4 minute read

IUElDWOOD

Pr.AsflcREsrNGLuE

For making things or fixing things, recommend Weldwood Glue-for all wood-to-wood bonds and manv other uses. Makes joints stronger than t.he wood itself. Mixes easily with water. Stain-free, rot.proof, highly water-resistant! For hobbyists, home owners. contractors, carpenters! Jn self.selling display cartons! lOc, lSc, 35c,65c, 95c; 5 lbs., l0 lbs.. 25 lbs.

Blond or pkklcd cffedr coll for

WH'IE FIRZITE*

RecommendWHITE Firzite for magical woodsy effects on hardwood or soft, plywood or solid lumber, For light pastel tones, recommendWHITEFirzite tinted with Colorsin-Oil. I'or soft wood and fir plywood patnt johs, recommendWHITE Firzite as an undercoat, to help prevent grain raise or checking. (For soft wood or 6r plywood srorn jobs, recom. ment CLEAR Firzite, to tame wild. unsightly grain. Over zlo million leei of fir plywood sold every week-whst a market for Firzite! r

Big demond for nqlurol wood finishes, sells

-1a"3L. Thebigmodernstyle !f, rrcrlrl rs rur lrgrrf, ll$tlJlf{Jtt natural wood fin- I-ry? rsnes-on rurnllurer

