ultimate load 5 x WLL

Specifications:

Main Features:

• Hot dipped galvanised steel

• End fittings are quenched and tempered; bodies heat treated by normalising

• Turnbuckles recommended for straight on in-line pull only

• Proof load 2.5 x WLL

• Ultimate load 5 x WLL

Main Features:

• Hot dipped galvanised steel

• End fittings are quenched and tempered, bodies heat treated by normalising

• Turnbuckles recommended for straight on in-line pull only

• Proof load 2.5 x WLL

• Ultimate load 5 x WLL

Main Features:

• Available in a wide range of capacities

• Manufactured high strength Alloy Steel

• Concrete lifting clutches must be load tested every 12 months in accordance with Australian Standards

• Manufacturer and working load markings in accordance with Australian Standards

• Surface finish: blue powder coat

ZERO HARM Product Features:

• Designed to not spontaneously disengage whilst the system is under load at any orientation when installed correctly

• Proof load tested accordance with the AS3850

• Designed and manufactured with a 5:1 safety factor

• Unique serial number and test certificate supplied with each item

Lifting Clutches must be checked for compatibility with the lifting insert before use. Always refer to the erection documentation.

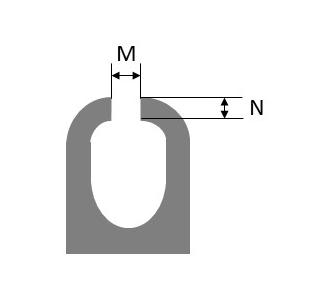

Technical Drawings:

• Metric coarse female thread

• Zinc plated finish

• Complies with DIN 582

• Suitable for Low Duty Applications

• Not suitable for lifting

Eye nut

Full WLL in any direction with 4:1 design factor

100% electro-magnetic crack detection tested

Manufactured using high tensile CrNiMo - steel

MADE IN GERMANY

clear marking of the WLL. 360° rotation

Full WLL in any direction with 4:1 design factor 100% electro-magnetic crack detection tested Manufactured using high tensile CrNiMo - steel Side loading permissible when adjusted to the correct plane

Shape: star shaped (clearly distinguishable from other collared eye nuts) Complies with EN 1677

Painted in the unique durable RUD

VRM-M6 0.50.10.05289720232817133711M697900786 VRM-M8 1.00.30.13511925253021164714M8127992989 VRM-M101.00.40.13511925253021164714M10127990311

VRM-M164.01.50.349151335364031226521M16197990314

VRM-M206.02.30.558171640415035297623M20247990315

VRM-M248.03.20.970201949516041359229M24307990316

VRM-M3012.04.51.5872624606675514411436M30367993008

Weld on Lifting Points are manufactured in Australia using only heat certified Australian Steel. The Working Load Limit and Batch identification is clearly marked on both the Loop and Lug.

Main Features:

• Multi-directional loading

• Forged from fully tested and certified steel

• Ideal for lifting and lashing

• Welding must always be carried out by a qualified welder under AS 1554.1:2014

• Supplied with welding instructions

• Complies with AS 3776

Specifications:

Bullivants Grade 80 Weld on Lifting Points are manufactured using forged alloy steel. The Working Load Limit and Batch identification is clearly marked on both the Ring and Lug.

Main Features:

• Grade 80 Alloy Forged D Ring

• Fatigue tested to >20,000 cycles at 1.5x WLL

• Ideal for lifting and lashing applications

Specifications:

• Each unit is packaged with welding instructions

• Welding must always be carried out by a qualified welder under AS/NZS 1554.1

Loa d ing Ring f o r W eldin g

Full WLL in any direction with 4:1 design factor

100% electro-magnetic crack detection tested

Clear marking of the WLL

Full WLL in any direction with 4:1 design factor

100% Electro-magnetic crack detection tested

Patented wear markings on the inside and on the outside

MADE IN GERMANY

forged lifting point clear marking of the WLL

Full WLL in any direction with 4:1 design factor

100% Electro-magnetic crack detection tested

Manufactured in Germany using high tensile CrNiMo - steel lashing capacities

Clear marking of the WLL

Patented wear markings on the inside and on the outside Complies with EN 1677 Temperature Range -40ºC to 200ºC no reduction in WLL

