4 minute read

Year-End Review of Fir Plywood fndustry

By Thomas C. Sias Douglas Fir Plywood Association

\Mest coast plyrvood manufacturers approached the turn of the vear with another all-timc pr.rduction rccord in sight. At the same time most sigus poilted to a good year in 1953 for Douglas fir plylood sales at the retail level.

Housing starts fcr 1952 rvhere the in-place cost of plvwood for structural applications is highly competitive appeared to be measuring up to eariier estimates that they rvould top a million. And 700,000 to anothei' million starts are predicteC for next ,vea:.

Remodcling, too. where plyrvood's competitive position in terms of end-use values is highly favorable constituted a continuing demand. Estimated dollar volume for all remodeling. maintenance and building repair in 1952 rvas $9 billion and next year is expected to be just as good.

The "do-it-yourself" trend was well established as a major outlet for plywood through retail dcaler yards and .very indication shows that this rna-rket rvill continue to expancl in 1953.

Throughout almost the entire i952 period, demand for plywood in all fields including hea.ry construction, remanufacture, boat building and other fields was strong and steady lrringing production to a record ar.erage of 56 million square feet rvcekly. The year opened, in fact, with a rush <rf business that sent 'lveekly sales to better than'70 million square feet for some six 'lveeks.

Output this year totaled 2.4 billion square feet as of October 25 and the industry expects the figure to equal or exceed the 2.8 billion record high set last year.

Although demand remains firm, the immediate shortterm outlook at the manufacturing level was marred some-

'"r''hat by fourth quarter sluggishness which resulted in a .len per cent drop in price by October.

Although this period of uncasiness came at about the same time as the sudden and precipitous plunge in the market last October, it bore ferv of the earmarks of that period. For one thing, with wages up a $1 a day and the cost of ra-n' materials holding steady or increasing, there was considerably less margin between profit and loss. Secondly, jobber stocks in October appeared to be far lou.er than at this tiine last year. To manufacturers these conditions point to a likely rush of orders again in the months ahead.

In assessing what's ahead for retail plyrvood sales in 1953, it is imperative to see rvhere the retail dealer fits into the picture. Investigation indicates that he gcts and sells more than 50 per cent of total industry output or an estimated 1.4 billion square feet of plyrvood in 1952. Arid a just completed indepenCent market survey ir-iitiated by the industry indicates that 10 per ccnt of output-practically all of which is sold by dealers-goes to home-on'ners.

This means that the dealer constitutes the plywood industry's biggest single outlet, and the manufacturers have long recognized this in their joint plyrvood sales promotion rvith a'continuing florv of dealer sales helps.

Hou'ever, in Scptember o{ this vear, W. E. Difforcl, t'ho held the post of managing director of the industry's trade association from 1938 to 1946, rvas lured back to the joli from his orvn plywood and lumber sales firm. Immediately after rejoining the Association, Difford put his finger on the strategic position of the retail dealer in the plyu'ood market oicture and within trvo u,eeks after he was on the job, the manufacturers had the ball rolling on the current "Best Buy" plywood sales promotion campaign.

This is a coordinated packaged promotion rifled at specific dealer sales outlets for plywood. It includes national advertising in Saturday Evening Post and Pathfinder, strong campaigns in builder and dealer trade journals, and a tie-in kit of dealer sales aids topped with a new display-mobile for pl1'u'ood being used in the building materials field for the first time.

The program bilLs Douglas fir plywood as "today's best buy" in terms of in-place cost and end-use values in new homes, remodeling, 1>uilt-ins, farm buildings, boats, and home rvorkshop projects. And it has been itiled on top of the industry's continuing promotion program to architects. builders, industrial users and home owners.

The program climaxed a y.ear of intense Dromotional a-ctivity in the industry-most of which was instrumental in maintaining or building dealer sales of plywood. Early in the spring plyu'ood .n,as selected as the primary structural material for the n.idely publicized "Farm-In-A-Day" horne and buildings erected in Washington's Columbia irrigation for the nation's most deserving young veteran.

Immediately follon'ing this project which is still resulting in follol,v-up publicity came the industry's "Room-for-fmpror.ement" plyrvood remodeling contest which drerv 36,000 requests for plyr,r'ood remodeling idea literature and 13,500 actual entries.

The promotion generated new interest in plywood for rer-nodeling and the entries have developed priceless information on rvhat the nation needs and prefers in remodeling developments. The announcement of r,vinners has lteen completed but the greatest benefits to dealers will be the before and after remodeling case studies which will be made available in the form of remodeling sales literature.

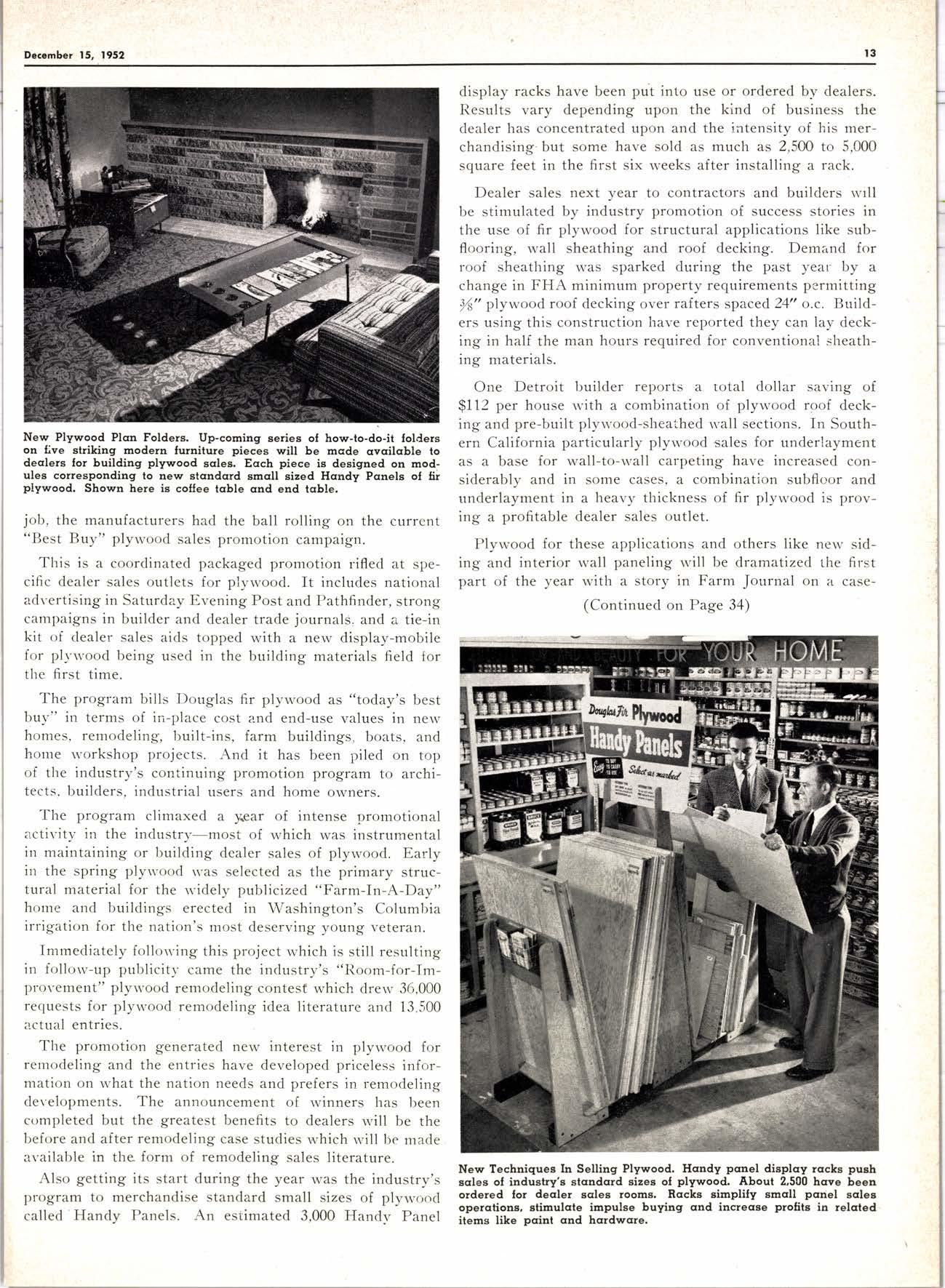

Also getting its start during the year was the industry's program to merchandise standard small sizes of plywriocl called Handy Panels. An esiimated 3,000 Han<ly Panel display racks have been put into use or ordered bv dealers. Results vary depending upon the kind of business the dealer has concentrated upon and the intensity of his merchandising.but some have sold as much as 2,50O to 5,000 square feet in the first six rveeks after installing a rack.

Dealer sales next year to contractors and builders r,vrll be stimulated by industry promotion of success stories in the use of fir plywood for structural applications like subflooring, rvall sheathing and roof decking. Demand for roof sheathing was sparked during the past year by a change in FHA minimum property requirements permitting 3f" plywood roof decking over rafters spaced 24" o.c. Builders using this construction have reported they can lay decking in half the man hours required for conventional -.l.reathing materials.

One Detroit builder reports a totai dollar saving of $112 per house rvith a combination of plywood roof decking and pre-built plyrvood-shea'ched \\'a11 sections. In Southern California particularly plyrn'ood sales for underlayment as a base for wall-to-wall carpeting have increased considerably and in some cases, a combination subfloor and underlayment in a heavy thickness of fir plywood is proving a profitable dealer sales outlet.

Plyrvood for these applications and others like new siding and interior r,vall paneling 'ivill be dramatized the first part of the year with a story in Farm Joumal on a case-

(Continued on Page 34)