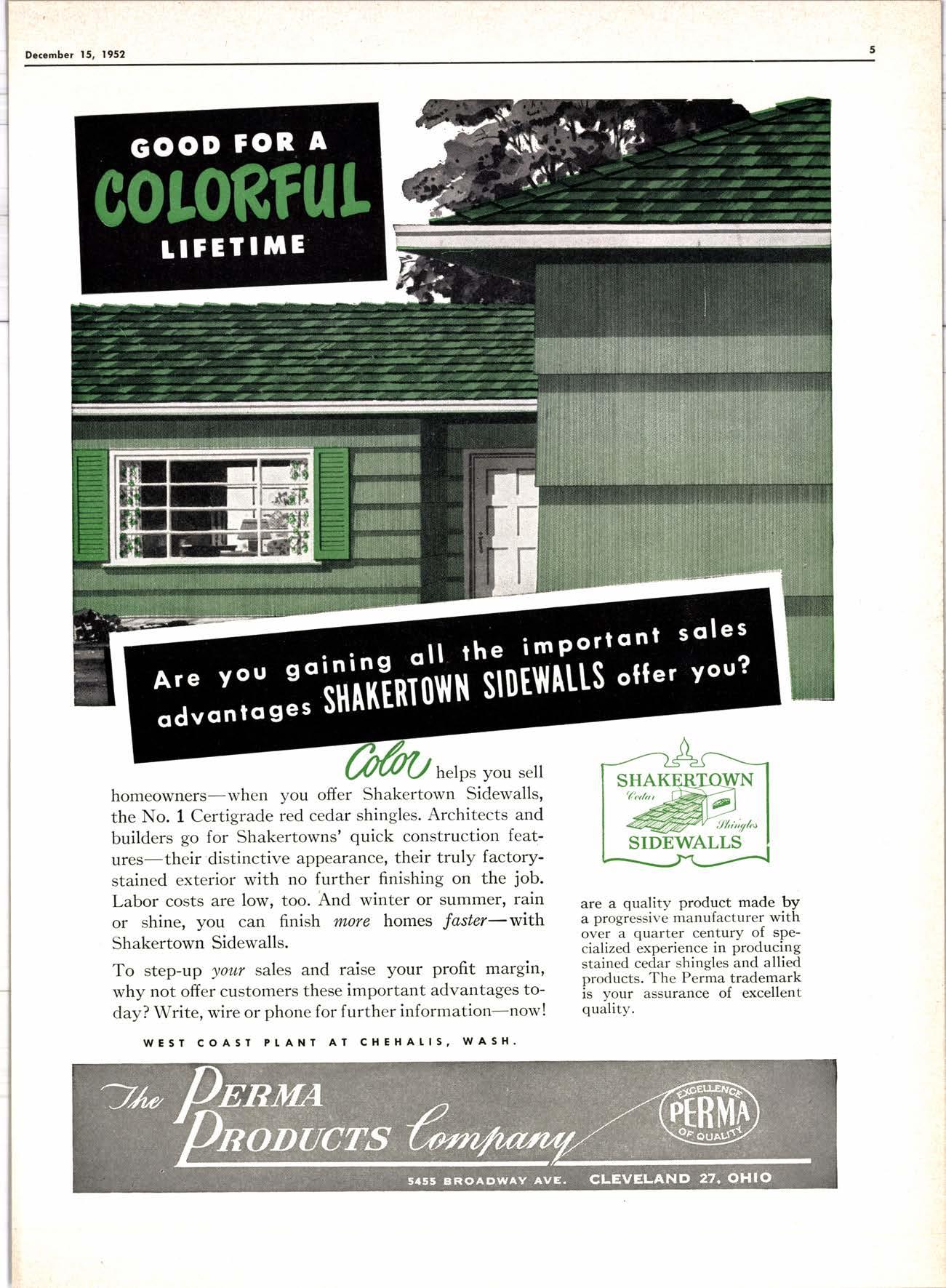

$/Ell wood panelling and Hffi;";;;;,T;j;;; k- wh.at to. use. you'll make lriends bv recomnrending SATINLAC. It biings It brings out and preserves the natural grain and color.beauty. of any plywood or solid wood. Water-clear Satinlac avoids that "built.up" Iook. Easy to brush or spray; dri-es "dust-freen in 20 minutes, ready for next coat in 3 or4 hours. helps you sell homeowners-\ rhcn you offcr Shakcrtox.'n Sidel-alls, the No. 1 Certigrade red cedar shinglcs. Architccts and builders go for Shakertorvns' quick construction features-their distinctive appcarance, their truly factorystained cxterior r,vith no further fir-rishing on the job. Labor costs are low, too. And winter or summer, rain or shine, you can finish ncore homes faster-with Shakertown Sidervalls. are a qualitl' product made by a pnrgressive nranufacttrrcr with ovtr a quart('r century o[ sPecializecl experience in producing stained ceclar shingles and alliccl products. 'lhe Perma trademark is 1'our assurance of excellent oualltv.

In pints, guarts, gallons, ilrums.

To step-u p lo'Ilr sales and raise your profit margin, rvhy not offcr customers these in-rportant advantages toclay? Write, u,'ire or photre for ftrrther information-norv!

WEST COAST PTANT AT CHEHAtIS' WA5H.

The night porter of the house where artist pablo Picasso, the extreme modernist, was staying in Paris; helped police catch a burglar by remembering the man's appearance and then sketching it. Picasso was impressed, so, when his place was robbed soon after, he observed the burglar who had bound him with a rope, and later did a painting of the man which he handed to the police. Guided by his sketch the police promptly rounded up two hundred people, a horse, a hearse, a pair of old boots, and a can opener;-l"", Madrid.

The above hasn't a thing in the world to do with what this piece will.be about, but it seemed funny enough to deserve top billing. ***

This will be a rambling editorial concerning ,,the planned program Weyerhaeuser has established for all its branches -permanent manufacture, development and improvement of forest products, and a permanent yield from its tree farms'

The above quotes are from a recent official Weyerhaeuser publication, telling numerous details of the drive toward perfection in all phases of lumbering which is being made by the various Weyerhaeuser enterprises of wood and lumber character'

This same publication on another page tells of the Weyerhaeuser progress "through the advantage of research and the sustained-yield plan of growing trees on a commercial basis." It is a fact well known to many that Weyerhaeuser owns and operates vast possessions that have to do with trees and wood; mighty sawmills in Oregon, Washington, and the Inland Empire. But the even greater fact, and not so well known, is that every unit of every sort is being operated and managed on a planned permanent basis. Every Weyerhaeuser wood enterprise is being operated for planned perpetuity.

And every Weyerhaeuser wood-using operation has hehind it certain selected forests-tree farms-certified by their army of foresters to be capable of supplying that unit perpetually with commercial trees. How much timber Weyerhaeuser owns is probably their own business, but it amounts to a staggering total in all the states in which they operate. And their timber growing, and timber cutting, and logging, has al1 been mapped out for one hundred years to COme.

No Weyerhaeuser wood using operation stands still. All of them must improve, and modernize, and progress. Through the research efforts of an army of chemists and engineers, new products are continually coming from Weyerhaeuser. As an example, take the Clearwater Unit of Potlatch Forests, Inc., located at Lewiston, fdaho. Here they operate the biggest White Pine sawmill in existence. They incorporated the outfit in 1900, and then spent 25 years buying timber, and getting ready to some day build and operate a mill there. They built the original plant in 1925 and 1926. It started just as a lumber mill, modern, and of large propotator..

In 1930 one of their engineers perfected the Pres-to-log, which has become one of their outstanding sidelines; a pressed wood log for use as fuel. This business has grown steadily. Glued-up lumber to build narrow boards into wide ones of any width desired, came.next, with specially created hot presses to cement the ltrmber together on the edges. Sound and solid boards of great width have been a famous Clearwater product ever since. ln t947 they added a huge cut-up department; in 1949 they built a veneer plant as a new unit; in 1950 they built a pulp and paper mill; in 1952 they expanded the veneer plant to produce Pine plywood; in 1952 they are expanding the pulp and paper mill to twice the original size. A sample of how Weyerhaeuser mills grow. And remember, there is a perpetual supply of trees for all this equipment, and all these units' * * * x< ,k *

They make Pine plywood in Idaho, and Fir plywood in Washington and Oregon. Their newest unit to reach completion and go into production is a Fir plywood plant at Springfield, Oregon. They boast that while the meat packers use everything except the squeal, at Springfield they use ever5rthing-no l'eftovers. They even use all the bark from the big Fir peeler logs. Sound wood from small peeler cores, veneer edgings and other l'eftovers from the plywood plant are chipped and sent to the sulphate pulp mill. Whatever is not suitable for pulp, and the bark removed from the logs by a dry debarker, go through the hog and then are burned in the power house to generate steam and electricity.

A product is made from the tree bark by a Weyerhaeuser formula in another Weyerhaeuser plant that helps extend the phenolic resins in plywood glue, and the Springfield plywood operation consumes about 13 tons of this bark product every month. The product is called Silvacon 472, and is manufactured at Weyerhaeuser's Longview operation. So it is that every bit of the log, bark and all, is made into valuable products at the new Springfield plant. The Spring-