W-ABA 0.8t 0.8221270321250320.27907698

W-ABA 1.6t 1.63016100351657420.457900352

W-ABA 3.2t 3.24123137502180591.157900353

W-ABA 5t 5.05127172602899722.267900354

W-ABA 10t 10.070382288035130955.377900355

W-ABA 20t 20.090522721154017513510.727902174

W-ABA 31.5t 31.5108643201305020415418.337902175

Dimensionsandsubjecttochange

Main Features:

• DLP has a hexagon bolt (RFID prepared) to disassemble/assemble with a wrench easily

• “Stay-up” function for easy on-hooking when there is limited space

• Ideal for narrow spaces, such as corners or edge position, angular lifts, tilting under load, multiple part lift

• Identification markings for traceability, Working Load Limit, mounting torque and manufacturer’s identification

• Safety factor 4:1

• Bolt, nut and washer according to: ISO 898-1 Class 10.9

Symmetric Load (tonnes)

WRB-2000-M48-ST-DLP(L)

Main Features:

• DLP has a hexagon bolt (RFID prepared) to disassemble/assemble with a wrench easily

• “Stay-up” function for easy on-hooking when there is limited space

• Ideal for narrow spaces, such as corners or edge position, angular lifts, tilting under load, multiple part lift

• Identification markings for traceability, Working Load Limit, mounting torque and manufacturer’s identification

• Safety factor 4:1

• Bolt, nut and washer according to: ISO 898-1 Class 10.9

Symmetric Load

WRB-0500-317-CP-Z102330(L)

Main Features:

• Compact and robust lifting point

• Ideal for top-mounting and when a quick and easy on-hooking is important

• RELP hexagon socket makes it easy to disassemble/assemble using a standard allen key

• Seats perfectly to the surface

• Eliminates risk of unintended loosening

• Automatically adjusts to the loading direction which decreases the risk to load it incorrectly and endangering the lifting operation

• Ideal for sensitive load surfaces, as the connecting sling hook will be positioned mainly parallel to the load surface; completely avoiding the hook to cause damage on the load

• The same load can be lifted with a smaller size RELP

• Proof tested 2.5 times WLL

Specifications – Metric Thread:

Specifications – Imperial Thread: Bullivants

Bullivants Mfr

WEB-0610-U220-G-

WEB-3200-U508-G-RELP

Symmetric Load (tonnes)

* Safety factor 4: 1

Main Features:

• RLP bow rotates 360° and pivots 180°, making it strong, flexible and reliable

• Easy assembly of roundslings, master links or hooks directly to the lifting point

• Open and spacious D-ring makes disassembly easy and facilitates inspection of all parts as well as replacement of the bolt

• The hexagon bolt makes it easy to mount and dismount the RLP

• Proof tested 2.5 times WLL

Specifications – Metric Thread:

Specifications – Imperial Thread:

Bullivants Mfr

5/8

WRB-0500-190-CP-Z101820 3/4

Technical Data:

Symmetric Load (tonnes)

WRB-1600-

* Safety factor 4: 1

VLBG-PLU S - no w wi t h 45% higher WL L

Up to 45% higher WLL at an average (M8-M30)

360° lifting point rotation 180° pivoting

ICE Bolt made from patented material

Stamped with RUD Markings

Grade120 providing greater wear resistance

One piece nut for quicker assembly Variable bolt lengths available

VLB G -PLUS V IP Load ring for bolting PLUS – metri c

VLBG-PLUS 0.63t M8

VLBG-PLUS 0.9t M10

VLBG-PLUS 1.35t M12

VLBG-PLUS 2t M16

VLBG-PLUS 3.5t M20

VLBG-PLUS 4.5t M24

VLBG-PLUS 6.7t M30

VLBG-PLUS 8t M36

VLBG-PLUS 10t M42

VLBG-PLUS 15t M42

VLBG-PLUS 20t M48

VLBG-PLUS 0.63t M8

VLBG-PLUS 0.9t M10

VLBG-PLUS 1.35t M12

VLBG-PLUS 2t M16

VLBG-PLUS 3.5t M20

VLBG-PLUS 4.5t M24

VLBG-PLUS 6.7t M30

VLBG-PLUS 8t M36

VLBG-PLUS 10t M42

VLBG-PLUS 15t M42

VLBG-PLUS 20t M48

Eye Bolt

Distributed by

Offers a full WLL in any direction with 4:1 design factor

100% electro-magnetic crack detection tested

Manufactured using high tensile CrNiMo - steel

pivoting 360°. adjusts to the direction of pull

clear marking of the WLL

Full WLL in any direction with 4:1 design factor

100% electro-magnetic crack detection tested

Manufactured using high tensile CrNiMo - steel

Adjusts to the direction of pull (allowing higher load capacities than the standard DIN-580-Eyebolts)

