1 minute read

IJACUU]Y| STALER

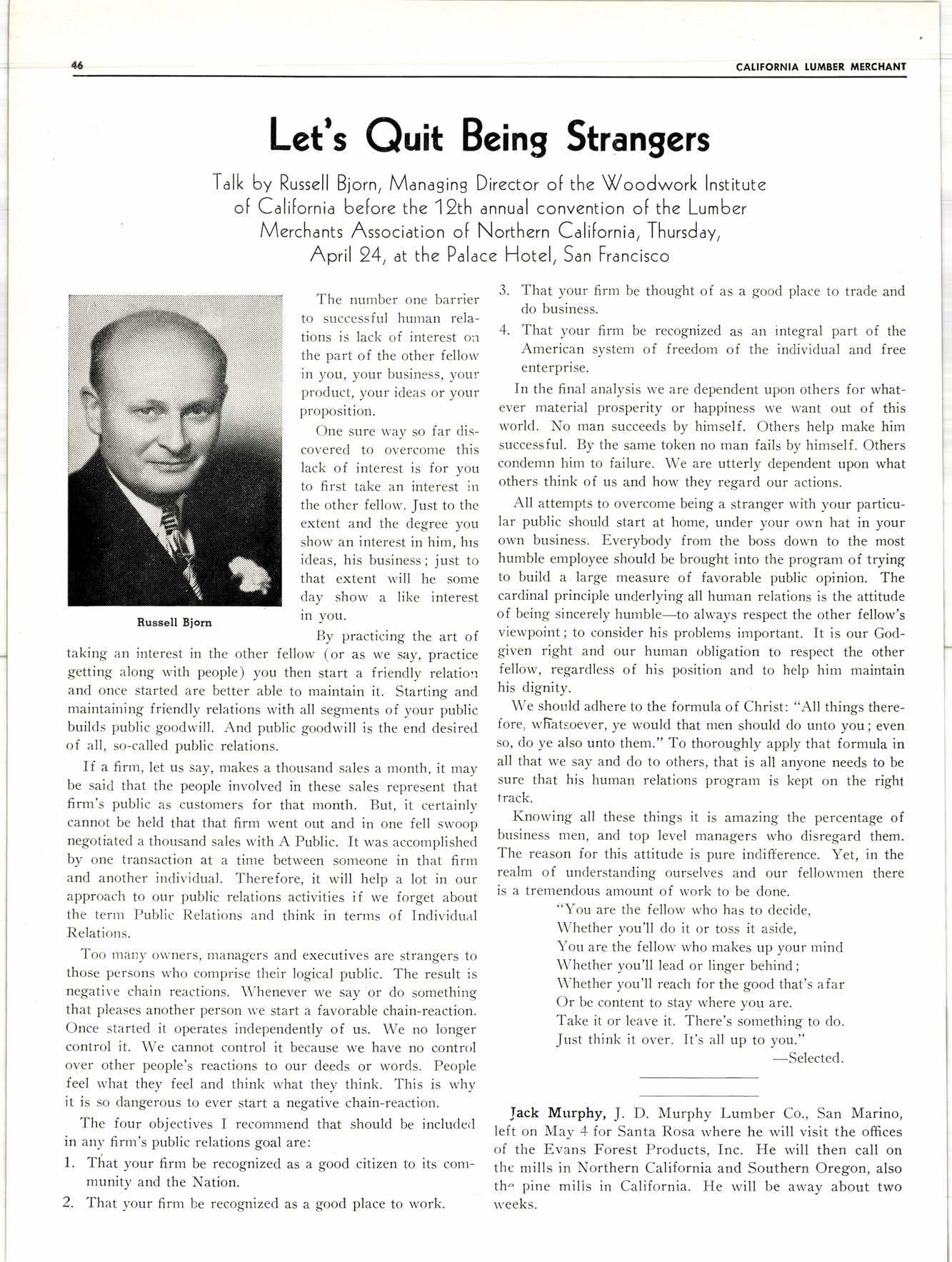

In Opercflon Ai CAR,R., ADA'NS & COLLIER, CO. DUBUGIUE, IOWA

The 3-minute open dip-tank treatment, with various methods to accelerate draining and drying, has been used for years by millwork manufacturers to meet NWMA standards for fungicidal control against decay, and for Swellograph dimensional control tests to determine water repellent efficiency. Many disadvantages are inherent in virtually all these procedures which add to cost by slowing up production, create expensive "housekeeping" problems and generate dangerous fire hazards. Now these disadvantages have been overcome by this new Wood-Treating "Vacuum Sealer" which makes available to the millwork industry the "final vacuum method" of quick'drying treated sash and doors-a method long employed by the wood preserving industry as the bestn cheapest and most practical of all. Briefly, this relatively inexpensive Vacuum Sealer offers these desirable benefits:

O Better dietribution and deeper penetration of preservative within the wood giives better protection

O A dryer surface faster for glazing, painting and finishing without lost production time

O No dripping on floors and equiprrrent elirrinatee housekeepin g problerns o Fire hazard is reduced to a minimum

O Initial vacuurn. ehorter dip, and final vacuum drying require no rnore tirne than the old dip-and-drain rnethods

O Easily adapted to put any arnount ofpreeervetivo into the wood for special requirernentst extra severe service. etc.