2 minute read

Modernized Plant Producing OREGONBORD in Larse

Quantities

OREGONBORD, a high quality hardboard produced by the Chapman Manufacturing Company of Corvallis, Oregon, is creating a strong impact in Western building circles. The hardboard is rolling off production lines at an ever increasing rate, following modernization of the Chapman plant last August. Improved facilities represent an investment of over a million dollars.

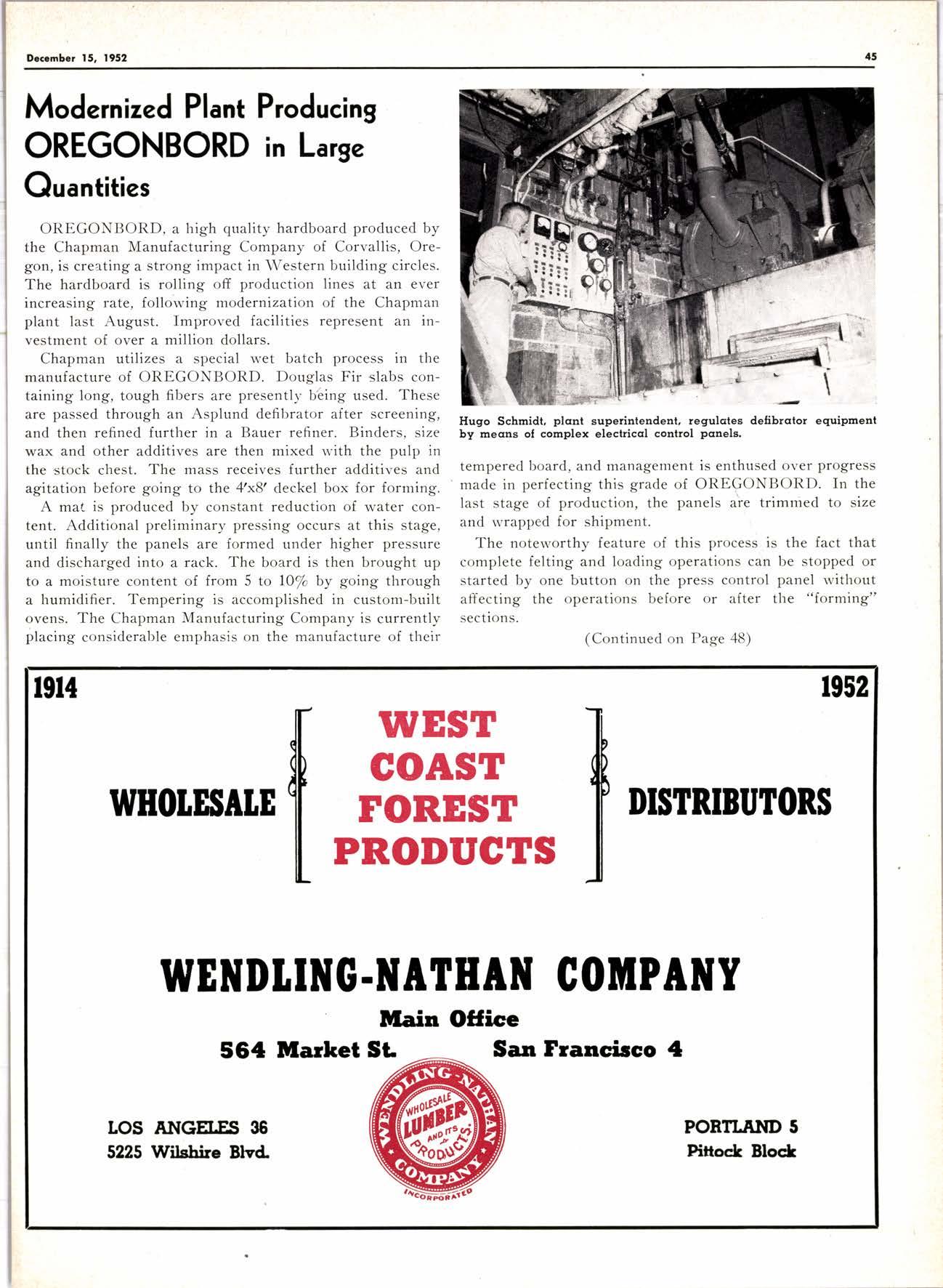

Chapman utilizes a special wet batch process in the manufacture of OREGONBORD. Douglas Fir slabs containing long, tough fibers are presently o"eing used. These are passed through an Asplund defibrator after screening, and then refined further in a Bauer refiner. Binders, size wax and other additives are then mixed with the pulp in the stock chest. The mass receives further additives and agitation before going to the 4'x8' deckel box for forming.

A mat is produced by constant reduction of water content. Additional preliminary pressing occurs at this stage, until finally the panels are formed under higher pressure and discharged into a rack. The board is then brought up to a moisture content of from 5 to tOV by going through a humidifier. Tempering is accomplished in custom-built ovens. The Chapman Manufacturing Company is currentlv placing considerable emphasis on the manufacture of their tempered board, and management is enthused over progress ' made in perfecting this grade of OREQONBORD. In the last stage of production, the panels aie trimmed to size and wrapped for shipment.

The notelvorthy feature of this process is the fact that complete felting and loading operations can be stopped or started by one button on the press control panel without affecting the operations before or after the "forming" sections.

(Continued on Page 48)

(Continued from Page 42)

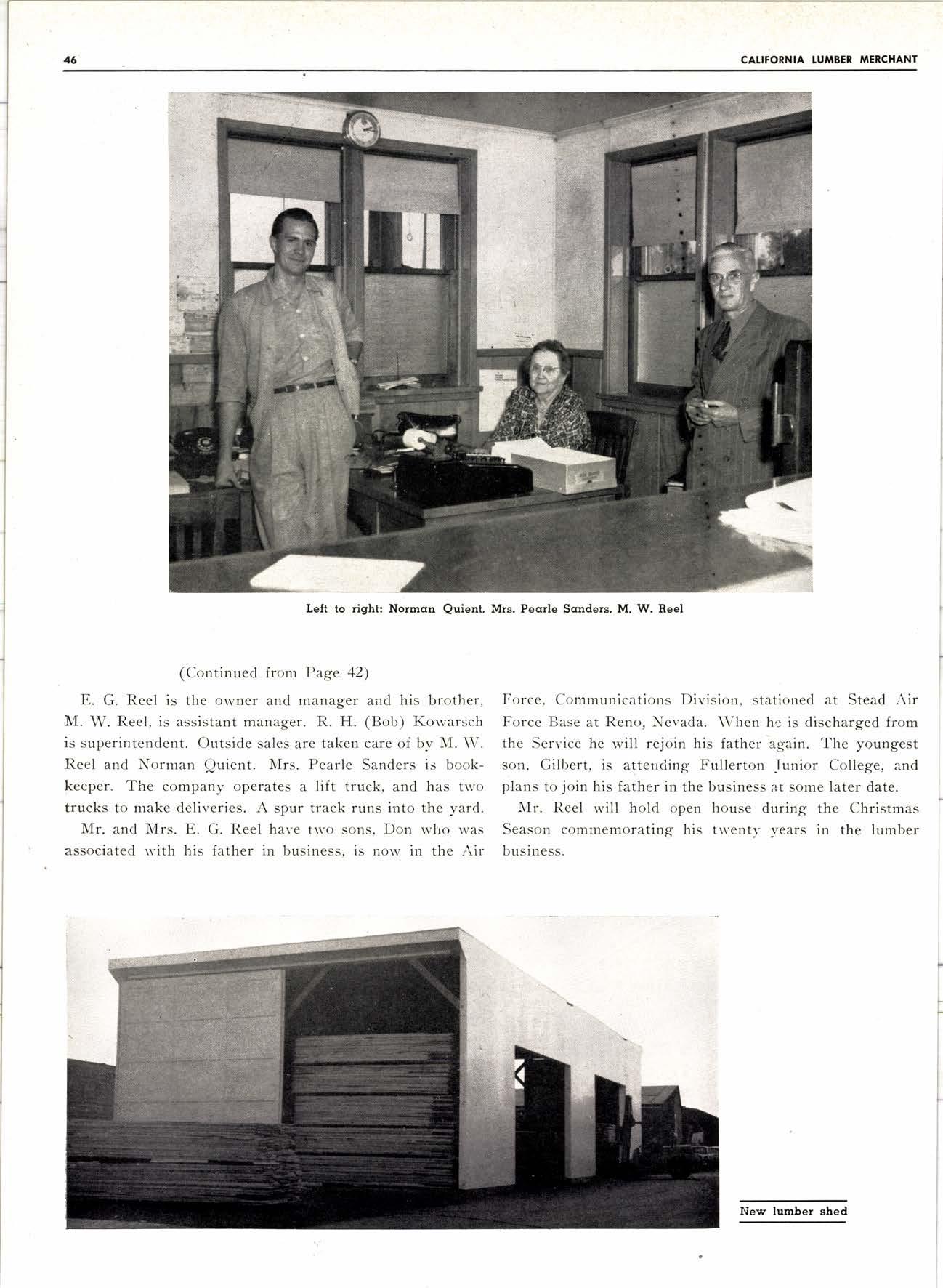

E. G. Reel is the owner and manager and his brother, M. W. Reel, is assistant manager. R. H. (Bob) Kowarsch is superintendent. Outside sales are taken care of by M. W. Reel and Norman Quient. Mrs. Pearle Sanders is bookkeeper. The company operates a lift truck, and has tu'o trucks to make deliveries. A spur track runs into the yard.

Mr. and Mrs. E. G. Reel have tn'o sons, Don wl-ro was associated n'ith his father in business. is now in the Air

Force, Communications Division, stationed at Stead Air Force Base at Reno, Nevada. When h,: is discharged from the Sen'ice he rvill rejoin his father -again. The youngest son, Gilbert, is atterrding Fullerton Junior College, and plans to join his father in the business ar some later date.

\'tr. Reel rvill hold open house during the Christmas Season commemorating his t'n'enty _years in the lumber business.

Hoo-Hoo Club No, 9 Christmas Party

Hoo-Hoo Club No. 9 n'ill entertain fifty children from Harold Meyer's San Francisco Boys' Home at the annual Christmas Party to be held at the Palace Hotel, San Francisco, Thursday noon, December 18. There u-ill be a Christmas tree and entertainment, also gif ts for the youngsters.

The Committee arranging for the party includes Chairman Ralph Mannion. Ernie Bacon, Jack Kaefer, Hac Collins, Bob Strable. Fred Ziese, Iack Pomeroy and Tack Butler.

Begin Shipments to Folsom Dcrm

Calaveras Cement Company has begun shipments on its 900,000 barrel contract for construction of Folsor.n Dam. H. C. "Pat" Nfaginn, executive vice president and chairman of the management committee, has announced. The company, wl.rich already is supplying cement for Pine Flat Dam near Fresno, u,ill continue to sl-rip to Folson.r through 1954.

Because of the recent expansion of its plant at San Andreas, Calaveras can fill its commitments to both dam projects 'rvhile at the same time making full shipments to dealers and other customers, Maginn reported.

He added that neu' equipment at the Calaveras plant also has enabled the company to make refinements in the manufacture of its u'hite Portland cement.

Selling the Producls of fhe ftlcGloud River lumber Go. tlcGloud, Golil.