ICE-Bolt made out of patented steel

Side loading permissible when adjusted to the correct plane

Shape: star (clearly distinguishable from other collared eyebolts)

Countersunk socket screw held captive, quality:

Grade 10.9 metric coarse pitch

Complies with EN 1677

Longer bolt lengths available on request

Also available in UNC thread sizes

Painted in the unique durable RUD pink powder

VRS-M42

*Stamped with F2 WLL

Load ing rin g for bolting

Full WLL in any direction with 4:1 design factor

Bolts 100% electro-magnetic crack detection tested

KEY POINT 3

Easy assembly with a single threaded tapped hole

ball bearing technology

360° rotation

Full WLL in any direction with 4:1 design factor

Bolts 100% electro-magnetic crack detection tested

High tensile suspension ring acc. EN 1677 - 4

Easy assembly with a single threaded tapped hole

large pivoting area ~230°

Turnable under load

clear marking of the WLL

VWBG is also available with UNC imperial thread sizes

Surface protection CORRUD-DT (20 times better than zinc plating)

Pink powder coating and zinc plated

VWBG 1212261116598856342-30095M42M42-M452346.155079990448600452

VWBG 12122611165988567-95M45-2346.245507900455-

VWBG 1313261116598856848-30095M48M48-M522346.3755079990458600453

VWBG 14143211970120957852-300120M52M5227110.5575079010818600158

VWBG 16163211970120958456-300120M56M56-M6027110.6880079990048600454

VWBG 16163211970120959464-300120M64M64-M7627111.480079990438600455

VWBG 31.531.5461309017014510872-300159M72M72-M7633829.96120079000978600456

VWBG 3535461309017014512080-300159M80M80-M8533831.19150079001008600457

VWBG 40404616811017014513590-300159M90M90-M15037833.16200079034088600458

Patented ICE Bolt Material

Higher WLL M12-

Wear Indicators

Unique Spring Mechanism

Available with longer RUD Bolt & Din Nut

Setting a new standard among centre-pull hoist rings, the ACP-TURNADO is a cut above the rest.

• The design of the ACP-TURNADO enables it to turn immediately into the direction of optimal force transmission, meaning there is no stoppage of the lifting ring that causes high shear stresses, bending or sudden movement of the load.

• Up to 30 percent higher working load limits (WLLs) than hoist rings of comparable sizes – thanks to RUD ICE-Bolt technology, and the ACP’s design. of operating equipment, ensuring inspection and maintenance as well as

ACP M12 7909314

ACP M16 7909316

ACP M20 7909317

ACP M24 7909318

ACP M30 7909319

ACP-TURNADO also available in UNC Thread, refer to rud.com.au for information

A game changer for lifting points

The RUD ACP-TURNADO sets new standards for the safe lifting of valuable loads. Thanks to its innovative spring mechanism, its lift bail immediately turns into the load direction when the load is lifted, so it cannot remain vertical. Dangerous transverse loads and a sudden drop of the load by sudden turning into the load direction are therefore impossible.

Since every application has special requirements, we have developed three different designs for the RUD ACP-TURNADO. Each of them is perfectly adapted to a defined WLL range and specific requirements. This is available only at RUD in this market segment.

ACP-TURNADO Max and Supermax also available in UNC Thread, refer to rud.com.au for information

Stainless Steel Lifting Point for Welding

Distributed by

Full WLL in any direction with 4:1 design factor

Manufactured from Duplex Steel 1.4462

Patented wear markings on the inside and on the outside

MADE IN GERMANY

Duplex Steel is is known for corrosion resistant properties against crevice corrosion and chloride pitting. It is also resistant to seawater, water vapour, nitric acid and sulphuric acid. It is also cost-effective due to its lower nickel content

Full WLL in any direction with 4:1 design factor

Manufactured in Germany from Duplex Steel 1.4462

Clear marking of the WLL

Patented wear markings on the inside and outside

Closed and circumferential fillet weld

Temperature Range -40ºC to 250ºC no reduction in WLL

Link bracket assemblies are usually used to lift components during maintenance and repairs of equipment.

Main Features:

• Requires less clearance than standard eye bolts

• Allows for faster and easier positioning of swing gear/ bearing

• Bolt Grade 8.8

• Complies with ANSI/ASME B30.9.1984

Specifications: